Seaeye SI-MCT01 User manual

Thruster SI-MCT01

Instruction Manual

Issue 7

© SEAEYE 2006

Unauthorised reproduction of this publication or any part thereof without prior permission is strictly

prohibited

THIS PAGE IS INTENTIONALLY BLANK

Thruster SI-MCT01

1

CE

In respect of the Electromagnetic Compatibility Directive 89/336/EEC, attention

is drawn to the following:

•The SEAEYE SI-MCT01 'as delivered' complies with the essential protection

requirements of the EMC Directive 89/336/EEC.

•In order to ensure that the SEAEYE SI-MCT01 complies with the Directive

when installed for operational use, the installation instructions contained

within this Technical Manual must be adhered to.

•The end user of (or authority responsible for) the installation of the SI-MCT01

becomes responsible for the complete installation's compliance with the

Directive, particularly under the following circumstances:

oadditional equipments are used in conjunction with the system (unless

they are supplied by SEAEYE MARINE LTD), or

omodifications are made to the system (or part thereof), or

osurface equipment is removed from its 'as-built' enclosures for

subsequent installation in third-party racks or consoles.

•During Maintenance Procedures, when the system is operated outside its

normal operating environment and/or screened enclosures are opened for

access, the equipment may emit, or be susceptible to, electromagnetic

interference (EMI). The equipment should be sited away from safety critical,

essential communication, or navigation systems during such activities. It is

advisable to site the surface equipment away from critical electronic systems

at all times.

•It is recommended that electrical power for the SEAEYE SI-MCT01 is

provided using a dedicated supply which is not also used to power safety

critical, essential communication, or navigation equipment.

•Any questions in respect of the Compliance of any SEAEYE MARINE LTD

equipment with the EMC Directive, or any field reports of EMC related faults,

should be addressed to the Technical Director at SEAEYE MARINE LTD.

Seaeye House, Lower Quay Road, Fareham, Hampshire, PO16 0RQ, England

Thruster SI-MCT01

2

WARRANTY STATEMENT

Products sold by SEAEYE MARINE LIMITED (hereafter referred to as SEAEYE)

are guaranteed to the original purchaser as follows:

Subject to the exceptions and upon the conditions stated hereafter, SEAEYE

agrees to correct, either by way of repair, or at SEAEYE’s sole discretion, by

way of replacement, any defect of material or workmanship which develops as

follows:

•SEAEYE MCT Thruster Motors : 12 months,

•SEAEYE parts returned on completion of Repair : 3 months,

of dispatch of the product to the original purchaser by SEAEYE or it’s

authorised representative, provided that the investigation and factory inspection

by SEAEYE disclose that such defect developed under normal and proper use

and not due to fair wear and tear or misuse by the user for its intended purpose.

Repair or replacement are the exclusive remedies under this guarantee, and

further provided that the guarantee granted hereby shall not include parts,

materials, or spare parts that SEAEYE considers as expendables under normal

operating conditions.

The exceptions and conditions mentioned above are as follows:

1. SEAEYE make no guarantee concerning components or accessories that

are not of it’s own manufacture. All goods sold and manufactured by other

manufacturers are sold subject to the manufacturer’s guarantee, which

shall be assigned to the purchaser or authorised representative. SEAEYE

in so far as it is appointed by the agents of a manufacturer to carry out

repair work under such guarantees will, where it considers it appropriate,

carry out the necessary repair work on terms agreed by SEAEYE and

purchaser or authorized representative having regard to the liability of the

manufacturer under it’s guarantee. Notwithstanding anything in this

paragraph, any goods sold but not manufactured by SEAEYE are not

supplied with any warranty whether express or implied and warranty

imposed by common law or statute including the warranty of merchantable

quality and the implied warranty of fitness for a particular purpose

contained in the UK Sales of Goods Act 1979 Section 14 is expressly

excluded although SEAEYE undertakes to take reasonable care in

supplying suitable goods and giving particulars of performance.

2. SEAEYE shall be released from all obligations under its guarantee in the

events that repairs or modifications are made by persons other than its own

authorised service personnel or trained and authorized representative,

unless such repairs or modifications by others are made with prior written

consent by a Director of SEAEYE. In the event of a failure, and the

Thruster SI-MCT01

3

purchaser or agent authorized by the purchaser or the operator fails to take

prompt and reasonable action to prevent further damage, SEAEYE will not

accept any responsibility for consequent damage. “Normal and Proper use”

of a product includes without limitation performing routine preventative

maintenance in accordance with the appropriate instructions within the

appropriate service and/or maintenance manual.

3. SEAEYE products, systems and parts are Ex-works at the company’s UK

site. SEAEYE is not responsible for carriage/shipment/duty/taxes/

insurance or any other costs for any product, system or part either

dispatched to or from the company’s UK site.

