if

I

I

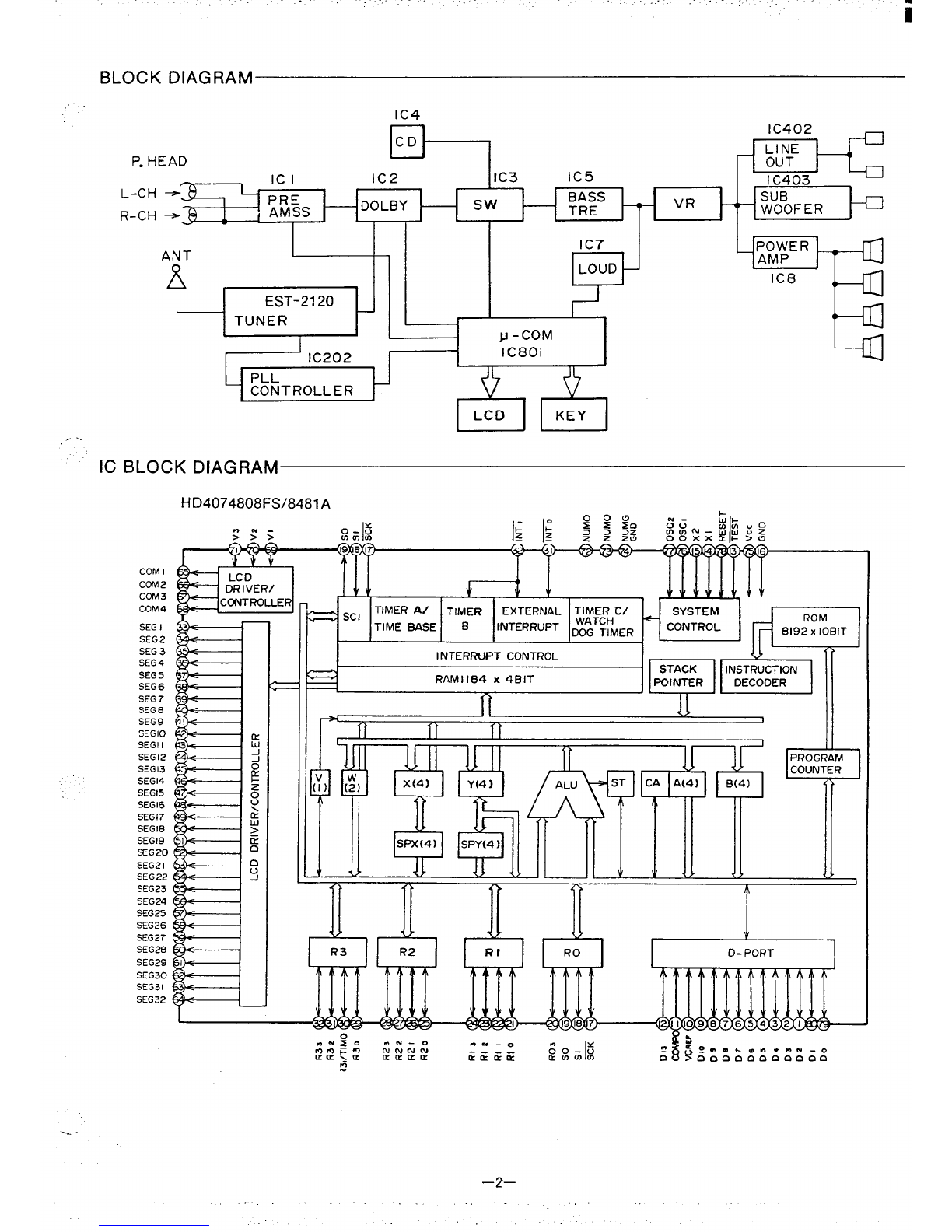

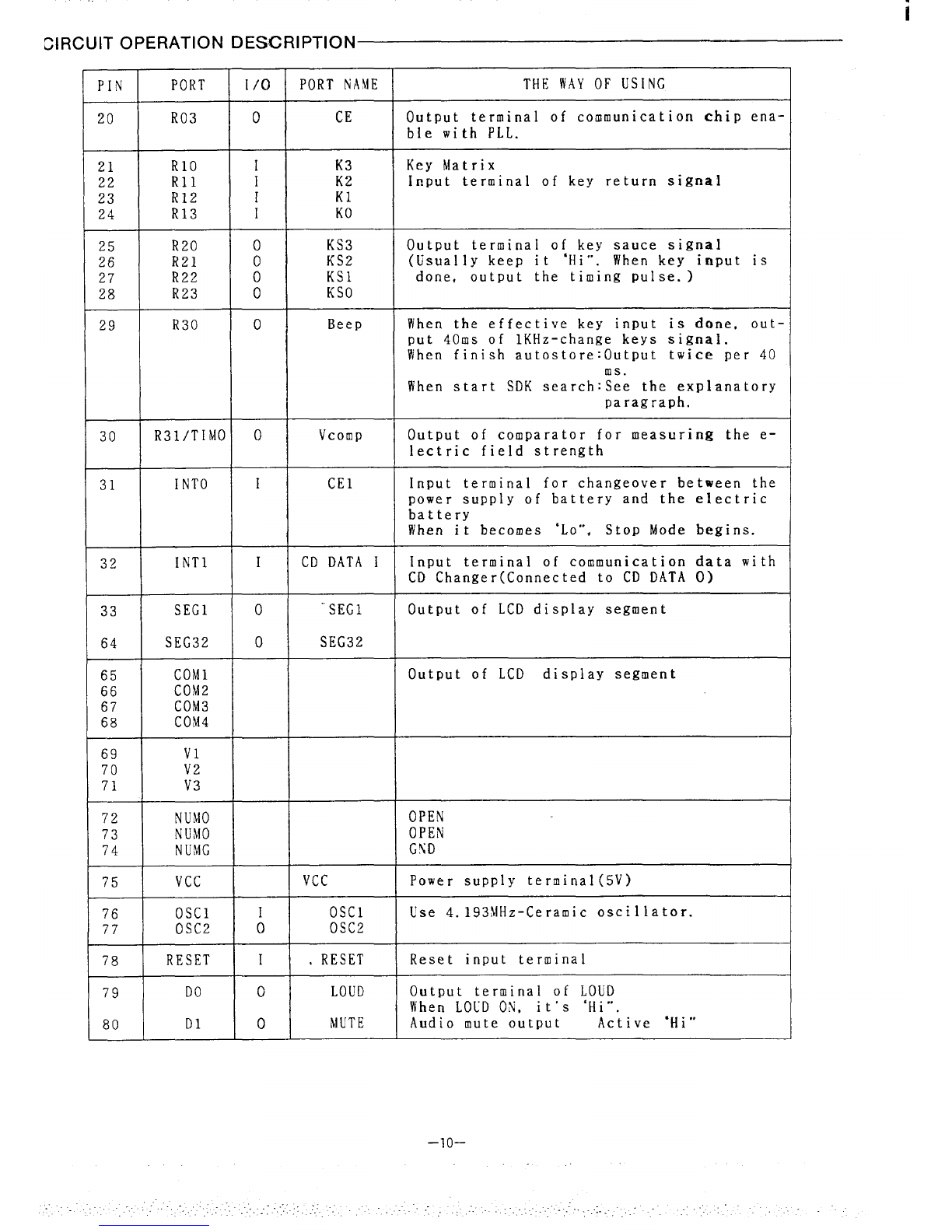

CIRCUIT OPERATION DESCRIPTION

1. BASIC OPERATlON OF PULL FREQUENCY SYhfTHESIZER

f-lFZ)2 {

——— ——— .—— ——— ——— ——— ——

7.2MHz Divider Phase detector 11 voltage Control oscillator

oOsc t1Id 1+

fr PD IVco I*fout

Ifr” I

ILow pass filter

Programmable divider L—————.———— —

Prescaler 1I

IP.D. &I

h—— —. ——. -—————. ——— _

m–--– ‘–––––7 “L--- ––(~J~)-– J

I—_——————— ———————— — ;

The illustration above is ablock diagram which is afwrsda-

mental PLL frequency synthesizer.

In order to obtain reference frequeqcy fr, the frequency

of 7.2 MHz generated from acrystal oscillator (OSC) is

passed into adivider circuit of I/d.

This fr is compared with fr’, and runs through phase detec-

tor (PD) “and low pass filter (LpF) to be inverted to direct-

current signal, which is then applied as “varicap voltage of

voltage control oscillator (VCO), thereby control Iing the

oscillation frequency.

This oscillation frequency fout is divided down to l/J$f by

programmable divider (PD), so that one closed loop is fixed

in the relation of

fout =frxN

therefore, the operation of PLL is stabilized

In the case of automatic channel selection, the dividing

ratio Nis altered by the PD by acommand from controller,

and fout is changed accordingly.

Programmable divider

Since the osci Ilation frequency of VCO is very high as

compared with fr, it is divided down to l/N (in the case of

AM) to decrease the difference from fr in this circuit.

Phase detector

This is acircuit to detect the difference in frequency and

phase between reference frequency fr and comparison fre-

quency fr in terms of pulses.

Low passfilter

This circuit is intended to vary and fix the output voltage

in order to deliver avaricap voltage necessary for desired

VCO frequency, on the basis of the output of the phase

detector.

Prascaler

The local oscillation frequency in FM is higher than the

