INDEX

0. WARNINGS.........................................................................................................................0-1

1. PREASSEMBLY INSTRUCTIONS......................................................................................1-1

1.1

STORAGE AND TRANSPORT .......................................................................................................................1-1

1.2

CONDITIONS FOR USE..................................................................................................................................1-1

1.3

GENERAL INFORMATION .............................................................................................................................1-1

1.4

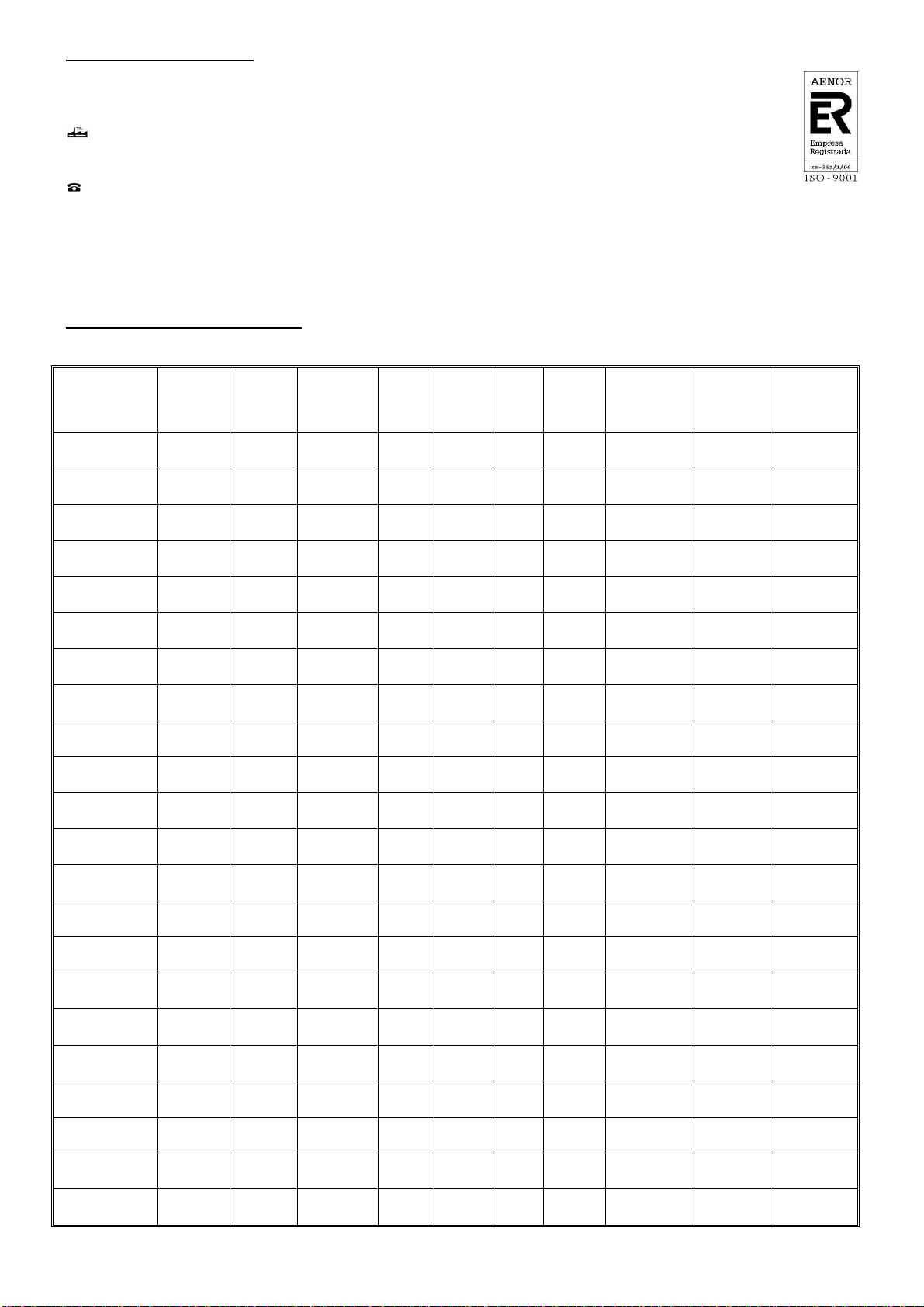

DIMENSIONS OF DIFFERENT COMPONENTS. ...........................................................................................1-2

