Scheibe Aircraft SF 25 C-FALKE Technical specifications

........

·-·--..--~-

·-·--=---

SCHEIBE

AIRCRAFT

GMBH

D - 73540 Heubach,

Am

Flugplatz 5

Tel.:

(0)7173/184

286 Fax:

(0)7173/185

587

e-ma

il:

info@scheibe-aircraft.de

F L I G H T M A N U A L and Maintenance Manual

Serial no:

SF 25 C - F A L K E

motorglider

ROTAX 912 A

()

or

ROTAX 912 5 (2)

maximum all-up weight 680

kg

(604

kg

•11ith

Folding

Wings)

610

kg

(634

kg

with

Folding

Wings)

650

kg

(674

kg

with

Folding

Wings)

690

kg

(714

kg

with

Folding

Wings)

MARCH 1997

Registration no:

44662

G-FLKS .,

Owner: London Gliding Club

~

I/

'

//

f

1£;/f"

/i.::

European Aviation Safety

Age

r

~,

PeulHATTCN

Edition March 1997 Rev.

9,

10.04.2014 Project

CeT1ffiCOlioo

Manager

Pages 1-30

of

this Flight manual are EASA approved

EASA.A.C.10048806

This manual is to be keet

on

board

at

all times.

' '

l

I

i

I

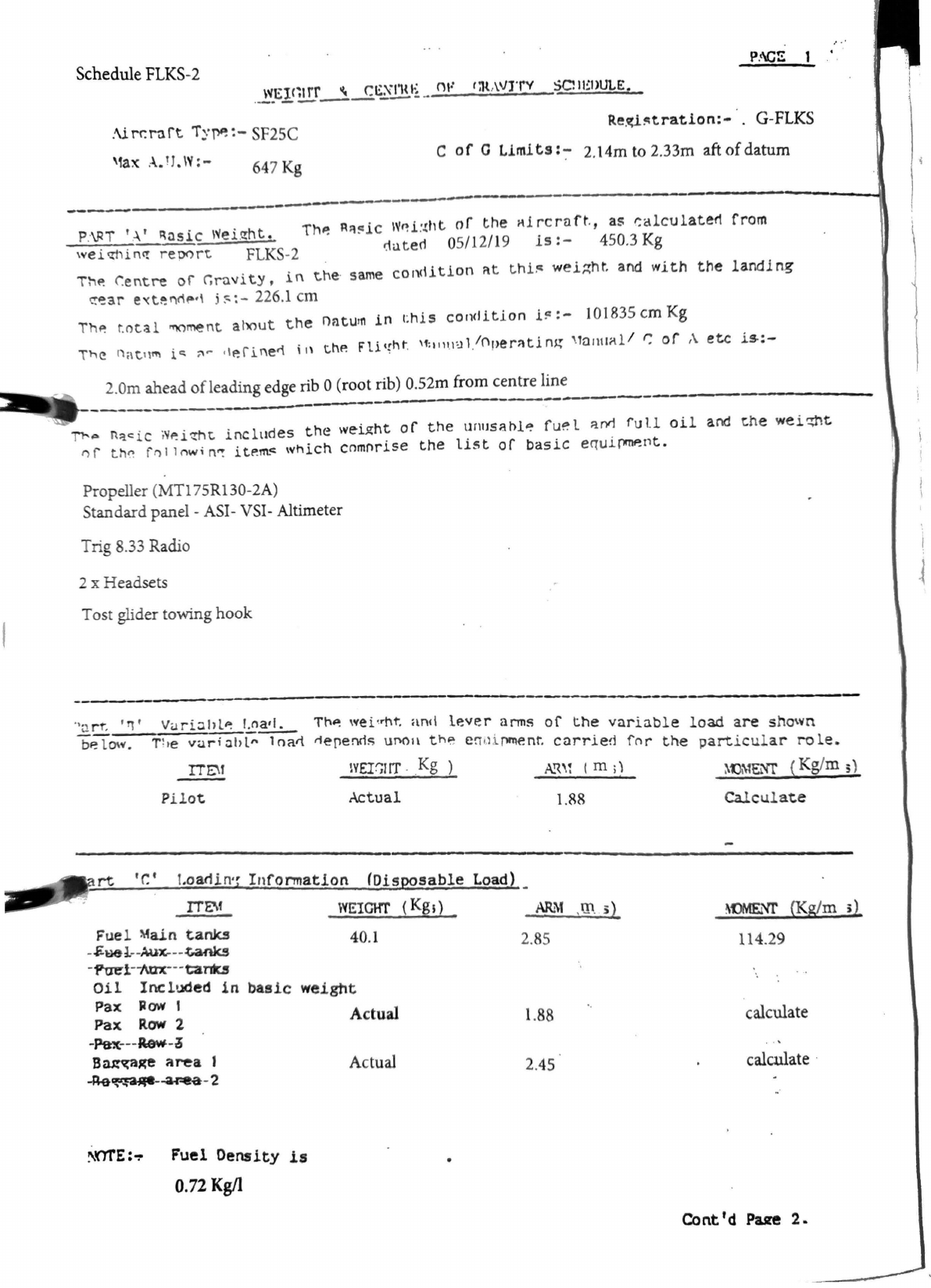

Schedule

FLKS-2

P

.

t\C~

WElC~trr

\

C~~·mi.;

<W

r;n,\VJ'rV SOll!l>Ul.E•

...

_.

-

--

----

----

--

:\i

rr.rart

iy~

:-

SF25C

Re.(i~tration:-

·.

G-FLKS

'fax A. !J.

\V:

-C

of

0

Llmlts

:-

2.14m to 2.33m aft

of

datum

64

7

Kg

~---------~--------------

---1

·~~

~------------------

P:\PT 'A'

~osic

\~ei

.

t?ht.

ThP.

R~!=.ic

WP.i

:.t

ht

or

the

1'\lrcrnft

.,

as

calculaterl

from

i:1ute<1

05/12/19

is:-

450.3

Kg

wei~

hiM:

report

FLKS

-2

ThP.

r.entre

of

r.ru

v

ity,

in

the

· same

con<\ition

r\t

t.hi1=

wel~ht.

and

with

the

landing

t!~ar

e'<t~l"trlP•\

j

~

~

-226.l

cm

ThP.

to

tal

"'IOment

ahout

the

naturn

in

this

condition

l!=

:-

101835

cm

Kg

The

1

atn

ni

ic: ;'\ r

<I

P.finer!

in

t.hP.

Flit{ht

.

'':1111

.

1u1

.

lnperntin~

\l<J111Jl-\l

/

~

of

,\

etc

.is-:-

2.0m ahead

ofleading

edge rib 0 (root rib) 0.52m from centre line

---------·---·---

.~~~--~-----------------------·--~-

Tl°'"' n::i.c:ic

;

v~ictlt.

includes

the

wei~ht

of

the

unusaol~ fu~l

::irY1

ful.l

oil

and

the

wei$t

l')f

t

~

ft'll

l

nw;

n~

itP.m.c:

which

cnmnrise

the

list

of

basic

e

Q"ui

pcnP.nt.

Propeller (

MTl

75R130-2A)

Standard panel -ASI- VSI- Altimeter

Tri

g 8.33 Radio

2 x Headsets

Tost glider towing

hook

·~

rt:~

Vuri::ihl~

t.o_a•I.

Th~

wei<rht.

and

lP.ver

arms

of

the

variable

load

are

shown

bP.

low. T

l1

e

vari

~hl"

1

naii

rlepenrls

UM1\

th~

e

!i

1,

li

fl1'11ent.

carr

1·

e'.~

fo

..

the

1 •

particu

l

ar

role.

lVEI'.;!IT

.

Kg

)

Pilot

Actual

rt

t.oarlin·r

Infonnatlon

(Dis

sable

Load)

ITE\f

WEIGHT

(Kg;)

Fuel

~a.in

tanks

-

$"1&1

--

Aux.-

--

.t.anks

-

1"tre'1

--

Aax---

tal"lb

40.1

Oil

Included

in

basic

weight

Pax

Jlow

I

Pax

Row

2 Actual

-Pax---Aew-d

BaJ?'{a~

area

1

-R-e~..a.r-ea

-

2

~OTE:~

Fuel Density

is

0.72

Kg/I

Actual

A.T'l\1

( m ;)

1.88

2.

85

1.88

2.45

~tJMENT

(

Kg/m

:;

)

Calculate

~f)MENI'

(Kg/m

;)

114.29

calculate

calculate ·

Cont'd

Pue

2.

'

