Setup Instructions

1. ENTER SETUP MODE: Press and hold touchpad 1 until lights illuminate from 1/8

through 7/8 after which the lights will turn off indicating the monitor is in setup mode.

Remove your finger from the touchpad. Repeat the setup instructions for tank 2 on

model TM2 using touchpad 2.

2. PARAMETER OPTION SELECTION: The setup mode sequentially advances to

each option for each parameter every 5 seconds and advances to the next

parameter. Tap the touchpad to select a desired option if its light is flashing.

Parameters and options are presented as follows:

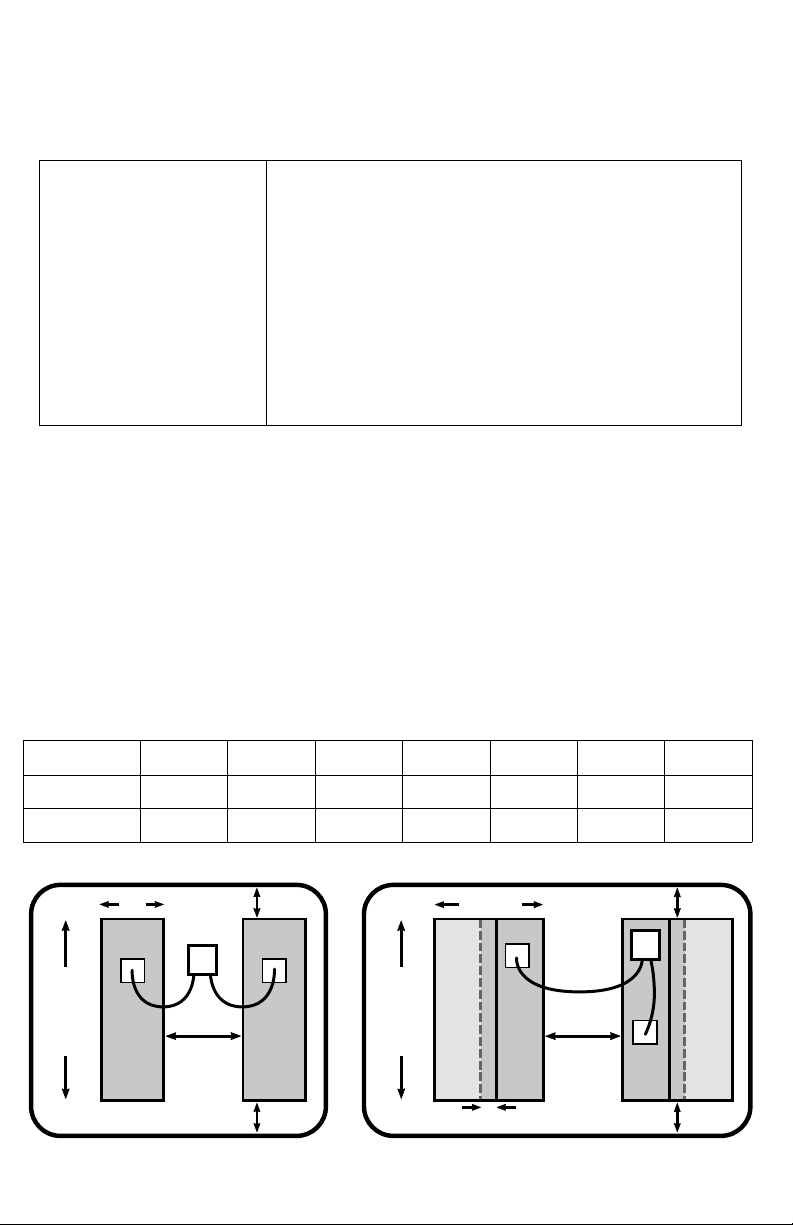

a. E light on = SENSOR TYPE parameter is active

i. F light = SCAD sensors: external 8” or longer internal 12” or longer

ii. 7/8 light = SCAD sensors: external less than 8” internal less than 12”

iii. 3/4 light = 240–30 Ohm resistor type float sensor option

iv. 5/8 light = 10-180 Ohm resistor type float sensor option

v. 1/2 light = Diagnostic mode: raw sensor signal voltages. Ignore during

setup. (more information at www.scadtech.com/TMHelp)