4. There are no guarantees which extend beyond those expressly provided

for herein and the aforesaid guarantee and SEAEYE’s obligations and

liabilities there under are in lieu of, and the customer waives, all other

guarantees, express or implied, and all other liabilities therefore arising by

law or otherwise, including without limitation any implied guarantee of

merchantability or fitness for a particular purpose, and all obligations and

liabilities with respect to loss of use, revenue or profit, or indirect,

consequential or incidental damages of any kind and from manufacture,

sale, handling, shipment, repair, maintenance or replacement of said

products.

5. Representations and warranties made by any person, including dealers

and representatives of SEAEYE that are inconsistent or in conflict with the

terms of this guarantee (including but not limited to the limitations of the

liability of SEAEYE as set forth previously), shall not be binding upon

SEAEYE unless reduced to writing and approved by an officer of SEAEYE.

6. SEAEYE’s liability arising from the sale or use of a product sold by

SEAEYE shall be limited to SEAEYE’s cost of correcting defects, as

provided herein, or the total cost of such product as shown on the purchase

order pursuant to which it was purchased, whichever is less. All such

liabilities will terminate upon expiration of the guarantee period.

7. This guarantee shall be provided for and governed by the prevailing laws of

England.

Thruster SI-MCT01

4

General Information

Specifications: SEAEYE reserves the right to change specifications at any time

without due notice and without incurring any obligation to incorporate any new

features in any of it’s previous products, whether or not they have been sold.

Damage in Shipment: Each new product is carefully examined and checked

prior to dispatch from SEAEYE’s premises. It should be carefully examined and

operationally tested on receipt by the receiving party. If the product is damaged

in any way, then a claim should be lodged with the carrier. New or repaired

product that has been damaged in transit should not be returned to SEAEYE

without first obtaining specific shipping instructions from SEAEYE.

Repairs: If any fault develops, the following steps should be taken:

•Notify SEAEYE and give full details of the difficulty. Include in this notification

the model type and its serial number. On receipt of this information SEAEYE

may elect to either issue service instructions or provide full shipping data for

the return of the equipment.

•After shipping instructions are supplied, forward the product(s) prepaid and

repairs will be estimated and the client informed prior to any repairs to the

fault(s) being carried out.

•The client may then issue SEAEYE an approved purchase order to cover the

costs of the repair, if the fault has been caused by misuse or is not under

guarantee.

Thruster SI-MCT01

5

Introduction

The SI-MCT01 is the culmination of Seaeye’s proven brushless DC motor

technology and impressive new developments in magnetics and materials

sciences. RS485 communication facilitates the rapid integration of the SI-

MCT01 into all manner of subsea applications from ROV and AUV propulsion to

prime mover applications such as pumps. With simplicity and versatility in mind

the SI-MCT01 can be controlled simultaneously with up to 128 similar nodes

from a single serial port.

