SEA 2 24v tr User manual

ON

P2

RV1

P3

Important: Before starting the programming stage please check the following:

A) All wiring connections.

B) That the power is turned on.

C) That the correct indicator leds are lit.

D) The operator(s) are securely fitted.

Programming Work and Pause Times

Put the gates into the closed position.

Press Programming Button P2 until led DL1 lights (approx 3 secs) and the

gate(s) start to open at reduced speed – The board is now in Programming Mode

During this phase adjust trimmer RV1 to obtain the desired motor slowdown

speed.

When the gate is fully open – Press P2 again and wait for led DL1 to stop

flashing & light continuously.

Continue giving 1 second presses to button P2 to set the following logic

parameters (a total of 6 more presses to set the logic).

Press 1 - Starts Motor 1 closing

Press 2 – Starts Motor 2 closing and sets the leaf delay in closing

Press 3 – Starts Motor 1 slowdown point

Press 4 – Starts Motor 2 slowdown point

Press 5 – When Motor 1 reaches the closed position

Press 6 – When Motor 2 reaches the closed position – Programming ends.

Setting the Open Pause Time

Press button P3 until led DL1 is lit – When the required Open Pause time is

reached – Press P3 again and the time is set.

All cabling, wiring and connections must be carried out by fully trained personal and

adhere to all the current electrical regulations in force.

The manufacturer or supplier of this equipment cannot be held responsible for any

damage or injury caused by improper or incorrect use of this product.

24V Transforme

r

Connections

5

4

3 SINGLE LEAF LOGIC – Put dip switch 3 ON to select

REVERSING STROKE LOGIC – Put dip switch 4 ON to select

CANCELL LEAF DELAY – Put dip switch 5 ON to select

When selected, both motors start at the same time

Battery

Connections

24Vac led

Used if batteries fitted

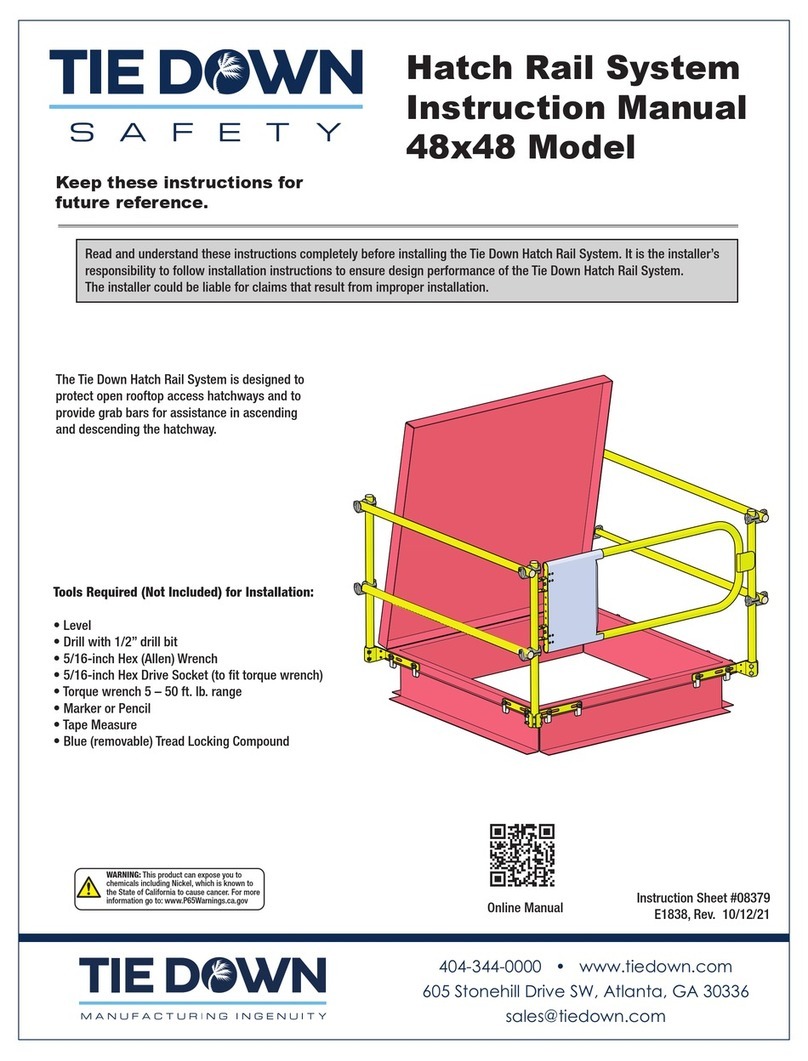

General Description:

The GATE 2 - 24V has been specifically designed to control all SEA low voltage swing gate

operators. Programming of the motor run and delay timings is carried out by push button (P2 & P3).

Features include: A normal paired motor start input - Pedestrian start input that controls one gate

(motor 2) of pair - Photocell and Electric Lock control - Selectable 12 or 24v accessory voltage output

– ‘led’ status indication – Adjustable motor run speed controller (RV1) - Dip switch selectable

operating logics – Battery back-up control (optional).

An in-built non-adjustable AMPSTOP device automatically switches off the supply to the motor(s) at a

preset level.

