Step 1 Look for this icon. It means a

video assembly tip is available at

www.sauder.com/services/tips

å Assemble your unit on a carpeted floor or on the empty carton

to avoid scratching your unit or the floor.

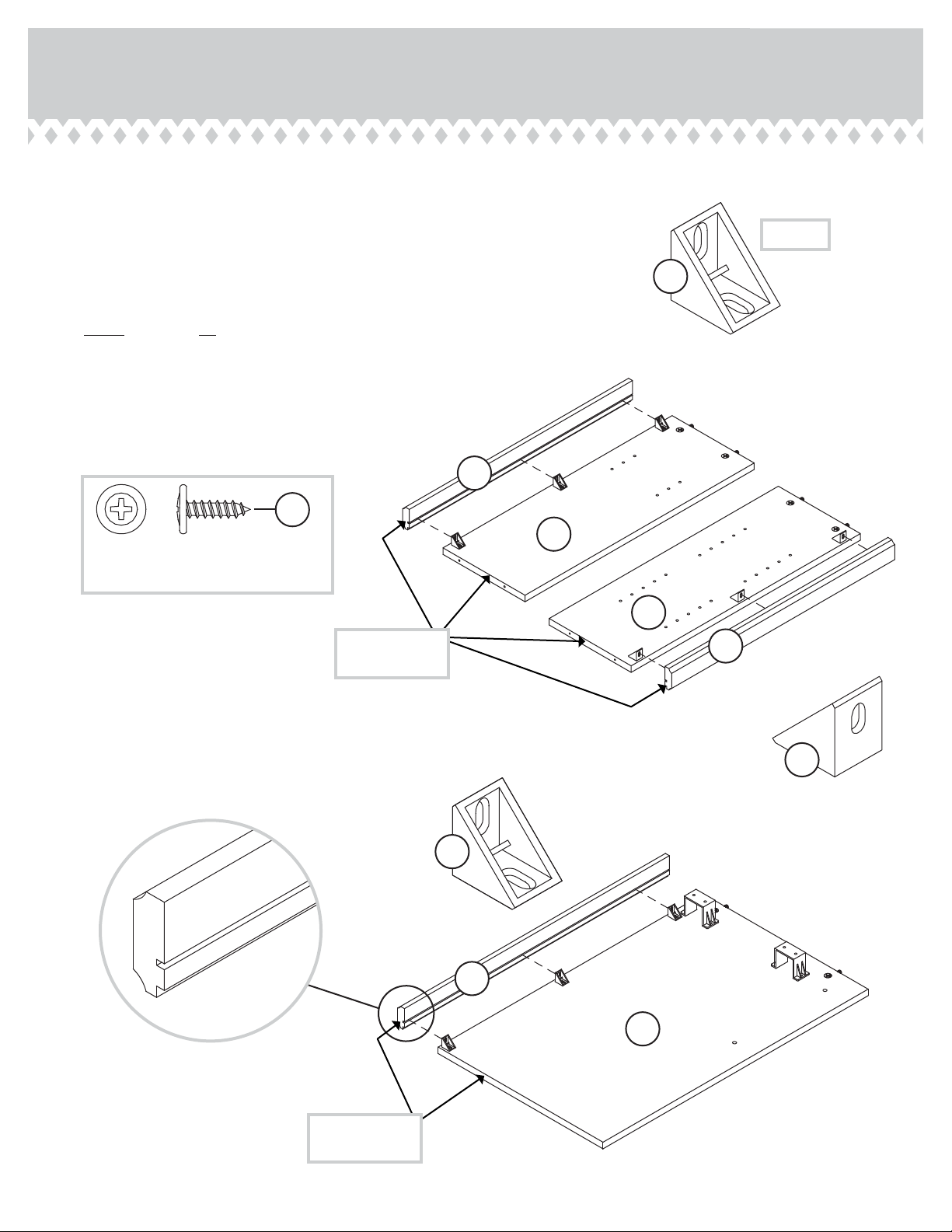

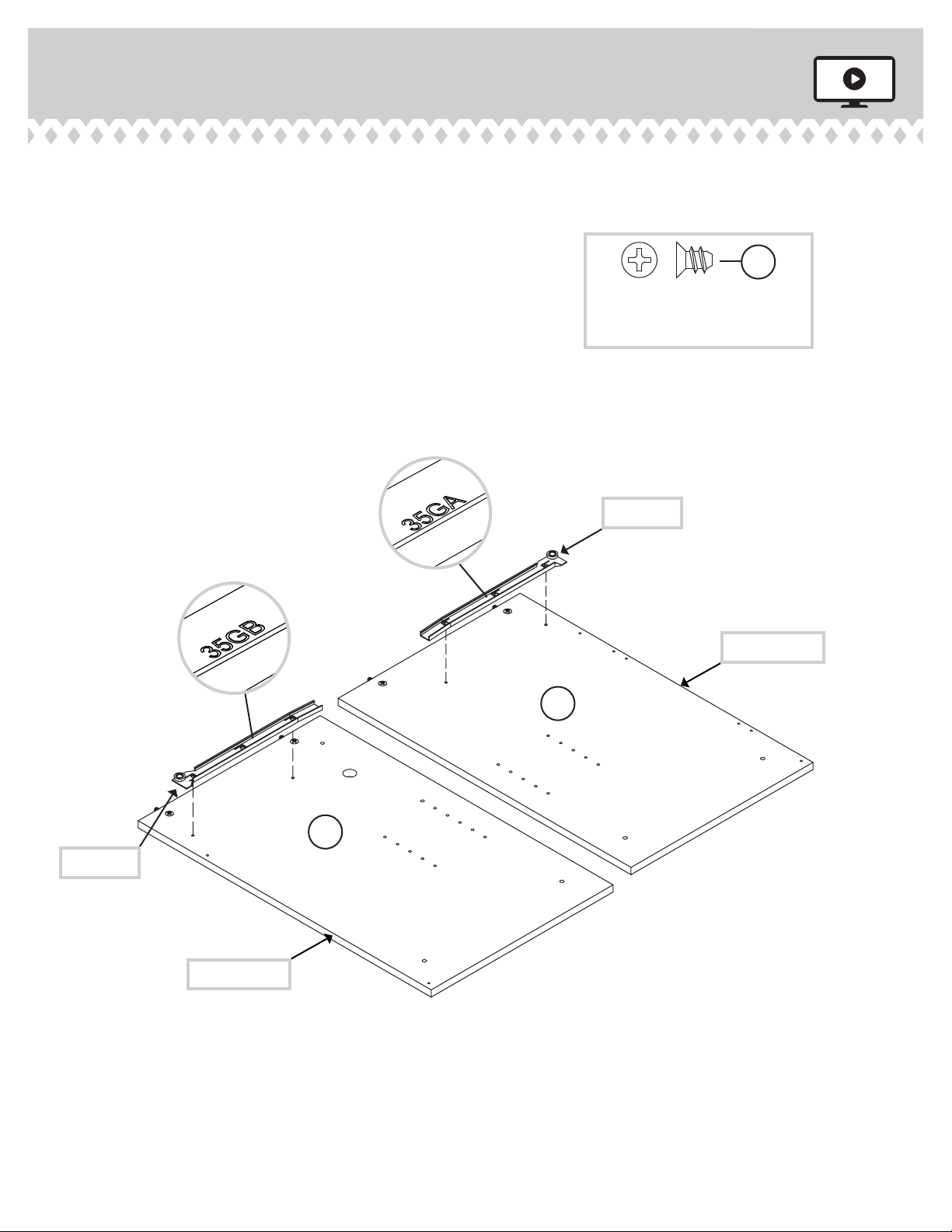

å Push sixteen HIDDEN CAMS (1F) into the ENDS (A and B),

HUTCH ENDS (C and D), UPRIGHT (E), MODESTY PANEL (I),

and BOTTOM (J). Then, insert the metal end of a CAM

DOWEL (2F) into each HIDDEN CAM.

418649 www.sauder.com/servicesPage 6

Arrow

1F

2F

(16 used)

Arrow

1F

2F

Insert the metal end of the CAM

DOWEL into the HIDDEN CAM.

Arrow

Do not tighten the HIDDEN CAMS in this step.

A

B

C

D

E

I

J