4. CHECK OUT YOUR NEW FREEZER

4.1 Lid Seal

The gasket on the door has a magnetic strip to help door seal.

Be sure to keep the gasket clean and free of debris. Clean

any frost that may build up. If the gasket does not seal

properly, the freezer may experience problems with

maintaining temperature and excessive frost build up.

4.2 Interior Compartment Temperature

The temperature is controlled by a CAL 9500 digital

temperature controller. When you first power up the freezer,

the high stage compressor and fan will start and operate for 3

to 6 minutes before the low stage compressor starts. Pull

down to minimum temperature will take from 3 to 6 hours,

depending on ambient temperature and size of cabinet. The

high stage compressor runs 100% of the time. The low stage

compressor will cycle on and off to maintain the temperature

of the controller setting. Set the control to the desired set

point. To view the set point temperature, press the * and the

UP arrow keys together. To decrease the set point

temperature, press the * and the DOWN arrows keys

together.

Freezers are shipped from the factory with the indicating

digital control programmed for proper operation. All but the

temperature settings may be adjusted. The temperature

sensor is a type “T” thermocouple located on the side wall of

the inner-liner.

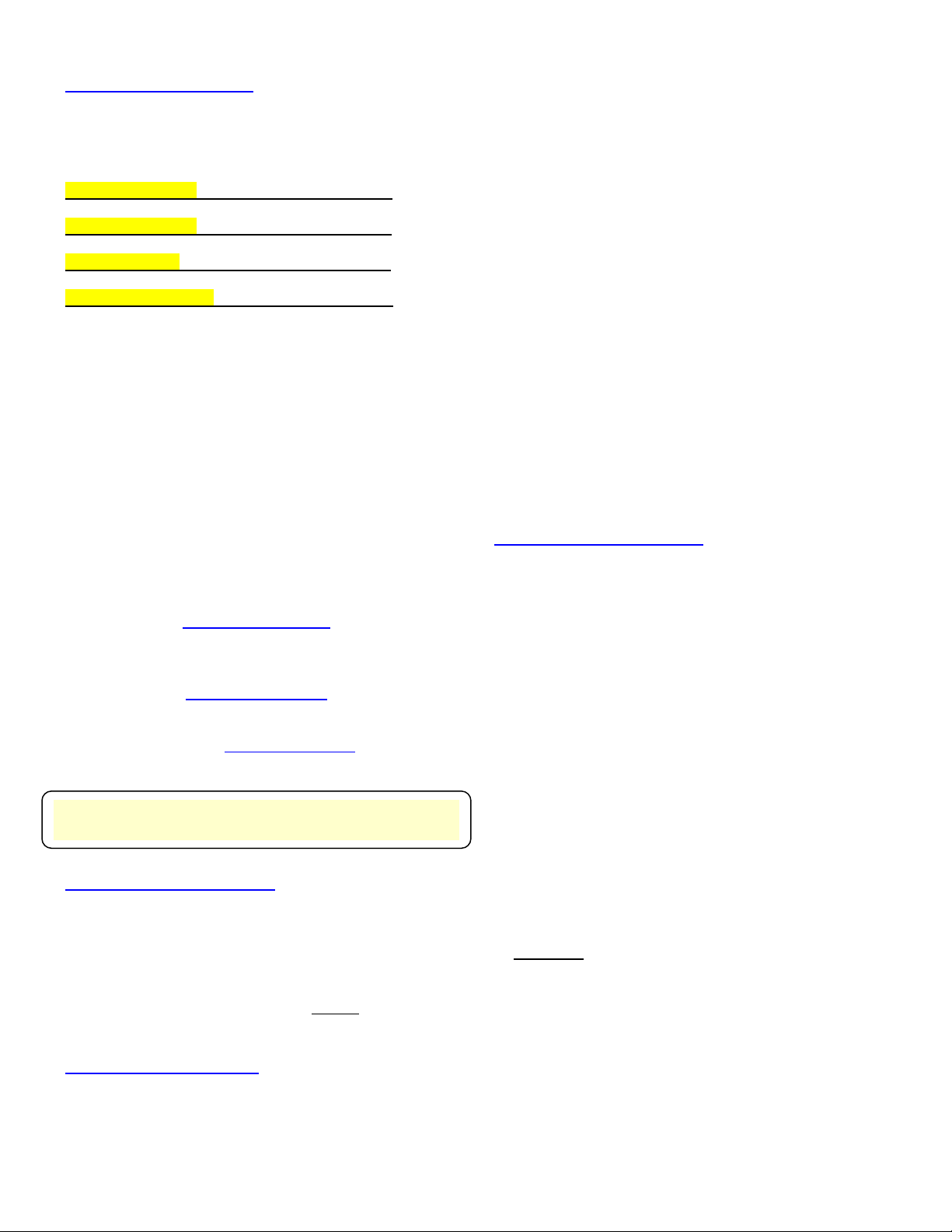

4.3 Alarm

The Alarm should be kept in the “OFF” position until the

cabinet temperature has reached the appropriate setting.

