3

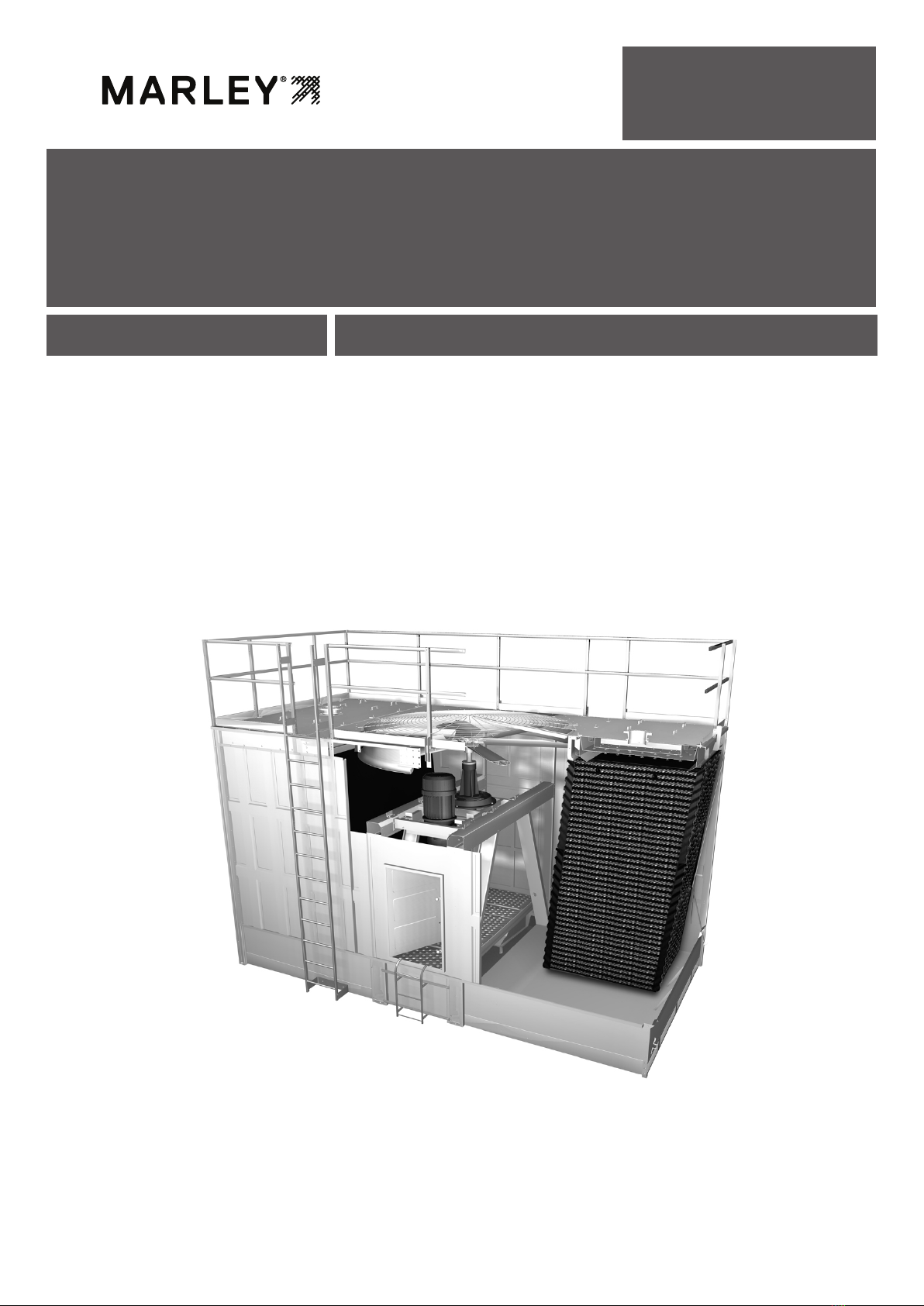

overview

This User Manual as well as those offered separately on motors, fans,

Geareducer, couplings, drive shafts, float valves, pumps, etc., are intended to

assure that this cooling tower serves you properly for the maximum possible

time. Since product warrantability may well depend upon your actions, please

read this User Manual thoroughly prior to operation.

This User Manual provides information regarding general cooling tower instal-

lation and operation. Any deviation from, change or modification to, the User

Manual, the original design conditions or the original intended use of the

equipment may result in improper installation and/or operation of the tower.

Any such deviation, change or modification shall be the responsibility of

the party or parties making such deviation, change or modification. SPX

Cooling Technologies, Inc. expressly disclaims all liability for any such deviation,

change or modification. The equipment shall be warranted in accordance with

the applicable SPX Cooling Technologies Certification of Limited Warranty.

If you have questions about the operation and/or maintenance of this cool-

ing tower, and you don’t find the answers in this manual, please contact your

Marley sales representative. When writing for information, or when ordering

parts, please include the serial number shown on the cooling tower nameplate.

Safety First

The location and orientation of the cooling tower can affect the safety of those

responsible for installing, operating or maintaining the tower. However, since

SPX Cooling Technologies does not determine the location or orientation of

the tower, we cannot be responsible for addressing those safety issues that

are affected by the tower’s location or orientation.

Tower Shipment

NC Fiberglass towers ship by truck unassembled. Responsibility for the

condition of the tower upon its arrival belongs to the shipper—as does the

coordination of multiple shipments, if required. Refer to the NC Fiberglass

Assembly Manual for instructions.

Receiving Tower

Prior to assembly, inspect the shipment for evidence of damage in transit. If

damage is apparent, note the freight bill accordingly. This will support your

future recovery claim.

Find and remove the installation instructions and bills of material. This informa-

tion should be kept for future reference and maintenance purposes.