Operating Logics

The Gate 2 24v has three types of operating logics. They are as follows:-

Step by Step – Selected by setting ‘dip switches’ 1 OFF and 2 OFF.

Security – Selected by setting ‘dip switches’ 1 OFF and 2 ON.

Automatic – Selected by setting ‘dip switch’ 1 ON - dip 2 is then disabled

Automatic Logic takes priority, when switch 1 is ON switch 2 is disabled.

Please Note:

All Changes of the ‘logic’ settings or timings must only be carried out when the gate(s) is at rest in the

closed position.

Operating cycles are initiated by giving either a ‘start’ or a ‘pedestrian start’ input.

On ‘power-up’ of the Gate 2 24v, the first start input given will initiate an opening cycle regardless of

the gate(s) position.

Step by Step Logic

This is a sequential logic. From the gate(s) closed position a ‘start’ input’ will open the gate(s). The

gates will remain in the open position until the next ‘start’ input is given to close the gate(s).

The ‘slowdown’ stage occurs toward the end of an operating cycle and the motor(s) stopping position

is controlled by either the in-built AMPSTOP device or expiry of the run time??

A ‘start input’ given during an opening or closing cycle stops the gate(s) movement – The gate(s) stay

in this position awaiting the next ‘start’ input. When this second (next) input is given the gate(s) travel

on the opposite direction i.e.

If the gate(s) were stopped during opening – They will start to close.

Security Logic

This logic works in a similar way to ‘Step by Step’ logic apart from the following important differences:-

When the gate(s) reach the open position they will pause for the preset time and automatically close.

A ‘start’ input given during the open pause time cancels the automatic cycle. The next ‘start’ input

given closes the gate(s).

i.e. A ‘start’ inputs given during the open and close cycle will still halt the gate(s) movement and the

next ‘start’ input given inverts the gate(s) original direction.

A ‘start’ input given during the open pause cancels the pause time, the next ‘start’ input will close the

gate(s).

Automatic Logic

This logic works in a similar way to ‘Automatic Logic’ apart from the following important differences:-

A ‘start’ input given during the gate(s) opening cycle is ignored.

A ‘start’ input given during the gate(s) closing cycle, stops and re-opens the gate(s) after a 1.5 second

delay.

A ‘start’ input given during the open pause time recharges and lengthens the pause time.

A maintained ‘start’ input will delay closing until it is removed.

N.B. For ‘hold open’ switches and time clocks, use Automatic Logic.

Single Gate Logic:

For single gate (motor) control (dip switch 3 ON) – When selecting this logic, previously described

logics remain unaltered.

When using ‘single gate logic’, dip- switch 4 - Reversing Stroke Logic need consideration.

The explanation of ‘reversing stroke’ is:

Starting with the gate(s) at rest in the closed position - When a ‘start’ input is given, the first action of

the motor(s) is to run towards the closed direction for approximately 1 second before reversing and

starting to run toward the open direction. The electric lock is energised before the motor starts to run

towards open and stays energised for approximately .4 of a second after is starts opening.

This logic is normally used to overcome ‘wind induced face pressure’ problems that are often

associated with electric locks that are fitted to solid sheeted gates.

1) Dip-switch 4 OFF – No Reversing Stroke

2) Dip-switch 4 ON – Reversing Stroke selected.

Safety Control Inputs:

STOP INPUT: Terminal 5 & Negative -. This is a ‘normally closed (nc)’ input and will require a wire-

link to a negative– terminal if a ‘Stop Button’ is not fitted.

When a ‘Stop’ command is given, it immediately stops operator movement or cancels the automatic

cycle if the gates were on open pause.

On reconnection of the Stop Link, the first ‘Start’ input given will either run the gates toward open if

the motors running at the time of the command or close the gates if the ‘Stop’ command was given

during a ‘open pause’ period.

PHOTOCELL: Terminal 6 & Negative -. This is a ‘normally closed (n.c.)’ input.

When the photocells infra-red beam is broken it either:-

Immediately halts and re-opens a closing gate(s) or if the beam is broken during the ‘open pause

time’, the pause time is re-charged and lengthens the time before the gate(s) start closing.

PHOTOSTOP: Terminal 8 & Negative -. This is a ‘normally closed (n.c.)’ input.

When the photocells infra-red beam is broken:-

If the motors are running, it immediately stops all gate movement, no matter which the direction the

gate(s) are travelling. When the infra-red beam is restored (obstruction cleared), the gates will always

run towards open. If the photocell beam is broken during the ‘open pause time’, the pause time is re-

charged and lengthens the time before the gate(s) start closing.

Both the above Photocell Inputs are inactive when the gate(s) are at rest in the closed position.

PEDESTRIAN START input: Terminal 2 & negative -. This is a ‘normally open (n.o.)’ input.

When a Pedestrian Start input is given, the first opening motor (motor 2) will open the one gate of a

pair and allow pedestrian access./egress.

The normal paired ‘Start’ input (terminal 3) has priority over a ‘Pedestrian Start’ input.

Operating Logic Selection

1

2

1

2

1

2

ON

Step – by Step Logic

Dip Switch 1 & 2 OFF

Security Logic

Dip Switch 1 OFF & 2 ON

Automatic Logic

Dip Switch 1 ON – Switch 2 is now inactive