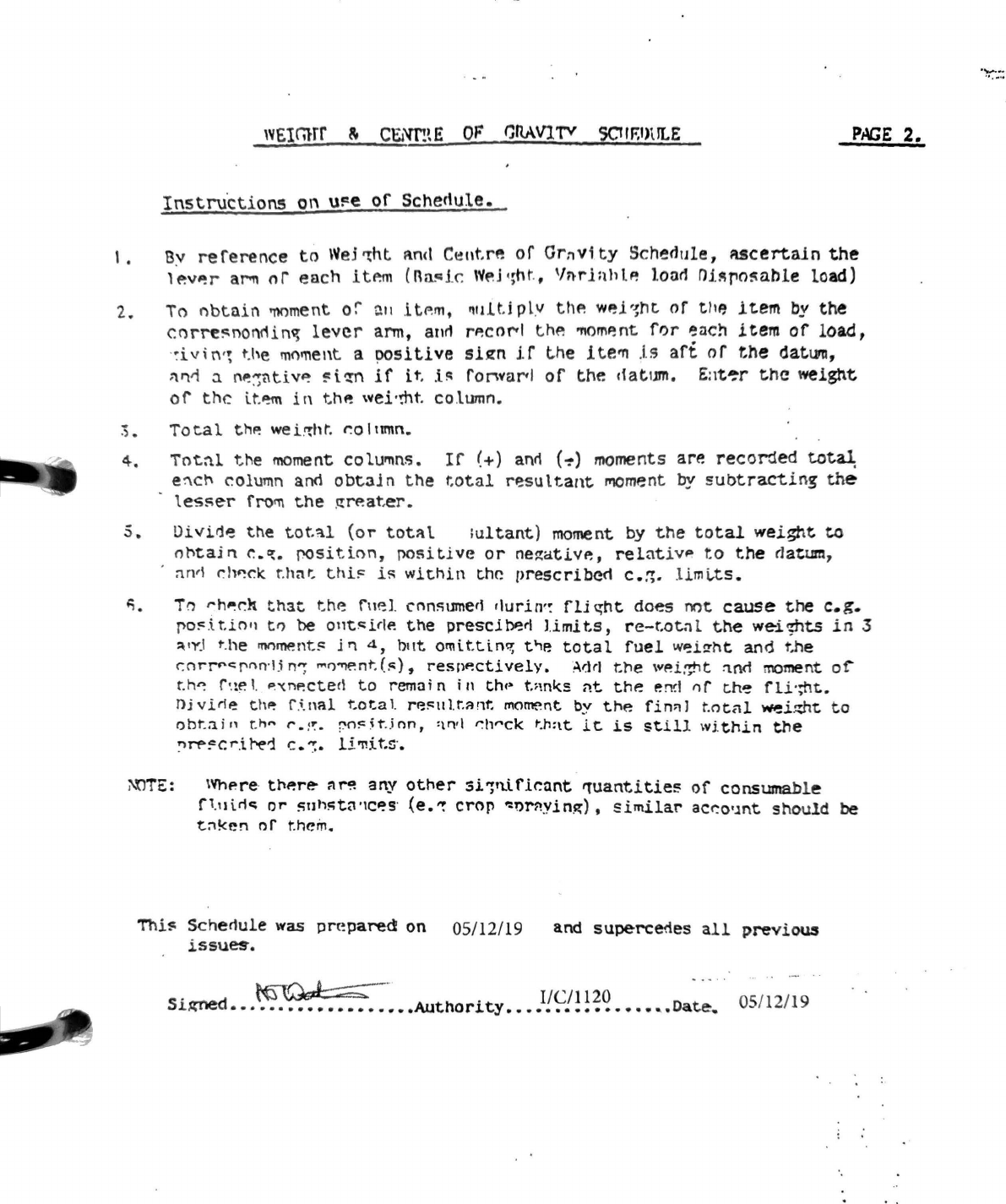

wE1rnrr

~

CENT!~E

OF

CRAVl'f'V

SCtlF,1)\ILE

PAGE

2.

Instru

'

ctions

on

ui=e

of

Schedule.

1•

By

reference

to

We5

rcht

A.n<I

Cent.rft

of

Grnvity

Schedule,

ucert.aln

the

l~v~r

ar-n

nr

each

itP.m

(Rac:ik

\'t'~J

c;ht

.

,

Vn-rl:thlP.

loot!

rHllltio~ahle

load)

2.

To

obtain

mment

or'

a11

.itP.rn, 1

u11t.i

pl

.v thP.

WP.i

-~nt

of

t!IP,

item

by

t~

cnrre~nonrlin~

lever

arm,

arn1

rP.cor<I

th~

'YIOmP.nt

fl)r

l!!nch

item

or

load,

·

~iv

i

tv~

t.

he

moment a

!)OSiti

ve

slsm

H

the

i

te'TI

J.s

aft

or

the

datum,

:vl'i

:i

l'\P.~ntiv"?

~i~n

if

it

.

.i~

ro~varl

of

the

cfatum.

Eat~r

t.hc

weight

or

the

lt.~

in

thP. wei·mt.

column.

:;.

Total

thP.

wei.~ht.

~olnmn.

4,

iot~l

the

moment

colu~ns.

If

(+)

anri

(~)

moments are recorded

total:

e:"lcl°'

column and

obtaln

the

total

resultant

l"IOment

by

subtracting

th

e

tes~er

fro~

the

~~ater.

5.

Divid~

the

total

(or

total

iultant)

moment

by

the

total

weight

to

nl°'tajn

~-~·

f'OSition,

positive

or

ne~ativP.,

relat

iv

P

to

the

rJa~um,

nn'\

~h~r.k

r.har:

thii::

iR

within

the

prescribeci

c.:;.

limi.,ts.

~-

Tn

rh~dl

that

thP.

rnel.

cnn!'iumert

rlurin'~

fli

~ht

does

not

cause

the

e.g.

po!=

.

i.tio11

trJ be 011tc:;i<IP.

the

presci~rl

limits,

re-r.ot

;}l

the

we-ic;hts

in

3

~

·

YJ

t.

he

rMrnent~

j

l'l

d.,

b11t ornittin-;r,

t'ie

total

fuel

w~izht

and

the

<:nr!f'c:f'nn

·

l.in~

""fJ~nt

.

(~),

respP.ctlvely,

Adrl

ttie

wP.i~t

:in<l

moment

of'"

th~

r•.te

I.

P"(nP.ctecl

to

rem:ii

n

in

th(>

t~ml<s

nt.

thP.

en~!

nf

t.h'!

fli·;ht.

njvirle

th~

f .

i.nal

total

rP.~111.t.~nt

morrent

by

the

fin;il

t.ntnl

~i~t.

to

obt

.

:iin

t.h"'

r.rr:.

f'O~~t

.

.inn,

<\ri•I

~h,,ck

t-.h:\t

it.

is

still

within

the

'.'l~~cr.it-e1

C.";.

li'l'!HS.

;\tlTE: WhP.re· tl"IP.re-

:ir~

any

other

:si-;rtlfkant

'lUantitie5

of

consumable

fl.u\rlc:;

or

s11h!itn

·1

c~s

·

(e.~

crop

-:oNwin~),

similar

ac~o·.mt

should

be

t~!<en

or

t.hein.

Thi~

Scher1ule was prc!paredi

on

05/12/19 and

superc~es

all

previous

iSSUe!t.

.

~~

-

. l/C/1120 -·- . 05/12/19

Si,ctned

•••••••••••••••••••

Authority

•••••••••••••••

,.Date.

.

.,..._

.

......

FLUGHANDBUCH SF 25 C (Beiblatt: Austohrung)

This SF 25 C

Equipmen

t:

1.

E

ng

ine:

2. Propeller:

Se

ri

al N

°:

Ca

ll

Sign:

ROTAX

91

2 A 2)

.

:i'.·

ROTAX

91

2 S(2)

''

44662

G-FLKS

ROTAX 912 A 3)

x

ROTAX

912 S

3)

has following

ROTAX

912

A(4

ROTAX

912 S 4

Only

for ROTAX

91

2 A(1) , A(2)

or

A(4)

HO

11

AHM

-1

65130

Onl

y

for

ROTAX

91

2 A(1) , A(2) or A(4)

MT

165 R 130-

2A

Only

for ROTAX 912

$(2

) or S(4) MT 170 R 135-

2A

~

n1v

·

f~

fttta

'i·'f

a~l!8

tf

.

JW

'

d

s

$

:

~s

o

/"69"0~~

\

~

~?4•

1t:

~

;~W~t~;

MT 175 R 130- 2A x

O

nly

for ROTAX 912 A(2) and A(4) or 912

$(2)

and

$(4)

MTV

1A/

175-

05

~1

ftit®'tfx

.

'

:fa'k

e

~

'&W'ffi

at:l

~l3

·

q

7

t(o

t

(~t);(

.}

rco1

;~*~"5\1~<'~i-:'21i

.:z~f

~·:;

{0i'J/'.

3. Spacer for

fi

xed pitch Propeller: SF 653 C- 71- S1.4 E1

MT A 548

Limbach 20

1.

032. 070

4. Prope

ll

erdome for fixed pitch Propeller: .

MT

B-

030

(ALU)

MT

B-

030/1 {GFK)

Hoffmann- Prope

ll

e

r:

VP

30-63

Toqether with VP

30-

64

5.

Take-off mass:

650

k *

490 k

7. Version

of

landing gear: Sinqle Main wheel (fixed) 8.00x 4

Sinqle Main wheel (spruno) 6.00 x 6

Two wheel

ma

in

landing gear 5.00x 5

with tailwheel 21

0x

65

Two wheel main landing gear 5.00x 5

with nose wheel 330x 130

360°- tailwhe

el

210x

65

8. Wings: of ailerions

9. Fuel capacity: 441

551

80 I

Fixed Aerotow device with TOST- Noselaunching hook

x

x

x

x

x

C:\MSOFFICE\WINWORD\TECHN\FHBWHB25\BEIBL

_25.D

OC

10

.

02.2

0

15

FLIGHT MANUAL SF 25 C

Contents

Revision status

of

manual

1.

Speciflcati n

nd

limitation

1.1. Engine

1.2. Fuel

1.

3.

Lubricants

1.4. Cooling system

1.

5.

Propeller

C n n

1.

6.

Engine instrumentation and

markings

1.7. Master switch

1.8. Circuit breakers

1.9. Ammeter

1.10. Antenna connection

1.11. Connecting other consumers.

1.12. Airspeed limitations and load factors

1.13. Weights

1.14. Centre

of

Gravity at flying weights

1.15. Placards

1.16 Approved operation

2.

Operating

instructions

2.1. General

2.

2.

Daily

in

spection

2.2.

1.

Airframe

2.2.2. Engine (see also Engine Manual)

2.2.3. Propeller (see also Propeller Handbook)

2.2.3.1. Electric Constant-Speed-Prop

MTV1A/175-05

and

Hydraulic Constant-Speed-Prop

MTV21A-C-F

/(CF)175-05.

2.2.3.2. Fixed pitch propeller

2.3. Pre take-off checks

2.4.

St

arting the Motorglider

2.4

.1

. Starting the engine (see also Engine

Manua

l)

2.4.2. Hand starting the engine

2.4.

3.

Warming up, static rpm

check

(see also

Engine

Manual)

2.4.4. Taxiing

2.5. Take off and climb

2.5.1. Winch start

2.5.2. Aerotow

2.

6.

Cruise

2.7. Landing

2.

8.

Stopping and starting the engine in flight

Flying with the engine stopped

Edition

:

March

1997

2 J

~

' i

"

page

2

4

5 '

'

\

5

5 I

6 1

7

7 I

7 I

8 I

!

8

8

8

9

9

11

12

12

14

15

15

15

15

16

17

17

17

17

17

18

19

19

19

19

20

20

20

20

21

21

FLIGHT MANUAL SF 25 C

2.10. Slow flying and stall characteristics

2.11. Spinning

2.12.

Wet

wings -warning

2.13. Cold weather flying and risk of carburettor icing

2.14. Operating without outriggers

(only applies

to

single mainwheel undercarriage version)

2.15. Safety factors and engine reliability

2.16. Attachment points for parachute static release

2.

17

. Emergency canopy

re

lease

2.18. Type familiarisation

2.19. Crosswind

2.20. Field landings

3. Performance data

3.1 . Take-off performance

3.

2.

Rate of climb

3.3. Airspeeds

3.4. Range

and

endurance (zero wind conditions)

3.5. Gliding performance

4. Centre of gravity and weight limits

4.1 . Empty weight centre of gravity

4.2. Centre of gravity at flying wei

gh

ts

4.3. Weight placard

5. Minimum equipment

6. Optional auxiliary equipment

7. Additional electrical fuel pump

8. Noise reduction requirements

Edition: March 1997,

Rev.

