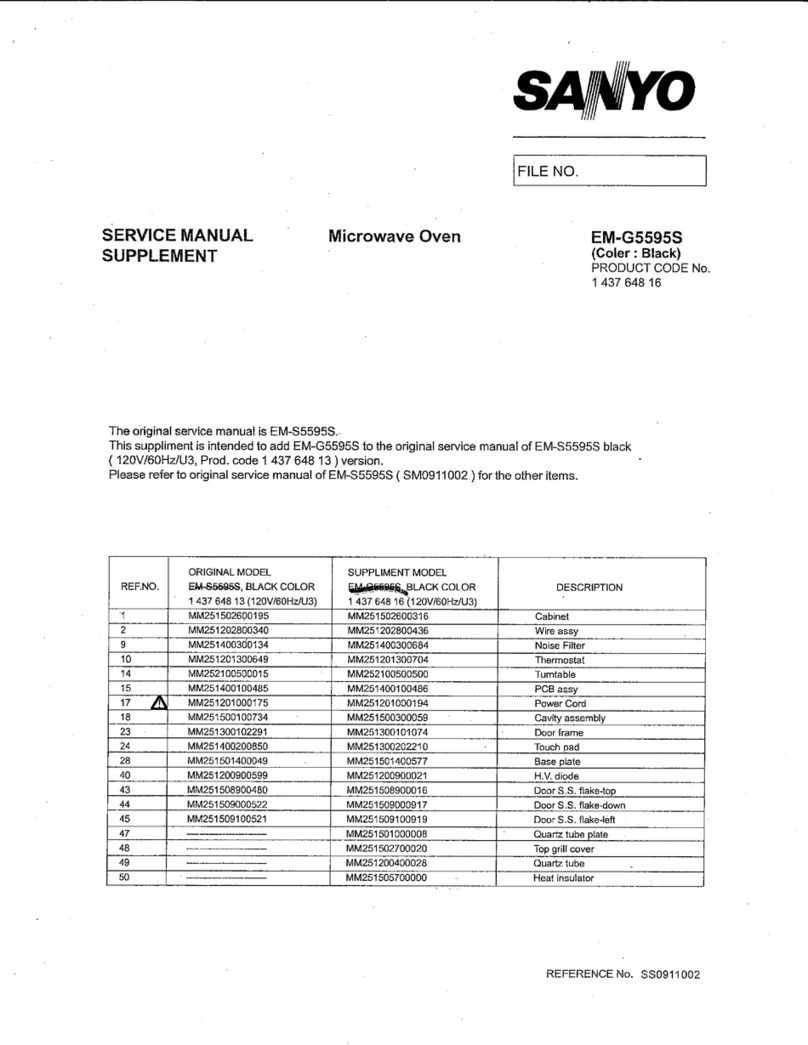

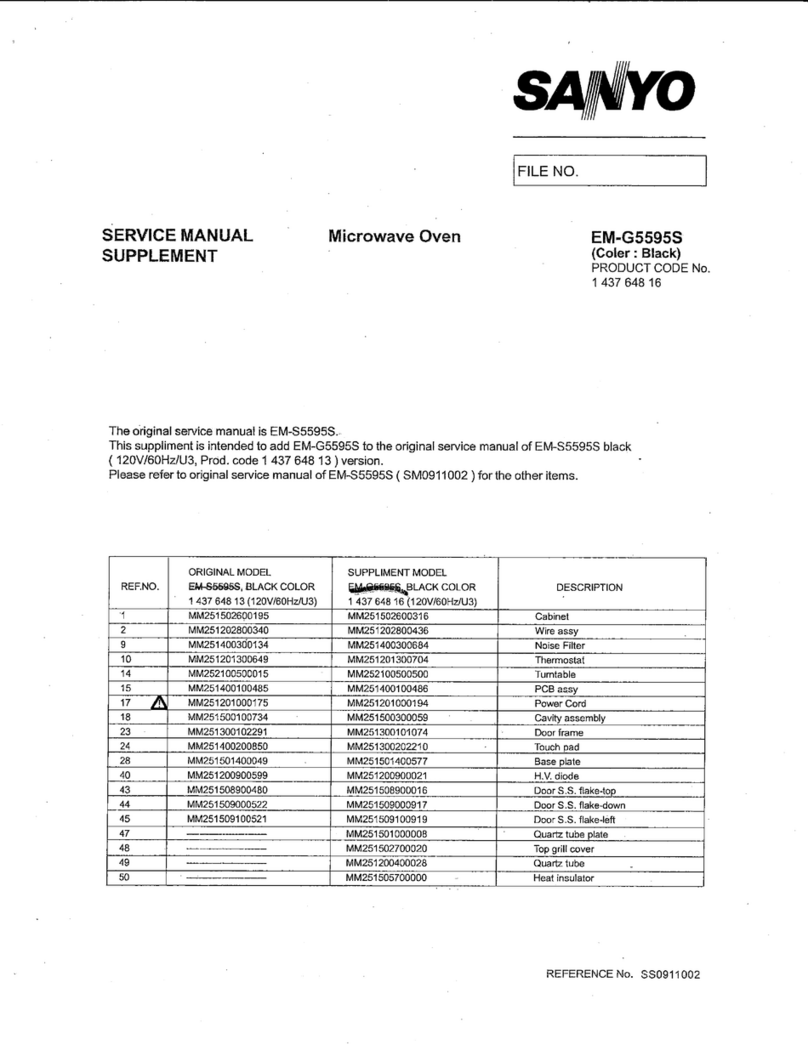

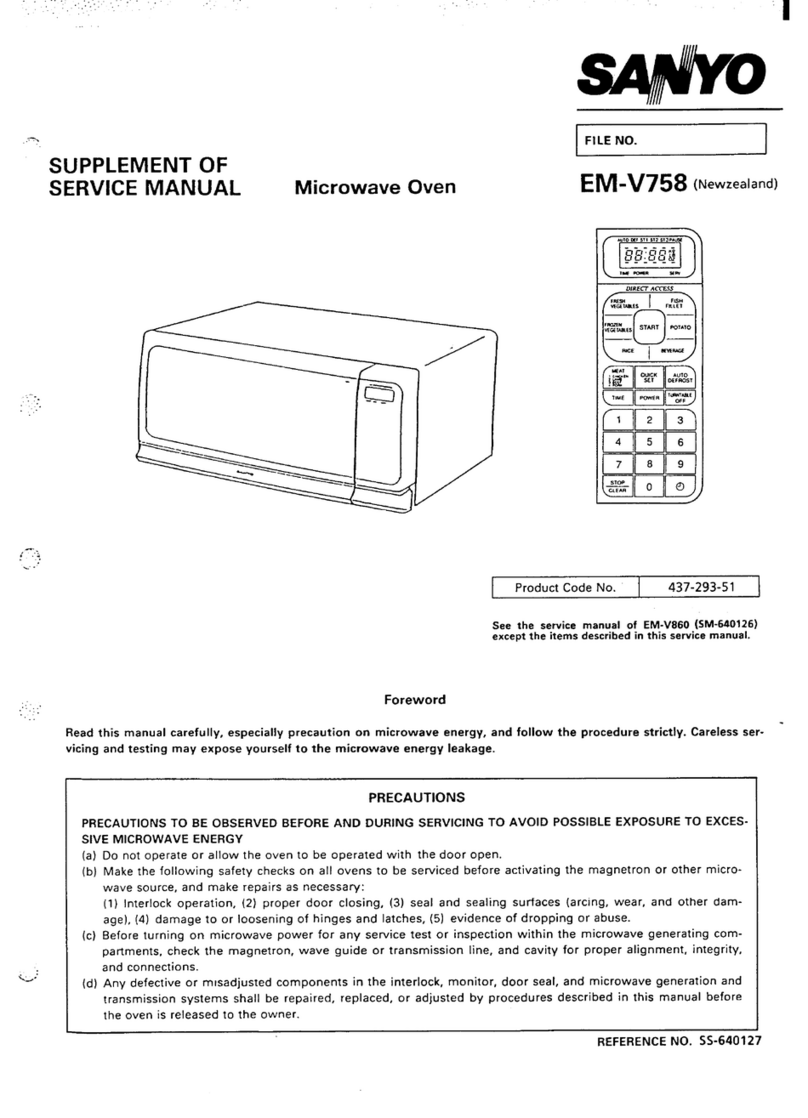

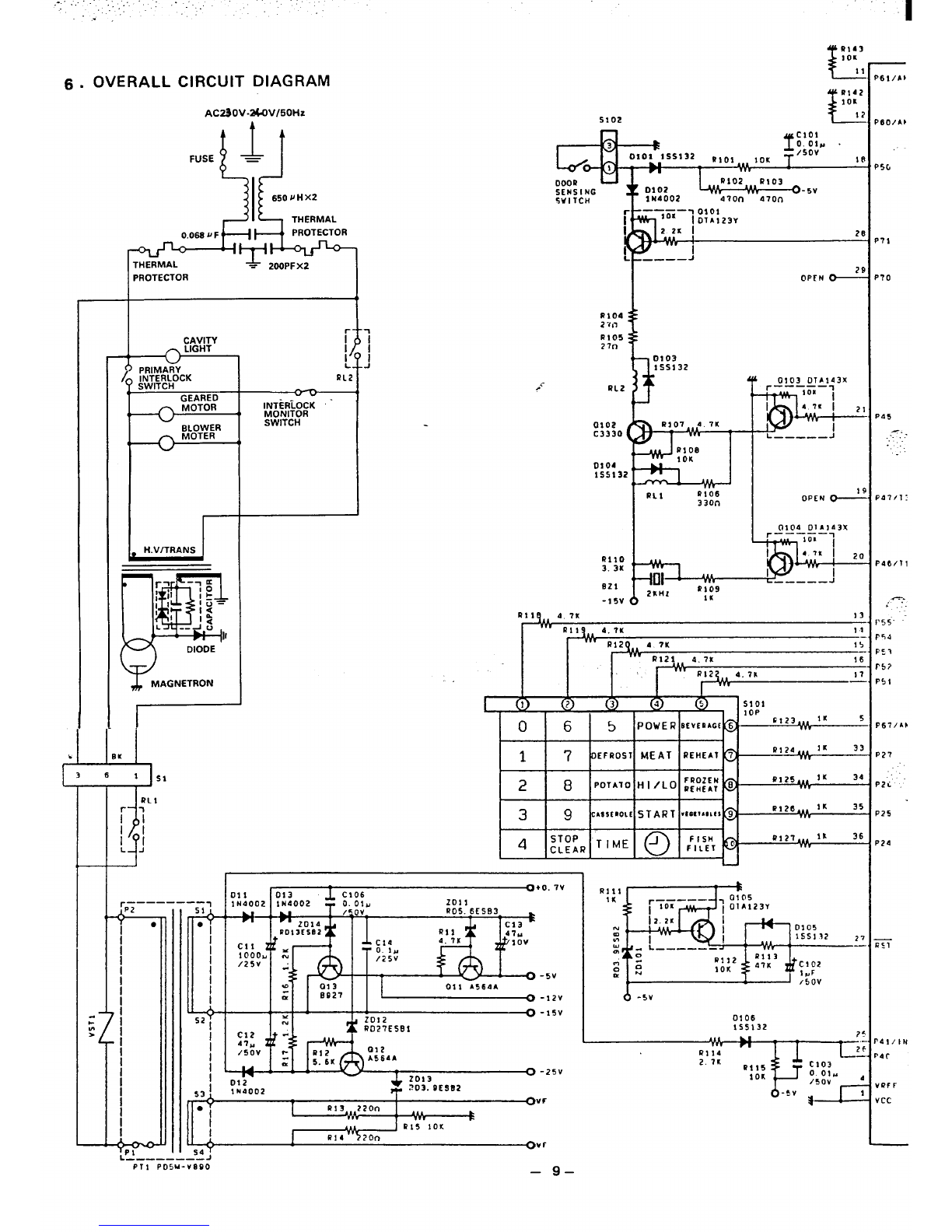

SWITCHES AND MICROWAVE PARTS

27

(l”

Notes The sign ❑-The pa ❑

rts marked with $are supplied high

voltage which is exceeded 250V.

The sign @-The parrs marked with@ have special char-

acteristics important for microwave leakage.

When replacing any of these parts use onlv

manufacturer’s specified parts,

Key

No. Part No. Description C1’ty

1 411 0825201 Screw, Truss Hd. Tapping, 4x10mm 6

26171385113 Power Supply Cord Complete 1

3 6171569605 High Voltage Transformer, 1

