SERVICE BULLETIN

HERMETIC COMPRESSOR ELECTRICAL TERMINAL VENTING CAN BE

DANGEROUS

******

When the insulating material, which supports a hermetic compressor electrical terminal,

suddenly disintegrates due to physical abuse or as a result of an electrical short

between the terminal and the compressor housing, the terminal may be expelled,

venting the vaporous and liquid contents of the compressor housing and system.

If the hermetic compressor terminal PROTECTIVE COVER is not properly in place with

its weatherproofing gasket (if required) and bale strap fastening device secured, there is

a remote possibility if a terminal vents, that the vaporous and liquid discharge can be

ignited, spouting flames several feet, causing potentially severe or fatal injury to anyone

in its path.

The discharge from a venting terminal can be ignited external to the compressor if the

terminal PROTECTIVE COVER is not properly in place and if the discharge impinges

on a sufficient heat source such as, but not limited to, an open flame, electric heater, or

an electrical spark.

Ignition of the discharge can also occur at the venting terminal or inside the motor-

compressor enclosure, if there is sufficient contaminant air present in the system and an

electrical arc occurs as the terminal vents.

Ignition cannot occur at the venting terminal without the presence of contaminant air,

and cannot occur externally from the venting terminal without the presence of an

external ignition source.

It is, therefore, essential that any air in a refrigeration, air conditioning, or heat pump

system be completely removed when the system is manufactured - when the system is

installed - and whenever the system is field processed as a result of field service. Field

service includes, but is not limited to, leak repairs or compressor replacement.

Eliminating air within the system prevents ignition at, or in, the hermetic compressor if a

terminal should vent, thereby reducing the hazard potential.

To reduce the possibility of external ignition, all open flame, electrical power, and other

heat sources should be extinguished or turned off prior to servicing a system.

Before using a soldering or welding torch to remove or repair tubing, make sure all the

system refrigerant charge has safely been released.

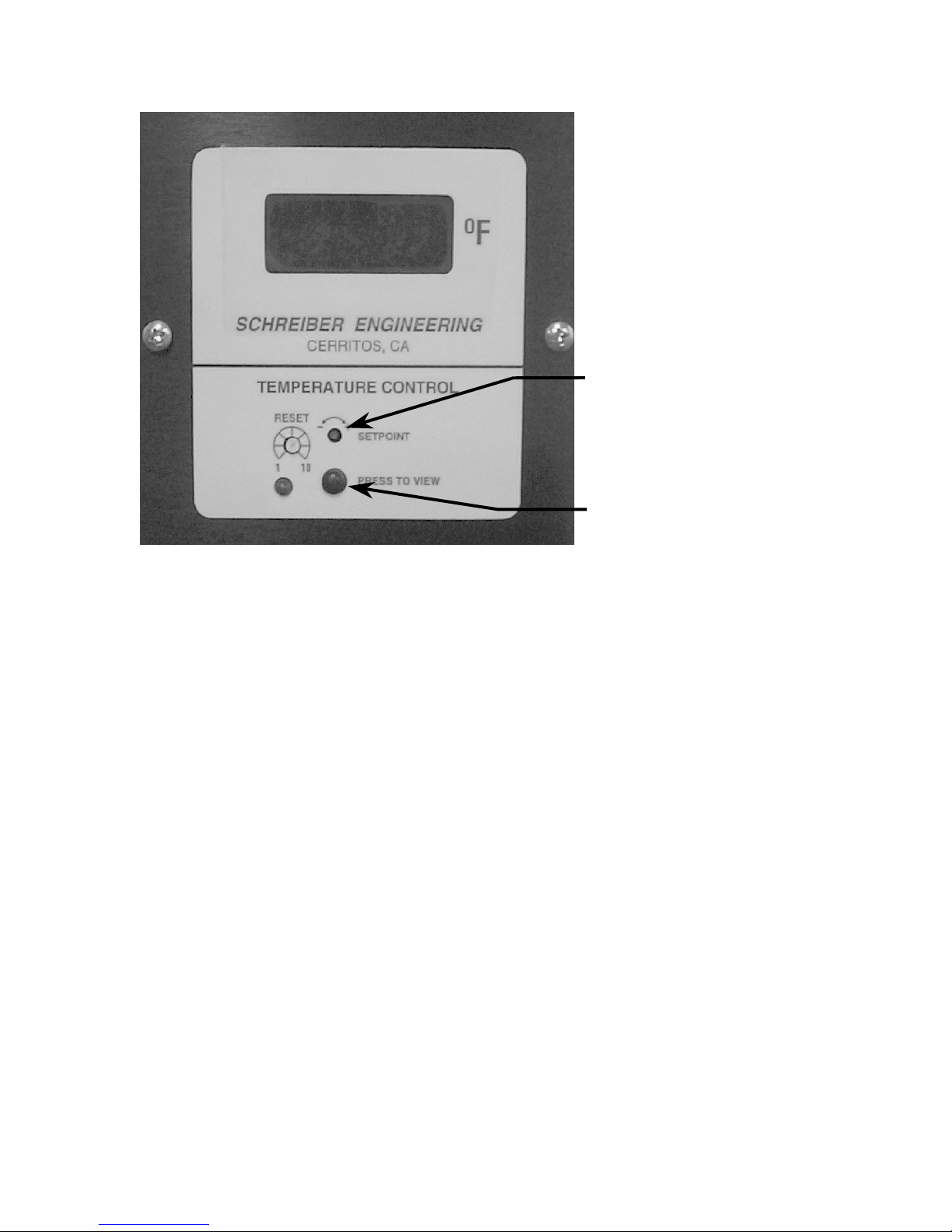

A venting terminal presents no danger to servicing personnel or anyone else in the

vicinity if the compressor terminal PROTECTIVE COVER is properly in place as shown

11