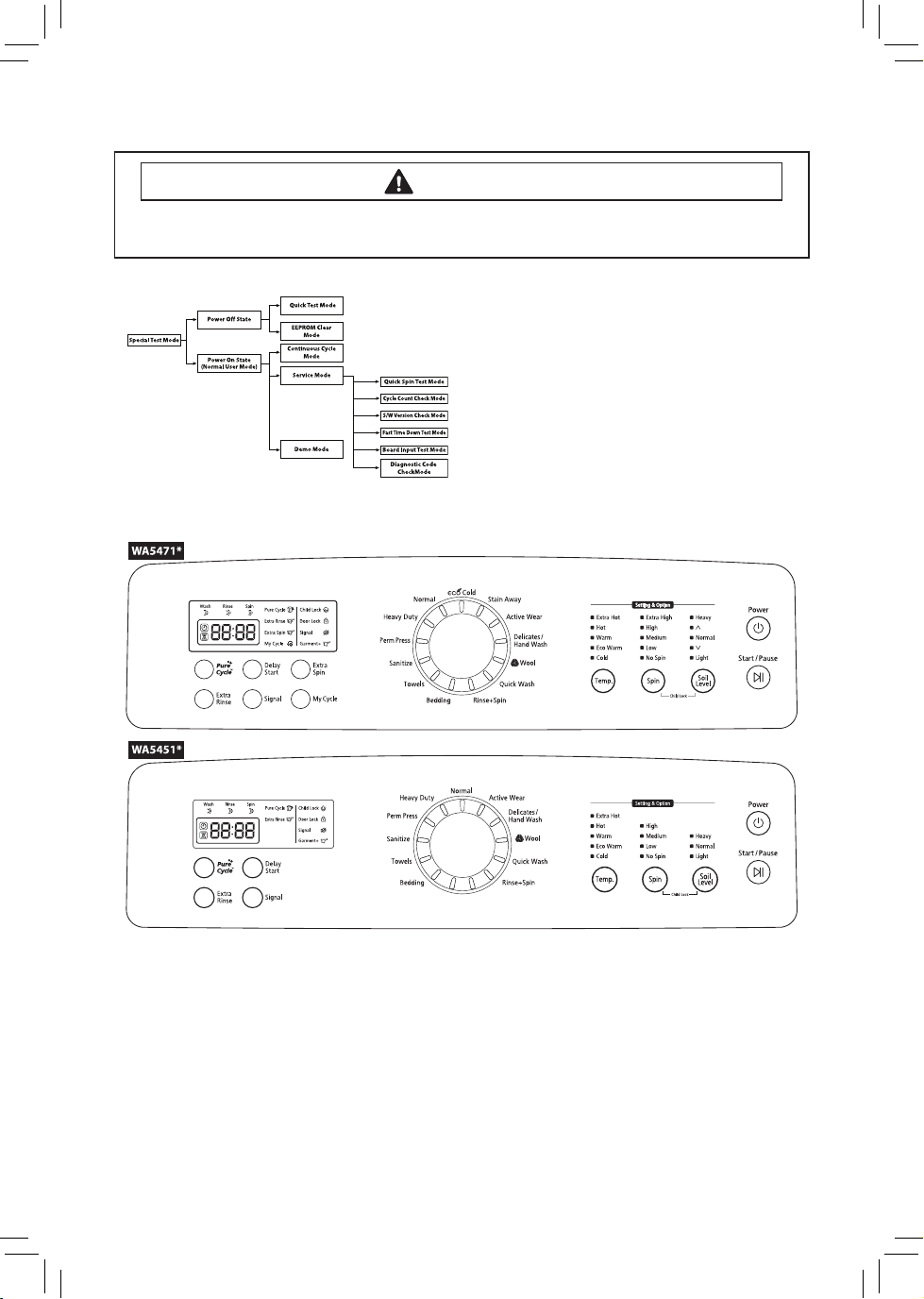

ALIGNMENT AND ADJUSTMENTS

3

NO

Error Code

(Diagnostic Code

Error Image)

Description Corrective Action

11 TE1

Thisoccurswhenthewater

temperaturesensorfaultisdetected

continuouslyfor5seconds.

Goto“BoardInputTest”andcheck

WaterTemperature.Checkloose

orpinchedwires.ReplacePCBor

thermistor.

12 3E

MICOMisattemptingtodrivethemotor

butisnotgettinganyresponsesignals

fromthehallsensor.Visualcheckshows

motorisnotrunning.(Locked,Defective

HallSensororOverload)