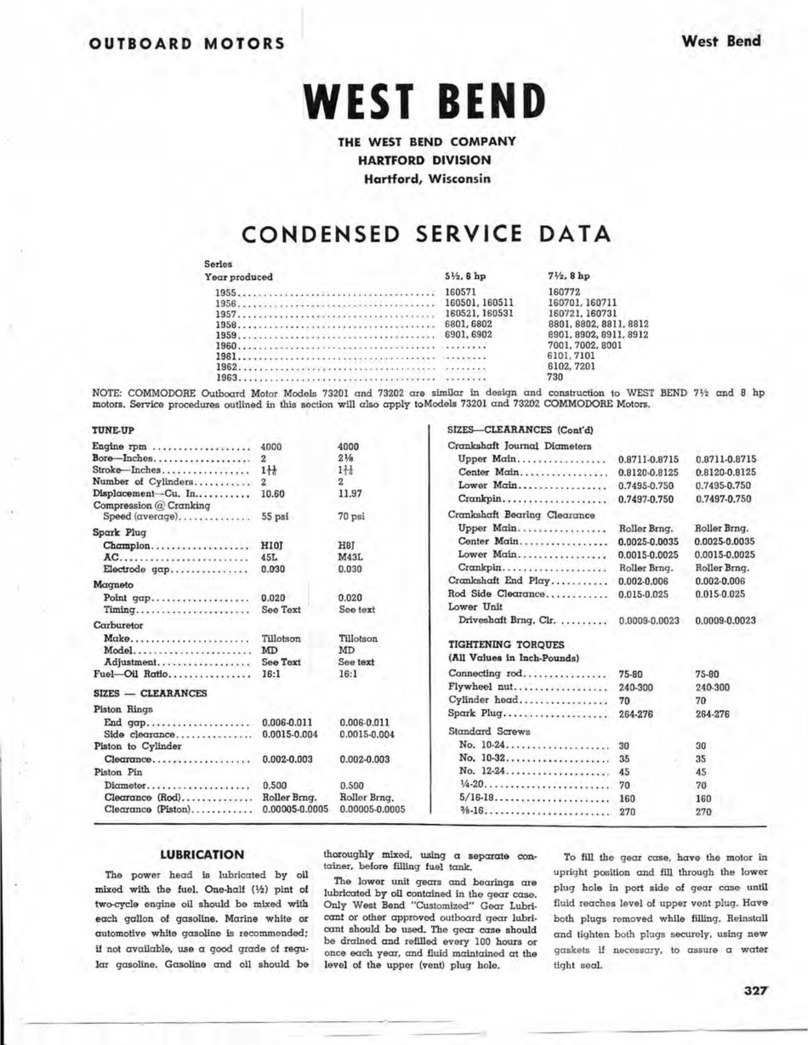

Specifications

Nominal Voltage: 48VDC

Nominal Power: 300W

Forward Thrust @ 300W: 13 kgf

Reverse Thrust @ 300W: 12.8 kgf

Propeller Speed @ 300W: 960 r.p.m

Propeller Diameter: 180 mm

Weight in Air: 4.3 kg (including propeller and nozzle)

Weight in Seawater: 2.5 kg (including propeller and nozzle)

Depth Rating: 300 m

Control Signal: RS485

Connector: 5-Way Connector

2 x Power

2 x Telemetry

1 x Earth

Thruster SI-MCT01

6

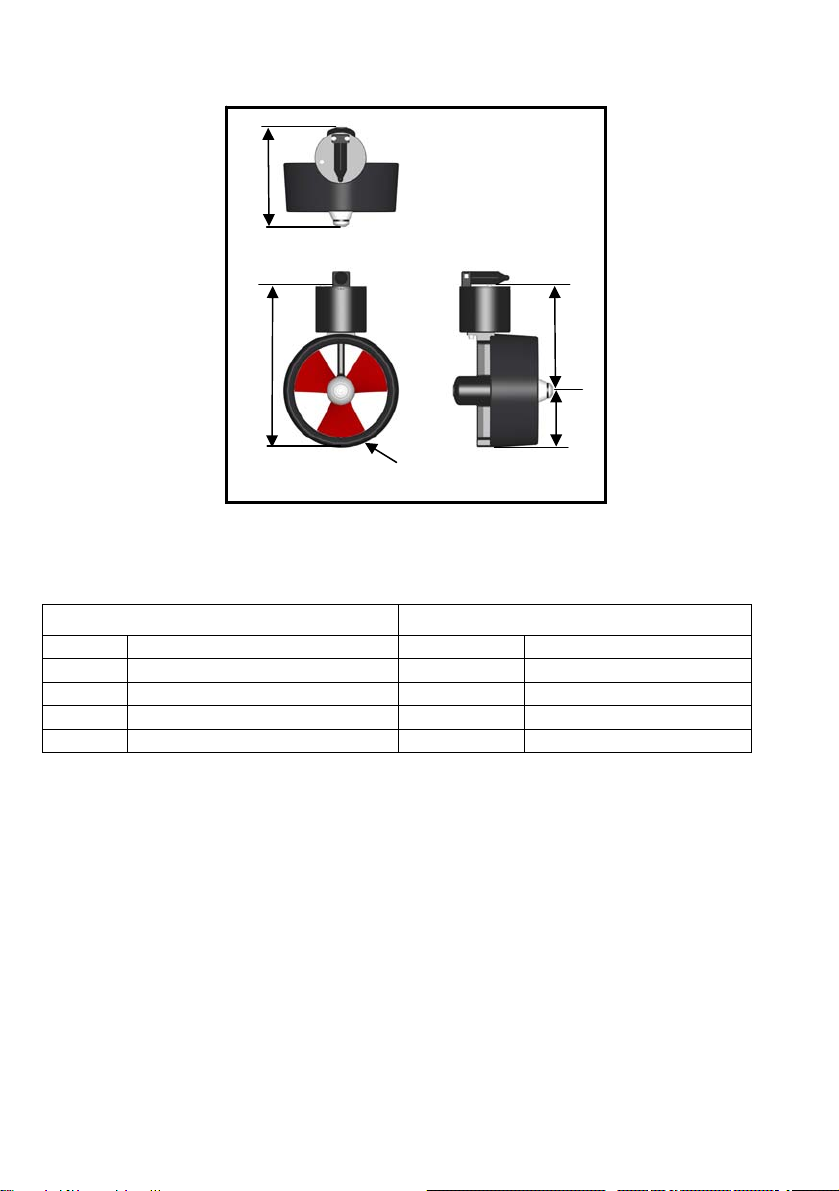

Fig. 1. Dimensions

Connection

External Internal

Pin 1 Brown Red/White +48/+24 V

Pin 2 Red Yellow Telemetry A

Pin 3 Orange Blue Telemetry B

Pin 4 Yellow Black/Grey 0 V

Pin 5 Green Green Earth

Telemetry MUST be fused at: F250mA

Supply MUST be fused at: F8A(T)

Size = mm

205

132

Ø220

192

337

Thruster SI-MCT01

7

Fig. 2. Thruster Connection

Thruster SI-MCT01

8

Seaeye Marine Thrusters - Electronics Explained

The Thruster Control Loop

To maintain constant speed under varying loads, Thrusters must operate within

a closed loop control system.