H5T-V860SAP

46171505603 Duct, Msg. Inlet 1

56171385984 Stay, Cavity &Magnetron 1

64110076900 Screw, Pan Hd. Tapping, 3x6mm,

C2-2 2

7~1”~ 124 f259 Thermostat, Magnetron, 135CC 1

84,50023308 Magnetron. 2M247H(8)*** 1

94230227503 Fuse, 250 V8A 1

10 6171414042 Terminal Circuit 8oard Complete 1

11 6171451627 Lead Wire Ass’y with Diode 1

12 617124379? Lead Wire Ass’y (Transformer to 1

Capacitor)

13 6171378870 Capacitor Band 1

14 6171449716 High Voltage Capacitor, l.1mfd.2.1 KV 1

15 6171241082 Space Partition (Blower) 1

16 6171306927 Blower Motor 1

17 4110772109 Screw, Truss Hd. Tapping, 2

4x20mm, Z1-1

Key

No. Part No. Description f.1’ty

18 6170751179 Blower Fan 1

19 411011 5609 Bolt HEX C-SCT 4x20 3

20 6171405330 Duct, Mag, Exhaust 1

21 6171103618 Lamp, 2413v25W 1

22 6171241280 Lamp Socket 1

23 6171241181 Latch Lever*** 1

24 6171524741 Micro Switch, primary, and Door** 2

Sensing V-5930D***

2.5 617004 557s Micro Switch, Interlock Monitor 1

V-5220 DZ***

27 6171241174 Lever Stopper’** 1

29 411 1025808 Screw, E- Tapping TRRS +TW 2

,4x10 mm, Z1

30 411 1606007 Scr~w TPG TRS +SRT 4x10mm 1

31 411 1606106 Scre~ S-TAP TRS +SRT 4x1O mm 2

32 411 0014704 Screw, Pan Hd. Tapping, 4x1O mm, 1

Z1

33 6171325713 Insulation Sheet 1

,-..-

....’

,,.

..

.

.,

–5-