Helio HT-295 User manual

HELIO

AIRCRAFT

COMPANY

HELlO MODEL

HT-295

OWNERS

MAN’UAL

SEcTLcm

x

Gemma

Description of Airplane

PAGE

c

Descriptfon

af

Structure

-

-

-

*

-

”

-

-

*

-

-

-

-

-

-

-

-

-

-

1

Ailerons

and

Interce$tore-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

2

2

2

2

SECTION

XI

Flight And Operating xastructions

--

I

Flight

Controls

c

(I)

0

a

II,

e

I,

e

I

e

m

a

L

a

m

*

m

e

w

m

a

m

Ir

Pre-Flfght

Inspection

a

m

e

a

a

a

a

m

m

-

c

w

m

m

.

r

m

m

w

o

Operation

a

-

-

m

0

a

m

a

-

-

-

a

a

-.

a

a

a

a

-

a

a

-.

.

w

General Operating

Instructfom

And

Lintitations-

-

-

-

-

-

-

-

Pilot

Check

List-

Ir

a

lit

m

m

a a a a

a

a

c

a a

I

a

a

a

m

a

m

a

Pilot Emergency Check

List---

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Summary

of

Operational

Afrspeab-

-

-

-

-

-

-

-

-

-‘-

-

-

-

-

Take-Off,

Cruise

and Landing

Technfques

-

-

-

-

-

-

-

-

-

-

-

Cross-Wind Take-Off

md

Landing

Techniques-

-

-

-

-

-

-

-

-

-

Mi8cellaneoua

Provisions

-

*

-

-

-

-

-

-

-

-

-

-

-

-

*

-

-

-

Brake System

Schmatic -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Fuel System SePtematic

-

-

*

-

-

-

-

-

-

-

*

-

-

-

v

-

-

-

2

2

3

4

6

7

10

12

13

13

21

24

25

26

i

f

. SECTION I

General Description of

Airplane

‘i

The

W-295

is a high wing monoplane.

The wing is fully cantilever and

of all metal construction. The fuselage cabin section is a metal

covered tubular structure and the aft section is all metal

semi-

monocoque.

The tail surfaces are of all metal construction. Power

is supplied as follows:

Model

I-IT-295

Engine

Propeller

Is-

Lycoming (295hp) GO-480-GlA6 Hartzell

Constant speed

96" dia.

The

Model

WT-295 is a six place plane, The occupants are seated

in two individual adjustable front seats, two individual middle

seats with two reclining posftians, and a two place rear seat,

Entrance to the front seat is through a left front door. Entrance

to the rear seats

fs

through a rear right door, the sill of which

is at

floor

level height for easy

loadbg

and unloading, The rear

seat is easily removable

i'or

added cargo space.

'

Surface control

is

by conventional wheel and rudder pedals.

Provisi

are made for wheel, rudder pedals and brakes on the right

sfde,

Toe

brakes are provided on the left side. (Brakes for the right side are

optional*) The flaps are actuated by an electric motor on the 1700

series.

Longitudinal trim is by an elevator trim tab actuated by an

electric motor on the 1700 series.

The airplane is equipped with long span slotted flaps and full span

leading edge slats for high lift operation. Lateral control is

obtained by short span Frieze ailerons operated in conjunction with

leading edge interceptors, The latter are provided for low-speed

control,

Pitch change is obtained with an all-moving horizontal

tail.

Directional control is obtained with a conventional type rudder.

The engine

section

is composed of the engine installatfan, oil cooler,

carburetor,

ram air filter screen, oil system piping, fuel

system

piping,

electrical system, cowl flap system and the necessary mechanical

control units* The engine section is completely enclosed by

aluminum wrap-around cowl. The engine mount is a welded steel tube

structure bolted to the forward end of the fuselage. The engine is

suspended on the engine mount by four vibration isolators.

The

fire-

wall is of stainless steel.

Description of Structure

-

WING PANEL. The wing is a two-panel full-cantilever unit and all metal

construction.

Ribs are formed 2024

alclad

members.

The main spar

consists of 2024

alclad

web and 2024 extruded angle capstrips.

The

rear spar is a 2024

alclad

formed channel.

The wings are attached

to the fuselage through a welded steel truss.

l

1

c

AILERQNS

AKD

INTERCEPT0RS.t

The ailerons are the Frieze type, of

2024

alclad

diagonal rib truss structure, fabric covered,

They

are

hinged at both ends and operated by a push-pull tube at the

ce&ex,

The interceptors consist of heavy aluminum alloy curved plates (inboard)

and forward of each

aileron).

They emerge from the wings

incon-

junction with the ailerons.

FLAPS.

The flaps are of a single spar all-metal

constructfon,

They

are supported to the wing structure by three flap tracks and are

actuated by push-pull tubes at the center and outboard tracks,

TAIL

GROUF.

The tail group is composed of a vertical fin and rudder,

and an all-movable horizontal surface equipped with an anti-balance

and

t&n

tab.

All tail surfaces are of aluminum alloy construction.

FIN:

Two-spar construction,

RUDDER:

Single-spar construction

STABILATUR: Sfngle-spar

construction

FUSELAGE. The forward fuselage structure is a welded steel tube

truss.

It is covered with

alclad

sheet in the cabin section; the

remaining portion is semi-monocoque.

LANDING GEAR.

-

The main landing gear is the Spring Steel type mounted

in a box

section

of the fuselage structure.

The Nose Wheel is the

air-oil shock strut type and is attached to the engine mount.

§PECXFZCATECMS

Gross Weight

Empty Weight

Wing Span

Wing Chord

Wing Area

(Slats retracted)

Overall Length

Aileron Area

(Each Surface)

3400

lbs,

Fuel Capacity (Useable)

2023 lbs.

Octane Rating

39 ft.

Oil Capacity

72 in.

Power

Plant

231

sq.

ft,

Take-off Horsepower

30 ft. 4 in. Normal Rated Horsepower

10135

sq. ft.

Flap Area (Each Surface)

Slat Span (Each Wing) 203.93 in.

Stabilator Area

Rudder and Fin Area

24.40 sq. ft. Wheel Tread

58,s

gals.

100 (Min.)

12 qts. (Max.)

10 qts. (Desired)

GO-480-GlA6

Lycoming

295

280

19.05

sq*

ft.

37.50

sq,

ft.

102.00

in.