Evaluatewireharnessforlooseor

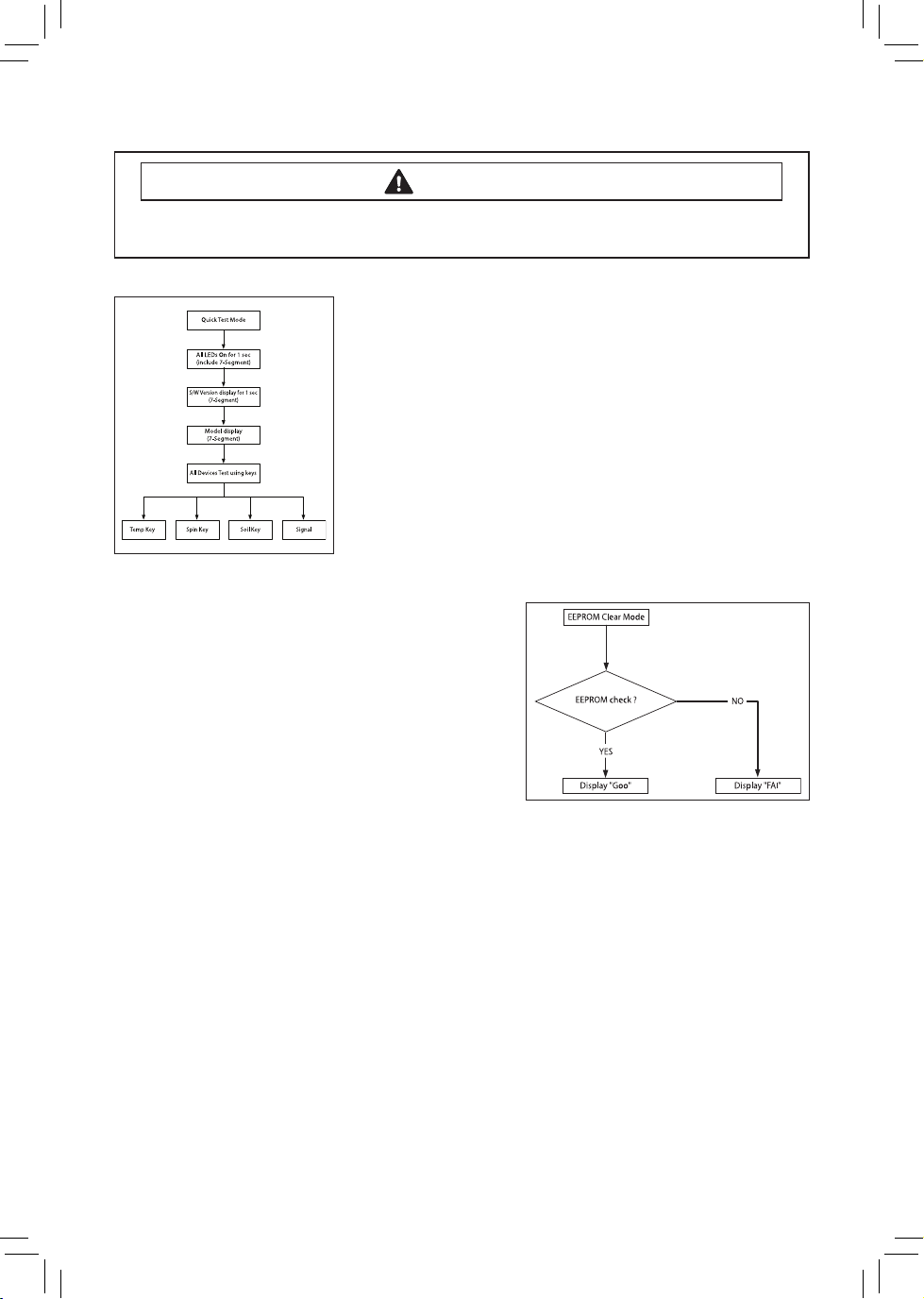

unhookedconnections.Goto“Quick

TestMode”andtestMotor.

13 HE HeaterRelayFailure(NoHeaterRelay

CheckSignal) ReplacePCB

14 nF1 Thehot/coldwaterhoseconnectionis

notcorrect.

Pleaseconnectthehot/coldwater

hoseconnectioncorrectly.

15 SUd

Sudsisdetectedduringthewashing

session.(“SUdS”isnotanerror.When

itnisheswashing,EndandtheSUd

codewillblinkinturn.)

Guideausertoreduceamountof

detergentusage.

16 AE

CommunicationerrorbetweenSUB

PBAandMAINPBA

CheckMainPBA,SUBPBA&Wire-

harness.ReplacePCB

17 PE

(ClutchMotorError)

Thiserroroccurswhenthepositionof

theclutchisnotdetected.

-Ifthepositiondetectionsignalisnot

received15secondsaftertheclutch

motorstarts,thespindrumisshaken

leftandrightandthenthemotoris

restarted.

Ifthemotorpositionsignalisnot

receivedevenafter3reattempts,aPE

erroroccurs.

1.Checktheclutchmotor.

2.Checktheassemblystatusofthe

clutchmotor.

3.Checkthewireconnectorterminals.

18

PE1

(clutchhallsensor

error)

Afterthecompletionoftheclutch

positiondetection,andtheclutch

hallsignalisinvalid,thespindrum

isshakenleftandrightandthenthe

clutchhallsignalisevaluatedagain.

This,iftheclutchhallsignalisstill

invalid,theclutchpositionswitching

statusischeckedandthenthe

operationisrestarted.

(Ifthe15reattemptsfail,thiserror

occurs.)

1.Checktheclutchhallsensor.

2.Checkthewireconnectorterminals.

3.Checktheclutchswitchingstatus.

-Checkthecouplingassemblyand

disassemblystatus.

19 8E

IftheoutputfromtheMEMSsensor

isover4.5Vorunder0.5Vandit

continuesfor5seconds,thiserror

occurs.

1.ChecktheMEMSsensorandPBA.

2.Checkthewireconnectorterminals

Toavoidriskofelectricalshock,personalinjuryordeath;disconnectpowertowasher

beforeservicing,unlesstestingrequirespower.

WARNING

WA5471ABP_03051A-02(Technical information).indd 3 2012-02-13 �� 9:36:22