7,

20.01.2009

3

22

22

23

23

23

23

23

23

24

24

24

24

25

25

26

26

1

26

27

l

27

I

27

l

27

28

,,

28

28

29

29

30

FLIGHT

MANUAL

SF

25 C 4

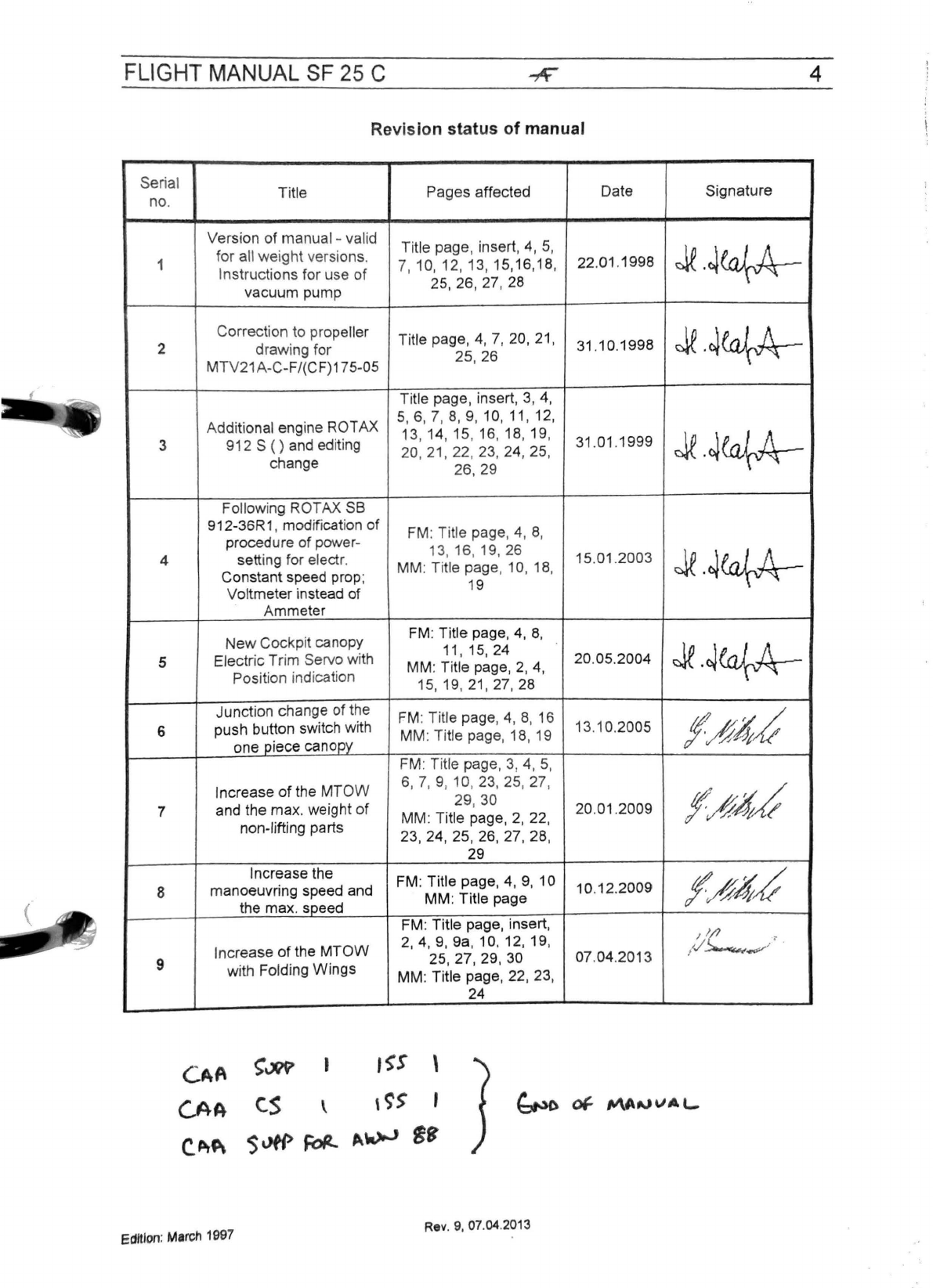

Revision status of manual

Serial Title Pages affected Date Signature

no.

Version

of

manual -valid Title page, insert, 4, 5,

Je.~ea{-A--

1 for all

weight

versions.

7,

10, 12, 13, 15,16,18, 22.

01

.1998

In

st

ructions for use

of

25, 26, 27, 28

vacuum pump

Correction to propeller Title page,

4,

7, 20,

21

, 31.10.1998

Je.~ea{-A--

2

draw

ing for 25, 26

MTV21A

-C-F/(CF)175-05

Title page, insert, 3, 4,

Add

itional engine ROTAX

5,

6, 7,

8,

9, 10,

11

, 12,

13, 14, 15, 16, 18, 19,

31

.

01

.1999

Je.~ea{-A--

3 912 S

()

and editing 20,

21

, 22, 23,

24,25,

change 26, 29

Following ROTAX SB

912-36R1, modification

of

FM: Title page, 4, 8,

procedure

of

power- 13, 16, 19, 26 15.

01

.2003

Je.~ea{-A--

4 setting for electr. MM: Title page, 10, 18,

Constant speed prop; 19

Voltmeter instead of

Ammeter

New

Cockpit canopy FM: Title page,

4,

8,

Je.~ea{-A--

11, 15, 24 20.05.2004

5 Electric Trim Servo with MM: Title page,

2,

4,

Position indication 15, 19,

21

, 27, 28

Junction change

of

the FM: Title page, 4, 8, 16 13.10.2005

f~~~

6 push button switch with MM: Title page, 18, 19

one piece canoov FM: Title page, 3, 4, 5,

Increase

of

the

MTOW

6, 7, 9, 10, 23, 25, 27,

f~%~

29, 30 20.

01

.2009

7 and the

max

. weight

of

MM: Title page,

2,

22,

non-lifting parts

23,24,

25, 26,

27,28,

29

Increase the FM: Title page, 4, 9, 1O

10

.12.2009

f/f4~

8 manoeuvring speed and MM: Title page

the max. speed FM: Title page, insert,

'L

,

Incr

ease

of

the

MTOW

2,

4,

9,

9a, 10, 12, 19, 07.04.2013

;/

._-

' .

25,

27,29,

30

9 with Folding

Wings

MM: Title page, 22, 23,

24

~vw

1

1~s

\

c.s

\

'~>

'

$~

~

~_,..,

~'

Edition

:

Mmrch

1997

Rev

.

9,

07

.

04.2013

FLIGHT MANUAL SF 25 C 5

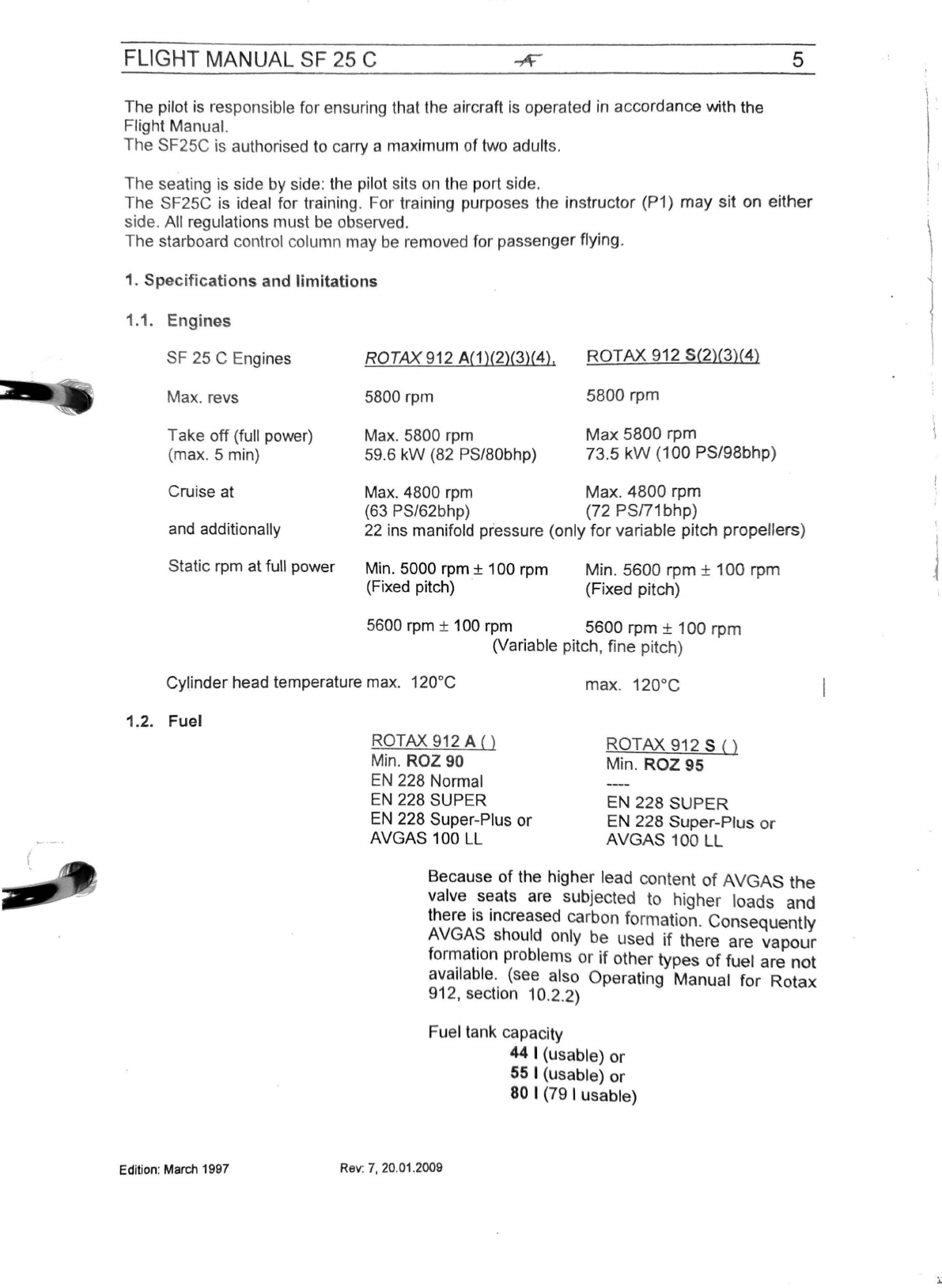

The pilot

is

responsible for ensuring that the aircraft is operated

in

accordance with the

Flight Manual.

The SF25C is authorised to carry a maximum of two adults.