1.5

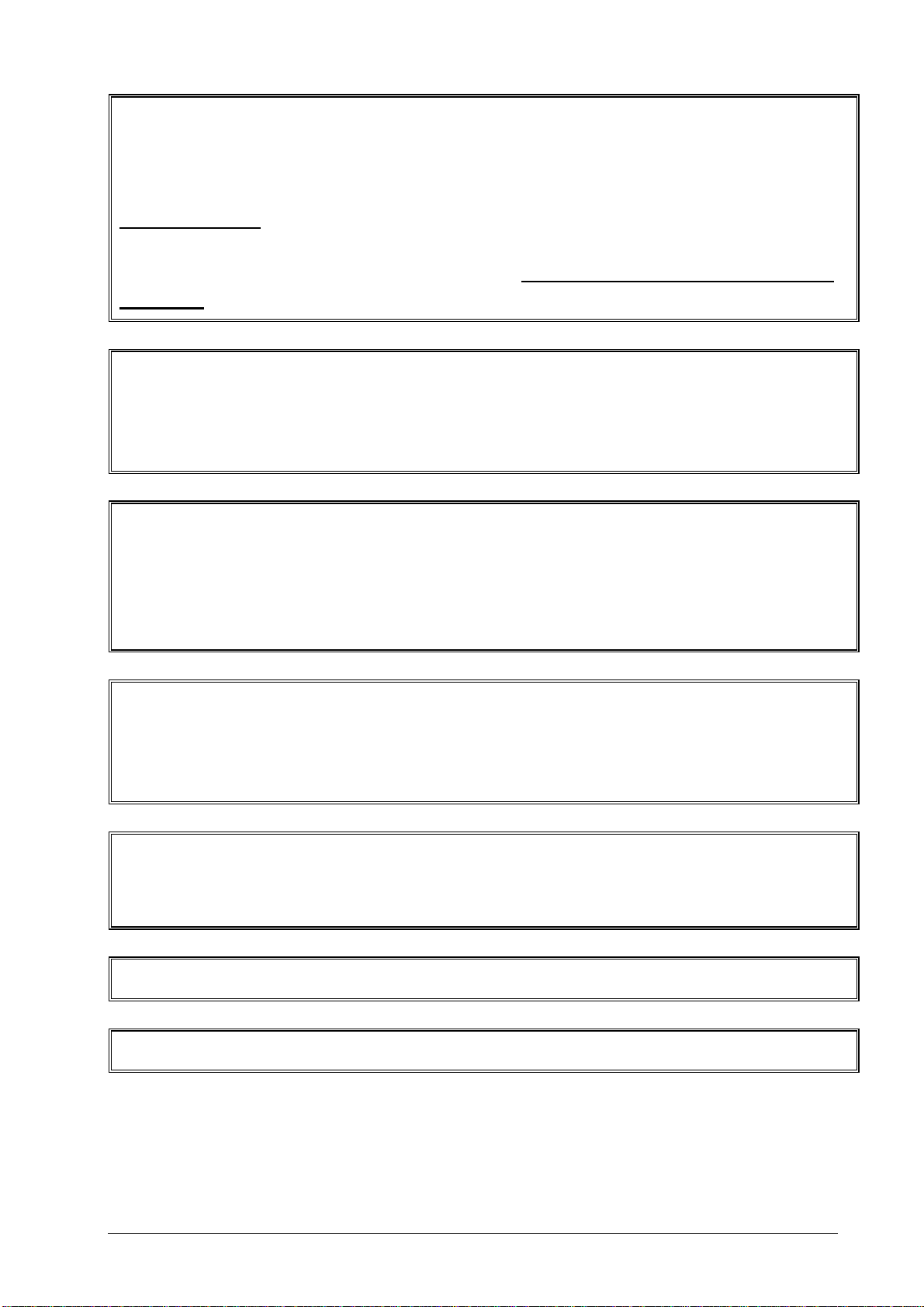

DELIVERY OF THE OVEN..............................................................................................................................1-4

1.5.1

Assembled oven........................................................................................................................................1-4

1.5.2

Unassembled oven ...................................................................................................................................1-4

