Samsung Electronics1-2

1-1 Safety Precautions (Continued)

7. Components, parts and wiring that appear

to have overheated or that are otherwise

damaged should be replaced with parts

that meet the original specifications.

Always determine the cause of damage or

overheating, and correct any potential

hazards

8. Observe the original lead dress, especially

near the following areas: Antenna

wiring, sharp edges, and especially the

AC and high voltage power supplies.

Always inspect for pinched, out-of-place,

or frayed wiring. Do not change the

spacing between components and the

printed circuit board. Check the AC

power cord for damage. Make sure that

no wires or components touch thermally

hot parts.

9. Product Safety Notice:

Some electrical and mechanical parts

have special safety-related characteristics

which might not be obvious from visual

inspection. These safety features and the

protection they give might be lost if the

replacement component differs from the

original--even if the replacement is rated

for higher voltage, wattage, etc.

10 Components that are critical for safety are

indicated in the circuit diagram by

shading, or . Use replacement

components that have the same ratings,

especially for flame resistance and

dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit's AC power cord

from the AC power source before

attempting to: (a) Remove or reinstall any

component or assembly, (b) Disconnect an

electrical plug or connector, (c) Connect a

test component in parallel with an

electrolytic capacitor.

3. Some components are raised above the

printed circuit board for safety. An

insulation tube or tape is sometimes used.

The internal wiring may be clamped to

prevent contact with thermally hot

components. Reinstall all such elements to

their original position.

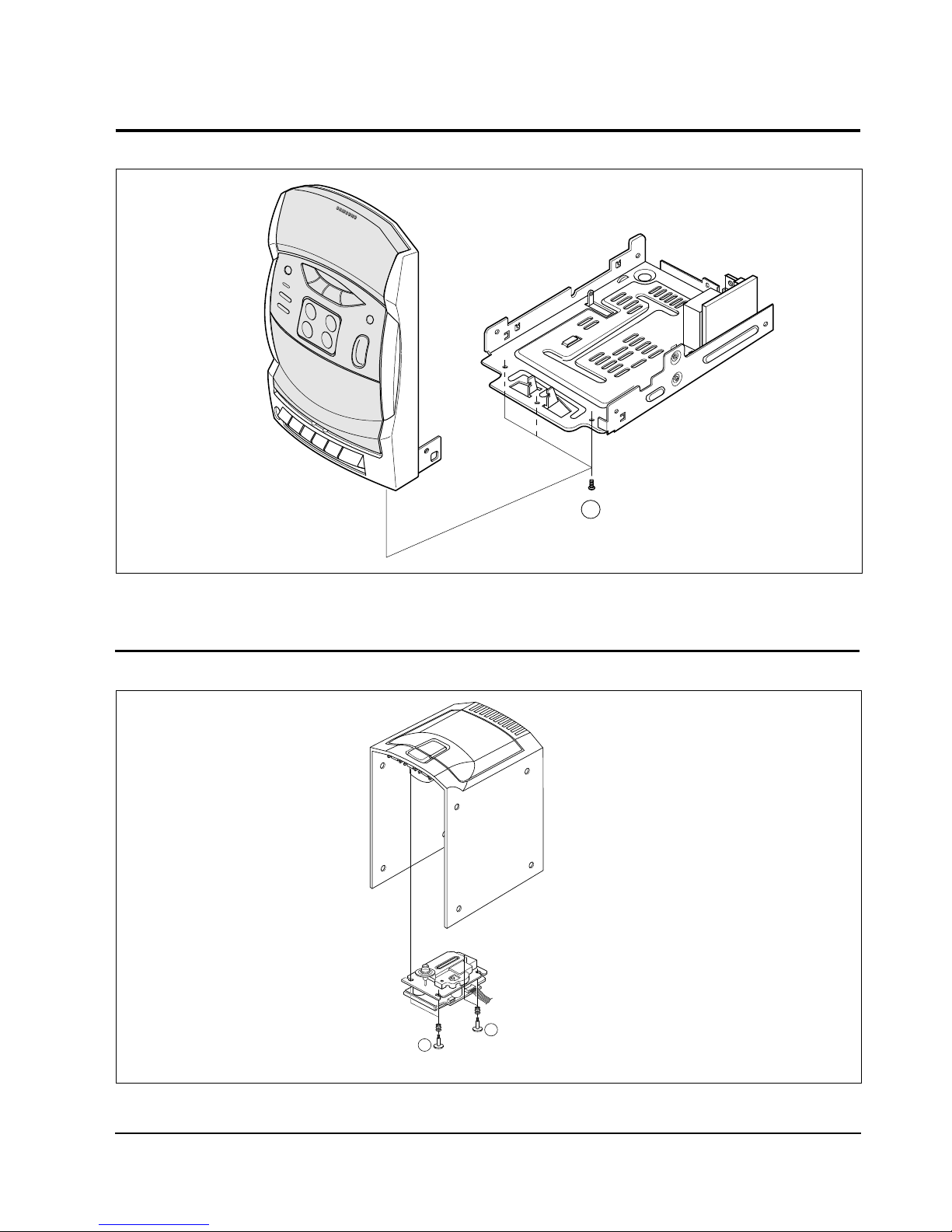

4. After servicing, always check that the

screws, components and wiring have been

correctly reinstalled. Make sure that the

portion around the serviced part has not

been damaged.

5. Check the insulation between the blades of

the AC plug and accessible conductive parts

(examples: metal panels, input terminals

and earphone jacks).

6. Insulation Checking Procedure: Disconnect

the power cord from the AC source and

turn the power switch ON. Connect an

insulation resistance meter (500V) to the

blades of the AC plug.

The insulation resistance between each

blade of the AC plug and accessible

conductive parts (see above) should be

greater than 1 megohm.

7. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

8. Always connect a test instrument's ground

lead to the instrument chassis ground

before connecting the positive lead; always

remove the instrument's ground lead last.

Precautions

Warning1: First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.