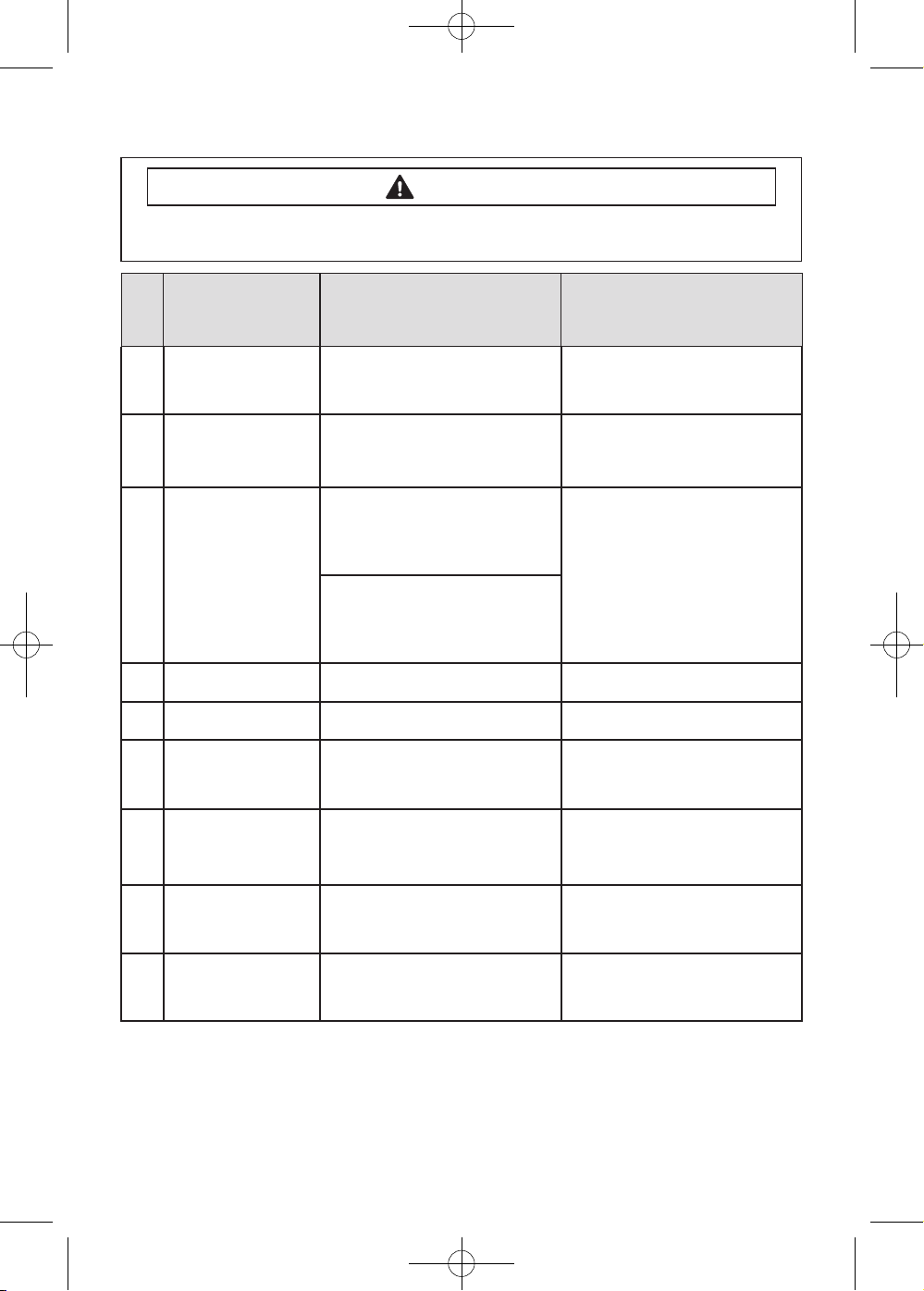

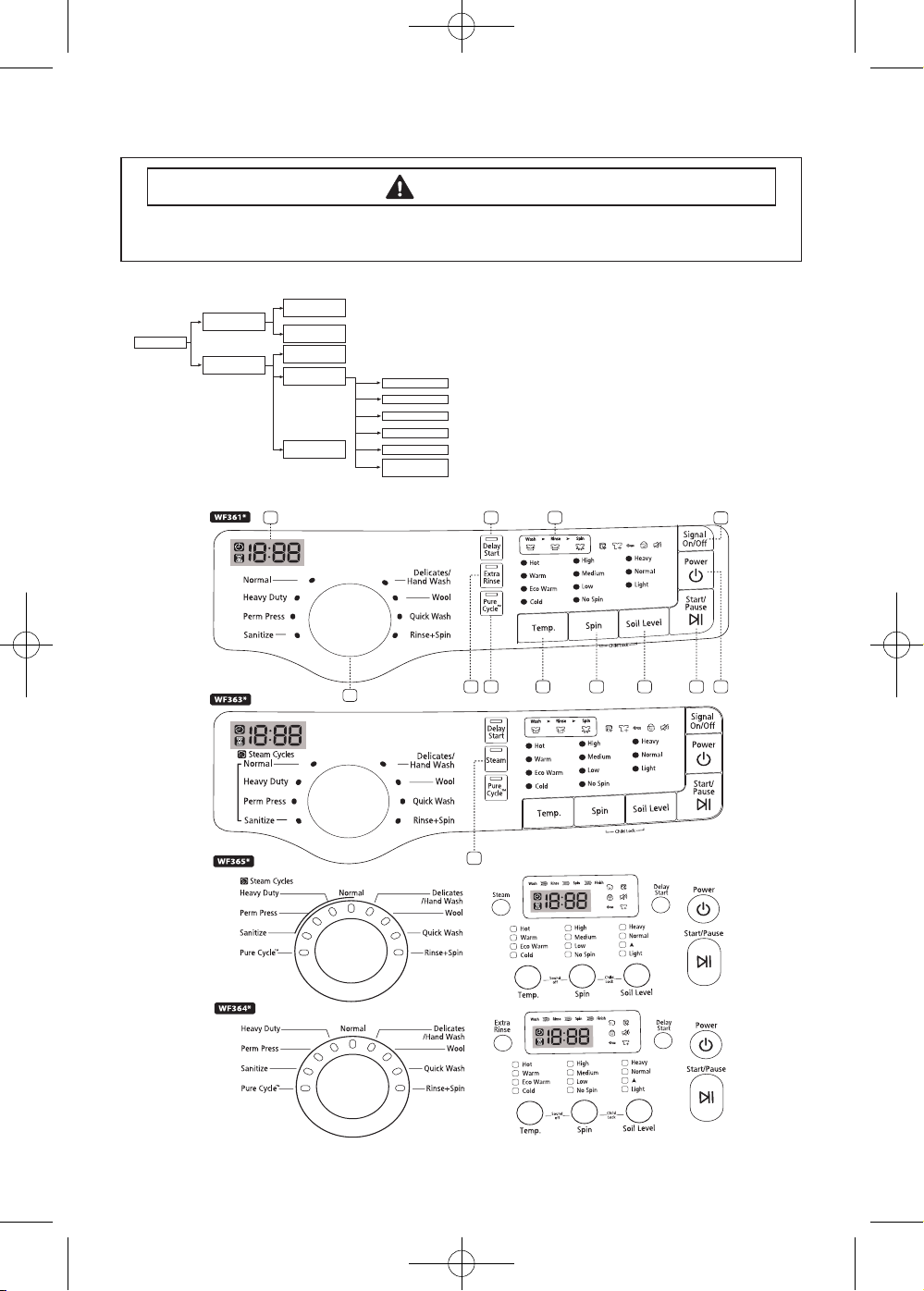

ALIGNMENT AND ADJUSTMENTS

2

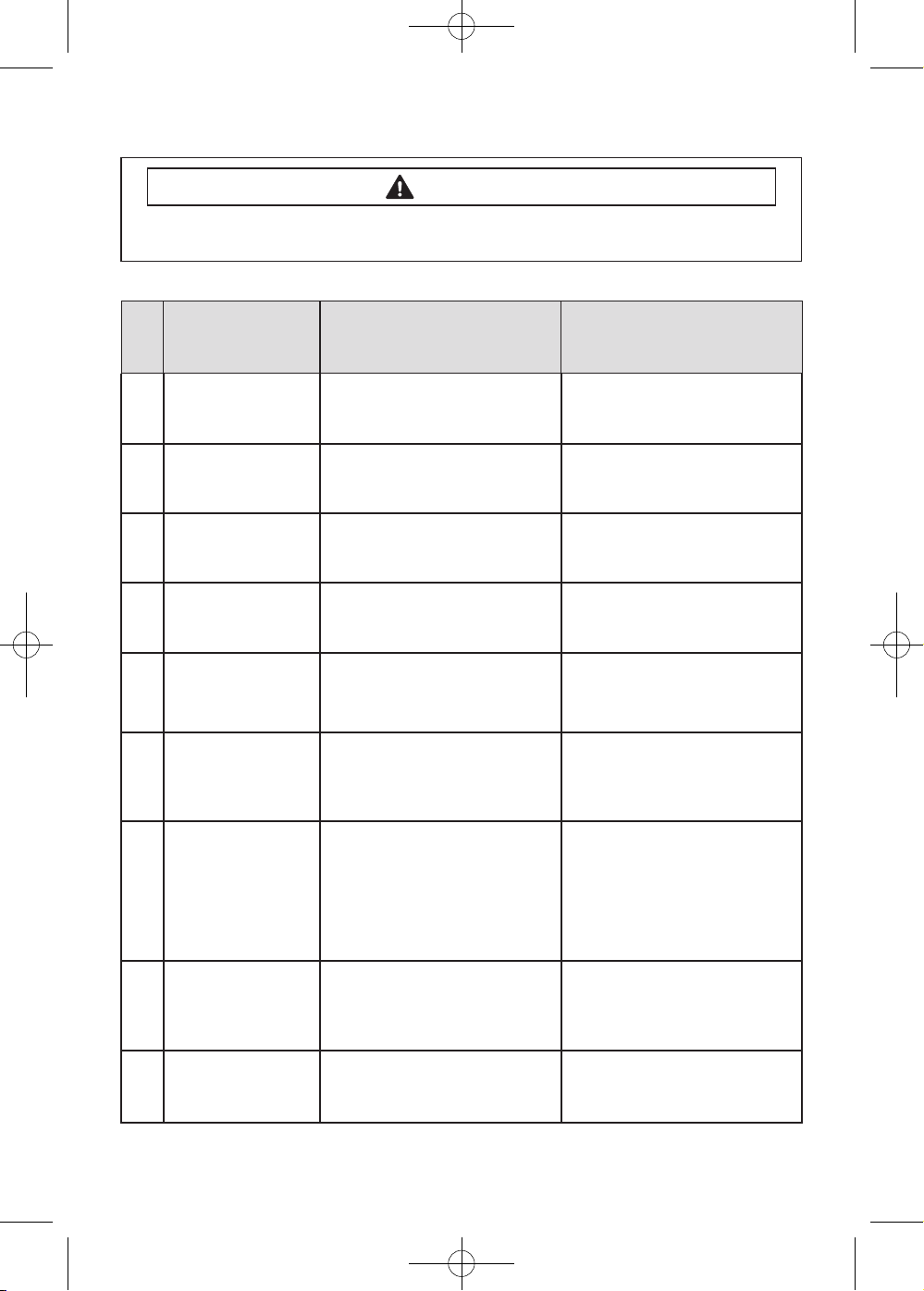

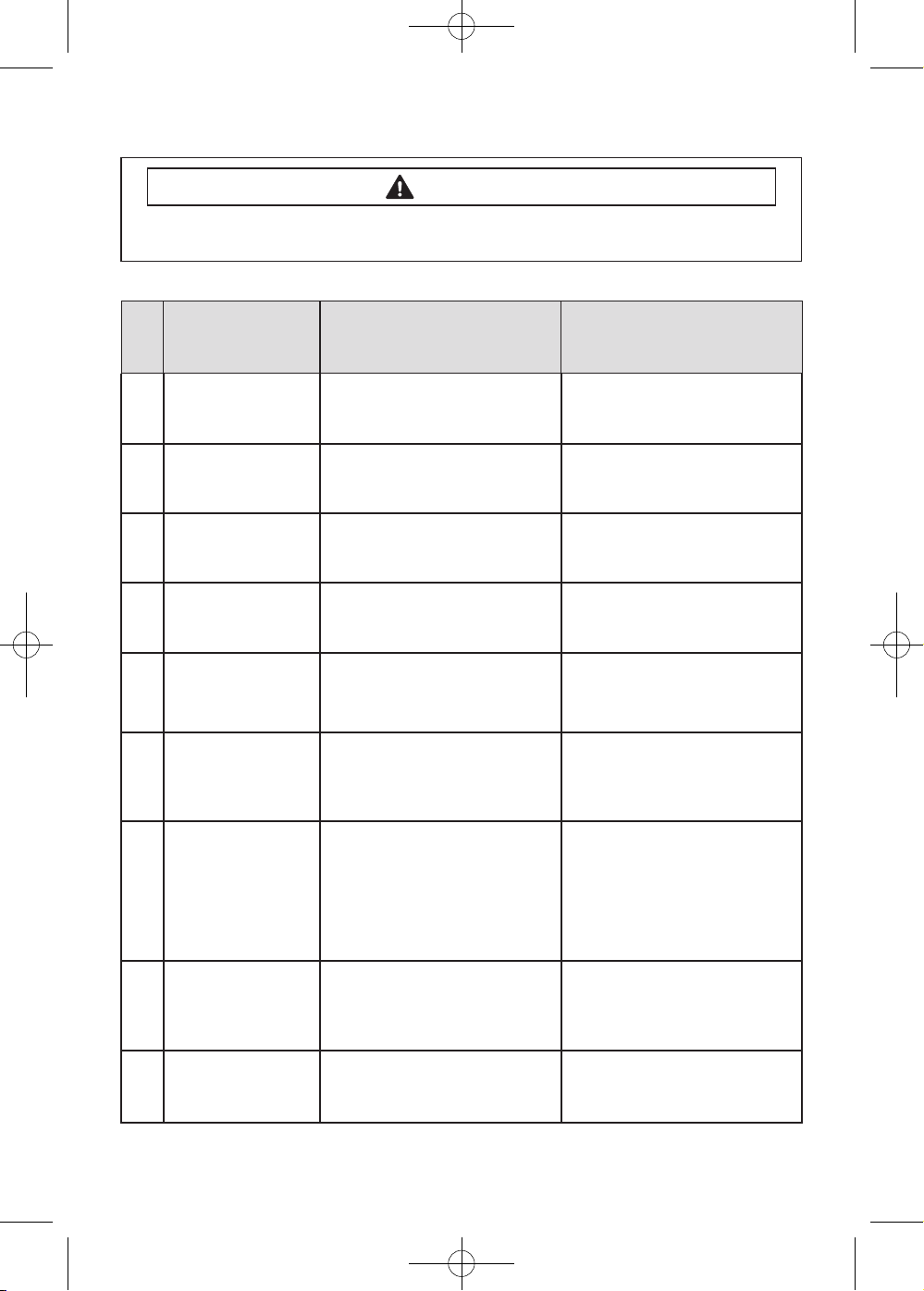

GENERAL ERROR FUNCTION

NO

Error Code

(Diagnostic Code

Error Image)

Description Corrective Action

1nd

Thewaterlevelfailstodropbelow

theResetWaterLevelwithin15

minutes.

Goto“WillNotDrain”

TroubleshootingSection.

2LO DoorfailstoUnlockAfter7attempts. Goto“WillNotUnlock”