When the temperature has been reached, the temperature

alarm should be switched to the “ON” position and is now

ready to operate.

The Alarm is equipped with a time delay relay to prevent the

alarm from going off every time the door is opened. This

relay can be adjusted from 1 to 10 minutes. This delay is

factory set for 10 minutes.

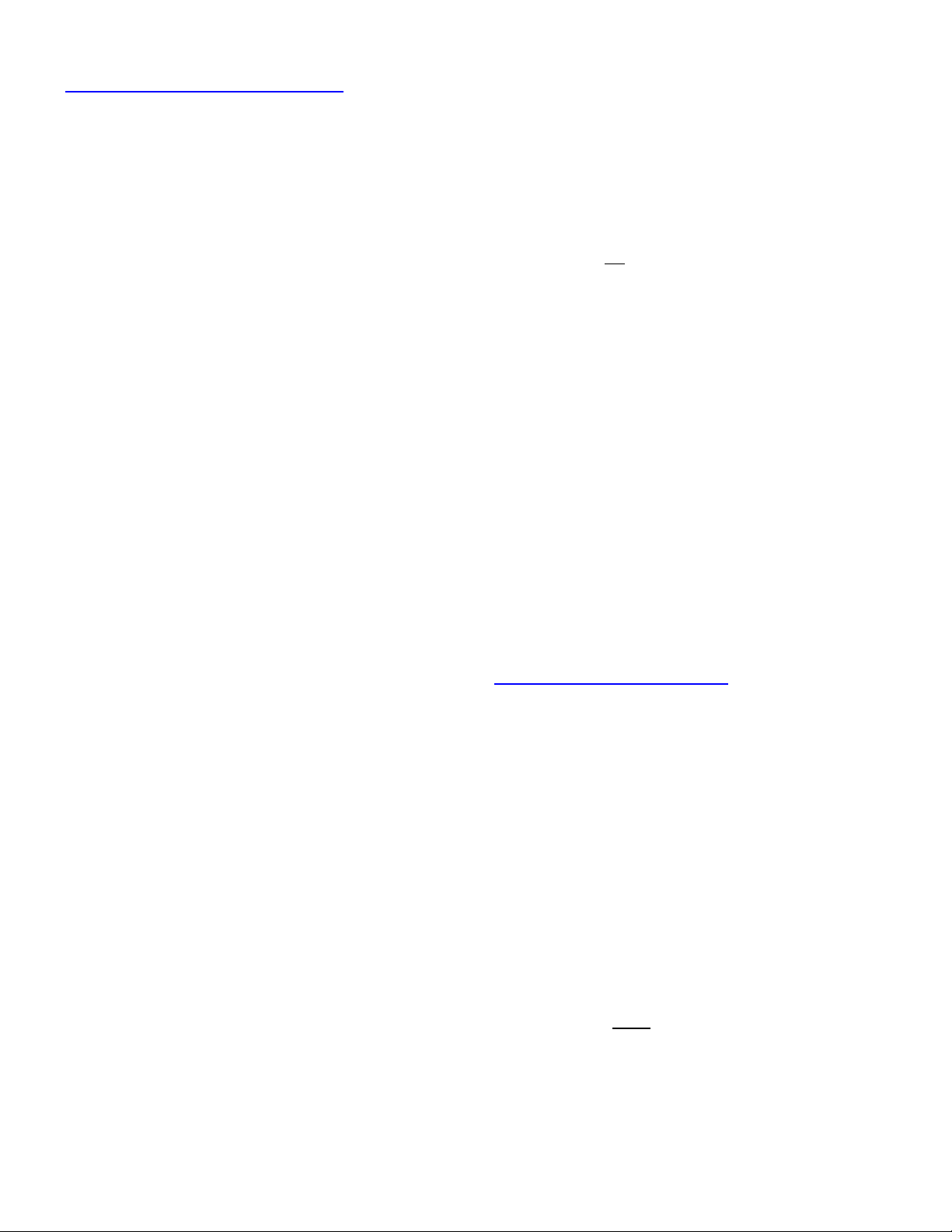

To adjust time delay relay:

a) Remove screw located on right side, middle of

instrument panel with temperature controller.

Instrument panel will hinge open. Time delay has a

dial and is located on lower right corner of electric

box.

b) If you have a chart recorder: Open glass door to get

to the black instrument panel with chart recorder.

Remove screw located on right side, middle of

panel. Instrument panel will hinge open. Time delay

has a dial and is located on lower right corner of

electric box.

NOTE: It is recommended to keep the freezer operating

continually rather than turning the freezer off and on.