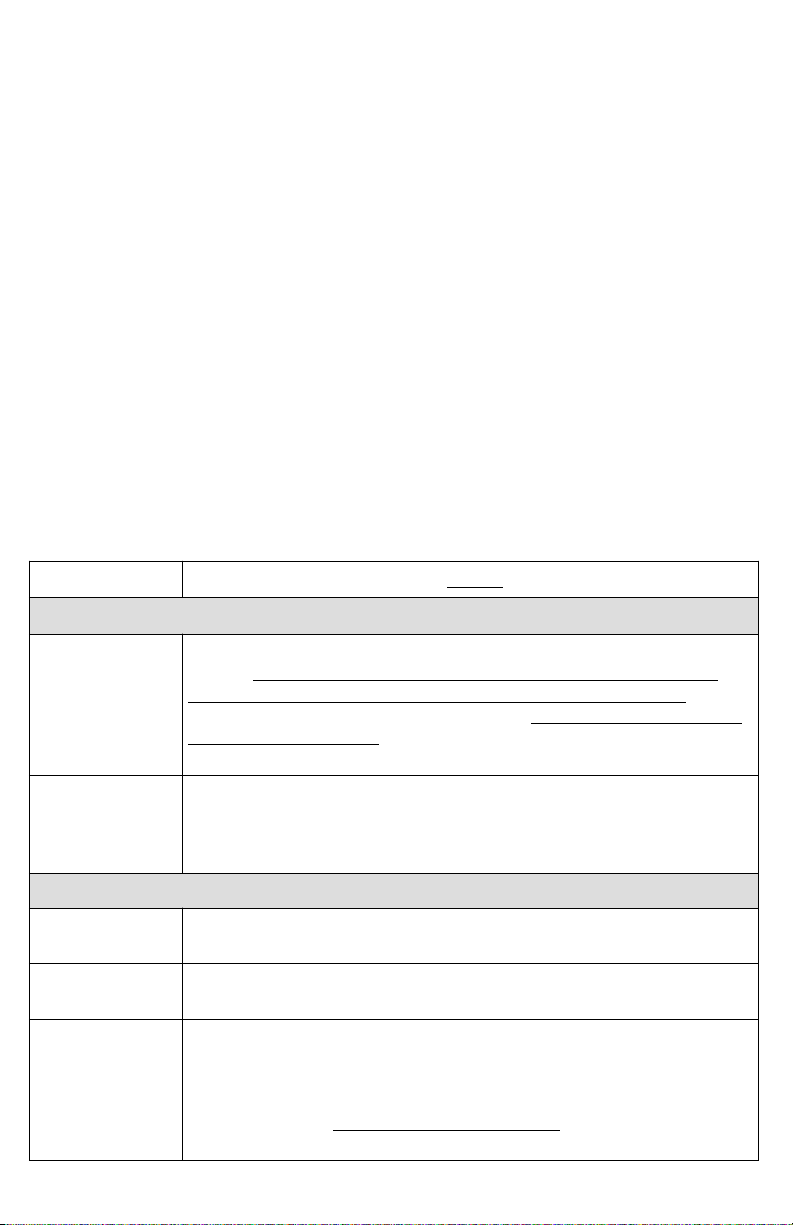

b. 1/8 light on = TANK SHAPE parameter is active

i. F light = Rectangular

ii. 7/8 light = Mild taper

iii. 3/4 light = Severe taper (almost triangular shape)

iv. 5/8 light = Horizontal cylinder

c. 1/4 light on = ALARM TYPE parameter is active

i. F light = Alarm on full

ii. E light = Alarm on empty

iii. 1/2 light = No alarm

iv. 3/4 light = External alarm wire energized on alarm condition. This is

selectable if “Alarm on full” or “Alarm on empty” were previously selected.

When the 3/4 light is flashing the wire will not energize on alarm condition.

Tap the touchpad to turn this option on. The 3/4 light will stop flashing.

3. EXIT / RE-ENTER PARAMETER OPTION SELECTION: All lights will turn off

then on again for five seconds. If you want to re-enter the parameter option

selection setup again tap the touchpad. If you do not tap the touchpad the

monitor will proceed to calibration setup.

4. ENTER CALIBRATION SETUP: Next the three top center lights will flash (3/8 1/2

and 5/8) for five seconds. To enter the calibration setup tap the touchpad while

the lights are flashing. To skip the calibration setup do nothing and the monitor

will proceed to normal operation.

5. CALIBRATION: The 1/2 light will stay on to indicate the monitor is in calibration

setup mode. Empty and full calibrations can be set at any time in any order. For

example if the monitor is in normal operating mode and you need to set an empty

or full calibration enter setup mode wait for the parameters and options to

sequence through and then enter calibration mode as described above. Then

calibrate as follows:

a. EMPTY Calibration – With an empty tank while the E light is flashing tap the

touchpad to record the empty level. Do not tap the touchpad if you don’t want

to set the empty calibration.

b. FULL Calibration – With a full tank while the F light is flashing tap the

touchpad to record the full level. Do not tap the touchpad if you don’t want to

set the full calibration.

6. EXIT CALIBRATION SETUP: All lights will turn off after full calibration and the

monitor will return to normal operation.