3

Table of Contents

INSTRUCTION MANUAL.....................................................................................................1

Safety Guidelines ......................................................................................................4

Hazardous Area ........................................................................................................7

Safety Labels on the Machine................................................................................10

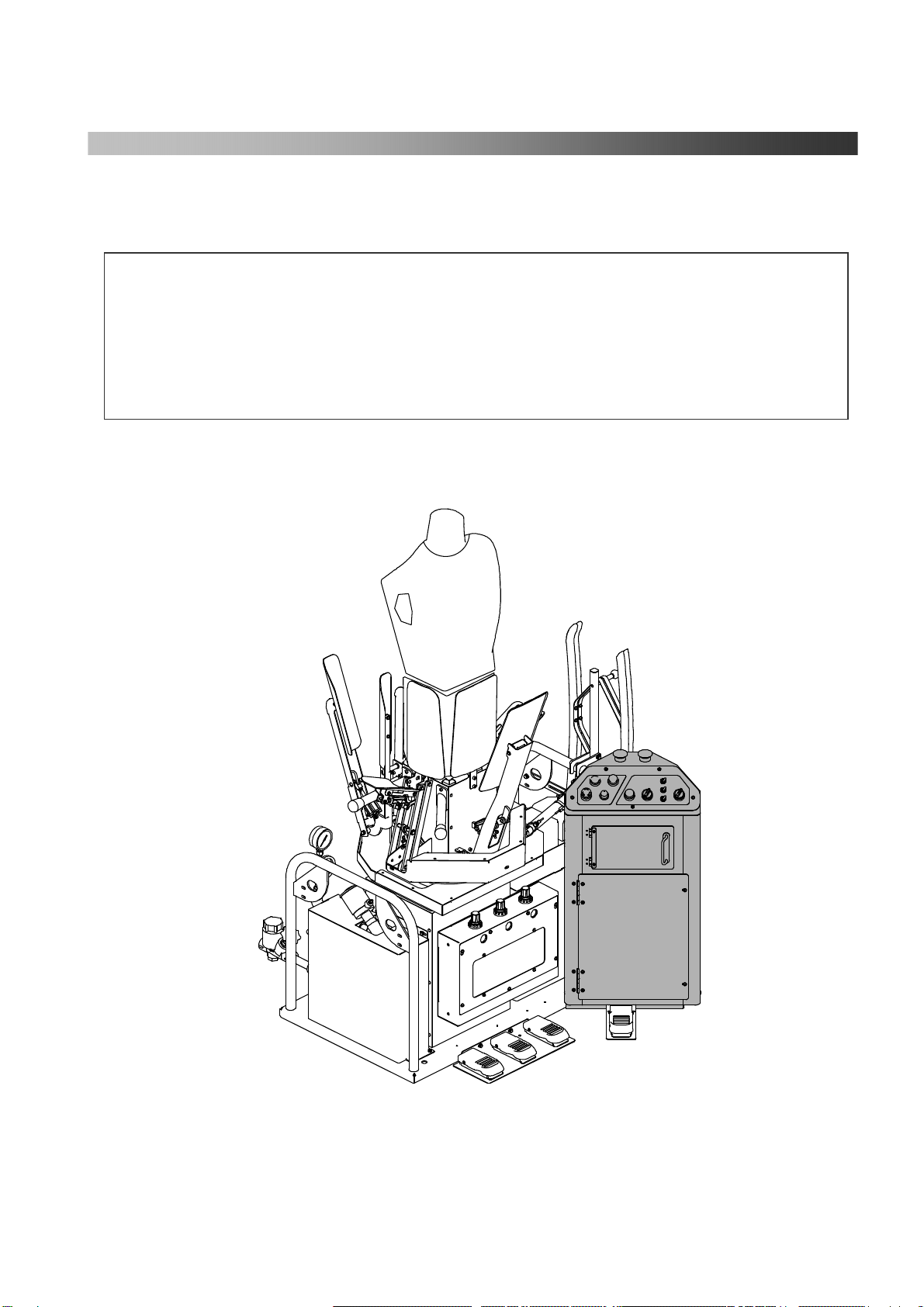

Parts Name.............................................................................................................. 11

Main device........................................................................................................ 11

Control box switch position ............................................................................... 12

Control Panel ..................................................................................................... 14

Foot pedal........................................................................................................... 15

Operation Procedures.............................................................................................16

Provide Air ......................................................................................................... 16

Provide Steam .................................................................................................... 17

Turn the Power On............................................................................................. 17

Select finish time................................................................................................ 17

Set the clothes on the body ................................................................................18

Turn the power off.............................................................................................. 21

Other Operations................................................................................................ 21

Cover/Pad Change Instruction..............................................................................22

1. Lower Body Cover setting ............................................................................. 22

2. Upper Body Cover setting.............................................................................. 23

3. Mat and cover setting of front and rear clamp / left and right side clamp ..... 23

Test Operation.........................................................................................................24

Operation Procedures......................................................................................... 24

Test Number List ............................................................................................... 25

Service Menu...........................................................................................................26

Trouble Shooting.....................................................................................................31

DAILY MAINTENANCE......................................................................................................35

Check Item List.......................................................................................................35

Check Item (Daily)..................................................................................................36

Check Item (Annual)..............................................................................................38

Maintenance Check List.........................................................................................39

SPARE PARTS LIST..............................................................................................................41

Front Diagram ........................................................................................................42

Rear Diagram..........................................................................................................44

Switch/Solenoid Valve Diagram.............................................................................46

Switch/Solenoid Valve Diagram.............................................................................48

Steam Piping Diagram............................................................................................50

Cover Diagram........................................................................................................52

ATTACHED DIAGRAM.......................................................................................................54