2

SECTION

II+F&IGHT,AND

OPERATING

INSTRUCTTONS

c

The

HT.295

incsrporates

flight control devices to insure safe

flight at slow air speeds without detriment to high-speed flight.

The cockpit

contmls,

however,

are

conventional and their operation

is the same as in any

ather

fixed-wing airplane. The exceptional

degree of control is obtained by the use of

reading

edge slats,

large flaps,

interceptors and a fully movable

horimntal

tail

surface with its anti-balance tab.

Each

contml

is described in

detail

in

the following discussions.

AILERONS.

The ailerons are operated in a

conventionaL

manner by

efther

of the dual control wheels.

In

addition to the

ailerms,

the control wheels actuate interceptor blades which extend through

the upper surface of the wing directly behind the outboard slat,

The ailerons are

csnventional

and they provide the

nomal

corrective

forces at high speeds. The interceptors provide the extremely

positive lateral control at

the

slowest speeds obtainable, This

-

control is so effective that it

is

possible to overcame the effect

of full rudder in a stall by use of the aileron-interceptor

control and roll into a turn

in

the opposite

direc3tion.

The aileron

interceptor combination produces a very high

rate

of

sollat

all

speeds with comparatively small control movements. Violent, full

throw contra1 movements are not necessary

ta

produce satisfactory

xates

of roll at all airspeeds.

RUDDER.

The rudder and controls are conventional. The rudder pedals

are ground adjustable

to

four positions.

Toe brakes are provided

on the left-hand pair of pedals.

SWLBZLATOR.

The horizontal tail surface, or

stabilator,

is a single

movable surface instead of the usual elevator and horizontal

stabilizer.

The control operation is

canventional

and control feel

and reaction in the cockpit are the same as in other aircraft.

There are two tabs attached

to

the horizontal surface, a trim

tab and an anti-balance tab.

The right hand surface has the

anti-

balance tab attached to it. It is an anti-balance tab because

it moves in the same direction as the surface, thus providing a

force which always returns the surface to the trim position, The

actuating arm and pivot paint for this tab, which is mounted

otz

the fuselage directly under the fin, should be inspected as a

part of the daily pre-flight inspection.

The trim tab is located an the left hand surface. It is of the

conventional type with a trim tab position indicator located on

the

instrment

panel.

sup

l

The leading edge wing slats operate fully automatically

by the air-loads on them. Their use provides the very slow

speeds possible with this airplane. All slats are fully visible

from the cockpit, they should normally be open on the final

approach,

If it appears that any

of

the

four

slats have stuck,

it is advisable to land about 10 MPH faster than the minimum landing

speed.

3

It

should be noted that the lateral and

dixectiana.1

control

is

so

effective that through their normal use, it is possible to overcome

the effects of both slats remaining closed on one side.

c

FLAPS l

All 1700 series aircraft have electric powered flaps as

standard with

a

flap position Indicator on the instrument panel.

Full flap can be used for landing under all normal wind conditions.

Shortest take-off runs,

under

standard air, sea-level conditions,

are performed

with

30'

flaps,

although

ZOO

will give a better rate

of climb once the airplane is airborne and provides better take-off

at higher altitudes,

or

with maximum

gross

loads,

B.

PRE-FLIGHT

INSPECTIUN

s

1

e

Check interior of cabin for Fuel Valve "ON", ignition

and

Master

Switch "OFF",

mixture

control "Idle

CUTOFF”, remove gust

lock,

2

l

Pull propeller through several revolutions

and

inspect blades for

nicks and

cracks.

3

e

Open engine cowl;

check oil level

and

inspect fuel

rend

oil lines

for leaks.

Give engine compartment

a

complete visual check.

4

(I

Check

nose

wheel

olea

shock

strut

and

tires

for

proper

inflation,

5

8

Check main gear brakes and lines for leaks and security.

6

l

Drain

sediment

bawl,

(Accessible through small door under the

forward windaw on right side fuselage.) Drain auxiliary fuel

tanks if applicable. (Drains located on the bottom of each wing,)

7

a

Check fuel laad and make

certain

that the fuel caps are firmly

secured on the

fillernecks.

8

&

Check slat operation for freedom of movement and any unusual play.

9

*

Move

all control surfaces and check security of

all

hinge bolts

and push-pull tubes,

10

l

Check security of anti-balance tab on horizontal tail and its

pivot point on the fuselage,

11

0

Remove cover

if

installed on

pitot

tube, and make sure it

is

free

from dirt or other obstructions,

CAUTION:::

WHEN CLEANING OR WAXING AIRPLANE, DO NOT ALLOW

WAX OR CLEANER TO PLUG STATIC VENT

HOLES,e,,,,,,

After entering the airplane and before starting the engine:

1

0

Adjust and fasten the combination seat and shoulder straps.

4

2

a

Check all

controfs

for

freedom

af

mavement

and proper direction.

3

l

Pnsure

that all

cargo is secured and that the load is properly

located,

4

0

Check

positim

of electrical and ignition switches.

5

l

Open cowl flaps.

ENGINE

STARTING.

The following starting procedure is taken from the

Lycoming Operator's Manual,

A copy of the Lycoming

rfanual

is furnished

with each airplane and is considered

a

part of this manual,

Lock

the wheels by efther wheel brakes

OT

chocks,

I

Set the propeller control lever all the way forward in INCREASE

RPM

position.

Be sure fuel valve is

ttUNtt.

set throttle

to

l/4

open position*

Place mixture

control

in the

"Idle Cut-off" position (Full out).

Turn on auxiliary fuel pump and check pressure.

Turn ignition switch to extreme right and push (this energizes

starter)*

NOTE

On aircraft with control lock pin

located

on pilot's

control wheel shaft, it is necessary to remove the pin

before attempting to start the engine, The aircraft

is

designed

so

the

starter

circuit

is inoperative with the

control

lockpin

installed.

The magneto circuits are not

involved in

any

way.

When the engine begins to fire, immediately put mixture control in

Full Rich position (full in) and allow ignition switch to return to

"both'" mag position. CAUTION

-

If engine fails to start immediately,

return mixture control to Idle Cut-off position. Failure

to

do so

will

create

an excessive amount of fuel in the carburetor air scoop

constituting a fire hazard.