Open loop systems apply power to the motor in proportion to the operator

demand. The actual motor shaft speed, however, is dependent upon loading

and will change under different operating conditions. Only in calm, minimal sea

currents and tides would the vehicle remain stable, otherwise Auto function

control would be very unreliable.

In a closed loop control system, the power applied to the motor is determined by

the difference between the user demand and the actual shaft speed.

For a fixed user demand:

•Increased propeller loading causes the motor to slow down. This increases

the difference between actual and demand speed which is a difference

known as error. This error is measured by the thruster electronics feed

back loop and causes more power to be applied to the motor until the actual

speed equals the demand speed reducing the error to zero.

•Decreased propeller loading causes the actual speed to rise above that

required, the difference or error is negative, causing a reduction in applied

power until the motor shaft speed falls and the error is again reduced to zero.

Control loop INPUT signal

The propeller speed is determined by the mark-space ratio of the SPEED input

signal to the thruster. The actual shaft speed (as determined by the speed

feedback circuit) is subtracted from the input demand signal to produce an error

voltage, which is proportional to the difference between the required speed and

the actual propeller speed.

Overload trip

Jamming of the propeller or gradual fouling causes the thruster current to rise

above safe levels. If left unchecked, either gradual or instant current growth will

exceed the permitted levels causing thruster overheating or destruction of the

drive FETs. A current sensor provides indication of a fault condition. A

temporary over current trip may be cleared by reversing the direction of the

Thruster. If the overload condition persists, then the trip condition will continue

preventing damage to the thruster.

Thruster SI-MCT01

9

SI-MCT01 Thruster Control

Introduction

This document details the telemetry specification for the SI-MCT01 Thruster.

Node Configuration

The network of nodes uses a Master/Slave configuration. The controller Input

being the master and all other nodes are slaves. The master node initiates

communication and the slave will then reply.

Packet construction

There are two types of packets a Surface to Subsea (controller to thruster) and

Subsea to Surface (thruster to controller).

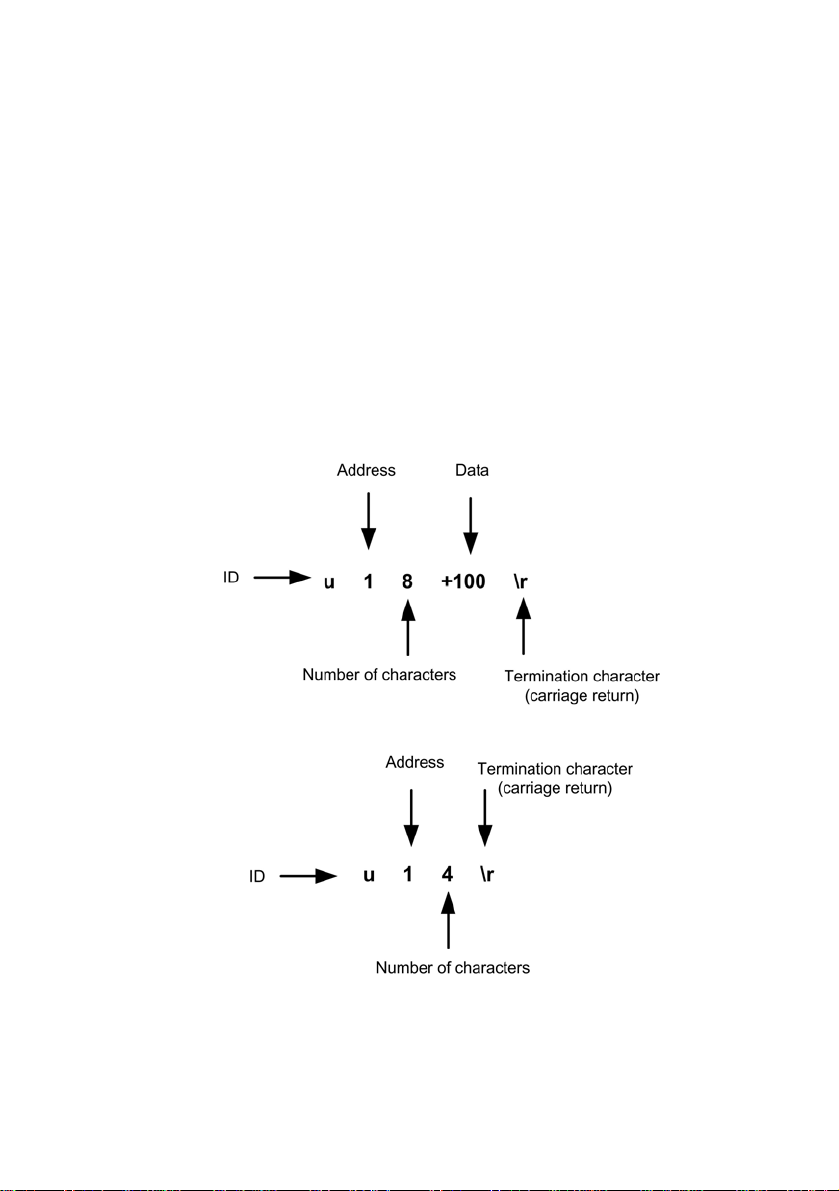

Fig. 3. Example of surface to subsea

Fig. 4. Example of subsea to surface

Thruster SI-MCT01

10

Field name Field

width Example

Character Description

ID 1

u ID of thruster node. Lower case indicates

surface to subsea, uppercase indicates

subsea to surface.

