ScopeDome Clamshell 3M Instruction Manual

Assembly and Installation of

ScopeDome 3M Clamshell Observatory

Table of Contents

ScopeDome Clamshell 3M observatory specification........................................................................ 3

Observatory components............................................................................................................... 3

Observatory automation ................................................................................................................ 3

Clamshell 3M observatory installation site requirements ................................................................ 3

Packaging of a Clamshell 3M Observatory......................................................................................... 4

List of necessary tools and materials for the installation of the observatory................................... 5

Assembling the Base Elements of the Observatory ........................................................................... 7

Preparation for the installation of the Observatory ...................................................................... 7

Moving of Individual Parts from Pallet to Assembly Location ....................................................... 8

Marking out the Observatory Position upon the Slab.................................................................... 9

Securing Observatory Base to Slab .................................................................................................. 10

Installation of the Upper Base Elements...................................................................................... 13

Installation of the Upper Aluminium Ring.................................................................................... 16

Installation of Observatory Shutters ................................................................................................ 18

Preparation for the installation of shutters ................................................................................. 18

Installation of Observatory Shutter #1......................................................................................... 21

Installation of Observatory Shutter #2......................................................................................... 24

Installation of Observatory Shutter #3......................................................................................... 27

Testing of Observatory Operation.................................................................................................... 30

Adjust Position of Limit Switches ................................................................................................. 31

Installation of Internal and External Observatory Covers................................................................ 31

Installation of Observatory Cover Seals ........................................................................................... 33

Installation of the seal on shutter #1 ....................................................................................... 34

Installation of the seal on shutter #2 ....................................................................................... 35

Installation of the seal on shutter #3 ....................................................................................... 36

Installation of an external seal ................................................................................................. 37

Maintenance, regulation of the observatory................................................................................... 38

SPECIFICATIONS................................................................................................................................ 39

ScopeDome Clamshell 3M observatory specification

Observatory components

- Observatory base –2 segments

- Aluminium stiffening ring –4 segments

- Observatory shutters –3 pieces

- Sealings of observatory shutters –4 pieces [3 types]

Observatory automation

- Shutter drive units integrated with the bases of the observatory

- ScopeDome Arduino 1.3 card observatory controller

- Clamshell observatory control relay module

- Limit switches module for observatory shutters

- Inverter control of the operation of drive motors

- Hygrometer with integrated thermometer

- Power cords for drive unit of the left side of the observatory

Clamshell 3M observatory installation site

requirements

Due to the structural and technical parameters, the Clamshell observatory should be placed on a

concrete slab with a load capacity being calculated inclusive of the weight of this observatory (ap-

prox. 300kg). The slab shall have a minimum diameter of more than 2800 mm (3000 mm recom-

mended), which is the diameter of the observatory base. It is necessary to ensure that the base is

adequately levelled and the smoothness of the surface made so that the maximum deviation does

not exceed 3 mm in each of the points (in particular on the perimeter) of the slab. At the design stage

of the observatory's foundation, it is also worth considering all necessary cable routes for power and

communication, as this observatory does not provide such conduiting from outside to its inside. The

slab should be sealed to prevent uprising of moisture, and at the least, with an appropriate concrete

top sealer.

Before proceeding with the installation, we encourage you to familiarize yourself with the photo

documentation of this manual. Through the associated text and the accompanying photos, please

familiarize yourself with the details of the work carried out during each stage. Before the installation

stage, you should also plan the different stages of work and prepare all necessary materials and tools

for installation.

Packaging of a Clamshell 3M Observatory

The observatory is supplied in three vinyl wrapped, oversized pallets [length x width x height of

2800mm x 2100mm x 2280mm], with the equipment being in partially assembled state. The ship-

ment contains the following:

- Pallet #1: Left observatory base with drives and their covers,

- Pallet #2: The observatory base with the drives, their covers and the control electronics, and

- Pallet #3: The 3 observatory shutters

Figure. 1 –Clamshell packed bases [x2 for Left and Right sides] and the shutter pallet

Figure. 2 –Clamshell parts boxes and safety covers

Inclusive within the consignment are the necessary Fixtures and Fittings for observatory installation,

the Aluminium Stiffener Ring that mounts atop of the observatory base, and a set of Shutter Seals.