The seating is side by side: the pilot sits

on

the port side.

The SF25C

is

ideal for training. For training purposes the instructor (P1) may sit on either

side. All regulations must be observed.

The starboard control column may

be

removed for passenger flying.

1.

Specifications

and limitations

1.1. Engines

SF 25 C Engines

Max. revs

Take off (full power)

(max. 5 min)

Cruise at

and

additionally

Static rpm at full power

ROTAX912

A(1)(2)(3)(4), ROTAX 912 5(2)(3)(4)

5800 rpm 5800 rpm

Max.

5800 rpm Max 5800 rpm

59.6 kW (82 PS/80bhp) 73.5

kW

(100 PS/98bhp)

Max.

4800

rpm

Max. 4800 rpm

(63 PS/62bhp) (72

PSn1

bhp)

22

ins manifold pressure (only

for

variable pitch propellers)

Min. 5000 rpm ± 100 rpm

(Fixed pitch) Min. 5600 rpm ±

100

rpm

(Fixed pitch)

5600 rpm ± 100

rpm

5600 rpm ± 100 rpm

(Variable pitch, fine pitch)

Cylinder head temperature

max.

120°C max.

120°c

1.2. Fuel

Edition:

March

1997

ROTAX 912 A

()

Min.

ROZ

90

EN

228 Normal

EN

228 SUPER

ROTAX 912 S

()

Min. ROZ 95

EN 228 SUPER

EN

228 Super-Plus or

AVGAS 100 LL EN 228 Super-Plus

or

AVGAS 100 LL

Because

of

the higher lead content

of

AVGAS

the

valve seats are subjected to higher loads and

there

is

increased carbon formation. Consequently

AVGA~

should only be used

if

there are

vapour

forn:iat1on

problems or

if

other types

of

fuel are

not

ava

il

ab

le. (see also Operating Manual

for

Rotax

912, section 10.2.2)

Fuel tank capacity

Rev

: 7,

20

.

01

.

2009

44 I (usable)

or

55

I (usable) or

80

I (79 I usable)

\.

) '

\

J

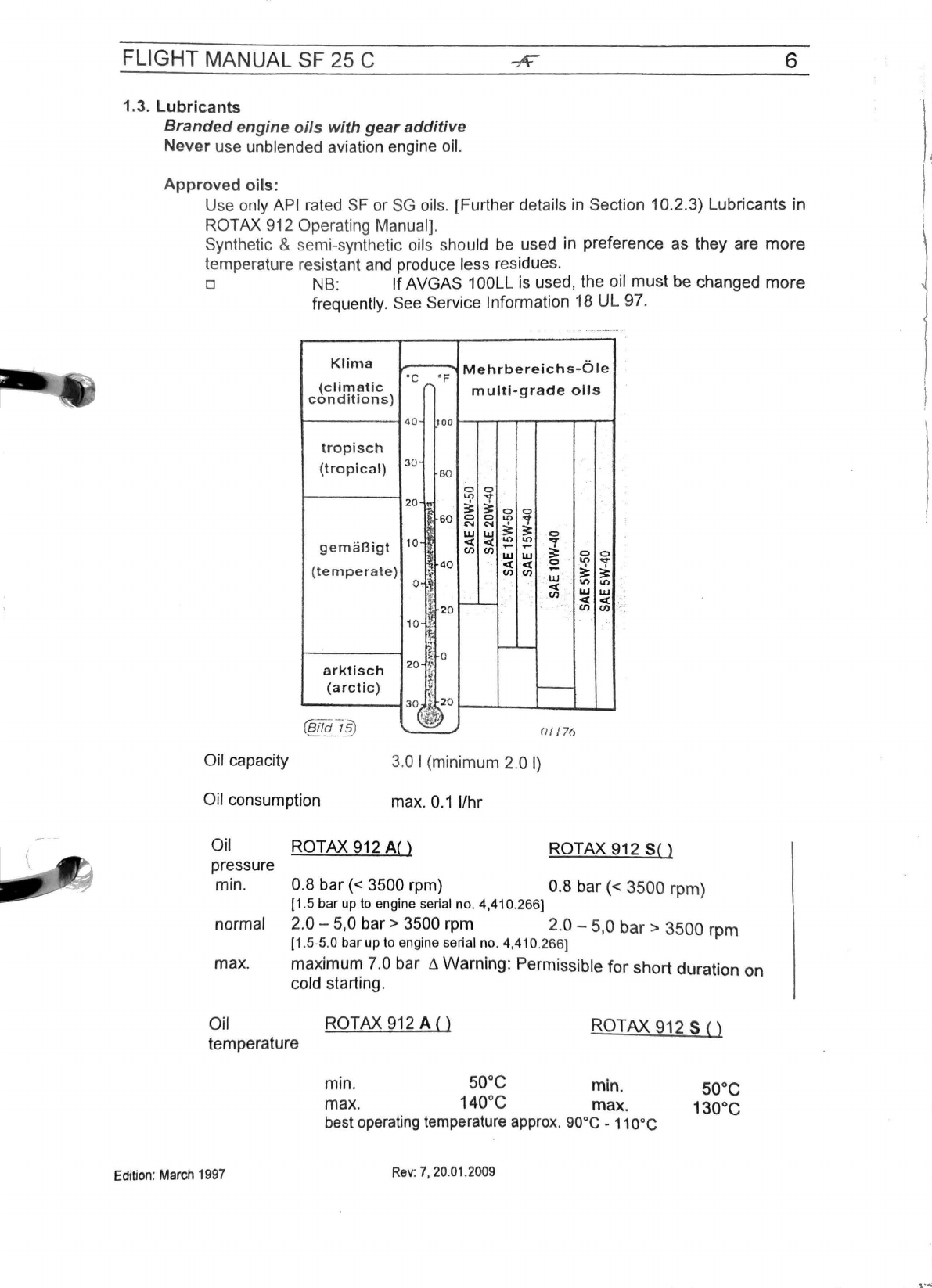

FLIGHT MANUAL SF 25 C

1.

3.

Lubricants

Brande

d engine

oils

wi

th gear additive

Never

use unblended aviation engine oil.

Appro

ved o

ils

:

6

Use only API rated SF or SG

oil

s.

[Further details in Section

10

.2.3) Lubricants in

ROTAX 912 Operating M

an

ual].

Synthetic & semi-synthetic oils should be used in preference as they are

more

temperature resistant and produce less residues.

o NB:

If

AVGAS 100LL

is

used, the oil

must

be changed

more

frequently. See Service Information 18 UL 97.

Klima

Mehrbereichs-Ole

·c

°F

(climatic

~

multi-grade

oils

con

d

itions)

40

100

tr

op

i

sch

(tropical)

30 ·

80

0 0

""

..,

20

.

11

~

3::

0 0

~

60

0 0

Ll>

~

N

<'I

~

UJ w 0

g

em

anigt

10

<(

<(

Ll>

Ll>

l

.

......

,_

en

<n

w w 0 0

40

<(

<(

0

Ll>

"'1'

(tem

pe

rat

e)

'1

<n

en

,...

~

3:

w ·

0 j ·.

<(

.,, .,,

l

20

<n

w w

,____

<(

<(

<n

en

.

10

~

-

$

~

0 --

arktisch

20

~·

~

{a

retie)

•

,_

30

i'20

(Bifd,

_-i_®

-~

-~

-

(J//7(

i

Oil capacity 3.0 I (mini

mum

2.0

I)

Oil consumption max.

0.1

l/hr

Oil ROTAX 912 A

()

ROTAX 912

S()

pressure

min. 0.8

bar(<

3500 rpm) 0.8

bar(<

3500

rpm)

(1

.5

bar

up to engine serial

no

. 4,410.

266]

normal 2.0 -5,0

bar>

3500 rpm 2.0 - 5,0 b

ar

>

3500

rpm

(1

.5-5.0

bar

up to engine serial

no

. 4,410.266]

max. maximum 7.0 bar

t1

Warning: Permissible

for

short

duration

on

cold starting.

Oil ROTAX 912

A()

ROTAX

912

S

()

temperature

Edition: March 1997

min. 50°C min.

max

. 140°C max.

best

operating

temperature approx. 90°C -

110°c

Rev:

7,20.01.2009

50°C

130°C

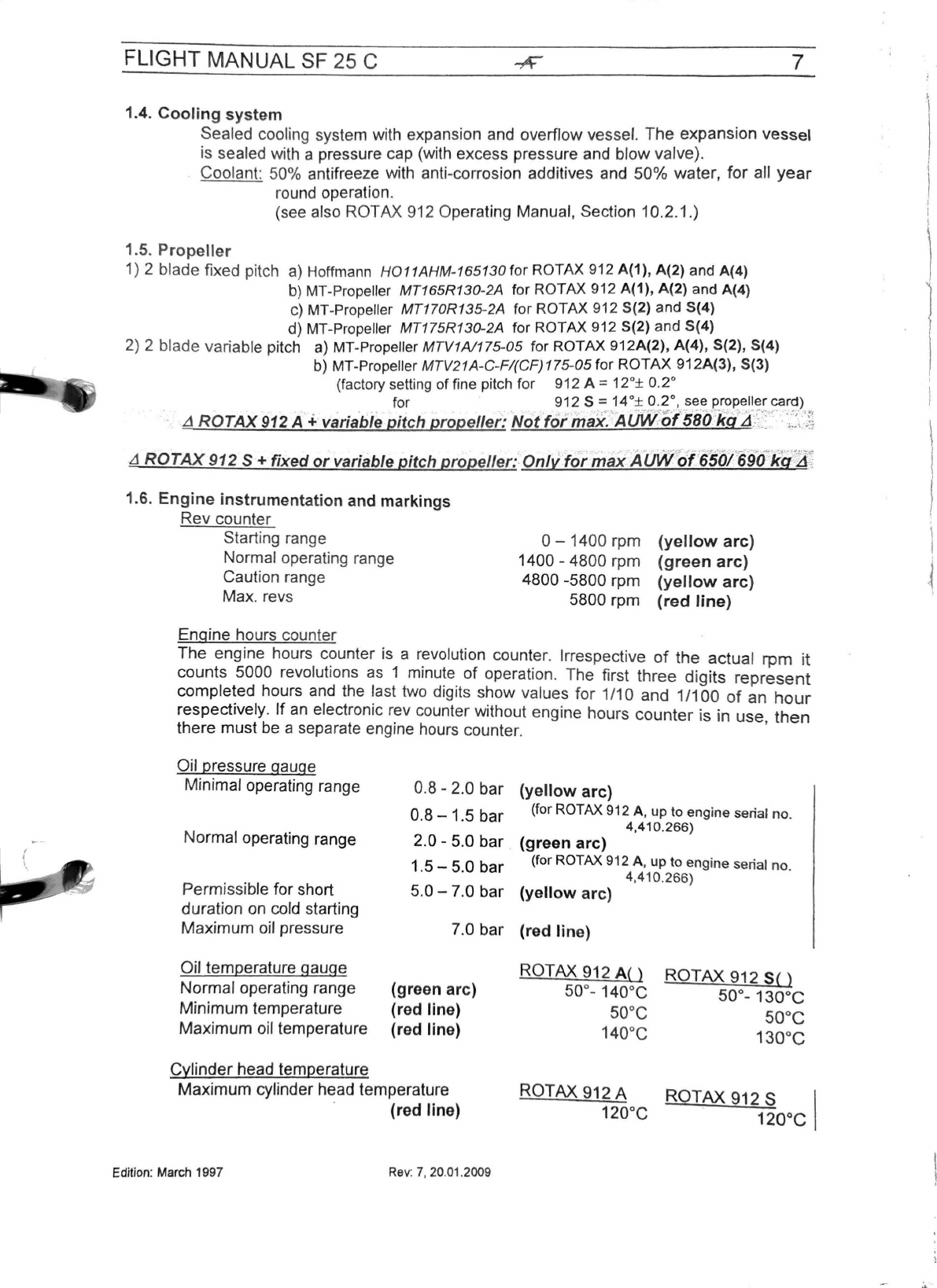

FLIGHT MANUAL

SF

25 C 7

1.4.