"Vapor locking is not a

common

occurrence on Lycoming

Go-480

engines,

However

9

under certain circumstances it can occur,

i,e,

when runway

and ramp temperatures exceed

lOOoF

particularly on sunny days and at

airfields of high elevation where temperatures exceed

80*F,

During

these conditions vapor locking can occur after a hot engine has been

shut-down and a start is attempted within a period of up to one hour

after initial shut-down.

Vapor lock symptoms are; zero fuel pressure

with the electric fuel booster pump on, and by hearing an unusual

sound

in

the booster pump which

indicates it is cavitating rather

than

pumping.

5

When it is suspected that a vapor lock exists, the

follawfng

procedures should be used:

Fuel selector ON, electric fuel booster

Pump

ON,

throttle opened

l/4,

push mixture control to full rich and

leave there until fuel pressure builds up and cavitating sound

disappears,

then return migture control

ta

idle

cut-off and proceed

with normal starting sequence. If a solid vapor lock exists, the

engine primer is usually ineffective until the vapor lock

2s

broken

by the method mentioned above."

If

of1

pressure does not build up after 30

seconds

running, stop

engine and determine trouble.

Check Engine Driven Fuel

Pump

for proper pressure by turning off

auxiliary fuel

pumps

I

Initial warm up should be at 1000 to 1200 RPM.

ENGINE

WARM-UP

Engine is warm enough for take off when the throttle can be opened

without backfiring or skipping.

,

Check magnetos at 2600

RPM.

Drop off should not exceed 175 RPM on

either magneto and should be withfn 50 RPM of each other.

Exercise pro eller

at 2200 RPM. Pull control to decrease RPM, note

drop to 1275

P

50 RPM,

Cowl flaps should be open for all ground operation (pull handle out).

Avoid prolonged ground operation as it will cause overheating.

For further

information

on cold weather starting and engine operation,

consult the Lycoming Operator's Manual.

c

9

OPERATION

TAKE-OFF: Prior to take-off, a check should be made to insure that;

I

1

e

Weight and Balance is

currect.

2

l

All occupants have properly secured the combination seat and

shoulder straps,

3

l

Stabilator

trim

tab set.

4

l

Flaps are extended

3Oo

or less for take-off.

5

l

Cowl flap lever is pulled out to fully open cowl flaps.

6

l

Propeller control

is

pushed in for maximum

RPM*

(3400

Max.)

7

l

Fuel selector valve is

"ON".

8

0

Parking brake control is *'OFF" position.

9

(,

Auxiliary boost pump

'*ON".

6

As

SQQ~

as possible after take-off,

reduce RPM

t=o

the maximum

continuous setting

(3000

RPM) and retract the flaps.

Take-off

power may be used for

8

maximum of five (5) minutes, but it is

advisable

to

reduce

power

a6

soon

as

practical. Best rate of

climb is obtained at 65

MPH

IAS

flaps down, and at 90 MPH

IAS

flaps up at

MET0

power.

A cylinder head temperature gauge is

provided as standard equipment, and power,

ctowl

flaps, and speed

settings should be selected

to

maintain the cylinder head

temperature somewhat less than

475’F.

The maximum

pernt.lssible

is

45O*F.

at

cruise

power,

For take-off and normal rated power,

the limit is

475*F.

LARDING.

During

the let down prior to the landing

8pproach:

1

e

Close

tile

cowl flaps so that the engine does nat cool

too

rapidly.

2

e

Open throttle occasionally to clear out

engine

and keep warm.

Prior to turning into the base leg in the landing

approach:

3

l

Auxiliary Boost Pump

"ON".

,

4

0

Extend the flaps to the desired position

(Maximum

flap speed is

80 MPH) l

5

l

Set propeller control to 3000 RPM.

TAXI

1

l

Retract

Flap.

2

&

open

cowl

flaps.

3

l

Auxiliary Boost

Pump “OFF”.

STOPPING ENGINE

1

l

Pull mixture control full

out

to the idle cut-off position,

(Apprax.

1000 RPM).

2

l

After

the engine stops,

shut off the ignition switch and then the

master

and

generator switch.

3

l

Leave fuel valve in the

*'ON"

position,

4

l

If

the aircraft is to be parked overnight,

push

the

mixture

control

in

l/3.

D.

GENERAL OPERATING INSTRUCTIONS AND LIMITATIONS

This airplane

is

licensed in

the

normal

category

and no

acrobatic

maneuvers, including spins, are approved.

7

5

PROPELLER

LIMITATIONS. None.

Avoid high engine speed (2800 RPM or higher) in

cambination

with

low manifold pressure operation

(under

15"),

Avoid

rapid closing

or opening of the

throttle

(especially

from

a high

RPM

and

manifold

pressure condition).

STALLS AKD SPINS,

The leading edge slats and the restricted nation

of the

stabilator

makes it impassible to fully stall the wing on

the HT-295.

As the minimum speed obtainable

is approached

with the

yoke

full back, a center section separation causes tail buffeting,

A slight aileron nibble is also noticed as the minimum

speed

is

approached.

Minimum

speed

power-off with the flaps down is

apprax-

imately

40

WH

IAS.

This varies with

load

and

C.G,

cbndition.

Voluntary

spins

are

prohibited,

Although the airplane can be

forced, under certain conditions, into

auto-xotatfon which is technically a

spin&,

this maneuver is not the

same as the well

known

"tailspin'*

in that it

cannot

occur accident-

ally

and

contrary

to the pilot's movement of

the

controls.

Na

dive

nor forward movement of the control wheel is required for recovery.

Recovery is effected by the normal

use

of either the aileron

or

rudder control.

SPEED LIMITATIONS.

The

Never-Exeed

Speed

(We)

for the

HT.295

is

200 MPH

C.

A.

S. A

red

line

appears

on the airspeed instrument at this

speed.

MAXIMUM

FLAP

SPEED (Vf) IS 80 MPH

C.

A.

,S.

The white range on the airspeed

indicator indicates the flap range. Cruising range is marked on

the airspeed indicator by a green arc, which extends

to

the

maximum

structural cruising speed, 160 MPH C.A.S.

In very gusty and bumpy

Etiq

the speed should be

reduced

ta

103

MPH

C.A.S.,

Flaps

Up.

This

speed is known as the "maneuvering" speed.

