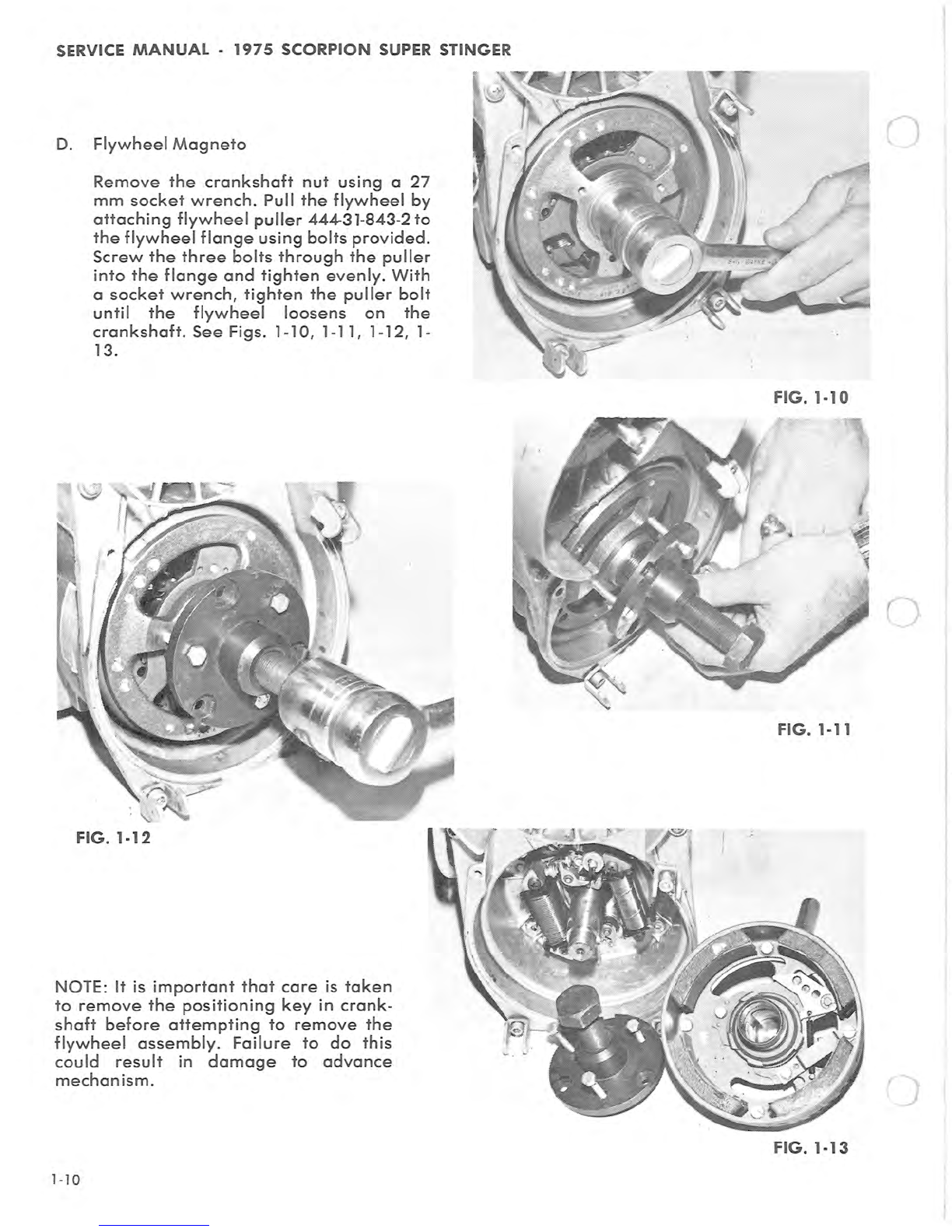

SCORPION Super Stinger 1975 User manual

Other SCORPION Snowmobile manuals

Popular Snowmobile manuals by other brands

Arctic Cat

Arctic Cat 2010 Crossfire 600 Operator's manual

BRP

BRP Ski-Doo MXZ 120 2023 Operator's manual

Arctic Cat

Arctic Cat ZR 900 Series 2006 Operator's manual

Arctic Cat

Arctic Cat Wildcat EFI Mountain Cat 1994 Service manual

BOMBARDIER

BOMBARDIER Ski-Doo Alpine 74 1959 owner's manual

Arctic Cat

Arctic Cat Cougar Service manual

Arctic Cat

Arctic Cat Pantera 1978 Service manual

Arctic Cat

Arctic Cat XF 2-STROKE Service manual

Yamaha

Yamaha VK540EF Service manual

BOMBARDIER

BOMBARDIER ski-doo Nordic 640ER 1974 owner's manual

Ski-Doo

Ski-Doo SKANDIC EXPEDITION 600 H.O. SDI 2005 Operator's guide

BRP

BRP ski-doo MXZ 200 2023 Operator's guide