Varistar LHX 3 60130-626 Revision 001

4

1. Description of the Air/Water Heat Exchanger (LHX 3)

This unit is designed to remove the high levels of dissipated heat generated by electronic racks

and components used in electronics and industry from the electronics or server cabinets in

which they are installed. The LHX 3 is based on the VARISTAR series and contains a space-

independent cooling system.

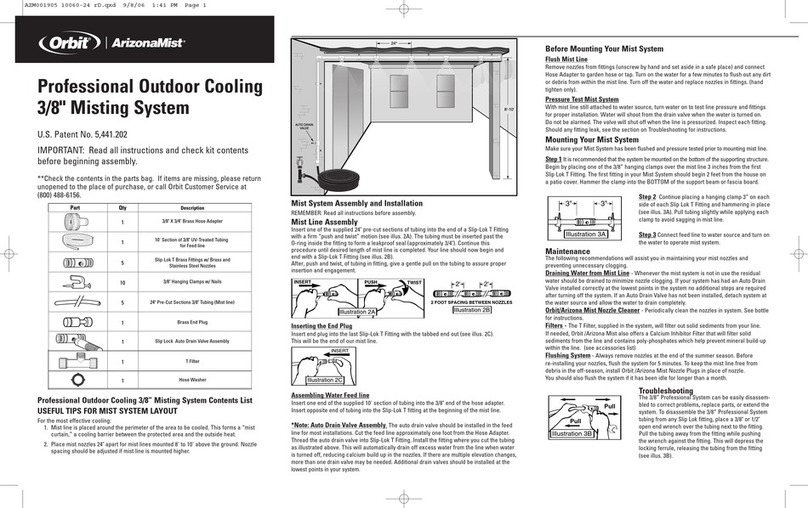

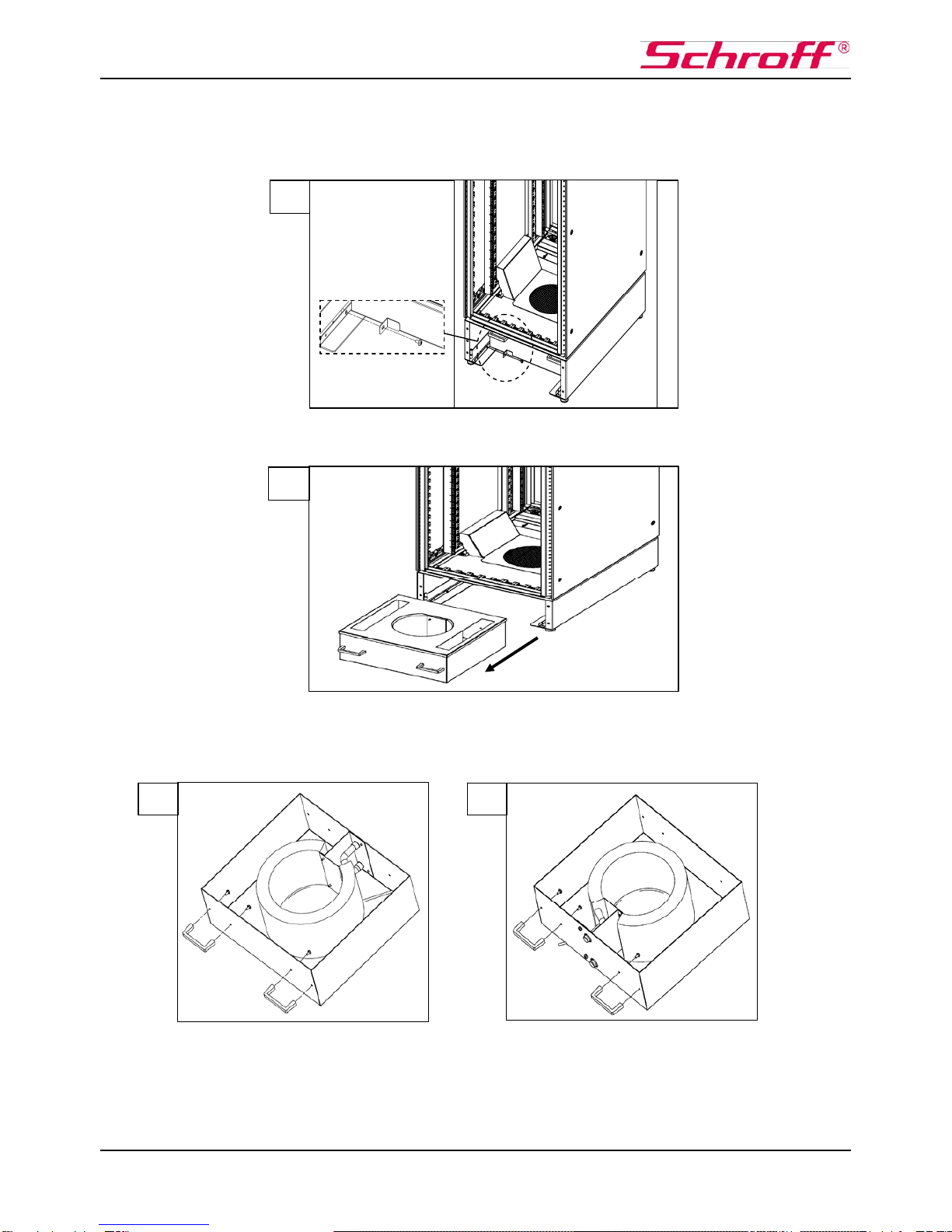

The system comprises a top fan, air channels in both side panels and a removable air/water

heat exchanger in the base of the cabinet.