Cooling

system

Sealed cooling system with expansion and overflow vessel.

The

expansion

vessel

is sealed with a pressure cap (with excess pressure and

blow

valve).

Coolant: 50% antifreeze with anti-corrosion additives and 50% water,

for

all

year

round operation.

(see also ROTAX 912 Operating Manual, Section 10.2.1.)

1.5.

Propeller

1) 2 blade fixed pitch a)

Hoffmann

H011AHM-165130for

ROTAX

912

A(1), A(2)

and

A(4)

b)

MT-Propeller MT165R130-2A for

ROTAX

912

A(1), A(2)

and

A(4)

c)

MT-Propeller MT170R135-2A for

ROTAX

912

5(2) and 5(4)

d) MT-Propeller MT175R130-2A for

ROTAX

912

S(2) and 5(4)

2) 2 blade variable pitch a) MT-Propeller MTVtA/175-05 for ROTAX 912A(2), A(4), S(2), S(4)

b)

MT-Propeller MTV21A-C-Fl(CF)175-05 for ROT

AX

912A(3), S(3)

(factory

setting

of

fine

pitch

for

912

A=

12°± 0.2°

for

· .

..

.

912

5 = 14°± 0.2°,see propellercard)

Li

ROTAX

912

A+varia'bie

pitch

propeller:

Not'tof'max:

·':

AtJW.

;

ol

5iiiFitg1

.E

'>.

~~:.'.~~

.

.1

RO

TAX

912 S

+fixed

or

variable

pitch

propeller:'.

On/Vfor

max

'.

AUW~fil5

'

{l/369<fkciYa

~

1.6.

Engine

instrumentation

and

markings

Rev

counter

Starting range

Normal operating range

Caution range

0 - 1400

rpm

(yellow

arc)

1400 -4800

rpm

(green

arc)

4800 -5800

rpm

(yellow

arc)

5800

rpm

(red

line)

Max. revs

Engine hours counter

The

engine hours counter is a revolution counter. Irrespective

of

the

actua

l rpm

it

counts 5000 revolutions as 1 minute

of

operation. The first

three

digits

represent

completed hours and the last two digits show values

for

1/10 and 1/100

of

an

hour

respectively.

If

an electronic rev counter without engine hours

counter

is

in u

se

then

there

must

be a separate engine hours counter. '

Oil pressure gauge

Minimal operating range

Normal operating range

Permissible for short

duration on cold starting

Maximum

oil pressure

Oil temperature gauge

Normal

operating range

Minimum

temperature

Maximum

oil temperature

Cylinder

head temperature

0.8 - 2.0 bar

(yellow

arc)

0 8 1 5 b

(for

ROTAX

912 A, up to engine serial

no

.

. - .

ar

4,410.266)

2.0 -5.0 bar .

(green

arc)

1 5 5 0 b

(for

ROTAX

912 A, up to engine serial no.

· - ·

ar

4.410.266)

5.0 -7.0 bar

(yellow

arc)

7.0 bar

(red

line)

(green

arc)

(red

line)

(red

line)

ROTAX

912

A{)

50°- 140°C

50°C

140°C

ROTAX

912

SO

50°-130°C

50°C

130°C

Maximum

cylinder head temperature

ROTAX

912 A

ROTAX

912 s I

· (red line) 12ooc 12ooc

Edition

:

March

1997

Rev:

7,

20

.

01.2009

F

LI

GHT MANUAL SF 25 C 8

1.

7.

Master

sw

itch

The master switch isolates the battery from the aircraft wiring. It is switched

on

at the

start

of

the flight

and

off after the flight

is

completed. It may also be switched off

whilst soari

ng

eng

i

ne

-off. With engine running

only

switch

off

in

case

of

eme

rgency

(e

.g. short circuit,jammed starter relay or similar).

With the option "

one

p

ie

ce co

ckpit

ca

nopy":

(up

to factory SIN 44709)

If

ca

nopy lock

mechani

sm

is

op

en, master switch

is

out of function. Engine is not to start, electric

equipment doesn't work.

1.8.

Circui

t breakers

Except for the starter circuit the aircraft wiring system is protected from overload and

short circuit

by

automatic circuit breakers.

Circ

ui

t breakers Battery

Gene

ra

to

r 25A

20A

A short circuit or overload wi

ll

trip t

he

button of the circuit breaker affected, causing it

to protrude. After correction of

th

e

fa

ult

th

e button

is

pressed

in

again to restore

the

circuit. As the circuit breakers get hot

when

they trip, they should not be pushed in

again

im

med

i

ate

ly

.

If the battery is subject

to

heavy discharge (e.g. lengthy starting attempts in the

wi

nte

r)

the alte

rn

ator

tri

p

may

pop

out

when

the engine

is

running (e.g. in flight).

If

this occurs, push it

in

aga

in after about 2 minutes or the battery will not be charged.

The 20 A generator fuse is

in

the

form

of a fuse switch and located next to the

master switch (which

is

ola

tes

the

battery from the aircraft wiring system, so that it

can

be

isolated from

all

power sources

in

case of emergency. This means

the

alternator

ca

n be is

ol

a

te

d fr

om

the

aircraft wiring system

in

case

of

emergency

by

tripping the fuse switch.

1.9.

Ammeter

When the engine

is

running, it

do

es n

ot

usually indicate a charging current, which

means that the battery is fully

ch

ar

ged.

If t

he

battery charge is low it will i

nd

icate the

battery charge (the

po

inter will

ind

icat

e+

o

r-

).

If a large number of consumers

are

in operation or

if

there are no consumers in

operation, but the engine is not running, the ammeter will indicate battery discharge

(the pointer will indicate

-).

A continuous reading

of

over + 1OA indicates that the

battery

is

no

longer able

to

hold a charge or that the generator regulator is faulty.

Instead

of

this ammeter a Voltage indicator

can

be

used together with a low voltage

lamp (see

MM,

wiring diagram)

1.10.

Antenna

connection

A radio antenna

is

incorporated inside the

fin.

The antenna coax cable is routed from

the fin to a position under the luggage compartment where the remaining length is

coiled and secured. From there it

can

be

routed to the radio. The appropriate

regulations must be observed when fitting the radio.

Edition: March 1997 Rev: 6, 13.

10

.2005

'

l

I

\

I

FLIGHT

MANUAL

SF

25

C 9

1.11. Connecting other consumers.

Further circuit breakers may be added to the terminal bar for additional consumers

This applies to ACL, nav lights, VOR, transponder, encoder etc. It is important to

ensure that the additional equipment

is

using the correct fuse rating.

The aircraft wiring system is 12 V DC, negative ground.

The appropriate regulations must be observed when fitting additional equipment.

The fuses

on

the firewall can be replaced with state of the art circuit breakers.

There is then no need for spare fuses and a

vi

sual check can be made to see which

sy

stem has tripped out.

The appropriate regulations must be observed when fitting additional equipment.