ADDRESS 1

1 Address of node. Total of 35 different

addresses for each type of node 0 to 9, then

A to Z. Address 0 is reserved for broadcast

to all nodes of ID specified. Only 35 nodes

of any type allowed.

NUMBER OF

CHARACTERS 1 8 Number of characters used in packet. This

includes the encoding characters and

carriage return. Therefore a miniumum of 4

will always be sent. Total of 36 characters

can be sent 4 to 9, then A to Z.

DATA 0 to 32 +100 Data sent in packet. This can only be up to

32 characters long.

TERMINATION 1

\r Terminating character ‘\r’ (carriage return).

The example u18+100\r specifies the following information

uthruster node addressed from surface to subsea

1address 1

88 characters in total used in this packet

+100 a demand of +100% required

A correct acknowledge reply from the node to the handcontroller would be U14\r

Uthruster node reply

1from address 1

44 characters in total used in this packet

This sequence of packets shows the demand from the handcontroller to thruster

1 of +100%. The thruster then replies with a acknowledge packet.

Thruster SI-MCT01

11

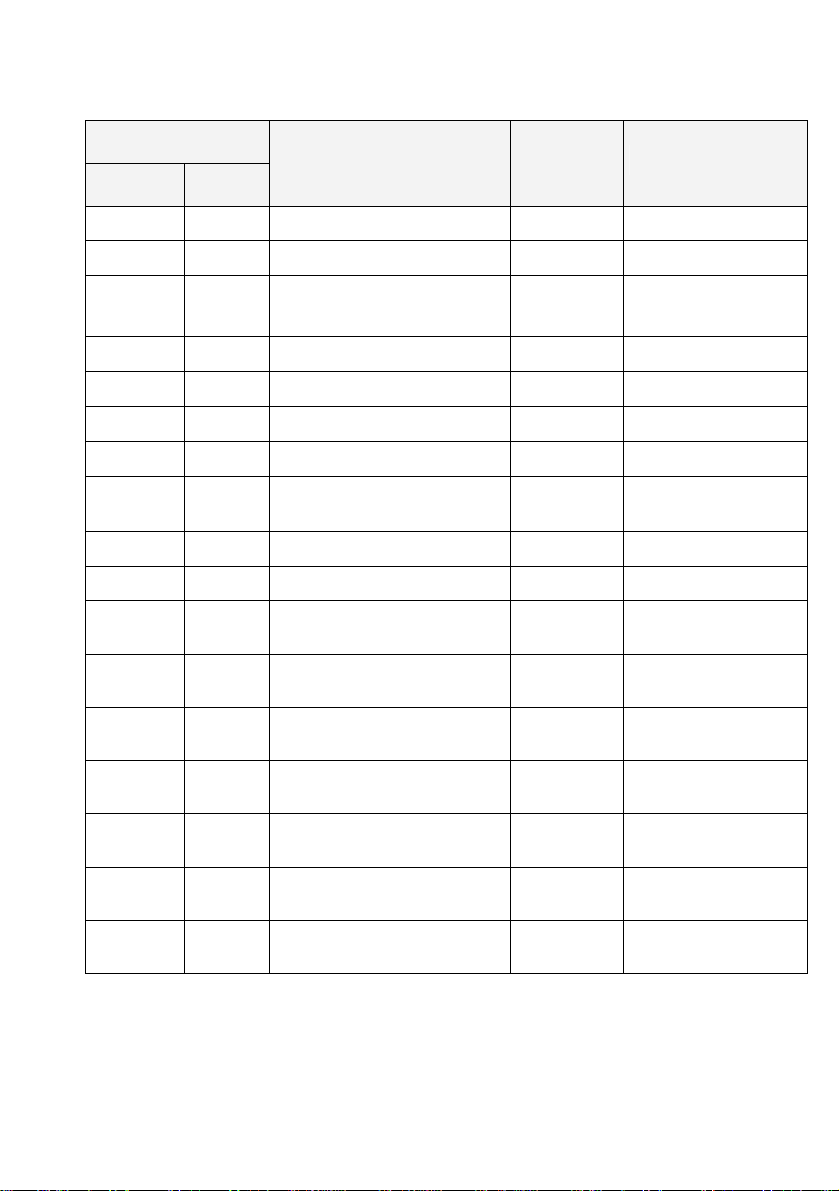

The following table gives the various commands available for the MCT1 thruster.