Figure. 3 –elements of the upper ring stiffening the base of the Clamshell observatory

List of necessary tools and materials for the

installation of the observatory

Tools:

- Phillips Head, cross-size PH1 and PH2 screwdrivers

- Small screwdriver with flat tip for turning electrical fittings

- Allen wrenches 3.0 mm and 2.5 mm

- Electric tester (neon tube)

- Universal multi-meter

- Open or closed spanners for nuts associated with the M5, M6, M8 screws

- Impact drill and drill for concrete anchors, and metal drills of 5 and 6 mm sizes

- Plain and plastic hammers for setting of part positions

- A tape measure or laser distance meter

- Transport belts for lifting and moving observatory elements

- Wooden or plastic wedges/ coasters measuring 5x5 cm and a length of approx. 15

cm for leveraging elements apart during the sealing processes

Materials required separately:

- Concrete anchors for fixing observatory base to concrete foundation. Suggested: M8 with a length

of at least 80mm, at least 10 pieces. Alternatively, your choice of preferred anchor with similar speci-

fication.

- Sealing silicone, and applicator gun –approximately 5 tubes with a capacity of about 300 ml

- fast-bonded adhesive in the tube –for the installation of brush seals [approximately x1 capacity of

about 300 ml].

Figure. 4 –sample set of materials and tools for mounting the observatory

Note: Due to the weight (approx. 100 kg) and the dimensions of the individual components, we

recommend using a gantry lift or a small crane for lifting and mounting components. The recom-

mended minimum load capacity of the crane is 400 kg.

Figure. 4 –electric gantry used for observatory mounting

Assembling the Base Elements of the Observatory

Preparation for the installation of the Observatory

Due to the size, shapes and weight of the individual components, there is a risk of

injury during the processes of disassembly, placing parts to storage, and that of

the assembly. Always implement adequate safeguards and comply with local

occupational health and safety requirements.

The installation of the observatory should be planned during a period of good, windless and rainless

weather. The assembly time frame for this observatory will vary in accordance to the efficiency and

size of the assembly team. Allow for approximately 16 hours for the unpacking through to assembly

completion.

Preparation for installation begins with unpacking of the components from their packaging. The in-

stallation of the base can be done in two variants:

1. Separating the top and bottom of the observatory base for easier transportation of observa-

tory elements to the assembly position. The disassembled components may in this case be

transported and manually positioned with the participation of 4 persons [without the help of

a lift or crane].

2. With no separation of the upper and lower parts: In this case, the gantry/ crane (Fig. 4)

should be used for lifting and part transportation. The manual cartage of these awkward,

oversized and heavy elements is very difficult when assembled, creating a risk of damage to

the bases and that of injury to the team. In this case of implementing a gantry/crane, 3 peo-

ple will be satisfactory for the assembly.

Figure. 5 –unpacked left part of the observatory base, with upper and lower segments defined

The illustrations below show the process of installing the observatory in accordance with Option 2

above, electing to separate the upper and lower segments of the Left and Right bases.

Moving of Individual Parts from Pallet to Assembly Location

To begin, the slab should be dry and clean. This will ensure the good adhesion of the sealing com-

pound that goes between the slab and the observatory base. Four persons will be required to safely

lift and transport the base elements from the pallet to the assembly position. You can still employ an

overhead gantry for this purpose, using material lifting slings that will protect the observatory’s sur-

face during the lifts. The slings can be placed between the top and bottom of the observatory base as

shown in Fig. 6 and 7.

Figure. 6 –putting the transport slings between the top and bottom part of the observatory base

The upper and lower elements of the base halves are joined by M6 bolts. Ensure to partially

dissassemble these to allow the slings to be safely passed through and then connected to the gantry.

Otherwise, have your team of at least four people ready whilst these are removed.

Figure. 7 –dismantling of M6 screws connecting the top and bottom of the observatory base to be

transported to the installation site

Marking out the Observatory Position upon the Slab

In the next stage of preparation, we place the bases on to the slab to mark out the contact area of

the observatory to the slab. Connecting the two base halves without bolts and positioning these rela-

tive to the centre of the slab, you can define the rotation and position of the observatory. This is not

a critical element of installation and can be carried out with a fairly high tolerance. At this stage, care

must be taken to ensure that the base of the observatory is properly oriented at the geographical

directions, if required.

Figure. 8 –positioning of the bases of the observatory

Figure. 9 –measurement of observatory position relative to the centre of the slab

In the next step, we mark the inner and outer edge of the observatory base on the slab with a car-

pentry pencil. This will provide an outline for applying the sealing compound that goes between the

base and that of the slab.

