3.1 General precautions on disassembly …………………………… 3-1

3.2 CLX-FIN40S disassembly ……………………………………… 3-2

3.2.1 AS-FRAME UNIT …………………………………………… 3-2

3.2.2 AS-COMPILER EJECTOR ………………………………… 3-17

3.2.3 AS-STAPLER ENDFENCE ………………………………… 3-28

3.2.4 ENDFENCE UNIT …………………………………………… 3-34

3.2.5 Finisher exit sensor ………………………………………… 3-35

3.2.6 AS-BELT ……………………………………………………… 3-37

3.3 CLX-FIN40L disassembly ………………………………………… 3-38

3.3.1 AS-FRAME UNIT …………………………………………… 3-38

3.3.2 Booklet unit ………………………………………………… 3-45

3.3.2.1 Feed Pulley …………………………………………… 3-45

3.3.2.2 AS-MAGNET …………………………………………… 3-46

3.3.2.3 Entrance guide sub assy ……………………………… 3-47

3.3.2.4 Pulley, Gear, Belt. ……………………………………… 3-50

3.3.2.5 AS-SADDLE stapler:EH-280 ………………………… 3-51

3.3.2.6 AS-MAIN-PADDLE …………………………………… 3-52

3.3.2.7 JOG UNIT ……………………………………………… 3-52

3.3.2.8 BM paper present sensor ……………………………… 3-54

3.3.2.9 Blade home sensor …………………………………… 3-55

3.3.2.10 CSP- GEAR …………………………………………… 3-56

3.3.2.11 Folding exit sensor …………………………………… 3-57

3.3.2.12 BM entrance sensor & Moving guide home sensor 3-59

3.3.2.13 Stopper guide upper magnet ………………………… 3-60

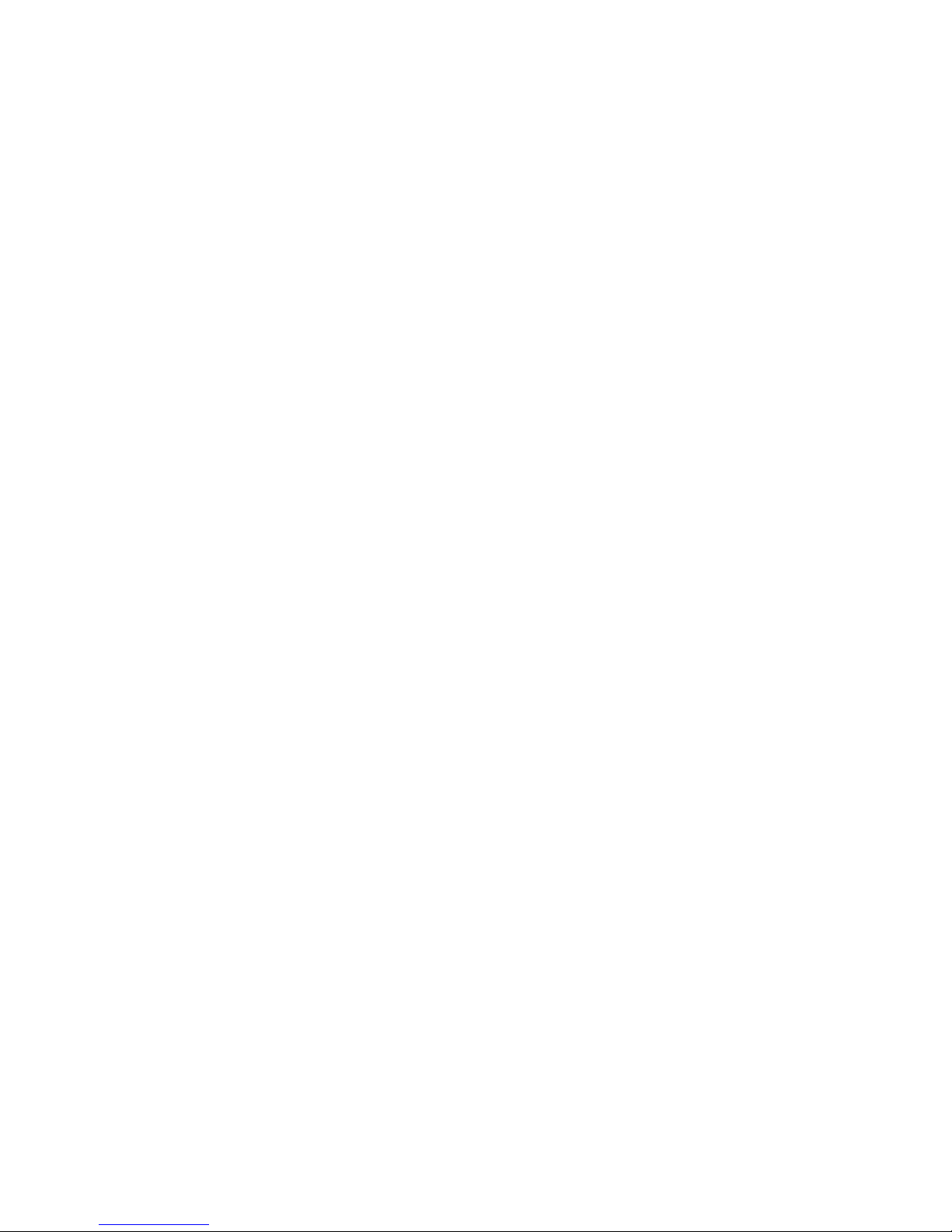

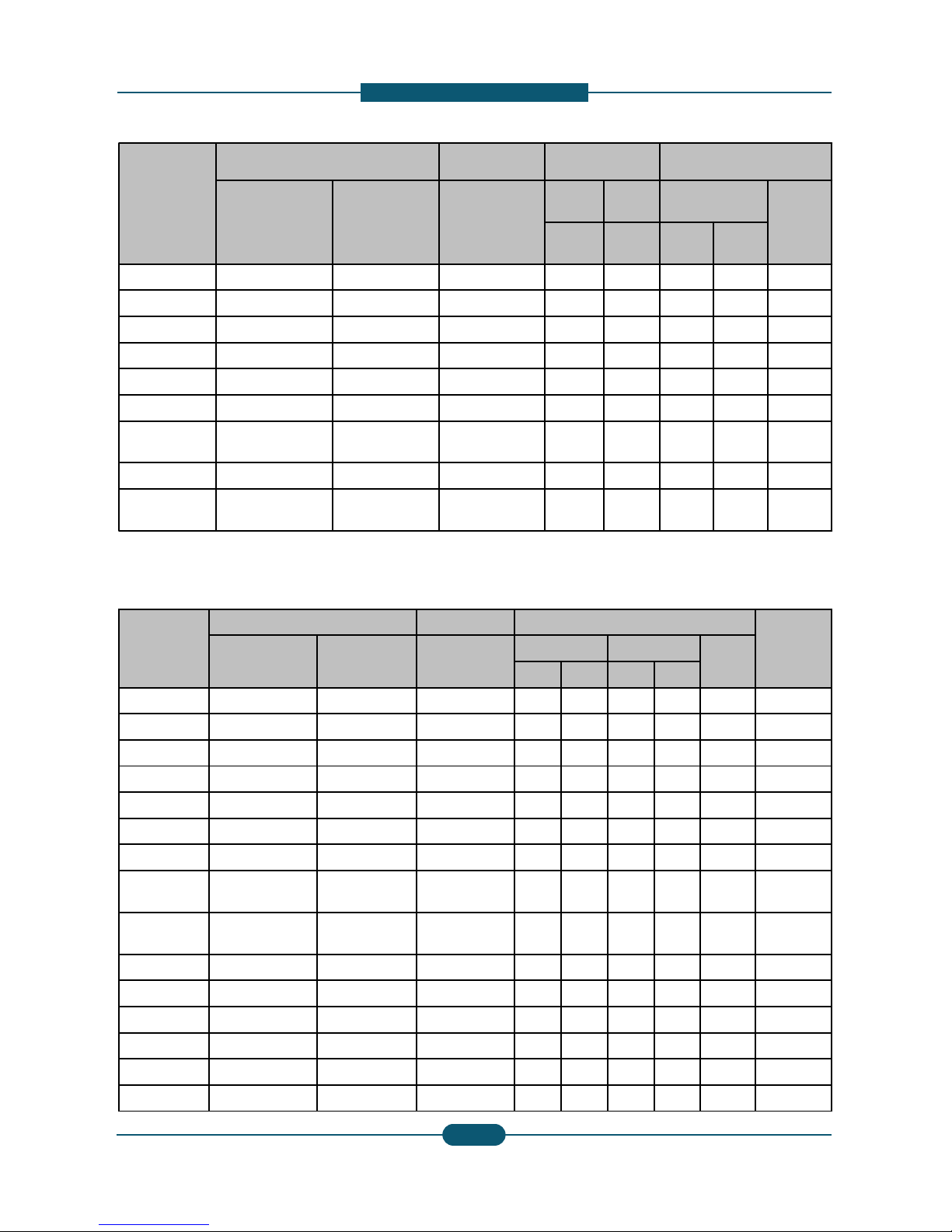

4.1 Error code and error message ………………………………… 4-1

4.2 Troubleshooting for error code ………………………………… 4-3

4.3 Finisher Self-Test Mode ………………………………………… 4-37

4.4 Adjusting the staple position (CLX-FIN40L) …………………… 4-40

4.5 Adjusting the Paper Skew ……………………………………… 4-43

chapter 4 Troubleshooting

Contents

chapter 3 Replacement procedure