The LHX 3 is designed for maintenance-free operation.

1.1 Principle of Operation

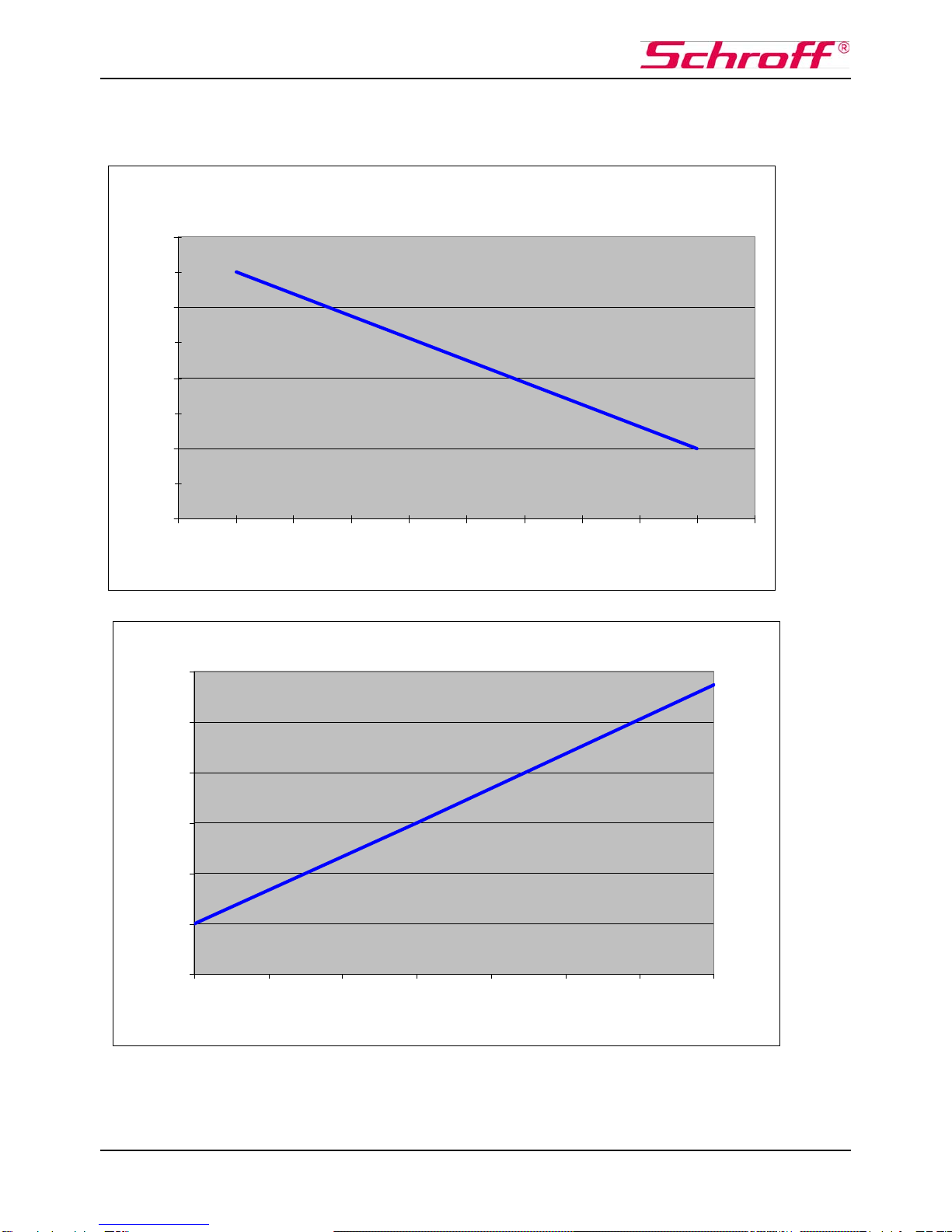

Warm air in the cabinet is sucked upward by a top fan into air channels which are integrated

into side panels.

Cooling water enters the heat exchanger, is warmed by extracting heat from the air, and flows

back to the cooling-water circuit. Meanwhile the air, now cooled, is reintroduced into the cabinet

from below.

General Remarks for Effective Cooling

An effective usable cooling capacity of the LHX 3 is achieved by:

- optimal positioning of the electronic components housed in the cabinet

- suitable guiding of the airflow

- air baffles fitted to increase functional effectiveness

1.2 Controls

The LHX 3 is not adjustable.

1.3 Benefits

The LHX 3 is based on a space-independent thermal concept and does not affect its

surroundings.

At full load the LHX 3 generates a noise level of no more than 45.2dB (A) and can thus be used

in an office environment.

Since the air/water heat exchanger is situated in the base, the LHX 3 does not pose a danger to

the installed systems from water leakage. Nor is there any danger of air short-circuits since the

fan (in the top panel) is spatially separated from the heat exchanger (in the base).