Figure. 10 –inner outline of the observatory base

Figure. 11 –outer outline of the base of the observatory

Securing Observatory Base to Slab

The first step is to mark location and drill holes for the fixing bolts that will secure the observatory to

the slab. Depending on the needs and quality of the concrete, a minimum of 10 holes should be pro-

vided. Drilling can be done directly through the laminate of the base halves however, care must be

taken by gently applying pressure through the drill upon the observatory surface so not to damage or

fracture the laminate.

Figure. 12 –drilling of base fixing holes

Figure. 13 –drilled holes in one of the bases of the observatory

In the next step, we raise the bases of the observatory on wooden or plastic spacers, making sure the

slab and base of the observatory are clean and ready for the application of the foundation silicone

sealant. When applying the sealant, ensure to apply between the previously marked inner and outer

contours. Silicone should be applied in the form of two parallel strips from the outer and inside of the

base. A good sealing of this element is crucial to protect the observatory from the inflow of water

during rainfall.

Figure. 14 –applying seals under the base of the observatory

Figure. 15 –applying seals under the base of the observatory

In the same way, we apply sealant seals on both planes of the connecting halves of the Left and Right

bases before connecting them with screws.

Figure. 16 –applying seals on the planes connecting the base

After applying the seals to the base connection surfaces, lower the base of the observatory to the

slab by removing the spacers. If possible, apply additional sealant to the surfaces where the spacers

once were. The entire base will be riding on a bed of sealant; glide entire base into position to align

anchor holes positions to holes in the slab. Apply anchors, tighten these to specification.

Figure. 17 –mounting the base with anchors

Next, both halves of the base of the observatory are secured by the supplied M6x25 bolts and nuts,

placing them in pre-prepared holes.

Figure. 18 –connecting the bases of the observatory with screws

Installation of the Upper Base Elements

Next, the upper Right and Left elements, together with their drives, are to be assembled upon the

installed lower elements. Before placing the upper parts into position, the mating surfaces should be

sealed with sealant, same way as with the lower parts to the slab.

Figure. 19 –preparation for installation of the top of the observatory base

Figure. 20 –sealing of the observatory base elements

Figure. 21 –sealing of the observatory base elements

After preparing the sealing layer, we can embed the upper element on the lower base, while helping

with a wedge pad that allows the transport slings to be pulled out at the last moment of the opera-

tion.

Figure. 22 –Lowering the upper base element onto lower one

After the lowering the top elements into place, we secure these to the lower elements with the

M6x25 bolts and nuts previously removed. If you can, please seal the spacers positions before com-

pletely the lowering upon the base. Before the final connection of the both elements, it is necessary

to remember to make silicone seals on the vertical planes of the upper elements of the observatory

base, which next should be screwed with the included M6x25 bolts and nuts.

Figure. 23 –Place of sealing of the upper elements of the observatory base

Figure. 24 –Place of sealing of the upper elements of the observatory base

Figure. 25 –Screw connections of the upper elements of the observatory base

After the initial combination of all the elements of the observatory base, confirm all bolts and nuts

are tight and secure.

Figure. 25 –Final connection of the upper elements of the observatory base with screws

Installation of the Upper Aluminium Ring

In the next step, we proceed to the installation of an aluminium stiffening ring for the upper part of

the base of the observatory. The ring consists of 4 numbered segments.

Figure. 26 –Ring element numbering

All segments have holes to attach it to the top of the observatory base with the included M6x25 bolts

and nuts. The wider part of the ring must be oriented in a way that it is on the front of the observato-

ry base.

Figure. 26 –Way of orientation of the wider part of the ring based on the observatory

Figure. 27 –Ring fixing holes to the base of the observatory

Before screwing the stiffening ring to the base of the observatory, make sure that

the anchor holes of the ring match the holes in the base mating surface. Second-

ly, carefully apply sealant in a dual parallel paths to ensure the prevention of

water infiltration and to reduce moisture condensation.

Figure. 28 –Sealing of the stiffening ring when connecting to the observatory base

Figure. 29 –Securing the ring with mounting screws

Ensure all stiffening ring elements are sealed, mounted and installed upon the base assembly the

same way.