1.6

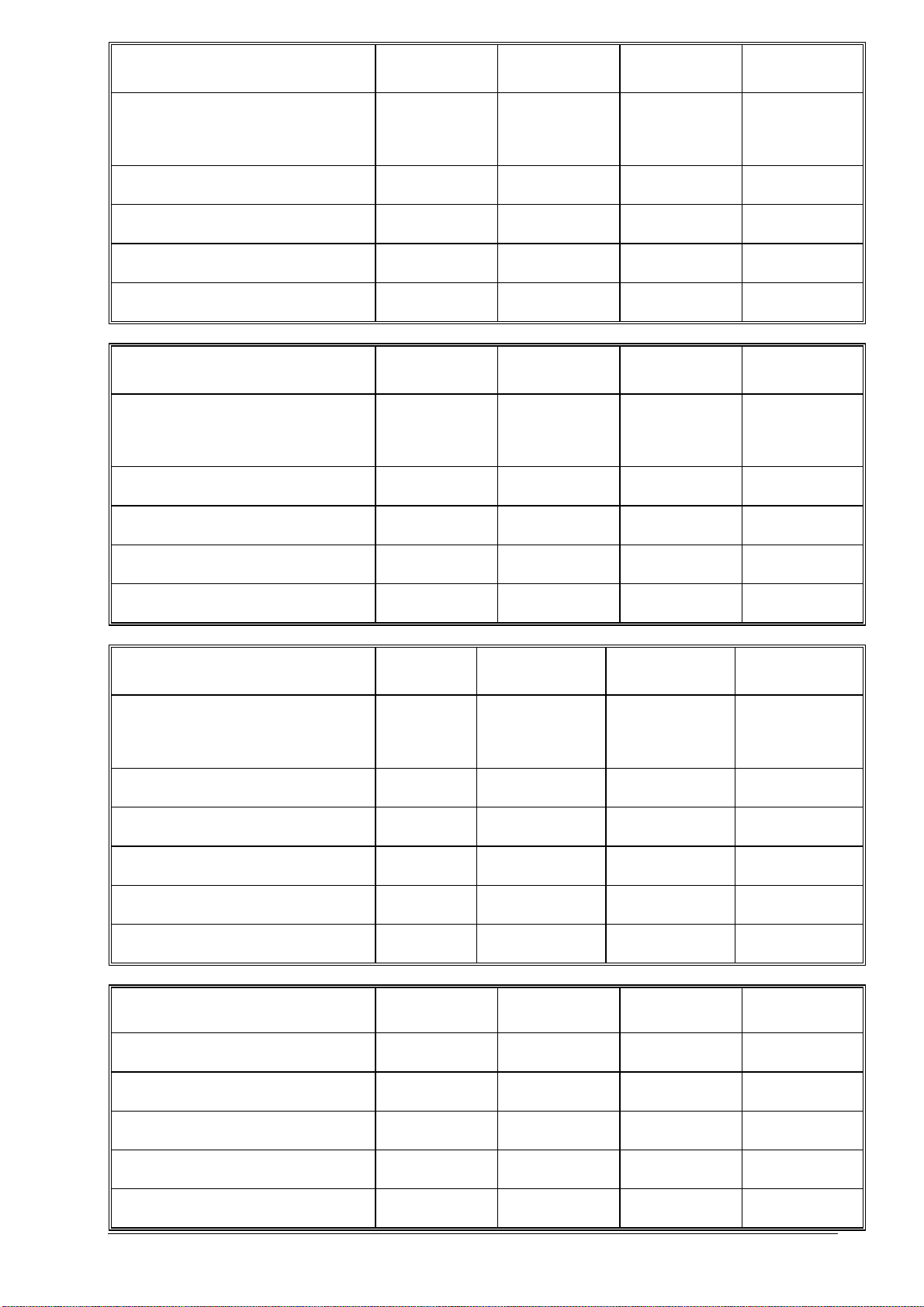

ELECTRICAL CONNECTION .........................................................................................................................1-6

1.6.1

Electrical connection between decks........................................................................................................1-8

1.6.2

Power control connection..........................................................................................................................1-9

1.6.3

Electric connection for the oven to the mains...........................................................................................1-9

1.7

WATER INSTALLATION (Only for decks with steam) ................................................................................1-1

1.8

DRAINAGE (Only for decks with steam)......................................................................................................1-1

2. DRAWING ...........................................................................................................................2-1

2.1

BASIC PARTS OF THE OVEN .......................................................................................................................2-1

2.2

KEY PLAN .......................................................................................................................................................2-2

3. OUTLET OF BAKING STEAM............................................................................................3-1

3.1

DRAFT .............................................................................................................................................................3-1

4. ELECTRONIC CONTROLPANEL.......................................................................................4-1

4.1

DETAILED DESCRIPTION OF CONTROL PANEL .......................................................................................4-3

4.2

OPERATION OF CONTROL PANEL..............................................................................................................4-4

4.2.1

Automatic regulation of deck temperature................................................................................................4-4

4.2.2

Compensating loss of temperature inside the chambers due to opening of door ....................................4-4

4.2.3

Regulation of baking time. ........................................................................................................................4-5

4.2.4

Only for ovens with steam production.......................................................................................................4-5

4.2.5

Power control............................................................................................................................................4-5

4.2.6

Timed start-up...........................................................................................................................................4-6

4.2.7

User setting sequence: .............................................................................................................................4-6

5. PERFORMANCE.................................................................................................................5-1

5.1

START-UP OF OVEN AND MODULES..........................................................................................................5-1

5.2

HEATING OVENS WITH CASE-HARDENED BASES FOR THE FIRST TIME RIMER ................................5-2

5.3

EXAMPLE OF A BAKE ...................................................................................................................................5-2

5.4

TURNING OFF THE DECKS AND THE OVEN. .............................................................................................5-3

5.5

DISTRIBUTION OF GOODS. ..........................................................................................................................5-3

5.6

INTERIOR DECK LIGHTING...........................................................................................................................5-3

6. MAINTENANCE INSTRUCTIONS.......................................................................................6-1

7. MISFUNCTIONS AND THEIR POSSIBLE SOLUTIONS. ...................................................7-1

8. GUARANTEE ......................................................................................................................8-1