operating speed of the programmable divider of PLL, there-

by opposing to accurate operation. To avoid this, the local

oscillation frequency is preliminarily divided down in this

circuit to aproper frequency permitting reliable operation

of the programmable divider.

Pulse swallow count system is employed. Acouple of pro-

grammable divider (swallow counter and programmable

counter) can be selected.

l-T~~——————

———————

Swallowcounter l/Nl 1

fosc Jcontroller

Ifr’

I1l/N2 Ii

L—-————— ——— —.-2

Programmable divider (N1<N2)

fosc= {(M+l) N1+M (N2--N1)} fr’

=(MN2+N1) fr’

Prescaler IM+ IM

,I

Swallow counter INI

Programmable counter

The prescaler at first starts the frequency division with the

ration M+l. Then swallow counter and programmable

counter start counting simultaneously. When N1inputs are

applied, swallow counter stops counting. Then the frequen-

cy division ratio of the prescaller is switched to M. Program-

mable counter continues to count however and stops when

the input reaches N2. The frequency division ratio of the

prescaller switches back to M+l ard swallow counter and

programmable counter start to count again.

FM reception employs the pulse swallow count system. AM

reception does not employ the pulse swallow count system

but employs the direct frequency division system and so

only programmable counter is operated.

2. GENERAL DESCRIPTION OF LOGIC IC (IC202)

@IC202 LC7218M

This IC includes PLL and controller is aC-MOS LSI for dig-

ital tuning of FM/AM PLL frequency synthesizer system

and controls such functions as FM/AM automatic chan-

nel selection, preset memory and frequency digital

display with Prescaler and liquid crystal digital frequency

display driver. His packed in a24-pin fiat package.

3. AUTO STOP

If count start, when High level signal is applied to SD ter.

minal (Pin No. 15). Then IF freqs.sency became 10.7 MHz

~30k Hz at FM or 450kHz &3kHz at AM. When SD and IF

is agreed radio auto search tuning stops.