TroubleshootingSection.

3nF

WhenthellingContinuesfor

morethan40minutesorthereisno

changeofwaterlevelfor6minutes.

Goto“NoWaterFill”

TroubleshootingSection.

4 FL Doorfailstolockafter7attempts. Goto“WillNotLock”

TroubleshootingSection.

5 LE

AwaterlevellowerthantheReset

waterlevelisdetectedfor5seconds

duringtheWash/Rinsecycle.

Goto“NoWaterFill”Troubleshooting

Section.

6 1E

WaterLevelSensorTrouble.(When

theinputsignalfromthewaterlevel

sensorisoutofrange,theunitwill

sendoutbeepingsoundsandhalts

thecycle.)

Goto“NoWaterFill”

TroubleshootingSection

7OE

Afaultisdetectedinthewaterlevel

sensor.Data(frequency)shows

thewaterlevelisatorabovethe

overowwaterlevel.(Whenthis

conditionisdetected,themachine

willautomaticallystartsdraining

wateruntilthewaterlevelfalls

belowtheresetwaterlevel)

Firstchecktoseethatallofwater

valvesarenotstuck.Ifwatervalves

areOK,checkwaterlevel.

8dc

Unbalanceorcabinetbumpis

detectedduringnalspin,which

preventsthedrumfromspinning

over150rpm.(Neverexceeds150

RPMduetounbalancedload)

Goto“WetClothes”Troubleshooting

Section.

9 E2

JammedKey.(Whenkeyinput

signalsarecomingoutformorethan

30seconds,itisregardedasajam.)

Checkallofkeys.IfAkeyissensed

tobepressed,allkeyswilldonot

respond.

Toavoidriskofelectricalshock,personalinjuryordeath;disconnectpowertowasher

beforeservicing,unlesstestingrequirespower.

WARNING

[BIGBANG]Technical_information-03207A-03_EN.indd 2 2013-7-16 17:15:01