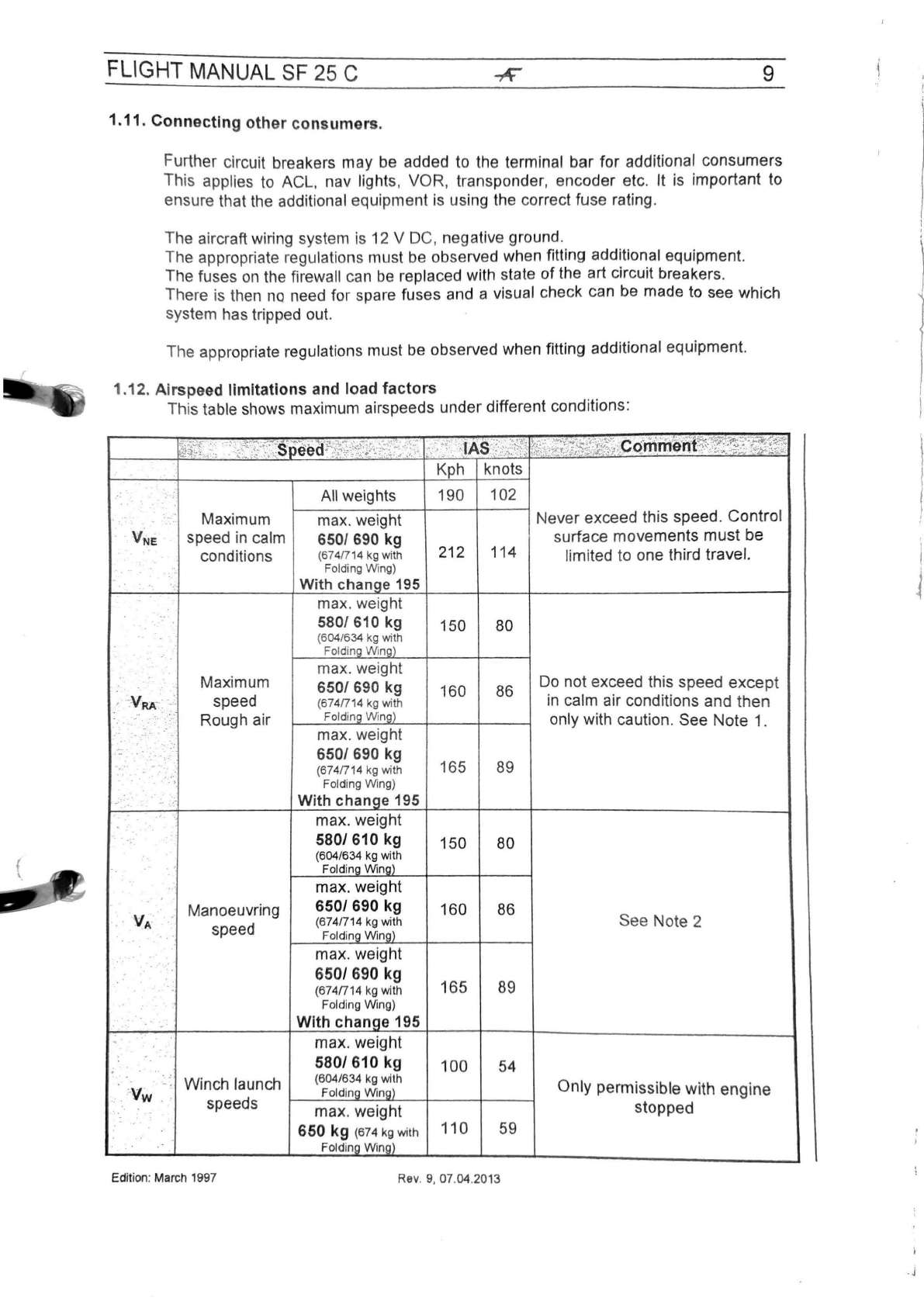

1.12. A

ir

speed

limitations

and

load

factors

This table shows maximum airspeeds under different conditions:

~\~j:{~:'

···-~-~;~:~~;·t~

~

s

:

p(teCt

~~~0~ff'.:\l~St~~~;.:;:-_

:.;<

·f:_\

1AS

/:.·£

1

~i·1

Sifi

-

'.={&~7;~f:~~;..:;~

ccl~tne~n

~

1

~:~r:~z-~1tz

Kph knots

: All weights 190 102

.··

·- Maximum max. weight Never exceed this speed. Control

V~i

speed in calm 650/ 690 kg surface movements must be

conditions (674/714 kg with 212 114 limited to one third travel.

Folding Wing)

-.

With chanqe

195

max. weight

5801 610 kg 150 80

(6

04

/6

34 kg with

Folding

Win!'.l)

Maximum max. weight

Do

not exceed this speed

exce

pt

.. 650/ 690 kg 160 86

'

VRK

:'.

speed (674/714 kg with

in

calm air conditions and then

-

..

Rough air FoldinQ

Win!'.l)

only with caution. See Note 1.

..

-

--

max.weight

·-

650/ 690 kg

--(674

171

4 kg with 165

89

> Folding Wing)

, -· -With chanQe 195

max. weight

5801610 kg 150 80

(604/634 kg with

. , Foldin!'.l Wino)

max. weight

v,.,

.·

Manoeuvring 650/ 690 kg 160 86

speed (6741714 kg with See Note 2

Folding Win!'.l)

max. weight

650/ 690 kg 165

89

(674/714 kg with

Folding Wing)

-With

chan~e

195

" max. weight

: -580/ 610 kg 100 54

-Winch launch (604/634 kg with Only permissible with engine

·.

·

-vw

speeds Foldlno Wino)

: max. weight stopped

-·

650

kg

(674 kg with 110 59

Folding

Winol

Edition: March 1997 Rev. 9,

07

.04.2013

'.

~

'

I

j

. j

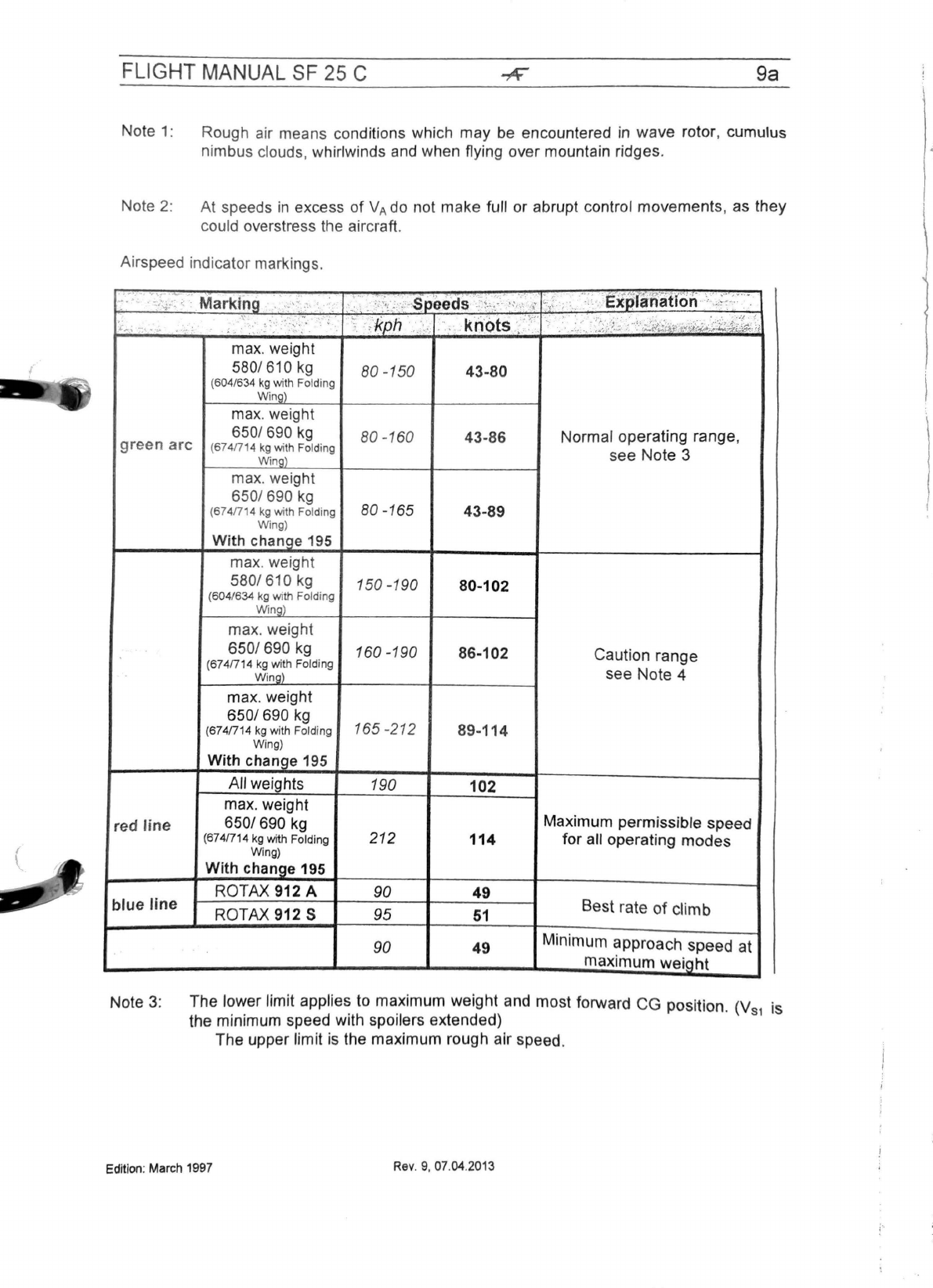

FLIGHT MANUAL SF 25 C 9a

Note 1: Rough air means

co

nditions which may be encountered

in

wave

rotor, cumulus

nimbus clouds, whirlwinds and when flying over mountain ridges.

Note 2: At speeds

in

excess

of

VA

do not make full or abrupt control movements, as they

could overstress the aircraft.

Airspeed indicator markings.

.

:.-:-·;-c\;,-:;2-;

Markfog

.·'

·

:.

, ,

<.

·

:·

_

;:\_,

,-

~peeds

..

'!

.,··

··,_.,::,

-.,.:

:.,

.

·:•,

..

exs)fan

·

atfon

·<,

;~-:::··

·

.

~

...

\

:·:·.

:.~>

. ;

~

\':

:'

.

,·~:

::·:,,

:. ' ; \.·,

kph

·-..·

.·

krl'ots

.,\·

...

.•

'.):·,·.:

..

?···"'

...

>::. ·

:."'

I

v'i-';;

...

-·

ma

x.

weight

580/ 610

kg

80 -150 43-80

(604/6

34

kg

with Folding

Wing)

max. weight

650/ 690

kg

80

-1

60 43-86 Normal operating range,

green

arc

(6741714

kg

with Folding

see

Note 3

Wing)

max. weight

650/ 690

kg

80-165

(674/714

kg

with Folding 43-89

Wing)

With change 195

max. weight

580/ 610 kg 150 -190 80-102

(604/634

kg

with Folding

Wing)

max. weight

6501690

kg

160 -190 86-102 Caution range

(6741714

kg

with Folding

W

in

g)

see Note 4

max. weight

6501690

kg 165 -212

(674/714

kg

with Folding 89-114

Wing)

With change 195

All weights 190 102

max. weight

red

line

6501690

kg

Maximum permissible speed

(6741714

kg

with Folding 212 114 for all operating

modes

Wing)

With change 195

ROTAX 912 A 90 49

blue line ROTAX 912 S 95

51

Best rate

of

climb

90 49 Minimum approach speed at

maximum

weight

Note 3: The lower limit applies to maximum weight and most forward

CG

position. (V is

the minimum speed with spoilers extended) s1

The upper limit is the maximum rough air speed.

Edition:

March

1997

Rev

. 9,

07

.

04

.2

013

FLIGHT MANUAL SF

25

C 10

Note 4: In this range manoeuvres must be conducted with caution and only in calm

air conditions.

.1

Warning: The following

lo

ads must not be exceeded when flying accurately:

With spoilers closed

at manoeuvring speed: +5.3g

at maximum speed +4

.0g

With spoilers extended +3.5g

1.13.

Weights

Empty weight (dependent

on

type

of

undercarriage and

equipment)

Permissible load

in

cluding fuel

Maximum permi

ss

ible AUW (all up weight)

Maximum weight of non-lifti

ng

components

approx.

400kg-450kg

approx

. 200kg

*) 580 kg (with Folding Wings 604 kg)

610

kg (with Folding Win

gs

634 kg)

650

kg

(wi

th

Folding Wings 674 kg)

690

kg (with

Fc;>ld

ing Wings 714 kg)

*

)430

kg/

450kg/490kg/

See Maintenance Manual

pp

. 24 and 25 .

".;.·"

'<·~·

~

·

~~

~

~!L(~t~~~l~

.•

n

.