Figure. 30 –Mounting the side elements of the stiffening ring

Figure. 31 –Connecting the stiffening ring from the base of the observatory

Installation of Observatory Shutters

Preparation for the installation of shutters

VERY IMPORTANT: Before installing the observatory shutters, make sure that all

components of the observatory base are properly connected to each other by

bolt and nut, and that the base itself is firmly attached to the slab.

If the external, internal and upper drive covers are in place, please remove these first so you have

clear access to the shutter mounting handles that are found on both Left and Right sides of the base.

In order to install individual shutters efficiently, it will be necessary to be able to drive the individual

drive units responsible for opening and closing them to designated positions. In your parts box, there

will the Plug N Play wire loom, having corresponding numbers per plug to assist with correctly con-

necting these to the plugs within each drive area. Before connecting the controller to the power sup-

ply, connect the wire loom of the drive motors of the left side of the observatory first.

Figure. 32 –power connection wires for the left side of the observatory base

To do this, unscrew the top fixing screws and remove carefully the right cover of the drive unit. Be

careful not to damage the controller connection wires to the buttons in the cover. The attached

wires shall be placed and retained in a comb strip located under the upper part of the observatory

base. The cables must be connected to the proper engine number marked on the cable plug and, on

the other hand, to the corresponding plug in the observatory driver.

Note: Always connect cables according to their numbering. Make sure that the

plugs are connected correctly on both sides of the plugs. Incorrect connections

can damage the observatory shutters or their drives!

Figure. 33 –connecting the motor power wires on the left side of the observatory base to the con-

troller

After the connections are made, the powered drive units must be tested for their correct operation

before proceeding to installing the shutters. To do this, when the controller is connected to the pow-

er supply, start the individual shutter’s drive units using the buttons on the inner cover of the right

side of the observatory.

Figure. 34 –Control panel for manual opening of observatory shutters

To start the drive for a specific shutter, press the S1-S3 button and while holding it press the OPEN or

CLOSE button, depending on the direction of operation of the drive. The engine drive unit has limit

switches preventing the shutter from exceeding the rotation limit. The drive of the shutter will be

stopped when the extreme position of the metal actuators of the switches are reached.

IMPORTANT DRIVE TESTS

Do not proceed until all drive movements are tested.

Tests:

1. Before proceeding with further work, make sure that all actuators and end switches are work-

ing correctly by moving drives to fully open and then fully closed positions.

2. Verify that the drive handles do not lock in the end positions with the drive axles.

3. Verify the angular position of the handles of all shutters, and ensure symmetrical movements

are occurring on both sides.

4. Do not proceed to shutter installation if shutter mounting handles move in opposing direc-

tions.

