SciCan HYDRIM C15wd User manual

Table of contents

Other SciCan Washer manuals

SciCan

SciCan Hydrim C61wd G4 User manual

SciCan

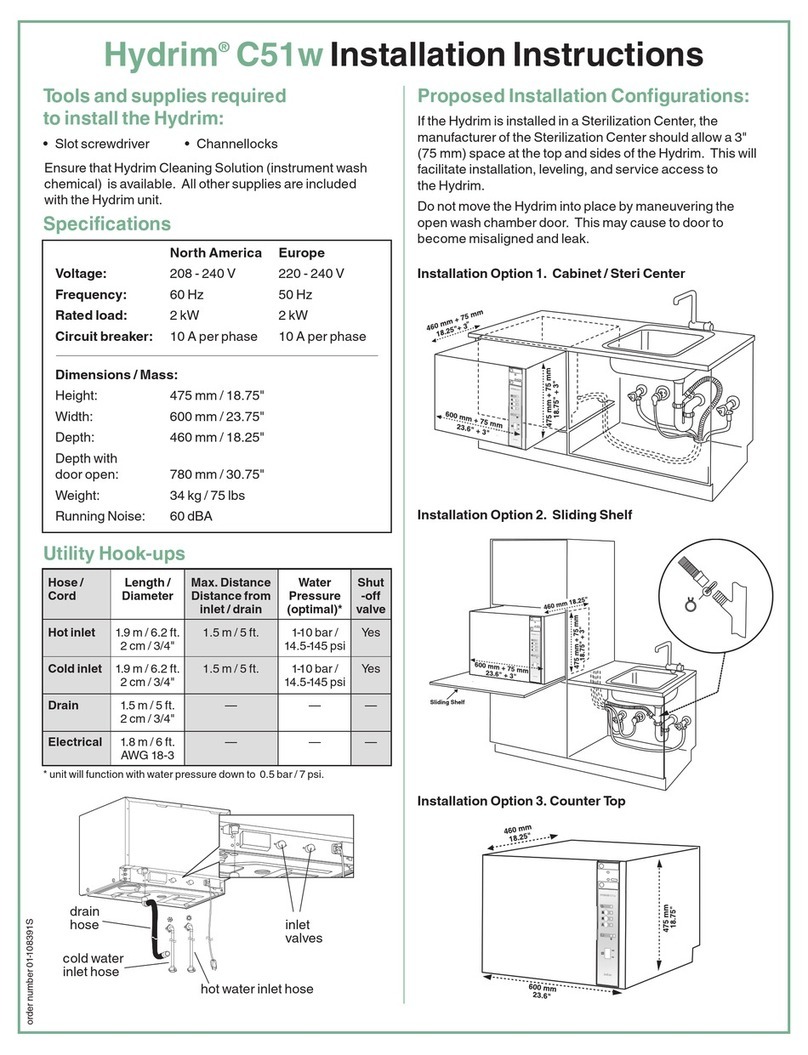

SciCan hydrim c51w User manual

SciCan

SciCan HYDRIM C61w G4 User manual

SciCan

SciCan HYDRIM M2 User manual

SciCan

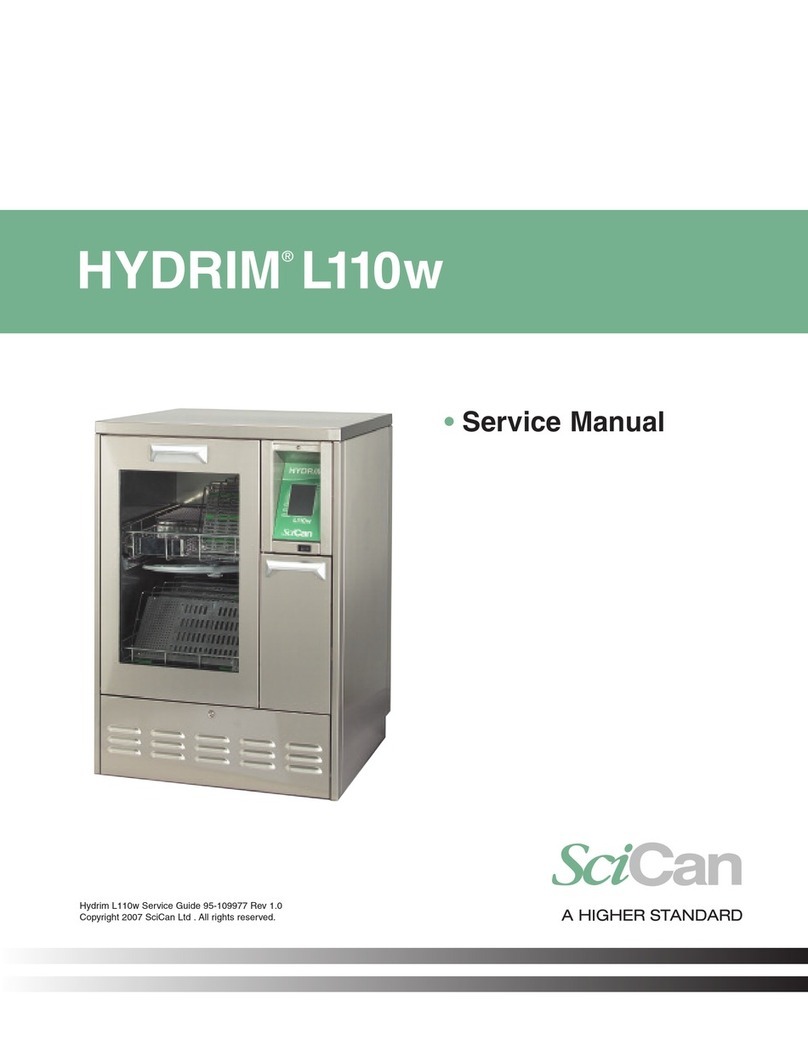

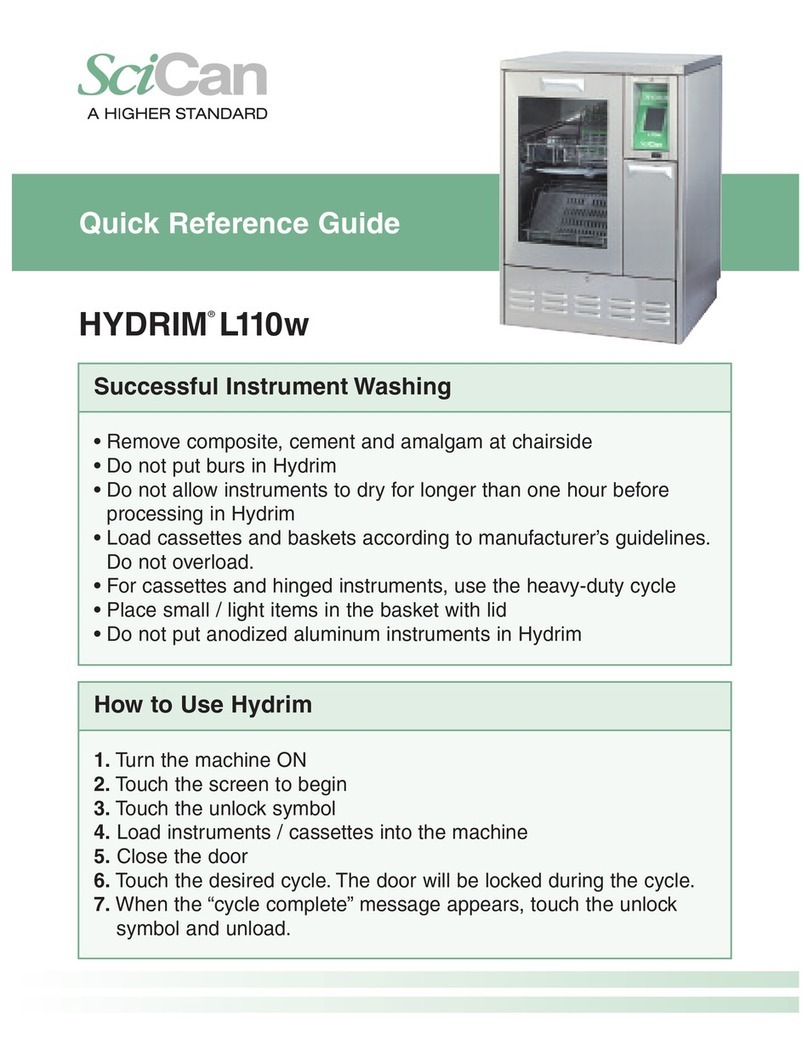

SciCan HYDRIM L110w User manual

SciCan

SciCan hydrim c51w User manual

SciCan

