CONTENTS —

LASER BEAM SAFETY PRECAUTIONS . . . . . . . . 1

OPERATING THE RESET SWITCH . . . . . . . . . . . 1

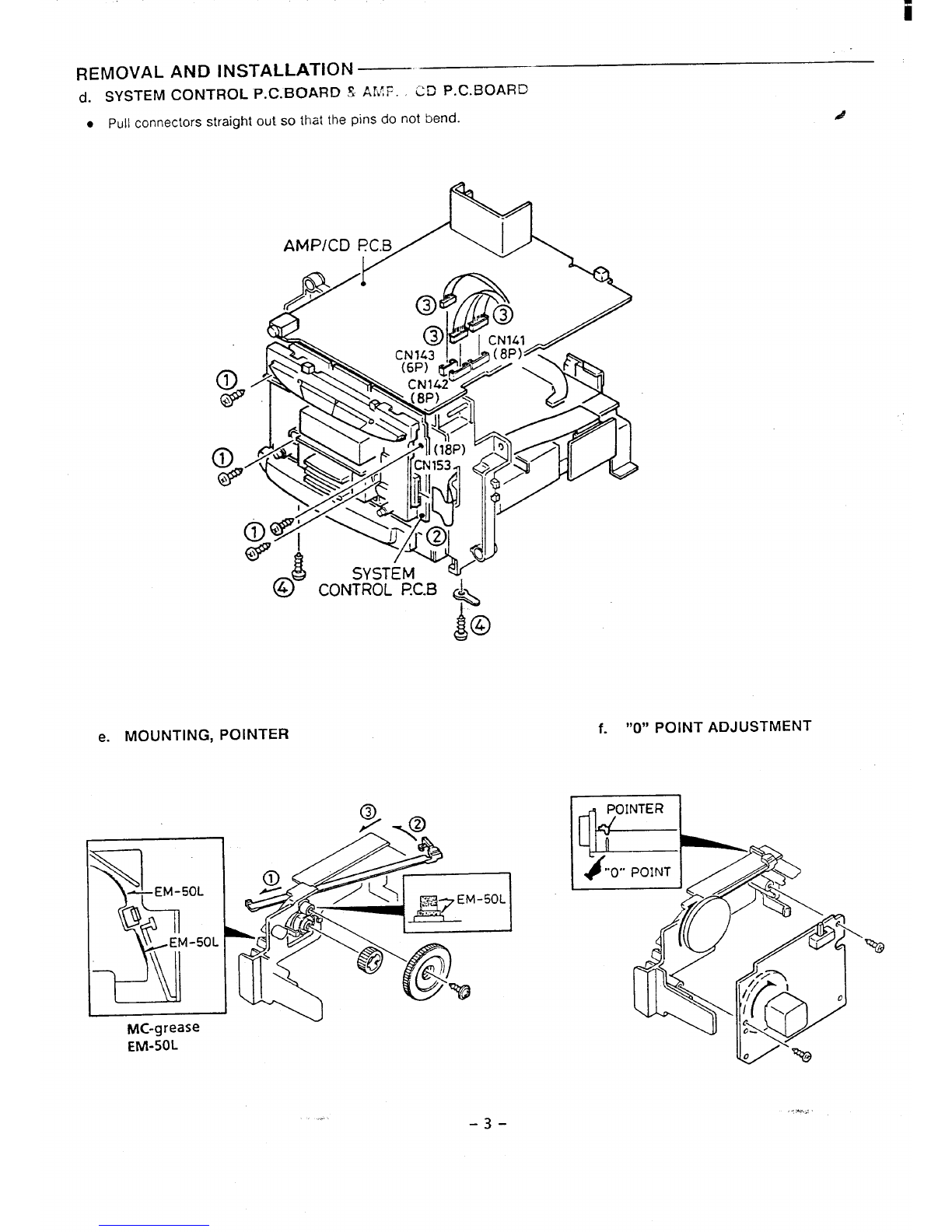

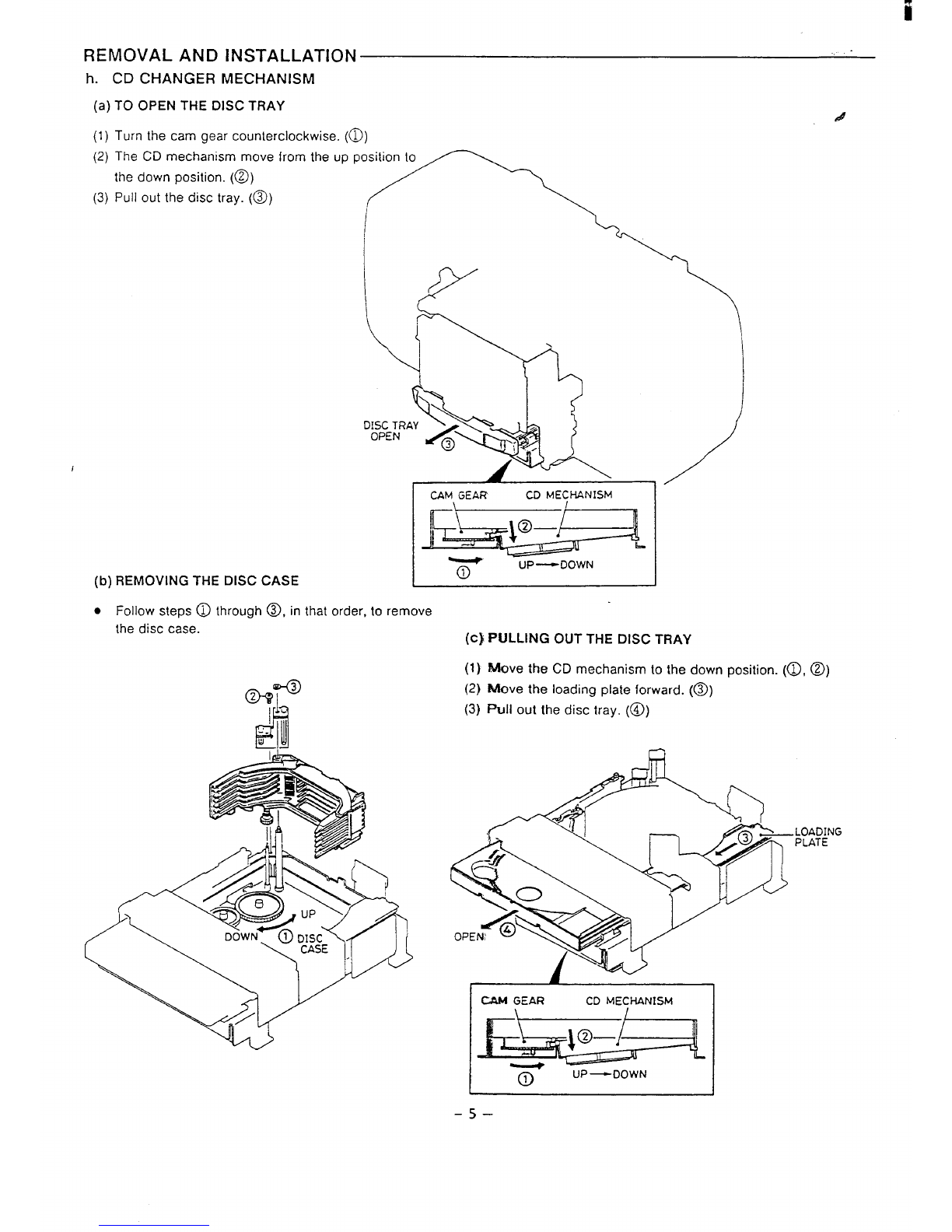

REMOVAL AND INSTALLATION ............. 2

TUNER ADJUSTMENTS ..................-6

TAPE DECK ADJUSTMENTS ...............7

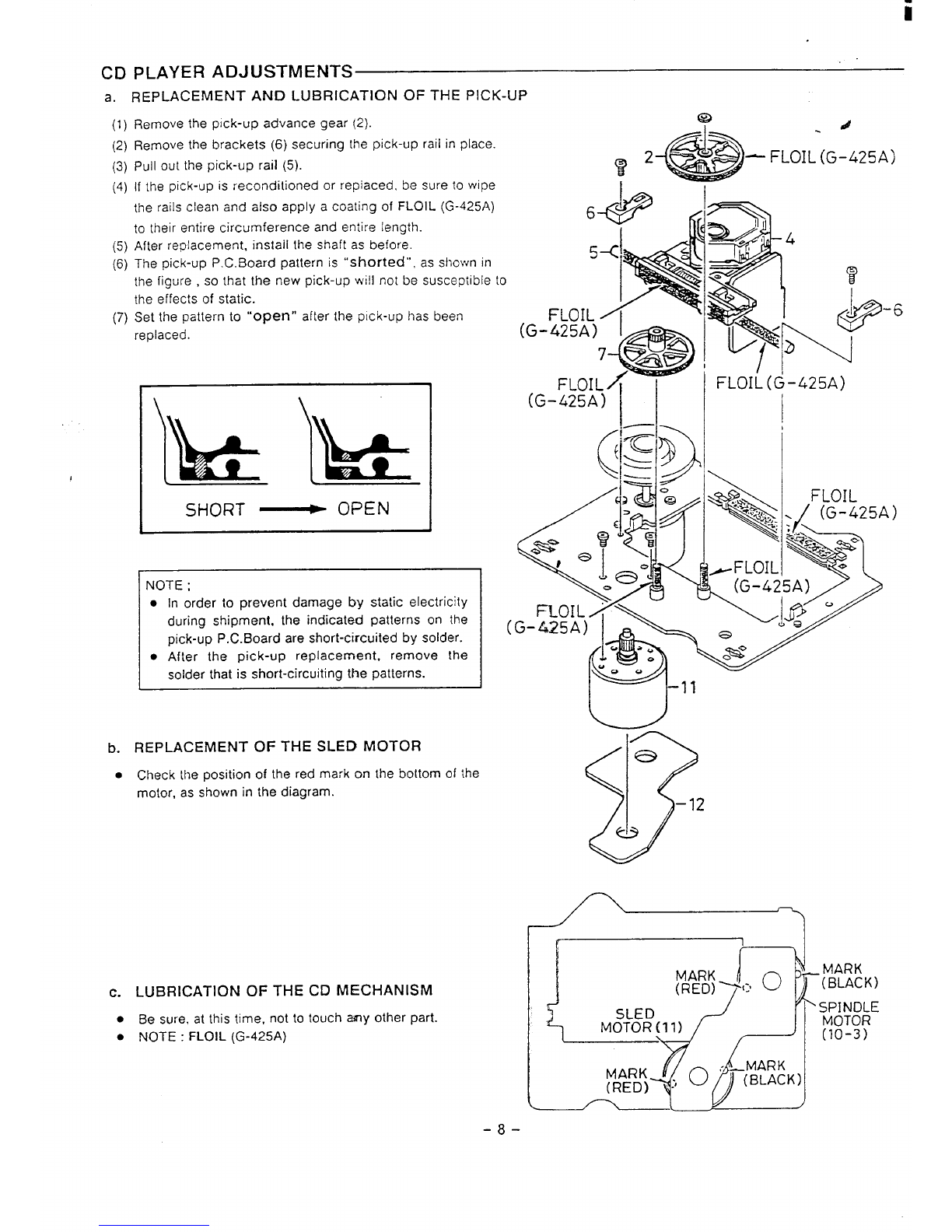

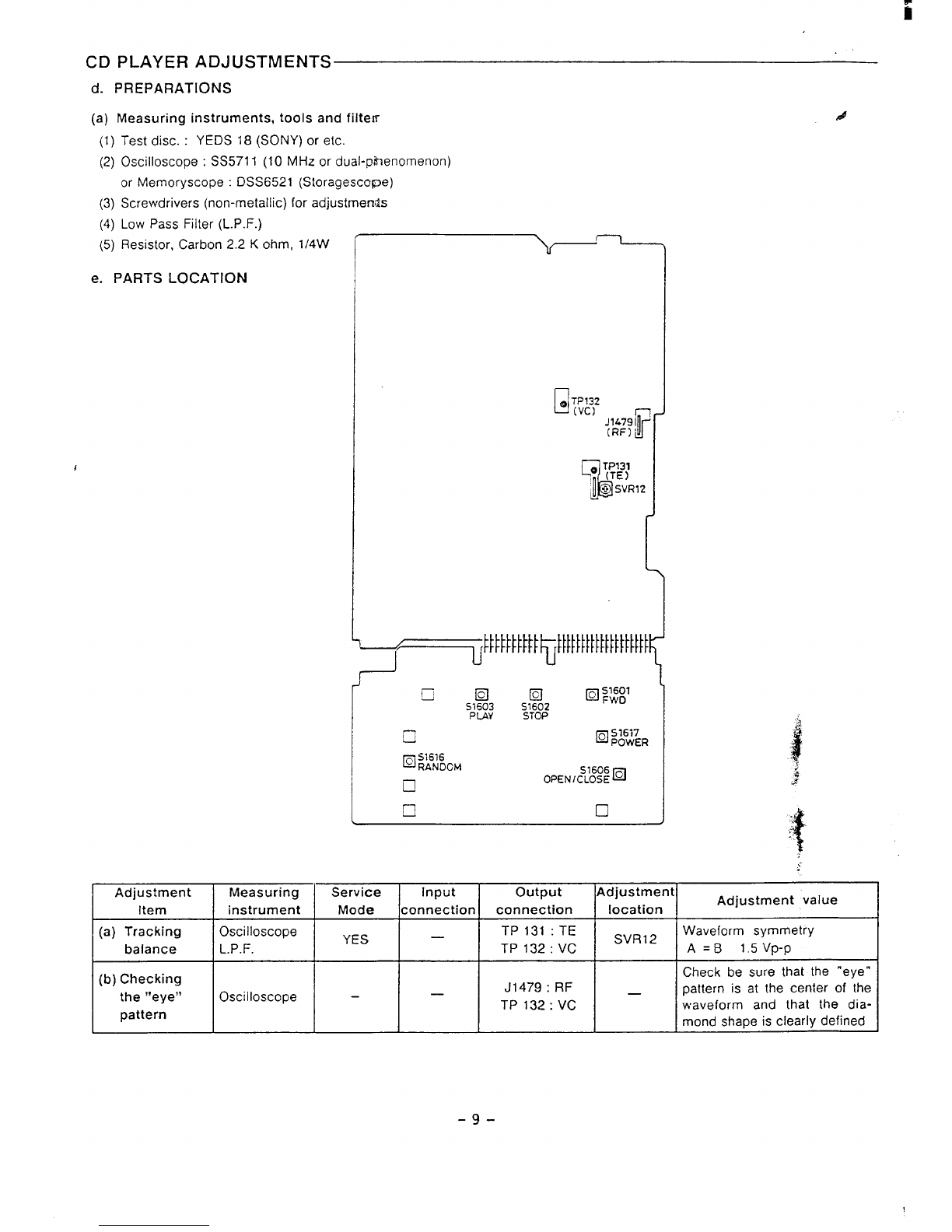

CD PLAYER ADJUSTMENTS ...............8

SERVICE MODE .........................11

CD CHANGER MECHANISM OPERATION