Data

Command Value Function Reply Notes

+ 0 to 100 Forward demand 0 to +100% Ack

- 1 to 100 Reverse demand 0 to –100% Ack

? R Request output speed 0 to 6250 Motor rpm (divide by 5

to give propeller rpm)

? C Request motor current 0 to 10 0 to 6 Amps

? b Request baud rate

? h Request total time run hH mM H = hours M = minutes

? n Request node name string Up to 8 chars

? v Request version number mmnn mm - major number

nn - minor number

x 0 Disable eeprom write

x 1 Enable eeprom write

z Reset node Non zero on

success

n 0 to F Set node address Non zero on

success Eprom Write must be

enabled

b 0 Set baud rate 57600 (default) Non zero on

success Eprom Write must be

enabled

b 1 Set baud rate 4800 Non zero on

success Eprom Write must be

enabled

b 2 Set baud rate 9600 Non zero on

success Eprom Write must be

enabled

b 3 Set baud rate 19200 Non zero on

success Eprom Write must be

enabled

b 4 Set baud rate 38400 Non zero on

success Eprom Write must be

enabled

Thruster SI-MCT01

12

Control Notes

The commands are in standard ASCII format, 1 Start, 8 Data, 1 Stop, 0 Parity,

user selectable Baud Rate {57600 default) and the terminating character ‘\r’ is a

single carriage return.

To set either a new address or baud rate eeprom write must be enabled. The

new address or baud rate will not take effect until the node is reset.

If the thruster does not receive a command for 1 second or more the thruster

demand is zeroed.

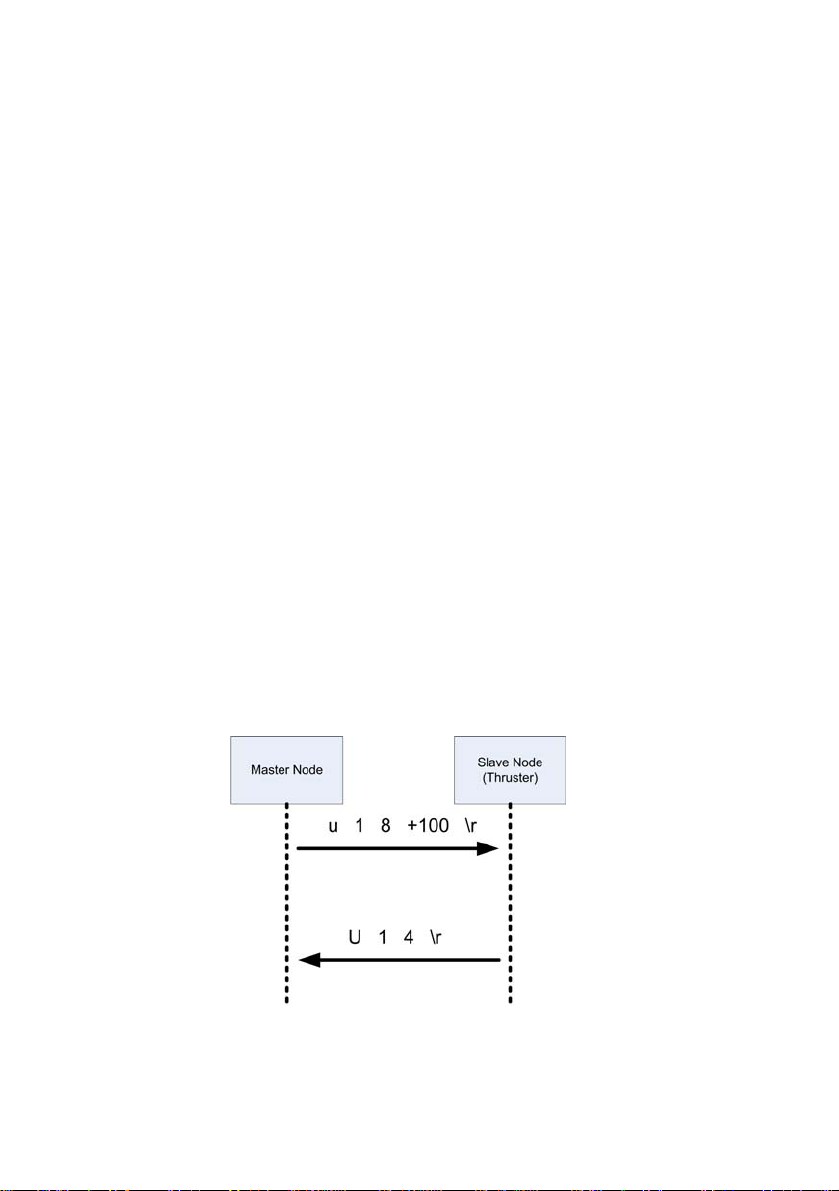

Communication Example

The example u18+100\r specifies the following information

uthruster node addressed from surface to subsea

1address 1

88 characters in total used in this message

+100 a demand of +100% required

A correct acknowledge reply from the node to the handcontroller would be

U14\r

Uthruster node reply

1from address 1

44 characters in total used in this message

The figure shows the sequence of messages for a demand from the controller to

thruster address 1 of +100%. The thruster then replies with an acknowledge

message.

