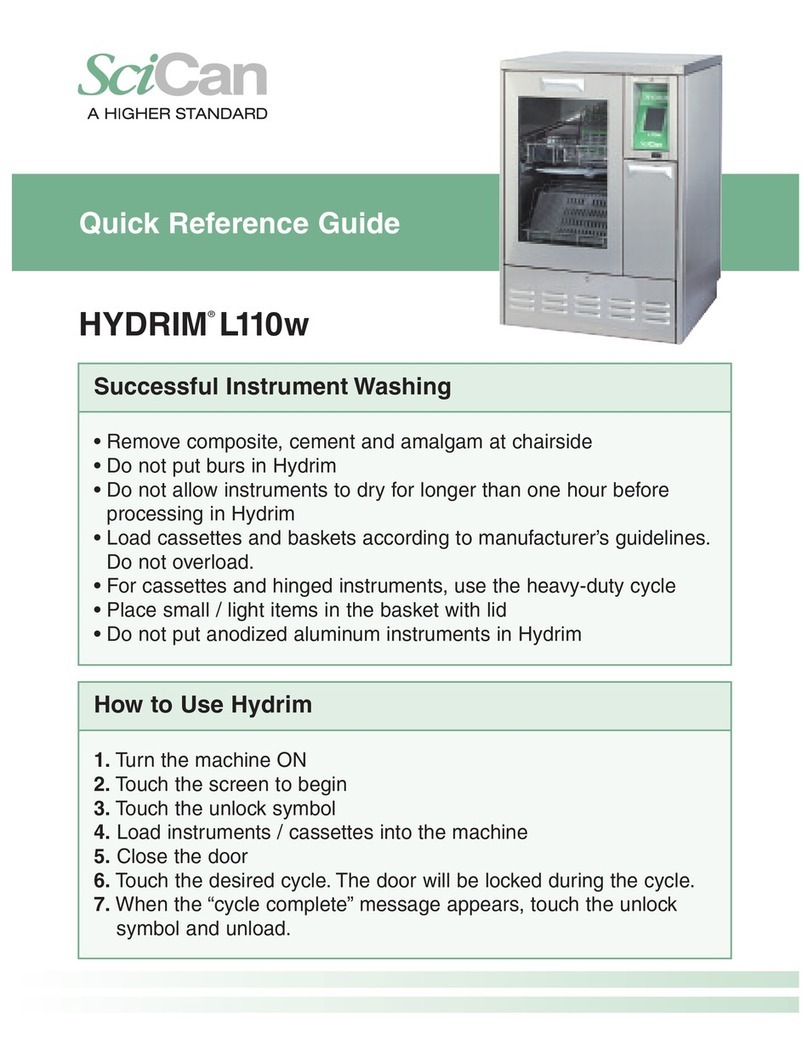

SciCan Hydrim C61wd G4 User manual

HYDRIM C61wd G4 Installation Manual 95-113166 Rev. 1.0 Copyright 2013 SciCan Ltd . All rights reserved.

HYDRim C61wd G4

INSTRUMENT WASHER

• Installation Manual and Preventative Maintenance Schedule

• Manuel d’installation et calendrier d’entretien préventif

• Installationshandbuch mit Wartungsinformationen und - intervallen

• Manuale di installazione e programma di manutenzione preventiva

• Manual de instalación y programa de mantenimiento preventivo

Environmental requirements ........................................................ 3

Unit installation checklist .............................................................. 4

Unit installation ............................................................................. 4

Installation configurations ............................................................ 4

Set up ........................................................................................... 6

Checking water quality ............................................................... 10

Connecting to a network ............................................................ 11

Connecting to a wireless network .............................................. 11

Testing the unit ........................................................................... 12

Performance Testing the unit ..................................................... 12

User training ............................................................................... 13

Unit handover ............................................................................. 14

Annual Service Requirements .................................................... 15

HYDRIM and STATIM are registered trademarks of SciCan Ltd. BRAVO, HIP,

and SysTM are trademarks of SciCan Ltd. All other trademarks referred to

in this manual are the property of their respective owners.