FUEL SYSTEM

The

PS-5-BD

carburetor should be operated at 9 to 15 psi in accordance

with manufacturer's recommendations,

ENGINE OPERATION

Complete operating instructions covering the care and use of the

Lycoming engine are provided with each airplane and should

be

used

as a guide in selecting power settings.

These instructions are in

the form of the Lycoming Operator's

MrPnual.

FUEL

Use fuel with

100/130

octane rating.

58.5 gallons usable with

standard

wing.

(See

page 26 for

fuel system

schmatic.)

8

QIL

Engine

Nodel:

GO-480~GlA6

Average An3iant

Air Temperature Straight

Multi-Grade,

For Starting

Minerai

Additive

Type Type

Above

60*F

SAE

50

SAE

40

or

50

30'

to

!?O°F

SAE

40

SAE

40

0*

to

7OoF

SAE 30

a

SAE 40

Below

lOoF

-

SAE

20

SAE

40

2ov30

ROTATING BEACON

LIGHT

Qil Inlet

Temperature

Desired Max.

IL80°

235'F

18V'

235*F

180°

235O~

/

170'

2100F

170'

210°F

If beacon light is installed, this light should be turned off before

entering overcast, as reflections from the

rotating

anti-collision

light on clouds or dense haze can produce optical

illusions

and

severe vertigo. This is particularly true at night.

9

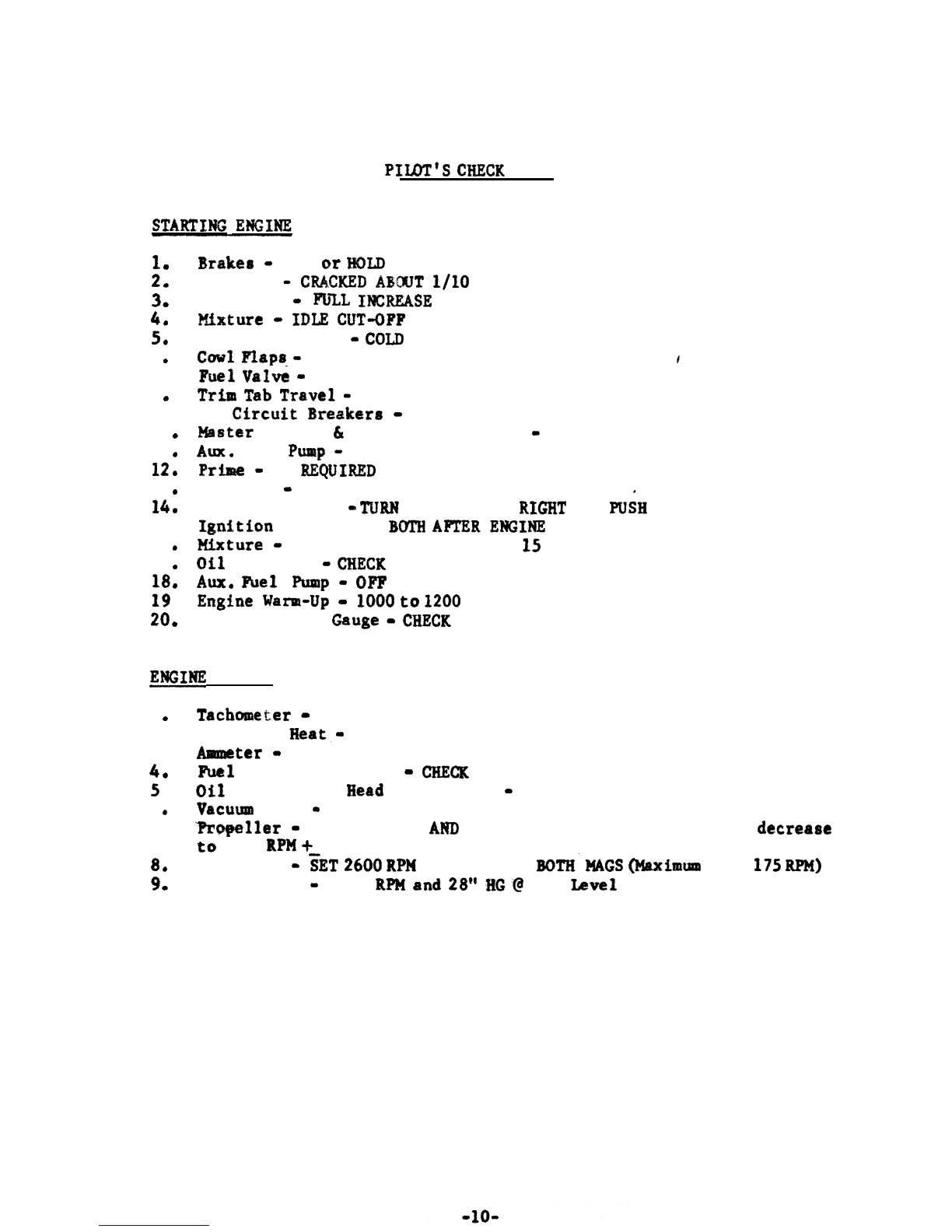

PSulrr’S

CEECIC

LIST

1

a

2

*

3

a

4

8

5

*

6

*

7

a

8

6

9

l

10

0

11

0

12

0

13

0

14

0

15

a

16

8

17

0

18

a

19

l

20

*

Brakere

=

SET

(zr

HDLD

Throttle

CKElD

AHXJT

l/IO

Propeller

-

FIsE;lL

INcIbEASE

l9fxture

-

IDLE

CUT-OPF

Carburetor Heat

-

Cow)

Cuwl

Fhps

-

OPEN

ptpel

VaPv6

-

ON

Trim

Tab

Trs.vel

-

CHECK

All

Cfrcuit

Breakera

-

IN

Master

Battery

br

Generator Switches

-

ON

AUK.