Thruster SI-MCT01

13

Thrust Direction due to Demand

The following diagram shows the direction of thruster travel depending on the

demand given.

Thruster SI-MCT01

14

Maintenance - Thruster Propeller Replacement

Frequency of Task

The propeller should be checked before and after thruster useage. The

propeller should be replaced when there is obvious damage to propeller.

Introduction

The purpose of this check is to ensure that the thruster is working efficiently

Tools Required

The following tools may be required:

•Allen Keys (common sizes)

Parts Required

The following parts may be required:

•Thruster Propeller (Part Number P01780).

•Loctite 222.

•Lubricating Oil (Aqua Shield or similar).

Procedure

WARNINGS:

DANGER OF FATAL ELECTRIC SHOCK. BEFORE REMOVING OR

OBTAINING INTERNAL ACCESS TO THE EQUIPMENT ISOLATE

ALL THE UNITS POWER SUPPLIES.

POSSIBILITY OF FATAL ELECTRIC SHOCK AND DANGER TO

PERSONNEL AND EQUIPMENT. BEFORE SWITCHING ON THE

THRUSTER ENSURE THAT THE SYSTEM IS FULLY ASSEMBLED

AND OPERABLE AND NO MAINTENACE ACTIVITY IS IN

PROGRESS.

DANGER TO PERSONNEL AND EQUIPMENT. THRUSTERS

MOTORS MAY OPERATE WITHOUT WARNING WHEN THE

SYSTEM DC SUPPLY IS ENERGISED. ENSURE THAT THE

THRUSTER IS CLEAR OF ANY OBSTRUCTION AND PERSONNEL

PRIOR TO ENERGISING THE DC SUPPLY.

Thruster SI-MCT01

15

Proceed as follows:

1. Visually examine the propeller to see if replacement is completely

necessary.

