SDS M1-03 User manual

Current modulator М1-03

User Manual

www.sds-max.com.ua

Contents

Page

1 Technical specifications 3

2 Completeness of set 4

3 Description of the current modulator, setting 5

3.1

Connection of the current modulator 6

3.2

Current modulator setting 8

4 Warranty obligations 10

1. Technical specifications

Threshold value of current limit (limiting current), А 5 … 35

(adjustable)

Operating frequency of modulator (adjustable), KHz 0,25 … 2

Range of the automatic control of consumed power and gas output, % 0 … 100

Possibility of combining modulators Present

Maximum operating temperature of electrolyzer (threshold of protection

operation), оС

77

Option

Stabilization of the output current Present

Protection against short-circuit in the electrolyzer Present (95А)

Protection against overheating of the modulator Present, 120oC

Operating voltage, V 10 … 28

Built-in power supply filter Present

Indication of solution density (Indicator “norm”) Present

Adjusting the sensitivity of the detonation sensor Present

2. Completeness

O. No. Name Quantity Notes

1 Current modulator 1

2 User manual 1

3 Cord set 1

4 Detonation sensor 1 Only for diesel

5 Fuse 1

3. Description of the current modulator, setting

Current modulator M1-03 is designed for control of the electrolysis process, it enables

adjustment of system’s consumption of current and the gas outlet. This lets to offload the electric

generator without damage for system efficiency. Similarly, when working together with the

optimizer the modulator allows controlling carburation depending on the engine work mode and

the amount of produced gas. Modulators are able to adjust the operating frequency, which also

can be used to achieve the best results.

Current modulator M1-03 has a connector for external control that allows you to combine

several modulators in a single system. This system can operate according to the required

algorithm.

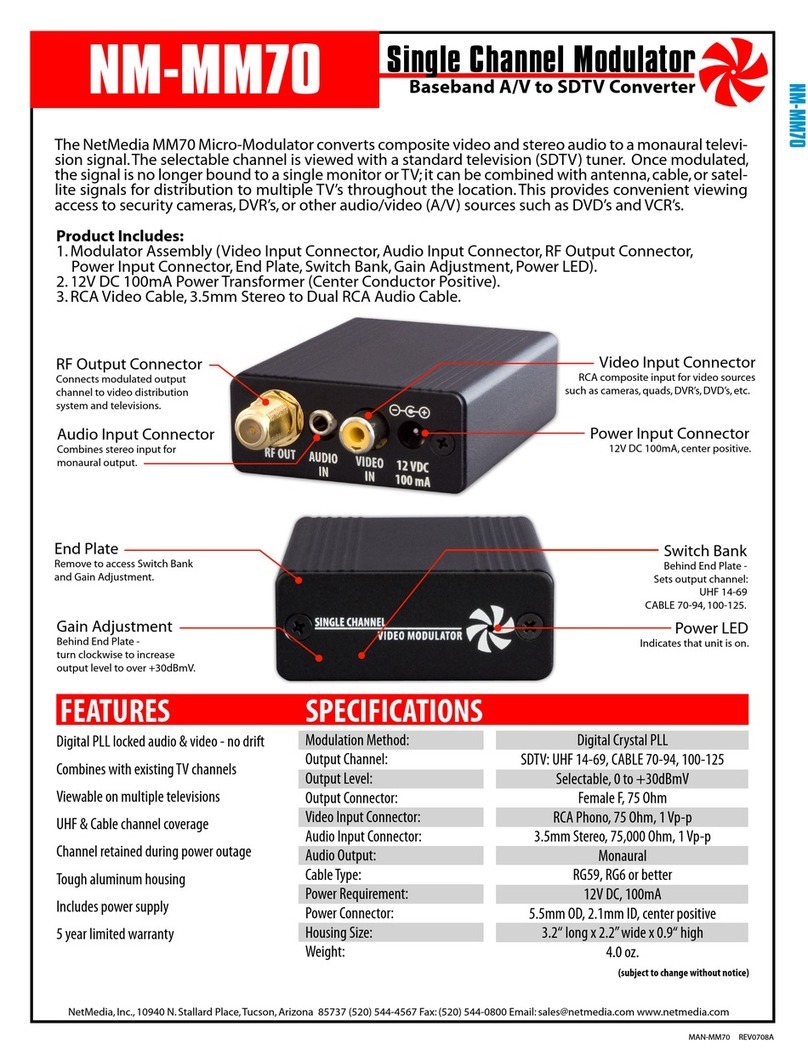

Figure 3.1. Exterior view of current modulator M1-03

.

By virtue of the use of a modern approach to the design of the modulator, the conversion of

electrical energy is made with the coefficient of efficiency of 99.9%, which made it possible to

minimize the heating of the block at fairly high currents.

Modulator with a current sensor M1-03 is designed so that the limiting current is selected

by the tuner and can be in the range of 5 ... 35A. The modulator has a built-in current sensor,

which helps to stabilize the current (and hence the generation of gas) even at significant change

of the electrolyte density.

The protection against overheating is provided for electrolyzer. When the temperature is

higher than 77 0С the power is not supplied to the electrolyzer (optional). Also protection is

provided in case of overheating of modulator (120 °C).

The remote light indicator “norm” is supplied in the set with a modulator. That remote

light indicator duplicates the indicator on the modulator and is placed in the interior of the car.

This indicator signals of normal system’s operation (if the current and gas generation can be

maintained within a set range).