Fuel

Ptupap

-

ON

Pl?h

-

AS

EtEQUlRED

Propeller

-

CLEAR

Ignition Switch

-

TURH

TO EXTREME

RPG)IT

AND

P&H

Ignition

Switch

-TO

BOTH

AFTERENGINE

STARTS

Mxture

-

RICH

(Simultaneously

with

15

above)

Oil

Pressure

-

CHECK

AWL

IPfxel

Pump

-

Ol?F

Ermghe

Wism-Up

-

1000

to

1200

RPM

Fuel Quantity

Gauge

II*

CEECK

fNGINE

RUN-UP

1

a

Taslchmcter

-

SET 1500 to 1700 RPM

2

a

Carburetor

&at,

-

HOT THEN COLD

3

a

ter

-

CHECK

4

*

he1

and Oil Pressure

-

c%fxcIR

5

l

8il

and Cylinder

Head

Temperature

-

CHECK

6

a

Vaculam

Gauge

-

CHECK

7

l

3kwq?eller

-

SET

2200 RPM

AI!tD

EXERCISE SEVERAL TIMES

(Should

decrease

ta’

1275

RPM

+50 RPM)

8

*

Propeller

-

iii3T

2600

RPN

AND CHECK

BOTH.

M&S

OiLpximm

drop

175

RPM)

9

*

Power

Check

-

3400

RPM

an8

28"

.$iG'@

Sea

Imrel

1

4

2

4

3

*

4

l

5

4

6

4

7l

0

4

9

0

10

0

11

4

Flight Controls

-

FREE,

FULLTRAWL

Flight

Instrtmmts

=

SET

Ehgine

Instruments

-

CHECKED

Trim Tab

-

SET

wing

Flaps

-

20 to

30

DEGREES

AS; DESIRED

Propa

f

hr

-

FULL

IHXEASE

RPM

Mixture

-

RICH

Carbe

Air

-

COLD

Cowl

Fup(I

-

OPEN

Seat

md

Shoulder Straps

-

TIGRTEN

Awr.

Fuel

Pump

-

ON

TAKI&-OFF

1

l

!Fhtottle

-

FULL

APtD

TXGHTEN

FRSCTXON

NUT

2

I,

Puwer

Reduction

-

A

R LIFT OFF FULL

THROTTLE

AND

IXXE

TO

30004kPM~

AIRSPEED

80

MPH

MAXLMJM

3

4

Fl

aprs

-

RAISE

4

l

Aux.

he1

Pimp

-

OFF

5

l

Cylinder

Head

Temp.

-

CHECK

(AIRSPEED

-

CLIMB

90

MPH)

6

4

Cruf.se

Cl%mb

-

WLL

THIKJTTLE

AND

2750

RI=

1

4

Thruttle

-

23”

??Gc,

M.P.

2

0

Propeller-

2600

RPM

3

4

Cowl

Flaps

-

AS

REQUIRED

1

*

Seat

8elts

-

TIGHTEN

2

4

carburetor

Heat

-

CfoLD

(EXCEPT IN

XCIms)

3

4

Mixture

G

RICH

4

l

Propeller

*

3000 RPM

5

4

Awe.

Fuel

Pump

-ON

6

0

Wing

Flapr

-

AS DESIRED

7

4

Propeller

-

FULL

ZYCREASE

ON FINAL APPROACH

1

4

Cowl

Flaps

-OPEN

2

4

Wing

Flaps

-

UP

3

4

A*.:-heI

Pump

-

OFF

4

0

Electricrl Switches

-

UNNECESSARY

SWISHES

OF?

I

4

Cylinder

Head

Temp.

-

CooL

(3SOop

or

LESS)

2

0

Throttle

a

1000

RPM

3

0

Propeller

-

FULL

mw

PXTICH

4

4

Mixture

-

XDLE

CUT-OFF

5

l

All Switches

-

OFF

IMPOR’EMT

NOTE:

It

fr

atrongls

reccmmndcd that

cl1

pilots become thoroughly

familbm with the

techntques

outlined

in

the

Omorr

Mstausl

before

operrtiqg

thirs;

aircraft

in full-flapped

STOL

rlaw-flight.

a

11

a

PILOT%

EMERGENCY

CHECK

LIST

1

0

Abort if

BEmRE

Airborne

8. Throttle

-

Clased

b

l

Control Wheel

-

Back

C.

Wheel

Brakes

-

Apply

d

l

*Propeller

-

Full

aaicreaae

RPM

e.

Mrture

-

Idle

‘Cut-off

f

l

*Fuel

ScPe;ctor

v&?e

-

Off

8

l

*Ignition

Switch

and

Master

Switch

-

Off

h

l

%rixq

Aircraft to Stop and Inveatigatc

t

2

*

Abort AFTER

kcasrrfng

Airbo+ne

8.

If bchw

50

feet

-

Hold

Yoke

Back

b

*

If

above

SO

feet

-

Hose over

artd

attampt

to pick up approximately

65

ME%

to facilitate a normal

ImHag

flare-out with flaps

down.

Wheu

flapa

are Up

-

Glide

at

80

KPH,

for

6eat

glfde

distance, If

time

perlarite,

luwer

flaps, glide at 65

MPH

and make

Normal

Landing.

c..

Throttfe

-

Cloud

d

l

Mixture -Idle Cut-Off

ENGINE

FAIUJRZ

OR

FIB*

DURING FLIGHT

1

0

Throttl+

-

‘Closhd

-

2

0

*PrqMBller

-

Full Decrease

RPM

(OUT)

3

l

Maxfmm

Glide

Di8tsnce

Airbpted

-

Attain

80

MEW,

IAS

with flaps up.

USC

the

txces~

in

aimpeed

0-r

80

W%

to

attain

altitude,

if desired,

4

l

mixture

-

Idle

Cut-Off

5

l

*Fuel

Selectors

-

Off

6

l

*Zgnition Switch

-

Off

7

l

mdio

Call

=

Acampliah

8

*

Flaps

-

As

Required

9

e

Generatar

Switch

-

Off

10

l

mater

Switch

-

Off

PROPELLER

FAIUJIXE

IN

FLIGET

1

lPropeller Overspeed

a.

Throttle

-

Retard

b

8

Airspeed

-

Reduce

c.

Propeller

-

Attempt

to

decrcgst

RpMt

with Propeller Control

d

0

If propeller govemmr regains

control,

maintain

2500

RPM

and

70

HP&

IAS

and lend at

mearercrt

airfield.

If net, use

an

hitucie,

airqmed

and

power

cmbination

to

attempt to

beep the

RPM

below 3400.

land

rt

nearerrt

landing

area.

