1

www.climacoolcorp.com

Introduction

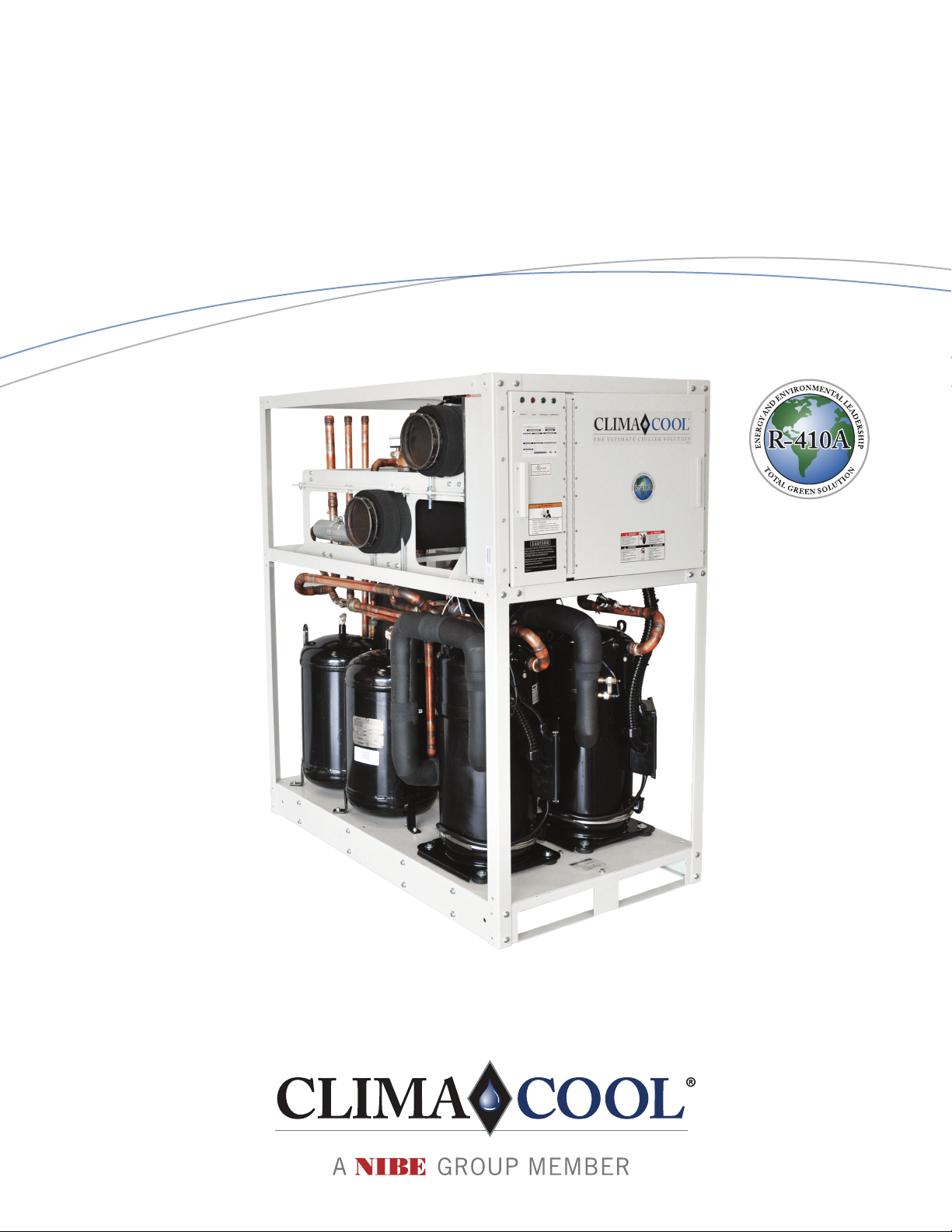

General Description

The ClimaCool®

cooled modular chiller is designed to provide the most

and serviceable modular chiller in the industry. The UCR

utilizes R-410A refrigerant.

Modules are available in 30, 50 and 70 tons, which when

capacity requirements from 30 to 400 tons per bank.

Safety

Throughout this manual, warning, danger, caution and

attention notices appear. Read these items carefully before

attempting any installation, service or troubleshooting

of the equipment. All labels on unit access panels must

be observed.