For all service and repair inquiries:

In Canada 1-800-870-7777

United States: 1-800-572-1211

Germany: +49 (0)7561 98343 - 0

International: (416) 446-4500

Email: [email protected]

Manufactured by:

SciCan

1440 Don Mills Road,

Toronto ON M3B 3P9

CANADA

Phone: (416) 445-1600

Fax: (416) 445-2727

Toll free: 1-800-667-7733

EU Representative

SciCan GmbH

Wangener Strasse 78

88299 Leutkirch GERMANY

Tel.: +49 (0)7561 98343 - 0

Fax: +49 (0)7561 98343 - 699

SciCan Medtech

Alpenstrasse 16

CH-6300 ZUG SWITZERLAND

Phone: +41 (0) 41 727 7027

Fax: +41 (0) 41 727 7029

HYDRIM C61wd G4 Installation Instructions

NOTE:

• TheHYDRIM C61wd G4 unit should only be installed by a trained, SciCan approved

technician.

• Installationshouldonlyproceedafterthesatisfactorycompletionofthepreinstallation

documentation.

Model Number________________________ Serial no.____________________

There are several factors that may affect the performance of your HYDRIM. Please review

these factors, before installation and ensure the location is suitable.

Temperature and Humidity

Avoid installing your HYDRIM in direct sunlight or close to a heat source (e.g. vents or

radiators). The recommended operating temperatures are +5 to +40°C with humidity of 80%

for temperatures up to 31°C and 50% for temperatures up to 40°C.

Spacing

The vents and openings on the HYDRIM should remain uncovered and unobstructed. Do not

move the HYDRIM C61wd G4 into place by maneuvering the open wash chamber door. This

may cause the door to become misaligned and can cause leakage.

Venting

The HYDRIM should be operated in a clean, dust free environment.

Work Surface

The HYDRIM should be placed on a flat, level, water-resistant surface. Never install and

operate the unit on a sloped surface.

Electromagnetic Environment

The HYDRIM has been tested and meets applicable standards for electromagnetic

emissions. While the unit does not emit any radiation, it may itself be affected by other

equipment which does. We recommend that the unit be kept away from potential sources

of interference.

Electrical Requirements

Use properly grounded and fused power sources with the same voltage rating as

indicated on the label at the back of your HYDRIM. Avoid multiple outlet receptacles. If using

a surge suppressor power bar, plug in one HYDRIM only.

WARNING: NEVER LOCATE THE HYDRIM WITH THE ELECTRICAL

OUTLET RECEPTACLE BEHIND THE MACHINE!

Page 3

HYDRIM C61wd G4 Installation Instructions

Page 4

HYDRIM C61wd G4 Installation Instructions

Unit installation checklist

NOTE: Refer to Operator’s manual during installation for operating the machine.

1. Inventory Check

Open box and check contents (add or as appropriate):

HYDRIM C61wd G4 unit

Operators manual

Carrier (trolley)

Cleaning solution carrier (installed in unit)

Water feed hose (red) – ‘hot’

Water feed hose (blue) – ‘cold’

Drain tube

Drain tube clips (x2)

Water hardness test kit

Salt for regeneration unit

Salt funnel

HEPA Filter (installed in unit)

NOTE: Additional racks/baskets will be needed to run the unit with instruments. Please refer

to the Operator’s Manual for different configurations.

NOTE! HIP™ Ultra cleaning solution (CS-HIPC-U) is required to run the machine and is NOT

included with the machine. Please ensure cleaning solution has been separately provided

prior to installation.

