FILE NO

Model NO. C20VTI I-M@

Videocassette Recorder (New Zealand /Oceania)

Service Ref. No. C20VT11 -M@-00

w

t,

;

Contents

Safety Precautions, X-Radiation Precautions ................. ~

Specifications .....................................................................

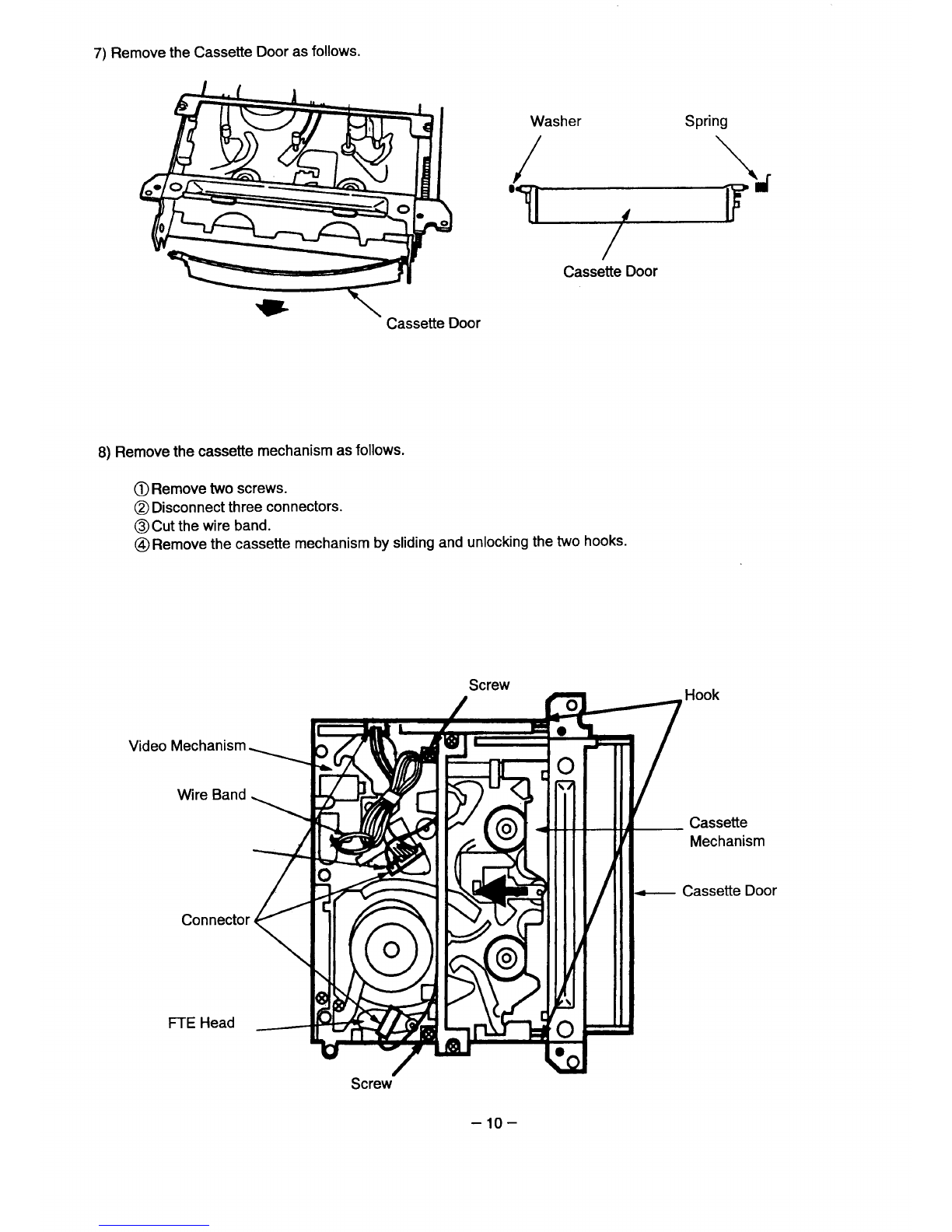

1. Mechanical Disassembles

1-1. Cabinet back removal ............................................ 4

1-2. Chassis removal .................................................... 4

1-3. Video mechanism removal .................................... 5

1-4. Service procedure ................................................. 7

1-5. Replacement of the reel drive belt ........................ 8

1-6. Video mechanism disassemblies .......................... 8

1-7. Cassette mechanism assembly .............................11

2, Service Mode ................................................................l2

3. Power Circuit Protection and

Self Diagnosis Display

3-1. Power circuit protection ........................................ 13

3-2. Power circuit problem self diagnosis .................... 13

3-3. VCR self diagnosis ................................................l4

4. ICS Pin Description

4-1. IC800 (CPU) pin description .................................15

4-2. IC1930 (DAC) pin description., .............................l5

5. Service Adjustments (TV Section)

+15V/+1 15V, Vertical size/center, Focus adjustment..l 6

Grey scale, AGC, Horizontal center adjustment .........l7

Horizontal width adjustment, High voltage check ........18

Clock frequency confirmation .......................................l8

6. WF Adjustment ............................................................. 19

7. A7TAdjustment ............................................................2O

8. Purity and Convergence Adjustment ...........................21

Product Code: 111321218

Original Version

Chassis Series: TC2-A

WE

9. VCR Main Mechanism Parts Location

9-1. Mechanism ass’y (Top view) .................................... 22

9-2. Mechanism ass’y (Bottom view) ............................... 23

9-3. Front loading mechanism .......................................... 23

10. Mechanism Dismantling and Reassembling

10-1. Cassette drive gear (Right) ................................... 24

10-2. Cassette drive gear (Left) ..................................... 25

10-3. COMPL motor bracket (Loading motor block) ..... 26

10-4. Tape loading mechanism ...................................... 29

10-5. Capstan motor ....................................................... 32

11. VCR Service Adjustments

11-1. Test points for tape path adjustment .................... 33

11-2. Location of adjustment point ................................. 33

11-3. Sewicejigs ............................................................ 34

11-4. Mode selector (VHJ-0050) handling instruction ... 35

11-5. Tape path adjustment ........................................... 37

11-6. Servo circuit adjustment ...................................... 39

11-7. Audio circuit adjustment ...................................... 39

11-8. Video still V-lock adjustment ................................ 40

12. Mechanism Maintenance and Checking

12-1. Periodic checking and maintenance items .......... 41

12-2. l_#mwo~e~roceedwhen the cassette cannot be

................................................................ 42

13. Cabinet Parts tist ........................................................... 43

14. Video Section Parts List ................................................ 44

15. TV Section Chassis Electrical Parts List ........................ 49

REFERENCE NO. SM 520130

(E7WY)