2

b

Propeller

Underrpeeding

Use

power

enough to maintain altitude without engine

overtorque

and proceed to nesrest airport, If

this

is not

pcralrfble

mka

emergency

landin& Use

excem

altitude

otnd

power

available

to

extend

glide to best available

area*

EmRGENCY

MkXIMj#

DESCENT

1

0

Throttle

-

Cleaard

2

l

Propeller

-

Full Iacrease RPM

3

l

Wing

Flaps

-

Full Down

4

&

Airspeed

-

Maintain

Maximum

of 80

MPH,

IAS,

Flaps

Full-Down

1

0

Make

a

8ai~iiwm

safe-epaed touch-down,

2

a

Wtren

landing

with

8

flat

tire

OR

the

msain

g8ar, the aircraft will turn

in the

direction

of

the

flat

tire.

mfntaiq

directfmal

control

with the rudder and brakes,

LANDING ON

U#P&EPARAED

TERRAIN

.

1

*

Xaudiug

pracedure

is

arfsaflar

to

Hlnimm

Run

Lmdings

(Full STOL)

2

*

On soft

or

rough ground,

use

caution in

.-lying

brakes.

3

*

If possible,

avoId

having

ts

re-start

and

rev-up

engine in

loose

sand

or

dirt

to

niaimize

propeller damage,

E

l

SUMRY

OF

QPERATXONAL

AIRSPEEDS AT GROSS

WXGHT

-

3rboo

LBS,

Mnimum

Speed

-

Paver

Off

Flaps Up:

60

MPH

I.A.S.

Flaps

lh?wu: 50

MPH I.A.S.

Never Exceed Speed:

200

MPH

I.A.S.

I$mimuma

Flap Speed: 80

MPH

I.A.S.

*Minimum

speeds

are given

because

it

fs

not possible to fully

stall

the

airplane

l

P

l

TAICGOFF,

CRUISE AND

lANDIlVG

TECHNIQUES

1

l Take-Off

It

fs

suggested that 30 degree flaps

or

less be used for all

take-offs

m

This

is

cmmred

in greater detail under STOL TAKE-

OFF

AND

LANDIMG.

When

taking

off,

firrt

align the aircraft

alang

the

intended

take-off track,

Release brakes and apply power

smoothly,

As

aircraft

accelerates apply Blight back pressure

m

cantrol

whee

1 l

When an

atirapetsd

of

approxiwaely

40

MFH

has been reached

the

awe

~hcel

will

rutrmte

and the aircraft will

bet-

aPrborne.

When

afrborae,

reEeasc

some

bmlc

pressure and

aTlw

tbe sirepeed to

bncrasse

to 64

Ki?it.

while

continuing

tu

climb

at

64

XI?‘&

reduca to

3000 RPM

and

mahmia

full

throttlr!

(5

slim&es

at

t&x!-off

WM

of

3400

and full throttle ia

permited),

Flaps may

remain

at

3Q”

and an

airspeed

of

64

MPH

used for

berrrt

rate

of

climb,

or until

cltaax

or

abatruct&ona.

when

opmIRting

fmm

8

clmw ama with

‘ITO

o’tbIrtruct$ons,

flaps my be raised, slowly

to

preveat

lev~baff

or settling, and

allsw

the air-speed to

fncrease

to 90

MP??

for best

rrate

of climb.

The

RI?M

may

be reduced again

ta

2750

and

full

throttle for

ellmb-out

to

insure

deqcmte

engfne

cool-

ing due td enriching

fmturer

of the carburetor,

Check

fuet

pseeaure

and

turn

off fuel

boost-pump,

Re-adjust

cowl

flaps

aa

raqutired

e

Mmhwm

penaiasibla cpIinder head

temperature

is

475*

for climb

and

450*

fur cruise.

Mast

new

pilots

to

the Currier tend to

over

rutate

on

take-off,

Due to

the

hLgh

lift of the

wfng

md

the large area of the all-

movable

hsriosuntal

tall,

it Es posafblc to

assume

an

excessive

mm

high attitude

when

making

a

short ‘field

takewff.

HCW@V~r,

the

mew

pilot quickly

hams

from experience

how

soon

the aircraft

rssy

be lifted off.

2

a

Cruise

Fl

ight

Tktottle

-

Set {Approximately 23”

HG)

PropelZer

*Set at 2600

Rm

Cawl

Flicpa

=

As Required

Carburetor

Heat

-

As

&q&&d..

The above cruirre

pwer

setting

isr

considered a good average

settfag

for

cross~country

flighta,

Cruise

power

settings can be determined

from

the appropriate engine

power schedule

charts

found in the

Lpcrrrafag

Operators

Pfamml.

No

Mmual

lesning of the

ntfxturc

fs

permitted. The

AMC

(Automatic

Mixture

Control)

ccmymmatts

fur

altitude

and

temperature changer.

3

a

Pmmr-Off

mad

Powm-On

Landing@

Since

the Courier,

In

the

20

degree

flap

(half-flap) configuration,

has csnventimal

or

normal landing

eharrctsriatics,

it

$8

apptapriate

to

rstart

out

on

half-flap landings during the first hour of

familiari-

tation,

Even

though

the

Cuurier,

with half-flaps, handles

liks

other

coavlenttaaal

aircraft,

it

rtill

hrs out-standing

ahurt

field

ckrracttr-

irtics.

For half-flap landings,

an

approach speed of

65

to 70 miles an

hour

its

~~llp

desirable

when

irastrectiag

a pilot

new

tu

the

Courier

l

As the pilot’s

profSciency

ihcreascls,

approcrch

speeds

wf,th

half-flaps

can

be reduced to 66

MI%,

though use

af

mxm

pmmx

then

becms

ctdvtsable.

When

appstaaehfag

for lauding at

this

speed, the pilot should be

rmitided

that the

darts

will pop

out

just

8s

ha

begins

his

flare-out

and

that

they will

have

nc)

effect

upon

the

control-sbititp

or

balance

of

the

aircraft.

With

half-flaps

at

60

MPH,

however,

the

acitcxaft

has little

@@floatVQ

and

should be

flared

or

rotated out fairly-close to the

ground

sc)

that it will

nut

develop

tcm

much

rate-of-sink before

touching

dawn.