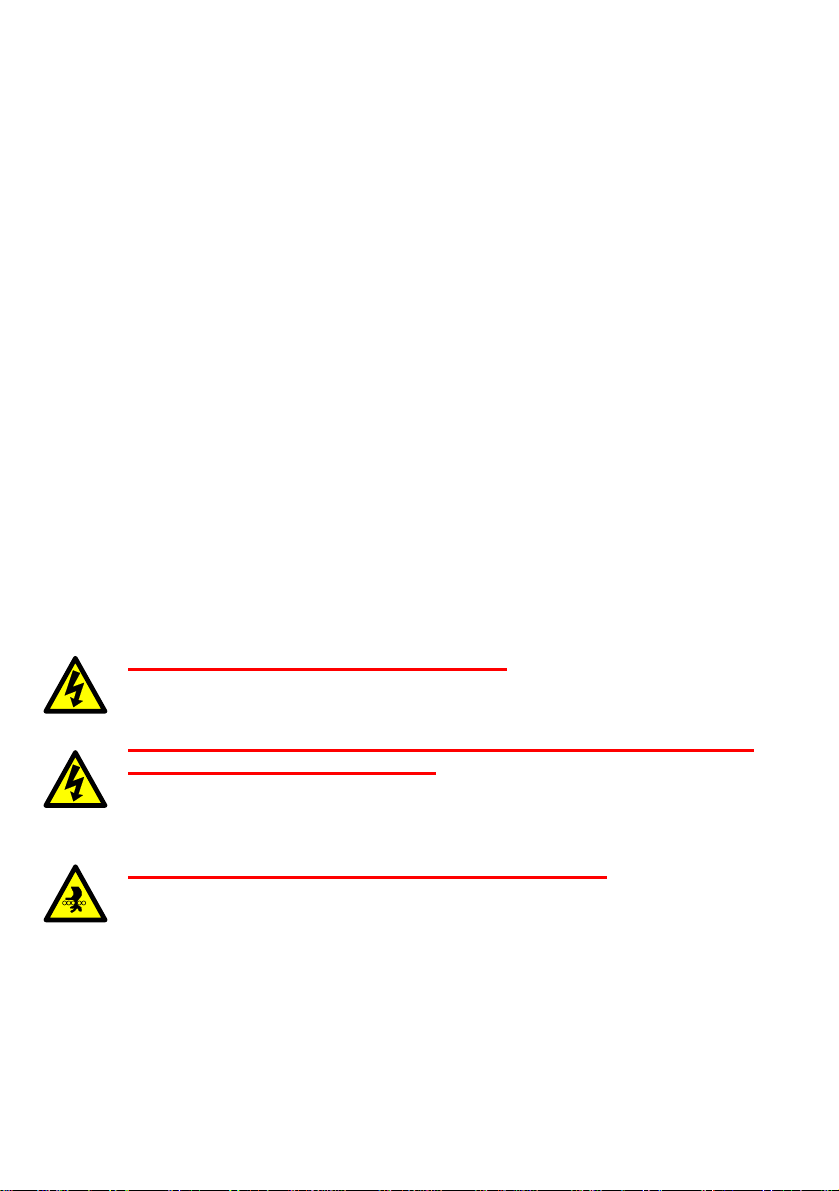

Fig. 5. Propeller Assembly

2. Remove the socket head screw, spring washer and propeller retainer.

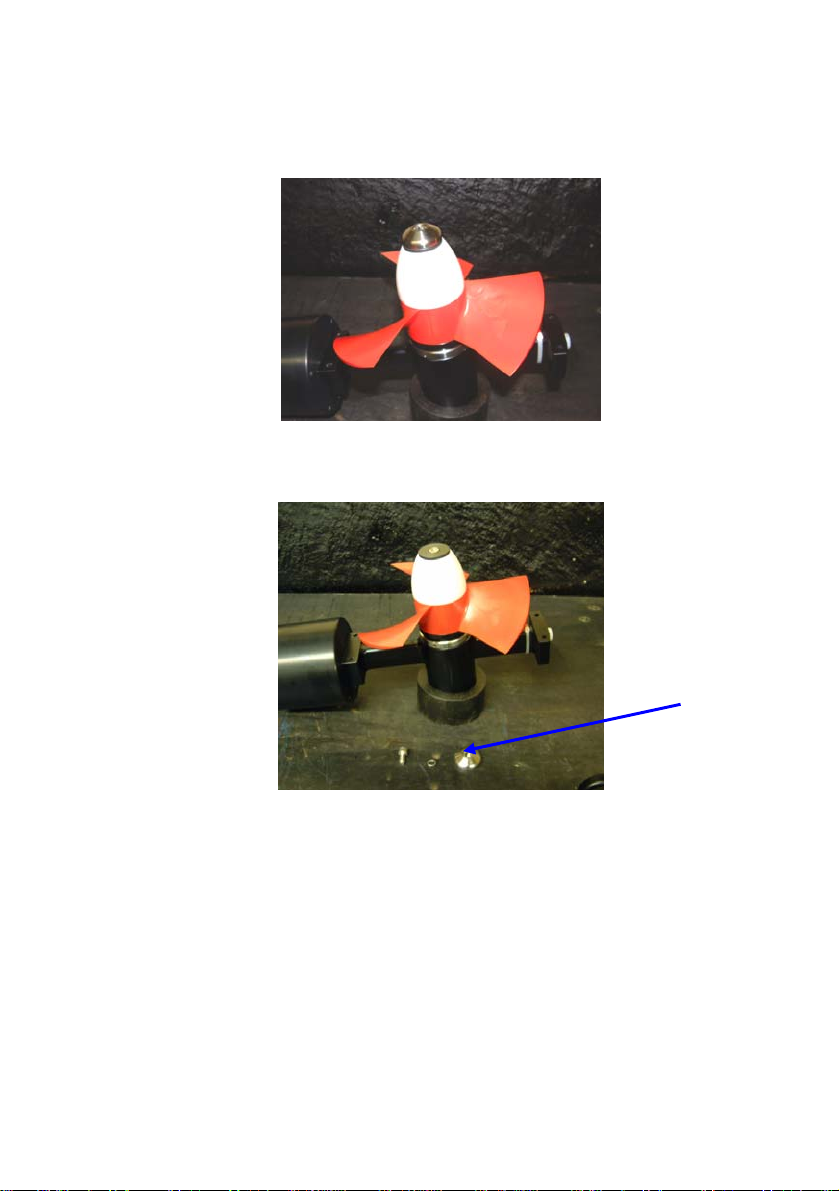

Fig. 6. Retainer Parts

3. The propeller assembly can now be removed; it may be difficult to remove

as it is magnetically coupled.

Propeller

Retainer

Thruster SI-MCT01

16

Fig. 7. Propeller Assembly Removed

4. The propeller assembly can now be dismantled, they are holes either side

of the nose cone and one in the magnetic coupling, these can be used for

the ‘C’ spanners to disassemble.

Fig. 8. Propeller Coupling Assembly

5. The propeller can now be changed.

Nose Cone Propeller Magnetic Coupling

Thruster SI-MCT01

17

6. When fitting the magnetic coupling to the nose cone, use Loctite 222 on

the nose cone threads.

Fig. 9. Propeller Fitment

7. Use the ‘C’ spanners to tighten the assembly together.

8. Apply a small amount of lubricating oil (Aqua Shield or similar) to the

internal propeller bearing assembly.

Fig. 10. Propeller Assembly

9. Refit the propeller assembly to the thruster using the retaining socket

screw and spring washer.

Fig. 11. Thruster Propeller Fitment

10. When fully tightened, there should still be a slight lateral movement of the

propeller to ensure that it is not ‘locked’ onto the thruster shaft.

Apply

Loctite 222

Apply

Lubricating

Oil

Table of contents