~~~~J~:!

.

_g)

~~

:~:·:2·

·~a

...

'

4~i

§

fi'\.'8'.!i

::.

~p

p

t~pfi.f~

i.

~

~;'.>~

Edition

:

March

1997

Rev

.

9,

07

.

04.2013

),

I

:

\

FLIGHT MANUAL

SF

25

C

11

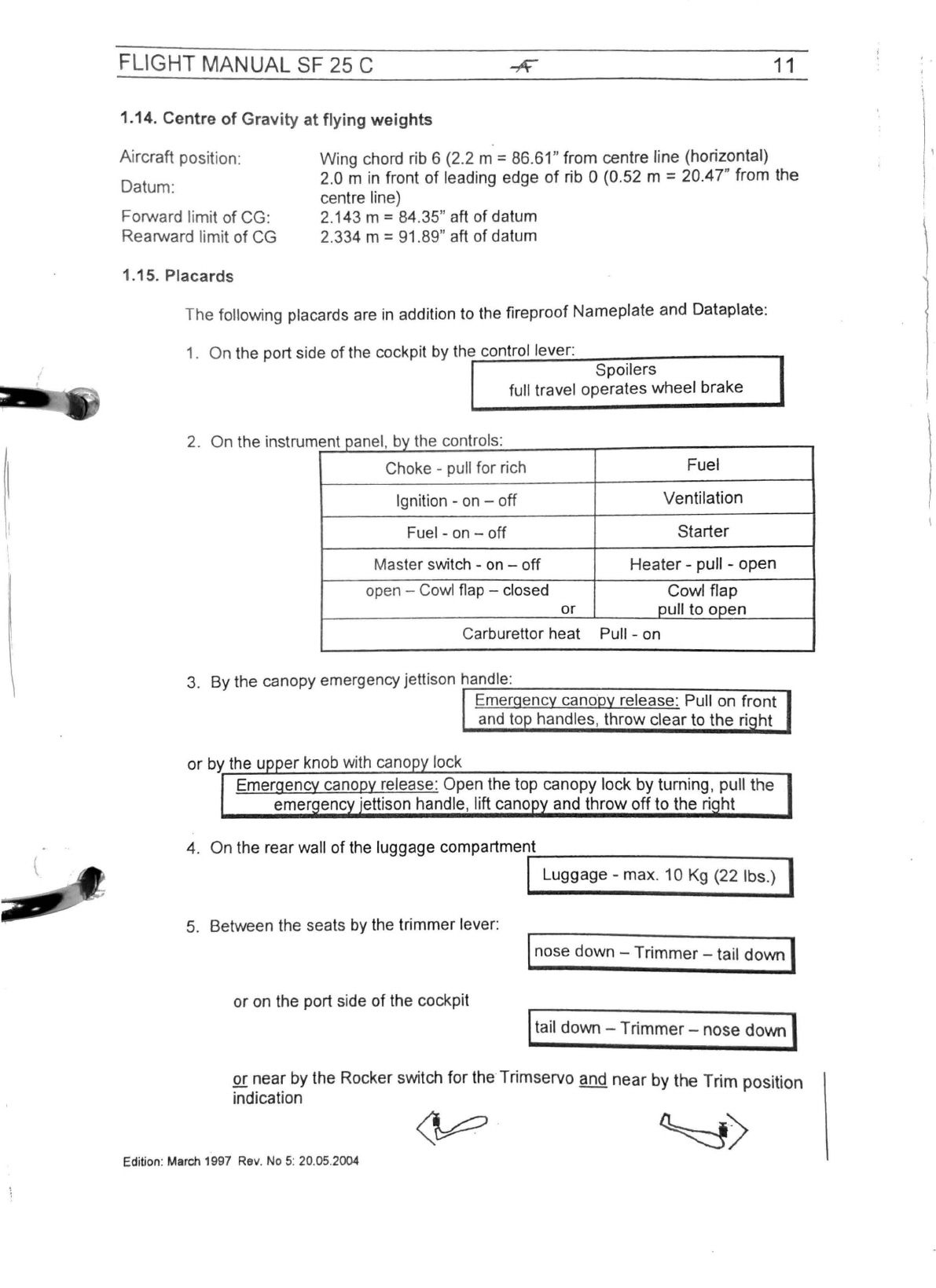

1.14. Centre

of

Gravity

at

flying

weights

Aircraft position: Wing chord rib 6 (2.2 m =86.

61

" from centre line (horizontal)

Datum: 2.0 m

in

front

of

leading edge

of

rib O(0.52 m = 20.47" from the

centre line)

Forward limit

of

CG: 2.143 m =

84

.

35

" aft of datum

2.334 m = 91.89" aft of datum

Rearward limit

of

CG

1.15. Placards

The following placards are

in

addition

to

the fireproof Nameplate and Dataplate:

1. On the port side

of

the cockpit by

the;..c~o::.:.n.:.::tr:..::o:..:..l

.:.:;le:.:.v.::.e:.:.r:

_________

_,

Spoilers

full travel operates wheel brake

2. On the instrum I b h t I

ent pane ,

lV

t e con

ro

s:

Choke -pull for rich Fuel

Ignition -

on

-off Ventilation

Fuel -

on

-off Starter

Master switch -

on

-off

Heater

-pull -open

open -Cowl flap -closed Cowl flap

or oull to ooen

Carburettor heat Pull -on

3. By the canopy emergency jettison

hra-::n:--d_le_

:

____________

_

Emergency canopy release: Pull on

front

and

to handles, throw clear to the

ri

ht

or

by the u

er

knob with cano lock

Emergency canopy release: Open the top canopy lock by turning, pull the

emer enc ·ettison handle, lift cano and

throw

off

to the

ri

ht

4. On the rear wall of the luggage compartmenr-t

___________

_

ILuggage -max. 10

Kg

(22 lbs.) I

5. Between the seats by the trimmer lever: lnose down -

Trimmer

-tail

down

I

or on the port side of the cockpit ltail down -

Trimmer-

nose

down

I

or near by the Rocker switch

for

the Trimservo and

near

by the

Trim

position

indication

~

·

~>

Edition:

March

1997

Rev

.

No

5:

20

.

05

.

2004

'.'

r

FLIGHT MANUAL SF 25 C

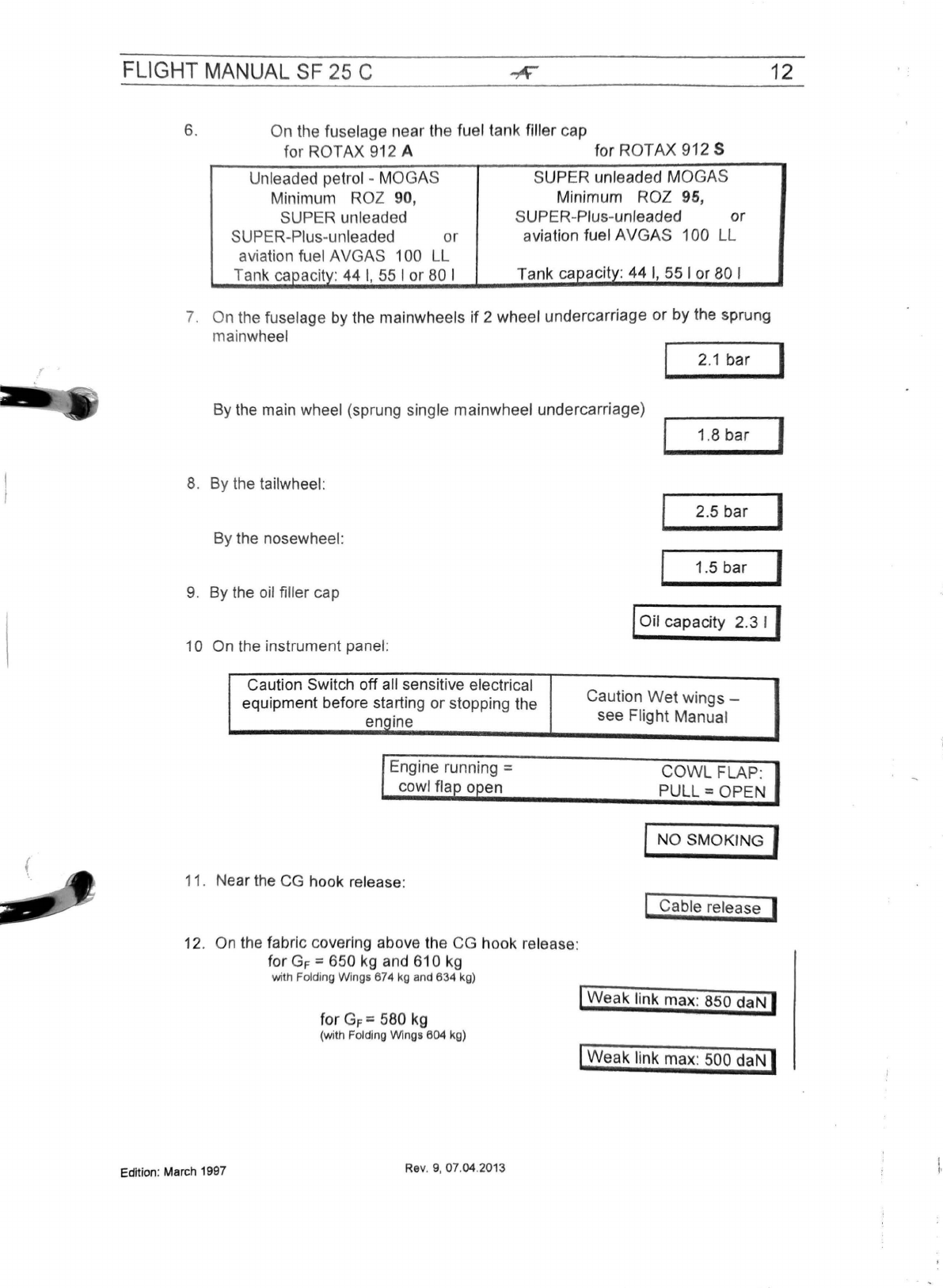

6. On the fuselage near the fuel tank filler cap

for

ROTAX

912 A for

ROTAX

912 S

Unleaded petrol -

MOGA

S

Minimum ROZ 90,

SUPER unleaded

SUPER-Plus-unleaded

or

aviation fuel

AVGAS

100 LL

Tank caoacitv: 44

I,

55 I

or

80 I

SUPER

unleaded

MOGAS

Minimum

ROZ

95,

SUPER-Plus-unleaded

or

aviation fuel

AVGAS

100 LL

Tank

capacitv:

44

I,

55

I or 80 I

7.