Fur

fu31-flap

landinga

the, best

technique

fcm

aXowing

the

air-

craft

down

in the

ap~romh

is

first to

extend the

f&alps

to

20°

startfag

it

80

MPH

or

less, Then, when aircraft has

s2uwed

to

about

65

MPIi

ta

half-flap condition, the

flaps

can then be

brought

into

fulI-dmm

position and

a

landtag

made

by touching

down

on

thet

main gear first at

~rrini.sm.sm

airspeed,

Qne

approach to the full-flap landing ts

tib

have the pilot pop

out the slats by

slowing

the

afrcraft

down

to

5f)

?%PR

acfrile

still

wweral

hundred feet in the

sir.

and then to

compcnsstc

for the

incaeased

rate-of-sink

by

maintaining

partial power until

touch-

d-n.

As we proceed to the

fullmflap

landings, it is well to realize the

fact

that

when the lift of

any

normal

wfng

is doubled by the

USC

of

a flap, the drag

is

increased

Buzr-fold.

This

high

drag at the

full-flap pssitfun

nm

only

producelr

a very steep

rate-ofmdescent

but

also

mearm

that

the

aircraft will have very

litt*‘flcmt*@

once

ths nose

Is

raised for flare-aut, Consequently,

%n

a

full-

ftap

no

puwer

landing,

the

ccirctaft

should

be

held in a nose-

dmm

glide until about ten

feet

fram

the

grotui&if

the

gliding

speed is

higher

or

lower,

the

altitude

for beginning the

flare-

out

can be higher or

lower

accordingly.

As

an

examplt,

if the aircraft

i8

lmmght

in at the relatively

ccmfmtable

gliding

aped

of 60

?%I%

power off and a flare out

is begun at

the

eustammy

approximate thirty-feet above

the

terrain, speed will be

lost

very rapidly and

a

high

rate-of-aink

ccmld

develop,

The

resulting impact could be quite hard.

No.

matter

huw

high the pilot levels out, the

autcmatfc

slats eliminate

all risk of tolling off into an uncontrolled stall

or

spfa,

al-

though high rates of

deocent

can

occur if insufftcLent

power

is

used

m

The best technique for full-flap

landiws

fftvolves

the

maintenance

of

a Xfttle ~cmer-on, just

sufficfent

tt=o

offset the added drag of the

flaps and to produce a relatively

normal

glide

mgle.

This

is

done

by

maintafnfag approximately ten to

flfteca

inches manifold

pressure,

depending upon the load

md

air conditfoa. The aircraft is then

flared out and

land&d

in a

cunventionaf

manner,

much

the

sm

as with

half-flaps,

The

approach

speed,

however, is

closer

to

50

M%

than to

6Om1

.

When

win&the

lower

aped

Irficiing

tzue,

the throt!fQ should

sot

be

cztsaed

camplletely

until

wheirlts

ma

grounds

at

wMeh

tfme

tlw

poke

ahuuld

be

hald

full

beck.

An

advcrntage

of the partial

power

approach is

eae,se

of glide path

cuntrol

by slight imxeases or reductiom in the amount of

pamr.

The

full-flap

no”~~“wer

landing,

while

not

difficult, fe usually

desirable

only

as

an.

emergency procedure,

Inatrucdon

in this

type of landing is

laeceasary,

In order to make

amooth

landings,

it

iavolves

a

different te&nique with which

Ccmrier

pilato

rahcmld

be famiI.iar. For

ful,I-flap,

no-pop~rer

Landingr,

it

is

advisable that the

pflot

keep

the

aipproach

*peed

st

60 to 65

MPH,

but not

below

60

WEi.

miatain

arpproach

speed of 60 to 63 MPH

=ii-&ec~f~s

just off

the

rummy,

With power-off, the

flare

out

ahould

not

be ataxted tm3.l

wfthfn

10

to

Z3

feet off

the ground mthat the

n6se:

barely

ecmm

up to the full landing

positfsa

just

as

the

sircxaft

sinks

dowa

to

gmuad

level.

whfch

is

a

safety feature for emergency

or

forced

land$.ngs,

Consequently,

a

stfghtly

high flare-out will quickly

re8uft

in

a

xelcrtfvely

high rate of descent,

Le,

j

a hard landing!

:

Use

of

full-flape

without

.puwer

iar

nomally

done

ocrly

in

emelpgency

landings

s

Normal

SIXJL

approaches with full-flap8

are

best

accomplighed

with

part&al

power

so

a~

to

xmintaia

tssentially

the

mme

flight-psth’arrgle

at about 55 MPH

as

results from 70

MPH

at

half-flaps and ao

puww,

The throttle

thenmtts

the

approcrch

control device.

4

e

STOL Take-0f.f and

Landings

The shortest ground run take-off under

aandetrd

conditbons

at

3000

Iba,

or

less can usually be accomplished with full-flaps,

Le.

4o”*

(This

W.11

nut,

howmmr

s

provfde

the

beslt

angle

of

clkab

if barrier clearance

fs

the objective,) The use of

3am

or

less, depending on load

and

prerraure

gltltude,

is

reammended

for

take-off.

Align aircraft

along

intended take-off track, Apply full power

in a steady

mannetr.

Do not

*@japP”

throttle

farward

l Release

brake

aa

power

is

applied,

Holding

brakes

on

while

full

povclr

is

being

applied is

not

necessary, or desirable. Keep aircraft

strafght

ontrack by

wing

rudder.

Try

to avoid

application of

the foot

brakes

unless

requfred

tu

matntaifn

dire,ctiemal

cantrol,

At

approxiastrtcIy

35

MPH, apply back

pressure on the yoke in

a

positive

manner

but

nut

LIU

fast

that

the aircraft ~QIS~S an

excessive mse high

attjttude

after lift-off. When the aircraft

breaks

ground j

ullar

it

to

remain

just above

the ground for

apprmctitcly

2 or 3

aecsnds,

so

that the

airaped

will build

up to over

SO

KFH

before

the airplane

rtarts

full-climb-out.

EstabZirrh

a

climb-out speed

af

SO

to 64

&SPH

as

SQQ~

aa

prmtical,

I

16-

Experience

galned

En

th%s

type

sf

take-off

w%ll

ermbh

the pilot

to determine

tha

aunt of yoke

mcw~mernt

and/or

rapidity of action

neceaaary

to get the

aircraft

airboxme

with

the

rpinimtm

of

gxourtd

run.

This type

.of

s~inimum

run

take-off

is

most useful when the

ground is rough, bumpy, muddy

ok

where

very

ICYW

obsrmles,

meh

us

hedgea

fmcerr,

dmzhes, etc.

are

present

r,

a.