DESCRIPTION .........................-14

LASER BEAM SAFETY PRECAUTIONS—

.Pick-up that emits alaser beam is used in this CD player.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED

HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE

LASER OUTPUT ........0.6mW Max. (CW)

WAVELENGTH ........... KIO nm

REPLACING THE PRINCIPAL PARTS &

OF THE CD CHANGER MECHANISM .........17

EXPLODED VIEW ........................25

PARTS LIST ...........................27

IC BLOCK DIAGRAM &DESCRIPTION ........38

SCHEMATIC DIAGRAM ....................40

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . ...41

CD CHANGER BLOCK

SYSTEM CONTROL TERMINAL LEVELS .......63

CD CHANGER BLOCK FLOWCHART .........65

CLASS 1LASER PROOU

LUOKAN 1LASERLAIT

KLASS 1LASERAPPAR

CAUTION–INVISIBLE LASER RAOIATION

WHEN OPEN AND INTERLOCKS OEFEATEO.

AvOIOEXPOSURE TO BEAM.

,AOVARSEL-USYNLIG LAiEtiTRALING VEO A8NING.

NAR SIKKERHEOSAF8RYDERE ER UOE AF FUNKTION,

UNOGk UDS /ZTTELSE FOR STR~LING.

VARNING–0SYNLN3 LASER STR~LNIN.G NAR

OENNA DEL AR OPPNAO OCH SPARR AR URKOPPLAO.

STRALEN AR FARLIG.

VORSICHT-UNSICHTBARE LASERSTRAHLUNG TRITT AUS.

‘WENN OECKEL GEOFFNET UNO WENN SICHERHEITSVERRIEGELUNG

uBERBRUCKT [ST. NICHT, OEM STRAHL AUSSET2EN. A

VARO! .Avawssa fa suoialuk!lus. ohilellaes~a Olel allliina

nakyma!lomalle Iasemileilylle. Ali kalso saleeseen. II

OPERATING THE RESET SWITCH

WHAT TO DO IF ...

If the operation of the unit or display is n

normal, disconnect the power cord from the P

outlet and remove the batteries (if applicabl[

then press the RESET bulton (back of the un

for at least 20 seconds.

-1-