On the fuselage by the mainwheels

if

2 wheel undercarriage

or

by

the sprung

mainwheel

12

2.1

bar

I

By the main wheel (sprung single mainwheel undercarriage)

1.8

bar

I

8.

By the tailwheel:

By the nosewheel:

9. By the oil filler cap

1O On the instrument panel:

Caution Switch off all sensitive electrical

equipment before starting

or

stopping the

engine

Engine running =

cowl fla o en

11. Near the

CG

hook release:

12

.

On

the fabric covering above the CG hook release:

for

GF

=650

kg

and

61

O

kg

with

Folding

Wings

674

kg

and

634

kg)

for

GF

=580 kg

(with

Folding

Wings

604

kg)

Edition:

March

1997

Rev

.

9,

07.04.

2013

2.5

bar

I

1.5

bar

f

lOil capacity 2.3 I f

Caution

Wet

wings -

see Flight Manual

COWL

FLAP:

PULL=

OPEN

INO SMOKING I

l Cable release J

I

Weak

link

max

: 850

daN

I

I

Weak

link

max

: 500

daN

I

FLIGHT

MANUAL

SF

25 C

13.

On

the instrument panel:

14. By the electric fuel gauge:

PRE

TAK

E-OFF

CH

E

CKS

Folding wings s

ecur

ed

(if

applicable)

Harness fastened

Trimmer

set

Spoil

er

s closed

Tailwheel locked (if castoring

ta

il

wheel)

Canopy locked

Controls: full & free

movement

Fuel shut-

off

valve:

open

Fuel gauge: check

Cowl flap open

Propeller set

for

take-off

(if vari

ab

le pitch)

13

or

or

I

44

I

usab

le I

I55 I

usab

le I

I

79

I

usab

le I

15.

On

the top of the engine cowling behind the propeller:

1.16 Approved operation

~WARNING~

Never

tum

the

propeller

backwa

r

ds

Th

e

SF

25 C

,,

Falke"

motor

glider is approved

for

VFR daytime operation only.

/l.

Warning

/1

Not permitted: IFR flying, flyi

ng

in icing conditions, aerobatics and spinning.

Edition:

March

1997 Rev.

No

4:

15

.

01

.2003

I

; j

\

\

i

(

)

I

.l

FLIGHT MANUAL

SF

25 C

2. Operating

instructions

2.1. General

The Fal

ke

is a self launching motor glider. It may

be

flown with

an

MGPPL

(Motor

Gl

ider Private Pilot's Licence).

14

It is

of

course necessary for the pilot

to

have a thorough understanding

of

motor

g

li

ders and operating the engine.

It is

ob

li

gatory to study the documentation and to gain a thorough knowledge

of

the

motor g

li

der

and

its engine.

2.2. Daily ins

pection

It

is

necessary

to

examine the airframe, the engine and the propeller

for

ai

rworthiness before flying, especially if it has been

ri

gged since the last flight.

( Essential checks:

2.2.1.

Airframe

Check

in

particular for correct functioning, security and condition

(n

o cracks

or

deformations);

also

check bearings

and

drives for lack

of

play.

I. Check

the

4

wing

attachment points, the seating and security

of

the main pin

and check that

the

two

rear

wing

attachment points are secured (only in case

of

fo

lding wing).

2. Check that the aileron contro

ls

in

the fuselage are connected and sec

ur

ed

3. Check that the spoiler

co

nt

ro

ls in

the

fu

selage are connected

4. Check

th

e

co

ntrols from

th

e

cockp

it for full

an

d free movement Check

th

at

the starboard control column is secured

5. Check rudder pedals

(and

nosewheel steering if app

li

cable

).

Check

for

correct

ad

j

us

tment

and

locking of rudder pedals

6.

Check pulleys,

fa

irleads

and

cables

fo

r wear and kinking

7.

Check operation of spoilers from the cockpit.

8.

Check correct operation

and

effectiveness of the wheel brakes.

9. Check the instruments

and

check the radio with a test transmission.

1O. Pitot. There

is

a drain facility

in

the pitot. which

is

accessible through

the

handhole under the tailplane. Check especially after exposure to rain or after

road transport and drain

as

necessary.

11.

Che

ck

that the safety harness

and

their fittings are

in

proper condition and

secure.

12. Any luggage must

be

secured

by

the straps provided

13. Check for foreign objects

14. Check the canopy, canopy lock, canopy jettison system and direct vision

window

15. Check that the spar cover plates

at

the wing/fuselage interface on both sides

of

the fuselage are

in

position

and

secure.

16

. Check

tha

t both outriggers

are

in

good order and correctly attached (only

applies

in

the case of single

ma

i

nwh

ee

l

un

der-carriage).

17. Check both pushrods at

th

e a

il

e

ron

s

18. Check the wing

fo

l

di

ng att

ac

hm

e

nt

s &

th

e

ai

leron drives at the folding points

(if applicable)

are

secured; check

th

at the wing joint fairings are secure

19. Check that both

ai

lerons are att

ac

hed and secured

Edition: March 1997 Rev. No 3:

31

.

01

.1999

FLIGHT

MAN

UAL

SF

25

C 15

20.

21.

22.

23.

24

.

25.

26

.

27.

28.

29.

Is

the tailplane forward ttachment tightened down and secure?

Check

the

elevator connection

is

locked.

a)

Check

the

trimmer connection

by

Bowden cabl

a1

the elevator or

b) electric plug for Trim servo fitted (Diod plug)

ground function test

of

Trim system

Rudder:- Check rudder bearings and cable connections. Check the taifwf'leel

pushrod at

the

rudder drive lever (with castoring tailwheel) and the tailskid,

check all locking arrangements and that the rudder movement ·

in

the

correct direction.

Check

that the tailwheel and

the

steering pivot are clear to rotate and

do

so

freely.

Check the underside

of

the front

of

the fuselage and the fuselage underside

for

damage

(risk

of

exhaust

gas

penetration).

Check the general condition

of

the mainwheel(s),

the

tailwheel

or

nosewheef

and

the

outriggers

(if

applicable) and also all tyre pressures.

Check the planking, fabric covering and paintwork

for

damage

.

Caution: Remove the towbar from the nosewheel (if applicable).

Check the operation

of

the

CG

release hook.

2.2.2.

Engine

(

see

also Engine Manual)

1.

Check

the engine thoroughly

for

missing

or

loose

nuts

, screws, bolts and

locking arrangements. Check cooling ducts, ignition

leads

for

secur

ity and

condition. Look out for chafing.

2.

Check

that

the following operate freely: throttle, choke, heating,

ve

ntilation

and carburettor heating flap and engine cooling flap.

3.

Check

that the rubberflanges on the carburettor are

undamaged

(

no

cracks

).

4.

Check

the oil level and top up

if

necessary. 0 Caution. Run

the

eng

ine

for

about

half

a minute before checking the oil. (Before a long flight

the

oil

level

should

be

at least halfway up between marks on the dipstick.)

s.

Check

the

coolant and top up

if

necessary.

The

fluid level in

the

overflow

reservoir should be at least 2 - 3 cm when the engine is cold (

see

Engine

Manual).

6.

Check

oil, fuel supply and cooling systems to

ens

ure

freedom

from

leaks

and

abrasion.

7. Operate the tank drainerbefore moving

the

motorglider

.

B.

Check the

engine

mountings and their locking

arrangeme

nt

s.

9. Check

the

exhaust system

for

damage

, leaks

and

genera

l condition.

10. Check

the

engine compartment

for

foreign bodies.

11

.

Check

the

cowling for cracks, reassemble and

check

th

patent

fasteners

are

correct

ly

seated.

12

.

Ch

eck

the fuel tank level

13.

Check

the tank vent.

Use

only

thi

origin I fll r P

with

vent

(bearing

the

words

"Patent

bla

l/).

Edition:

March

1997

Rev

.

No

5:

2-0

.

05.2004

' j

FLIGHT MANUAL SF 25 C

16

2.2.3.

Propeller

(see also Propeller Handbook)

2.2.3.1.

Electric

Constant-Speed-Propell

er

MTV1A1175-05

and

Hydraulic

Constant-Speed-Propeller MTV21A-C-F/(CF)175-05.

1. Check the condition of the blades and the spinner (no cracks).

2. Check for play at the propeller tips (up

to

3 mm

is

permissible).

3. Check for play

in

pitch

at

the prope

ll

er tips (up to 2° is permissible).

4. Check propeller blades for cracks and that the leading edge protective tape is

intact.

5. Propeller hydraulics: operating pressure 125

~si

(9.? bar). Check every

50

hours

and

top

up

as

necessary (using nitrogen

1f

possible). Only for MTV

1A

6. Check propeller pitch movement with master switch on and

~ngme.

~ff.

7. Check the commutators

and

brushes together with the electrical wmng.

2.2.3.2. Fixed pitch propeller . .

1. Check condition of the blades. (no indentations or sphntenng)

2.

Check the spinner for cracks.

3.

Is

the leading edge protection intact?

2.3. Pre

take-off

checks

1. Folding wings secured (if ap

pl

icable)

2.

Canopy closed

and

locked

3.

Safety harness secure

4.

Trimmer set for take off

5.

360° tailwheel locked (if applicable)

6.

Spoilers closed

and

locked

7.

Check for full

and

free movement of the controls

8.

Fuel shut-off valve

open

9. Sufficient fuel

in

tank

10. Cowl flap open

11. P

ro

pe

ll

er set to take-off pitch (if applicable)

2.4.

Starting

th

e

Motorglider

Has

th

e pre-flight inspection been completed? Move the throttle to full power,

check

for freedom

of

movement

and

full travel

and

return

to

idle position.

ti Caution: Wheelbrake on,

ignition

off

In

cold weather conditions turn the propeller several times by hand before starting*

and check for

un

usual noises

and

stiffness

in

the motor a

nd

al

so

for

even

compression. (See also E

ng

i

ne

Manual: Check the mechanical components) Before

starting the engine, close the

ca

nopy. Before startin

g,

check that all the electrical

trips (but not those

of

sensitive electronic equipment such

as

radio, transponder,

Avionics master switch etc.)

are

pressed hom

e.

After the pilot has confirmed that

the

propeller area

is

clear, start the engine.

With the option "one piece cockpit canopy" (starting from factory serial number

44710): If canopy lock mechanism is open,

th

e push button for the engine starter is

out

of

function. Engine

is

not

to

start

NEVER turn t

he

prope

ll

er backwards

ti Also ifthere is a vacuum pump for gyroscopic instruments (or damage

to

the pump blades will result).

Ed

ition: March 1997 Rev. 6:

13

.

10

.2005

)

I

l

I

j

Table of contents