SciCan HYDRIM L110w User manual

SciCan

SciCan HYDRIM L110 G4 Series User manual

SciCan

SciCan HYDRIM L110w User manual

SciCan

SciCan hydrim c51w Service manual

Popular Washer manuals by other brands

Hisense

Hisense WFQP6010EVM Series User's operation manual

AEG

AEG L7TDR722E user manual

Miele

Miele W 1903A WASHING MACHINE - OPERATING operating instructions

Zanussi

Zanussi ZWF 81443W manual

Zanussi

Zanussi FL 1016/A Instructions for use and care

Zanussi Electrolux

Zanussi Electrolux FAE 1026 V Instruction booklet

Bosch

Bosch WAN280L6SN User manual and installation instructions

Bosch

Bosch WAN24268ES User manual and installation instructions

Bosch

Bosch WVT 52458 Operating & installation instructions

Hotpoint Ariston

Hotpoint Ariston FMD 722 Instructions for use

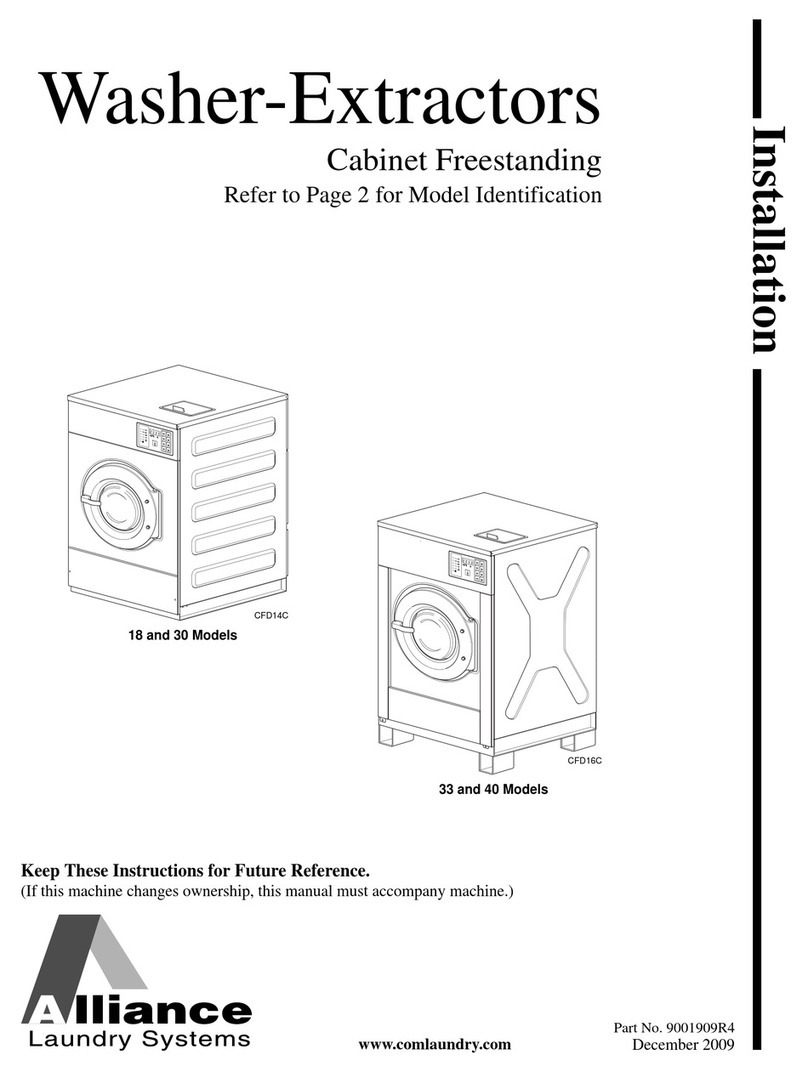

Alliance Laundry Systems

Alliance Laundry Systems CFD14C Installation

Frigidaire

Frigidaire FTF2140ES0 Factory parts catalog