2. Unit installation

Installation configurations

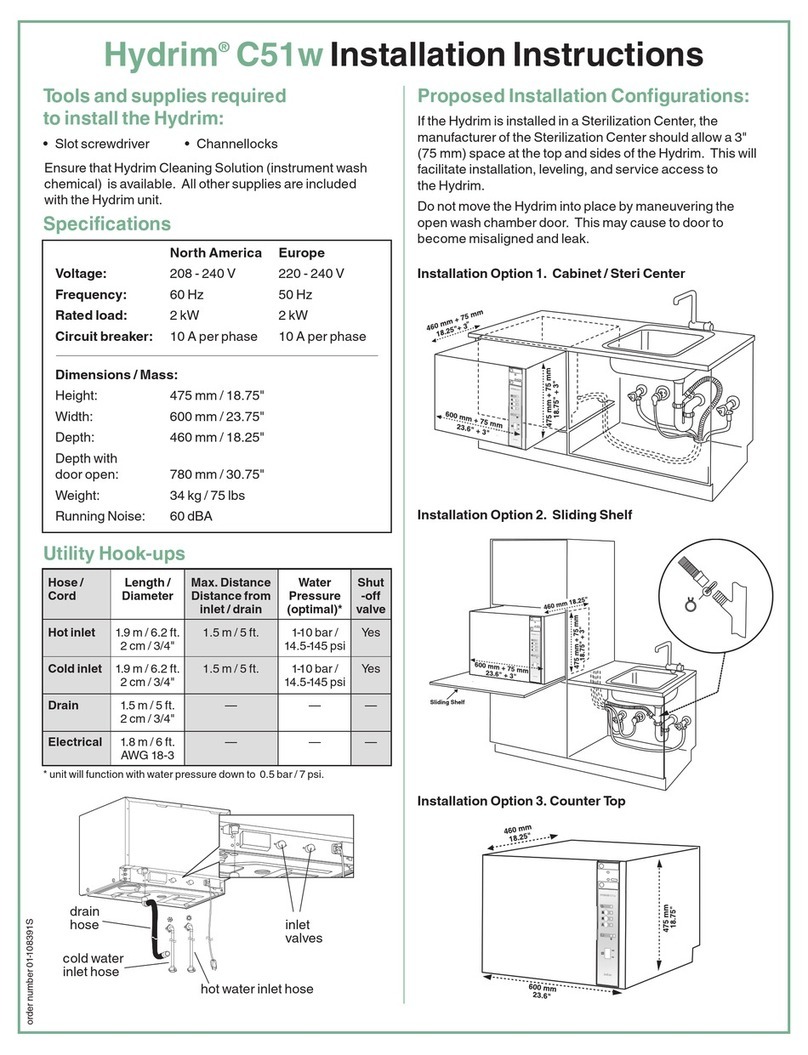

The HYDRIM C61wd G4 may be installed under-bench or free standing dependent on space

and service availability.

The configuration options are:

Option 1. Cabinet / Sterilization Center

Page 5

HYDRIM C61wd G4 Installation Instructions

Option 2. Sliding Shelf

Option 3. Counter Top

NOTE 1 - Although not required, if the HYDRIM is installed under a counter, it is

recommended to allow a 10 mm space at the top, back and both sides of the unit.

This will facilitate installation, levelling, and service access to the HYDRIM.

NOTE 2 - Important! Ventilation during drying is via the front of the machine. Some increase

in humidity may be apparent during this drying phase and it is imperative that sufficient air

circulation is available surrounding the machine to enable this humidity to be dissipated.

Failure to provide adequate ventilation may lead to equipment or cabinetry damage

(depending on installation configuration).

NOTE 3 - The drying system has a filtered air intake. The free movement of air to this intake

is important and failure to provide the required space may cause overheating of the dryer

motor and/or compromise drying efficiency.

Page 6

HYDRIM C61wd G4 Installation Instructions

Set up unit as follows:

• Unpackunitandremoveallrestrainingties

• Locateunitinapproximateposition

NOTE 1 - Do not move the HYDRIM C61wd G4 into place by maneuvering the open wash

chamber door. This may cause the door to become misaligned and can cause leakage.

n

1 Power switch

n

1 Kickplate

n

1 Bacteriological air filter

1n

1 (if fitted)

n

1 HEPA filter

n

1 Dryer exhaust

n

1 Door latch

n

1

n

1 USB port

n

1 LCD touchscreen

n

1 Dryer outlet

n

1 Water softener

n

1 Wash arms (top not shown)

n

1 Coarse filter

n

1 Cleaning solution

n

1 and drawer

n

1 Drain outlet

n

1 Ethernet port

n

1 RS232 port

n

1 Cold water inlet

n

1 Hot water inlet

n

1 R/O water inlet

n

1 Fuses

n

1 Power cable connection

n

1 Drain tube (behind kickplate)

2

Rear Connections

1

2

3

4

5

6

14

15

16

17

18

19

7

8

9

10

11

12

2

13

2 926 28

1 2 4 5

2118 19

15 17 2014

7

20

21

22

11 12

13

3

10

16

22

Page 7

HYDRIM C61wd G4 Installation Instructions

Connect water feed pipes to machine and relevant services:

Water feed requirements:

Hot water/RO feed with G ¾” shut off valve

(washing machine fitting)

• Maximum distance from installation less

than 1.50 meters

• Pressurebetween2and5bar

Cold water feed with G ¾” shut off valve

(washing machine fitting)

• Maximumdistancefrominstallationless

than 1.50 meters

• Pressurebetween2and5bar

Reverse Osmosis water feed with G ¾”

shut off valve (washing machine fitting)

