Scale Bracket and Load Cell Mounting

7900050 REVA Page 5

5. Install the front and back weigh-bar with the 2-1/4” x 3/8” pins (make sure the arrow

sticker on the end of the weigh-bar is pointing up). Weigh-bars with 16 ft cords to the rear,

and 11 ft cords 4 ft to the front (long cords go on back of drill, short cords go on front of

drill).

6. Let the seed bin down to about 1” and slide the rear bracket on. Use the 5/8” x 8” bolts in

the front 2 holes. On the rear bracket there is a 2” box tubing with a 1/2” hole. Use the 2-

1/2” x 3/8” clevis pins with a washer on each side; make sure the clevis pin is in the center

of the hole. (Note: the rear step grip is installed between the rear bracket and the step

bracket already on the grain drill. Do not tighten the bolts.)

7. Install the front bracket with new 5/8 x 8” bolts. Use the 2-1/2” x 3/8” clevis pin to go

through weigh bar and bracket. The clevis pin should be in the center of the 1/2” hole.

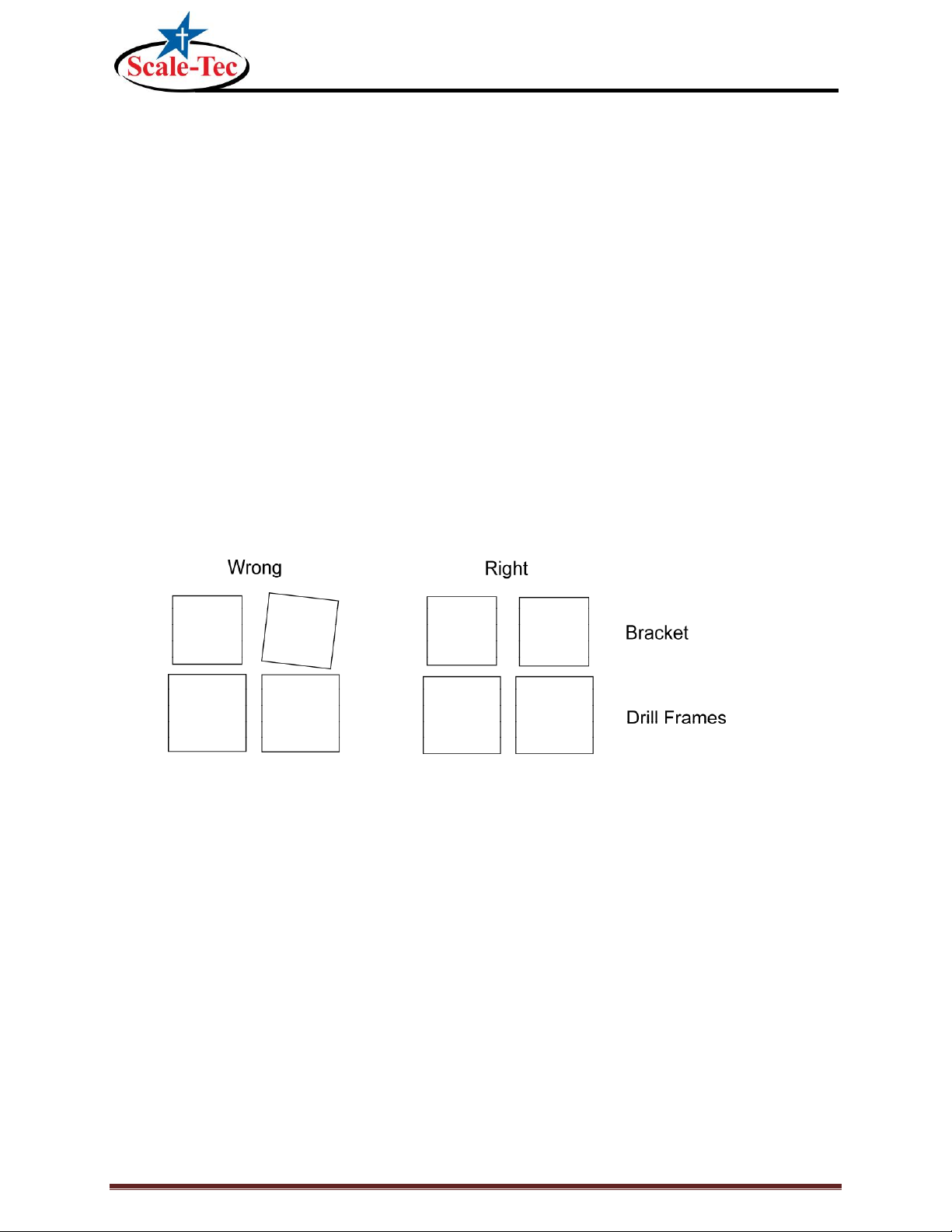

8. Make sure the middle, front and rear brackets are straight with each other. Tighten the

middle bracket first, then the front and back brackets.

9. Remove the bolts on the right side that hold the seed bin to the frame. Remove the drive

chain and clutch drive arm (1” x 1/4” flat steel) attached to the seed hopper and clutch

drive.

10. Repeat steps 3 to 8 on the right side of the drill.

11. When both sides are complete, all the brackets should stand straight.

12. Lengthen the drive chain with chain links provided. Do not over tighten chain. Leave the

chain loose enough so it is not pulling down on the seed bin.

13. Attach the new clutch arm. Drill a hole so the clutch is disengaged when the drill is up, and

engaged when the drill is down. The length extended on the clutch arm is approximately

1”, the same distance the seed bin was raised from the scale system. NOTE: Make sure

the clutch arm is mounted on the back side of the clutch.