Regulators of current

dependency on rotation

frequency of crankshaft

Connector for

additional

features

Connector for external

sensors and control signals

Indicator of power

supply to the

electrolyzer

Indicator signaling

overload

Indicator of solution

density

Current

frequency

regulator

3.1. Connection of current modulator

Work on the connection of the modulator must be carried out with the accumulator

switched off.

Before starting the installation, select a location for installation of the modulator.

The modulator must be installed in a place protected from excessive heat and moisture. It

is preferably to be nearby the accumulator.

After fixing the modulator, connect the wire of electrolyzer to its terminal block (see. Fig.

3.3., 3.4.).

On the electrolyzer install the temperature sensor, which is designed as a terminal for

fastening with the screw M8 (supplied optionally).

Connection scheme of the modulator is shown in Fig. 3.2. Note that the 12V supply (or

24V) is preferable to take from the terminals of the car’s electrical generator.

Installation on injection engine

Connect the blue wire from the modulator to the signal wire of fuel nozzle. The black wire

should be connected from terminal of modulator “Power –” to the car body.

A fuse wire from the terminal “Power + ” should be connected to the terminal “+” of

electric generator or accumulator (see. Fig. 3.2, 3.3.).

Fig. 3.2. Connection scheme of the modulator to the electrolyzer with a single wire.

(standard set)

Fig. 3.3. Connection scheme of the modulator to the electrolyzer with two wires.

Fig. 3.4. Example of connection to the wire using a special "crocodile", which is included

in the set.

Fig. 3.5. Purpose of the connector legs of modulator M1-03.

Measuring the current value can be made without external ammeter. To do this, connect

the probe “+” of the tester to the leg No. 2 of the small connector (Fig. 3.5). Connect probe “-“to

the leg No. 4 or No. 6 of the large connector. (Probe “-“ cannot be connected to the ground).

When current = 0A tester will show 2.4 Volts. The values will increase by 0.02 Volts with

increasing current by 1Amper. That is, with a current of 25 A the voltage will be 2.9 Volts.

Installation on the engine with carburetor

Connect the blue wire to the terminal “K” (can vary) on the ignition coil or the cam of

autotrembler. If the terminals on the ignition coil are not marked, it is necessary to determine the

information wire of the one coil: turn on the ignition, start the engine, touch with the blue wire

one of the terminals of the ignition coil, and make a short range sharp click on the pedal until

hard stop. If the LED “work” is lit - the connection is correct.

Installation on diesel

For the diesel version, the modulator is equipped with detonation sensor, which makes it

possible to determine the rotating speed of the crankshaft. On diesel engines, in which there is a

camshaft sensor - the detonation sensor is not required. In this case, the blue wire is

connected to the signal wire of the camshaft sensor for the removal of speed frequency.

Detonation sensor must be rigidly installed on the engine block or on the tube of fuel

supply. Fixing of the sensor should provide a tight mechanical contact with the engine. After

installing the sensor, connect the connector to it.

Modulator M1-03 has an automatic adjustment of the sensitivity of the detonation sensor in

a wide range. In the rare case when the sensitivity is not enough (the indicator of “work” is not

on), you must remove the jumper located behind the panel of modulator (see. Fig. 3.6.).

Figure 3.6. Increasing of the sensitivity of the detonation sensor

3.2. Modulator setting

The Modulator is set after electrolyzer system is set (filling the system with solution, etc.).

Figure 3.7. Influence of regulators "Offset" and "angle" on the current.

Adjusting the modulator is as follows:

Remove the fuse;

Instead of a fuse, connect pointer* ammeter with a scale up to 30A;

Start the engine;

Set the desired current with the regulator “offset”. Typically about 0 .... 10A;

Set the required current by frequency speed of crankshaft of 2000 rpm with the regulator

“angle” (select the main mode of rpm, which is used most often).

Note that regulators “Angle” and “Offset” are interdependent.

When the indicator “work” is on and indicator “norm” is not on, it indicates that the

electrical conductivity (density) of the electrolyte is not sufficient.

Threshold of indicator “norm” is equal to the threshold of current limitation.

If necessary, set the current limitation (the level of current limit) using switches located

behind the front cover of the modulator.

The position of switches is set according to Table 3.1., Fig. 3.8.

Table 3.1. Compliance with the location of switches and current limitation.

Current,

A Location of switches

No. 1 No. 2 No. 3 №4

35 ON ON ON

30 OFF ON ON

26 ON OFF ON

21 OFF OFF ON

20 ON ON OFF

15 OFF ON OFF

11 ON OFF OFF

5 OFF OFF OFF

Not used in your

version

Figure 3.8. Switches of limit adjustment of current limitation and indicator “norm”.

4. Warranty obligations

The manufacturer guarantees the operation of product subject to the rules of exploitation

set forth in the exploitation manual.

Warranty period of set - 12 months from the date of sale.

During the warranty period of exploitation the owner has the right to free repair in case of

failure of the modulator.

During the warranty period of exploitation, the repair is accomplished at the expense of the

owner, if he does not use the product in accordance with the exploitation manual, does not

follow the recommendations of the manufacturer...

The device is removed from the warranty in the following cases:

If the device is opened;

If there is mechanical damage;

If the exploitation is not carried out in accordance with this user manual.

Current modulator M1-03 meets technical specifications and is considered suitable for

exploitation.

Release Date ________________ 2015.

Seller: ____________________________Stamp

Brand of car (in which the equipment is installed): _____________________

Mileage at the time of installation: ____________

Set by: ________________ / __________________________ /

Install Date: _____________

Table of contents