Muddy

Terrain

Take-Off

*

The

Helllo

Courier

is

an

unusua1lp

good

“Blludder”.

A

modmately

muddy

field

ummlly

pre~cnta

no

problem;-

At

normal

pxassurt

altftudt

am?

with

loctds

of

3000

lbs,,

or

lbss,

fulll?flaps

ace

usually

nm-xe

advantageous

fn

breaking

free

from

clfngfng

mud.

The following

procc?dure

ie

rec~nded:

Apply

full

power,

(Da

raat

bald

pa~~-on

SO

Pang

am

to

ovlerhest

the

engixw

if tha aircraft

faire

te

move,)

HoId

poke

fur2

.back

then

rock

poke

abruptly, usiag

full, but not proloaged,

fmmrd

positfon,

to

help

break the

wheels

free!

(,

When

the

aLrmaft

begkns

to

mmm,

the

oscflIatfag:

mmmmmms

of

the

stabffator

athould

be reduced mthat

there

is

equal **float-

atiun” on all

three

wheels

as

the aircrrrf

nmves

fortim+.

Then,

when

rolling free,

use

esaentfallp

the

mme

te

hnique

far the

mtnimum

run

take-off. Since

the

consistency

and

effect

of

diffwetlt

types

and

depth8

aX

wd

vmy

grbi?

y,

nu

stngle

rule

or technique can

substitute

for

expcr%ence

aad jud

nkt:

cm

soft and

irrreguXar

field

surfaces,

A muddy landing

or

deep

smw

landing

cmz

u.sualXy

best be mde by

using

full-flaps and plrscfw the

aircraft

onto the

groutrb

iu a

slight nom-high position

st.minismm

speed,

Acttmlly

touching

the

fn

wheels

firat

may

bc

adwmmgeous,

but the

mm

should not be

allowed

to

slam

dawn

into

the

mud.

After the

mime-wheel

touch-duwn

take

rll

power

off

and hold

poke

fully back.

If

fcmard

speed is

thus

held

low

cTn

the

touchdown, it will

tend

to

prevmtt

mm-over.

(This

procedure is essentially the

ame

as that

coaerrtonly

rsccmmmded

for

ditching

in

water.)

Rough

ground

or other

condi.tEons

may be

a

datermfning

factor where,

iu spite of a barrier,

the

full-flap

minimm

ground

run

take-off

may be

neceauary.

It

should

be

re-emphmtzed

here

thrat

WG~

#hen

tryfng

to

climb

out

af

a

mall

mea

at

too low

u.

apeed

with

the

Helis

Cmrier,

there

is

no

danger

sf

stlllfag,

losing

lateral control,

or

gofag

iuta

a spin.

s!u~evar,

a

coaditfcm

can

develop,

aspectally

with

full-

flaps

dm,

whereby

ther

mme

ir

heId

taa

high

and the

Eapesd

too

tow

cafter

take-off,

So

that the

afrcraft

will

actually

loge

altitude

wLth

power

fall

ma.

The

asost

emoa

cause of HeIia

crsahe~

and major

daarage

-- though

nmmr

with

s~iatss

fnjuxy

to

occupants

--

has been

from

efforts to

pull the aircraft off the ground

prematurely

at

toa

law

B

speed

and/m

roactirr;ntly to try to

cltaab

aut

with

tao

low

an

airspeed

psith

flaps

dcwa

se

that the

remlting

high-drag

exceeda

the

re-

drtced

thrust

ef

the propeller

a;t

km

fmrvmrd

Bpeeds,

Thus, with

power full-on, the

rafrcr~ft

my

either

sink

?mck

ta

the

ground

or fail ta clear

otherwfiae

-joy-sasaaoontable

sbstactes.

It

takes considerable

expcricn~e

ta

rscogaize

the

point

at

which

I

the

nose

high attitude

starts to

reduce

the

rate-of-climb

aad

then

may

finally progmss

to

an

actual

rate-of+fnk

despite full power.

This condition is

often

referred

to

am

**the

back

side”*

af

the

thrust drag curve,

or

simply as

“the

back side

rof

the

mer

curve”.

Canstqueatlp,

a

**zocmw

after take-off

irr

order

to

clear

a cluse

barrier

should

be strictly

8~

cpergeiacy

ptocadure

fur

expcrfenced

Hcrli.0

pflots*

Climb-out

speeds

below

50 MPH

arc

nqt

recmmmdtd.

d

a

Sharcttst

Distance

Take-OffsOver

Barrier (Grass

Weight

3000Q

OF

Higher)

With

30

degree

flaps

alluw

the

aircraft to accelerate as quickly

818

pcmsible

to

40

KPH.

Wfth

the

airspeed

indicating at

feast

40

MPH,

fly the

ieircrsft

off by applying the

approprfPte

back

pxe8-

msre

on

the

elevator

until it is airborne,

Permit

the

sirsaecsd

to

build up

for

rpprcmimatalg

two

mxands

au

abaut

50

MPH,

then

begfn

rotation to the

point

that

will

climb

the

aircraft

over

the barrier

without

further build

up

of

airrpted.

After consfdtrable

txperi.mcel

ewea

shorter barrier

diatanee

can

be

attained

by

hoEding

the

aircraft

to

about

30

MPltI

&n

a smooth

ruuwuy

and

then

%omimg**

over

the

barrier

at an

amble

sufficiently

steep

to

clcrar

the barrier without

lass

of

airspeed

after

whfch the

~~cme

can

be

lowered

and

the

nmma

rate-of-climb airspeed

attaiaed.

Grcrt

skill

ia:

n6Ctssary,

hcnmmr,

ta

avoid

lass

of

speed and

consequent

Mweatrry sfaking

efthtr

just

before

or

just

after

craerslag

the

barrier,

Such technique

kr

not

rscmnmdcd

for

other

thaa

cmcrgency

tituutian&

18

Table of contents

Other Helio Aircraft manuals

Popular Aircraft manuals by other brands

GRAVITY

GRAVITY X duo manual

SOL paragliders

SOL paragliders SQUAD LIGHT owner's manual

Pipistrel

Pipistrel Virus 912 Flight and maintenance manual

Dancing Wings Hobby

Dancing Wings Hobby Savage Bobber instruction manual

Grob

Grob TWIN-ASTIR FLIGHT HANDBOOK

SOL paragliders

SOL paragliders ELLUS 2 Pilot's manual