DANGER: Immediate hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Potentially hazardous situation or an unsafe practice

which, if not avoided, could result in minor or moderate injury

or product or property damage.

ATTENTION: Notication of installed, operation or maintenance

information which is important, but not hazard related.

CAUTION/ATTENTION

installed wiring. Unit terminals are

not designed to accept other types of

conductors.

Utilisez uniquement des conducteurs en

cuivre pour le câblage. Bornes de l’unité

ne sont pas conçus pour accepter

d’autres types de conducteurs.

CAUTION/ATTENTION

3 PHASE SCROLL

COMPRESSOR UNIT

UNITÉ COMPRESSEUR

SCROLL 3-PHASE

If this unit uses a 3 Phase Scroll

Compressor, the following instructions

MUST BE followed:

• Unit power supply MUST BE wired

in the proper sequence to avoid

damage to the 3 Phase Scroll

Compressor;

• Scroll Compressors with

INCORRECT rotation show the

following characteristics:

- High sound level;

- High suction pressure and low

discharge pressure;

- Low current draw.

• If any of the three above

characteristsics exist, swap

two of the three supply wires

at the disconnect and recheck

compressor for incorrect rotation.

Si cet appareil utilise compresseur

scroll 3-Phase, les instructions

suivantes doivent être suivies:

• L’alimentation de l’appareil doit

être monté dans l’ordre correct

pour éviter endommager le

compresseur scroll 3-Phase;

• Compressuers scroll avec

rotation incorrecte montrent les

caractéristiques suivantes:

- Haut niveau de son;

- Pression d-aspiration élevée

et une faible pression de

décharge;

- Faible ampérage.

• Si l’un des trois éléments

mentionnés ci-dessus sont

remplies, échanger deux des trois

lignes électriques alimen tant la

la rotation du compresseur.

WARNING/ADVERTISSEMENT

To avoid possible injury or death

due to electrical shock, open the

power supply disconnect switch and

secure it in an open position during

installation.

Pour éviter les blessures ou la mort

par électrocution, ouvrir la interrupteur

ouverte lors de l’installation.

CAUTION/ATTENTION

Excessive Chlorine, undissolved

solids and other improper water

conditions WILL DAMAGE the

internal heat exchanger & WILL VOID

YOUR WARRANTY!

Chlore excessive, solides non dissous

et les autres impropre conditions de

l’eau ENDOMMAGERA l’échangeur

de chaleur interne et ANNULERA

VOTRE GARANTIE!

WARNING/ADVERTISSEMENT

WATER AND REFRIGERANT

SYSTEMSUNDERPRESSURE

EAU ET FRIGORIGÈNE

EQUIPEMENTS SOUS

PRESSION

• Isolate/Lockout source and relieve

pressure BEFORE servicing

equipment.

• Failure to relieve pressure may

result in property damage, serious

bodily injury or death!

• Isoler la source / de verrouillage

et de soulager la pression avant

entretien de l’équipement.

• Le défaut de soulager la pression

peut entraîner des dommages

matériels des blessures corporelles

graves ou la mort!

ATTENTION

To avoid the release of refrigerant into the atmosphere, the refrigerant circuit of

this unit must be serviced only by technicians who meet local, state and federal

All refrigerant discharged from this unit must be recovered WITHOUT

EXCEPTION. Technicians must follow industry accepted guidelines and all

local, state and federal statues for the recovery and disposal of refrigerants.

If a compressor is removed from the unit, system refrigerant circuit oil will

remain in the compressor. To avoid leakage of compressor oil, the refrigerant

lines of the compressor must be sealed after it is removed.

WARNING/ADVERTISSEMENT

Disconnect power supply(ies)

before servicing. Refer servicing

Electric shock hazard. May

result in injury or death!

Debrancher avant d’entreprendre

le dépannage de l’appareil.

pour le dépannage. Risque de

choc électrique. Résiltat de mai

dans dommages ou la mort!

CAUTION/ATTENTION

personnel only. Refrigerant

system under pressure. Relieve

pressure before using torch.

Recover refrigerant and store or

dispose of properly.

Conifer la maintenance à un

Décomprimer avant d’exposer

frigorigene et le stocker ou le

détrulre correctement.