Figure. 35 –view of limit switches and observatory shutters control mechanism

Table of contents

Other ScopeDome Telescope manuals

Popular Telescope manuals by other brands

Celestron

Celestron 80AZS instruction manual

Celestron

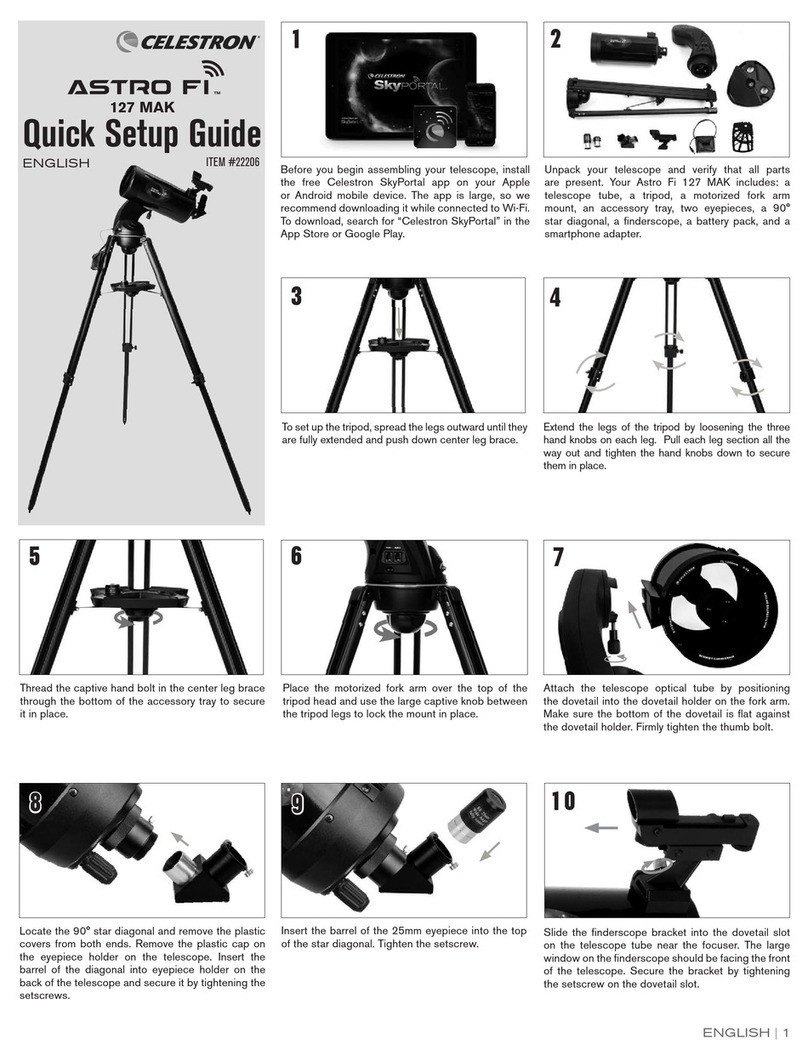

Celestron ASTRO FI 127 MAK Quick setup guide

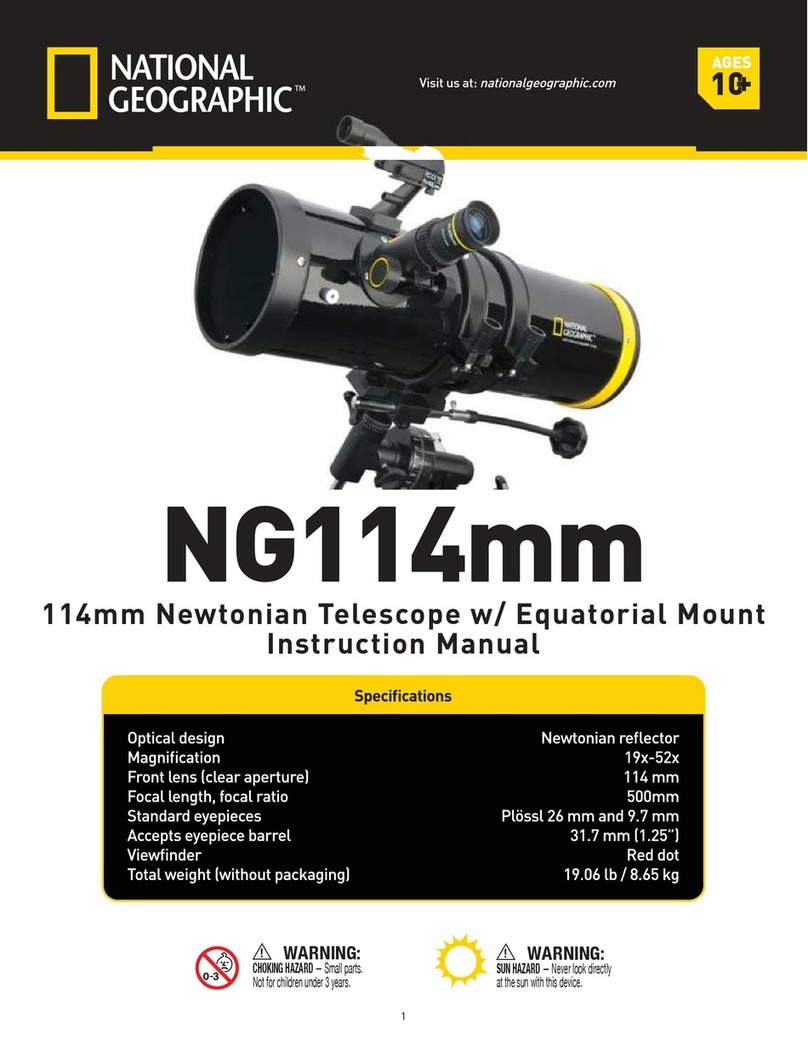

National Geographic

National Geographic 50/360 operating instructions

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS SKYVIEWPRO 6LT EQ 9872 instruction manual

iOptron

iOptron GoToNova 8401 instruction manual

Levenhuk

Levenhuk Skyline 70x900 EQ user manual