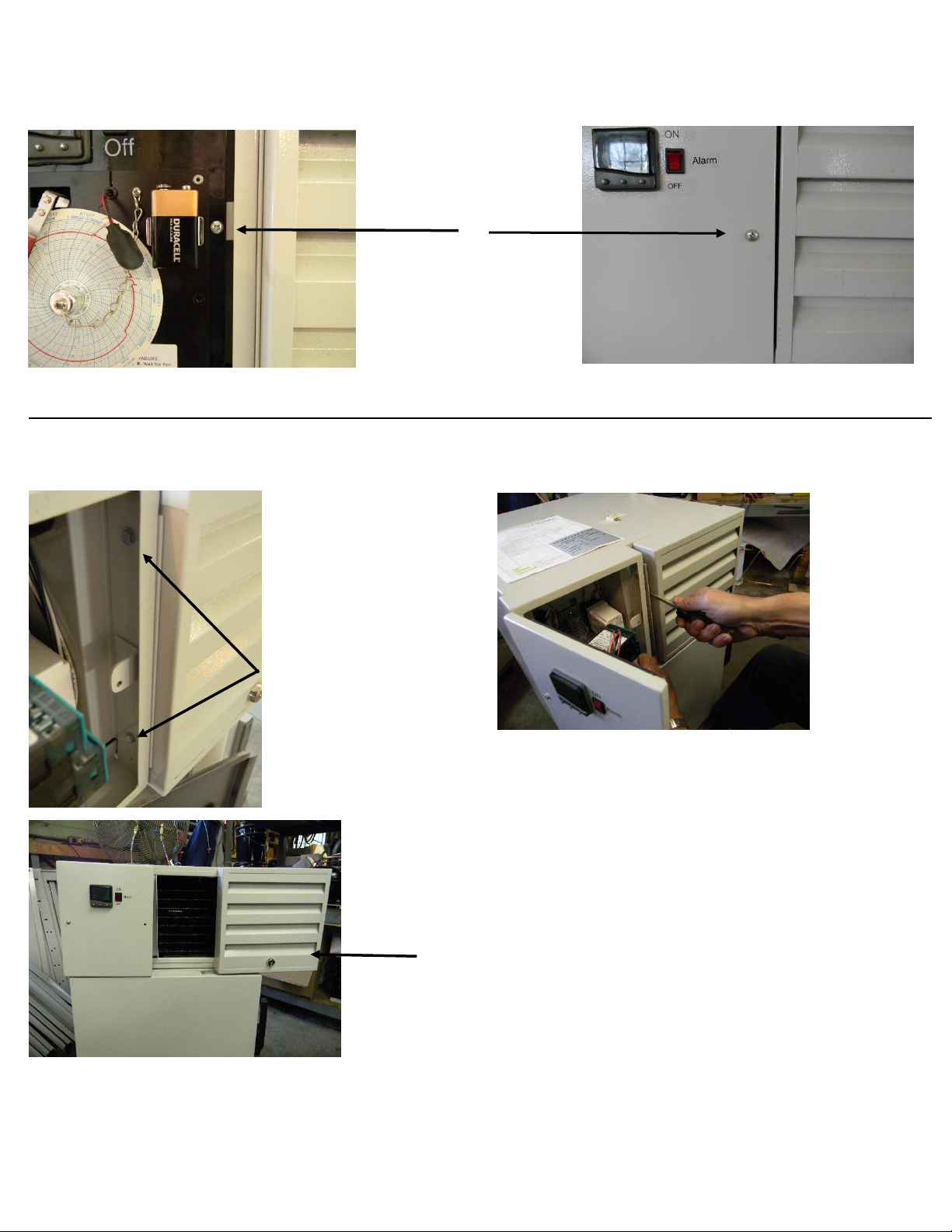

4.4 Chart Recorder (Optional )

If your freezer has a chart recorder installed. On initial start

up you must replace the round paper chart, connect the 9 volt

battery and remove the black rubber cap on pen.

WARNING: Do not lift the pen arm in order to slide a new

chart under the pen or to remove the black rubber cap.

To replace the paper chart: Press and hold the “change chart”

button (#3) for approximately one second until pen begins to

move to the left of the chart and then release the button. Wait

until the pen has moved completely off the chart paper. To

remove the chart paper, unscrew (counter-clockwise) the

knob at the center of the chart paper. Remove old paper and

position new one so that the correct time line coincides with

the time line groove on the chart plate. Re-attach the knob,

screw securely (by hand). (Do not over tighten. Over

tightening can damage the gears in the chart motor gearbox

assembly.) Press and hold change chart button (#3) again

until pen begins to move back and then release button.

To remove the black rubber cap at start up: While you have

arm moved off the paper for changing the chart, remove the

rubber cap.

5 ELECTRICAL CONNECTIONS

5.1 Wiring

This cabinet is equipped with a three-prong (grounding) plug

for your protection against shock hazards. The cabinet

should be plugged directly into a properly grounded three-

prong receptacle.

Where a two-prong wall receptacle is encountered, it must be

replaced in accordance with the National Electronic Code

and local codes and ordinances. A licensed electrician must

do the work.

The electrical outlet should not be controlled by a wall

switch, which might be turned off accidentally.

*WARNING: Do NOT under any circumstances cut or

remove the round grounding prong from the cabinet

plug.

*CAUTION: For personal safety and trouble-free operation,

this cabinet must be properly grounded before it is used.

Failure to ground the equipment may cause personal injury

or damage to the equipment. Always conform to the