• Maximumdistancefrominstallationless

than 1.50 meters

• Pressurebetween2and5bar

Connecting the water inlet hoses (see diagram):

Connect the hot water hose (red) to the hot water inlet valve (18) on the HYDRIM

(indicated by a red dot) and the cold water hose (blue) to the cold water inlet valve (17) on

the HYDRIM (indicated by a blue dot). Treated water from a reverse osmosis system can be

connected to the R/O inlet (19). If fitted with treated water, the software must be adjusted to

enable the function of the R/O inlet. The connector with the elbow should be attached to the

drain outlet (14) on the back of the HYDRIM unit. The end of the hose with the gasket and

the screen should attach to the water supply connector. Make sure that the inlet valves are

free of debris (17, 18 & 19).

NOTE 1 - If hot water feed is not available then it must be possible to attach a ‘Y’ fitting to

the cold water feed valve so that both machine pipes can be connected to the cold

supply. The machine will not work with only one supply attached as it requires pressure

in both the hot and cold water supplies to activate the feed pressure switches. If R/O

water is not enabled, the R/O supply does NOT need an attachment. Please note that

cold fill only will increase cycle times.

NOTE 2 – Water feeds should be adjacent to the machine and not behind it so that the shut

off valves may be accessed in case emergency isolation is required and to ensure unit can

be inserted fully under the work surface.

Page 8

HYDRIM C61wd G4 Installation Instructions

Connect drain tube to machine and relevant services

Drain requirements:

• Maximumdistancefrominstallationis1.50

meters with supplied drain hose

• Themaximumlengthofanextendeddrain

hose should not exceed 3.30 meters

• Drainshouldbenomorethan1meter

above the base of the HYDRIM unit

• ‘P’trapspurconnection(preferred

method) OR

• Standpipeconnection

NOTE 1 – The preferred method of connection of the HYDRIM to the drain is by the use of a

‘spurred’ ‘P’ trap fitting.

NOTE 2 – The waste connection pipe is clamped on to the spur by the clips provided with

the HYDRIM. Wherever possible, if the HYDRIM is located close to a sink unit, then this

method should be used. If the HYDRIM is not close to a sink unit and a ‘P’ trap cannot be

used, then a standpipe with ‘U’ bend fitting can be used. This must be a dedicated

standpipe. Under no circumstances should any other equipment share the standpipe.

NOTE 3 – Waste connection should be adjacent to the machine and not behind it.

Connecting the drain hose:

Connect the drain hose to the drain outlet. The drain hose can be attached to existing drain

lines using a 3.5 cm or larger standpipe/ P-trap combination. If the hose is connected

directly to the drain line, fittings and adapters should not reduce water flow. A floor drain is

acceptable (check local codes).

Level machine in final position with adjustable legs

For the unit to function properly, it will need to be correctly leveled. To level the unit, follow

these steps:

1. Adjust the legs underneath the unit.

2. Use a level as a guide

Page 9

HYDRIM C61wd G4 Installation Instructions

Connect machine to power supply

Electrical supply requirements:

• Dedicated12Aindependentsupply(see

Note 1 below). OR

• Standarddomesticoutlet

• Voltage:200-240VAC±10%,single-phase,

50 Hz or 60 Hz, 12A

• Locatedwithin1.50metresmaximum

• Supplylocation(seenotesbelow)

• Powercordrouting(seenotebelow)

NOTE 1 – The HYDRIM C61wd G4 is supplied with a domestic fused plug as standard.

A dedicated hard wired 12A supply can also be used.

NOTE 2 - Due to the power requirements of the HYDRIM, (Rated load 2 kW) especially

during drying, it is advised that no other equipment is connected to the same supply outlet.

NOTE 3 - Power supply outlet should be adjacent to the machine and not behind it.

The cable should be routed away from the back panel and hot water inlet hose.

Other manuals for Hydrim C61wd G4

1

Table of contents

Other SciCan Washer manuals

SciCan

SciCan HYDRIM L110w G4 User manual

SciCan

SciCan HYDRIM M2 User manual

SciCan

SciCan hydrim c51w User manual

SciCan

SciCan HYDRIM L110w User manual

SciCan

SciCan HYDRIM L110w User manual

SciCan

SciCan HYDRIM L110 G4 Series User manual

SciCan

SciCan HYDRIM L110w G4 User manual

SciCan

SciCan HYDRIM L110w User manual

SciCan

SciCan HYDRIM M2 User manual

SciCan

SciCan HYDRIM M2 G4 User manual