Installation and Operation of Electric Convection Oven

INSTALLATION INSTRUCTIONS

The oven should be placed in an area that is free

from drafts and accessible for proper operation

These installation instructions are for the use of qualified

installation and service personnel only. Installation or

service by other than qualified personnel may result in

damage to the oven and/or injury to the operator.

Refer to the Oven Placement Clearances Chart

before installing the oven.

Qualified installation personnel are those individuals,

firms,companies or corporations which either in personor

throughan agent is engaged in and responsible for:

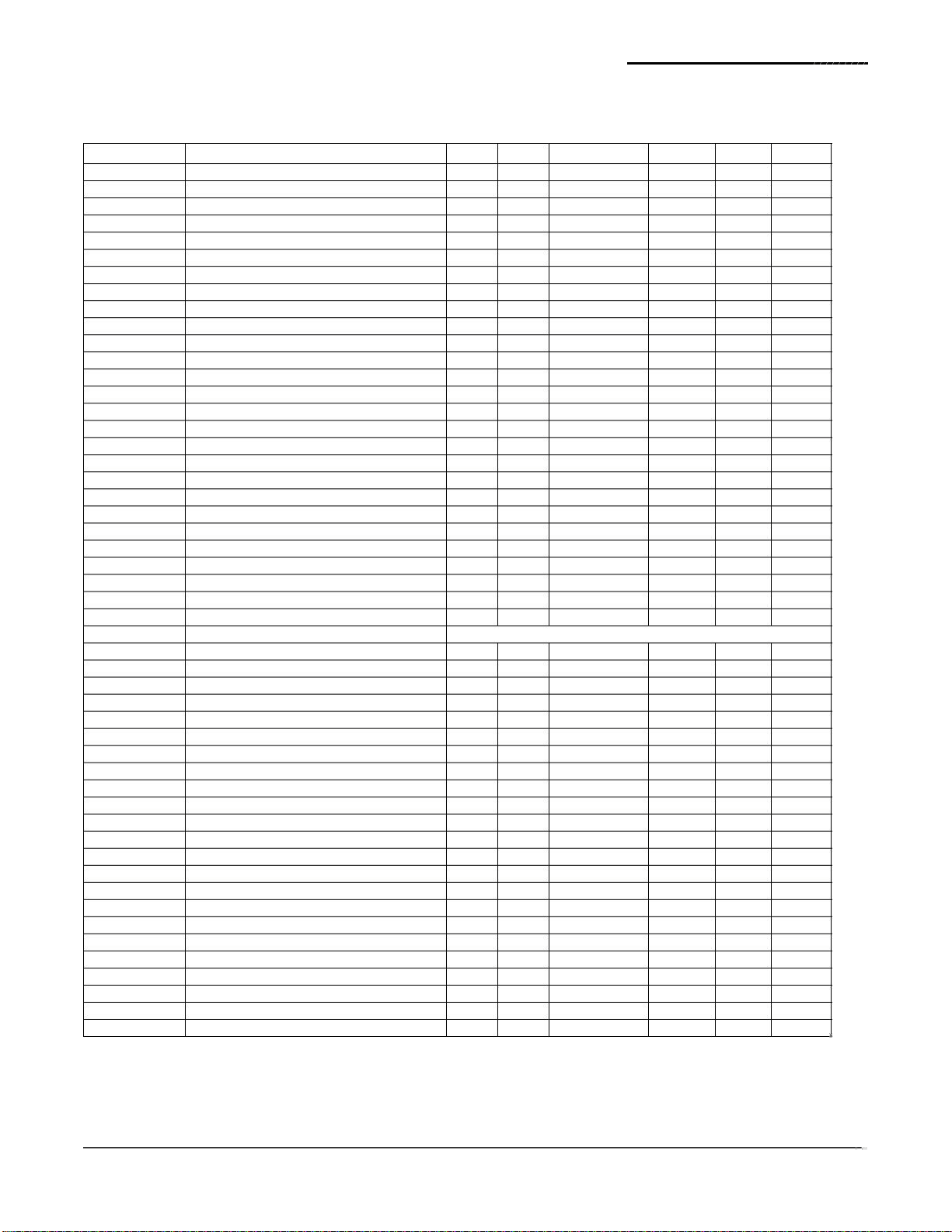

OVEN PLACEMENT CLEARANCES CHART

Left Side

Rear

1"

3"

8"

0"

3"

8"

The installation of electrical wiring from the electric

meter, main control box or service outlet to the

electrical appliance.Qualified installation personnel

must be familiar withall precautions required and

have complied with all requirements of state and

local authorities having jurisdiction. See: National

Electrical Code, ANSI/NFPA70.

B. DELIVERY AND INSPECTION

Core Pro does everything with in its power

to insure you received your oven in good condition.

They are strapped down on heavy wooden skids and

Surrounded by heavy “tri-wall” carton stop revent shipping

damage. They have all been carefully inspected before

they were packaged and consigned to the carrier.

Upon delivery of your Core Pro oven:

Look over the shipping container,carefully noting any

Exterior damage on the delivery receipt, which must

also be signed bythe driver/ delivery person.

Uncrate and check for anydamage, which was not

evident on the outside of the shipping container.

This iscalled concealed damage.The carrier must be

notified within five(5) days of the delivery ofthe oven

and the carton, skid and allpackaging materials

must be retained for inspection.

It isalso important not to obstruct the natural flow of

ventilation air if the oven is to operate properly. This

oven should not be installed on a curb base or sealed

to the wall. Either condition can restrict theflow of air to

or prevent proper ventilation of the blower motor. The

blower motor has a thermal protection device,which will

trip, because of excessive ambient temperatures at the

back of the oven. This condition should be corrected

immediately to avoid damaging the oven permanently.

Before making any connections to the oven, check the

specification plate to be sure the oven specifications

concur with the voltage andphase to be supplied to

the oven.

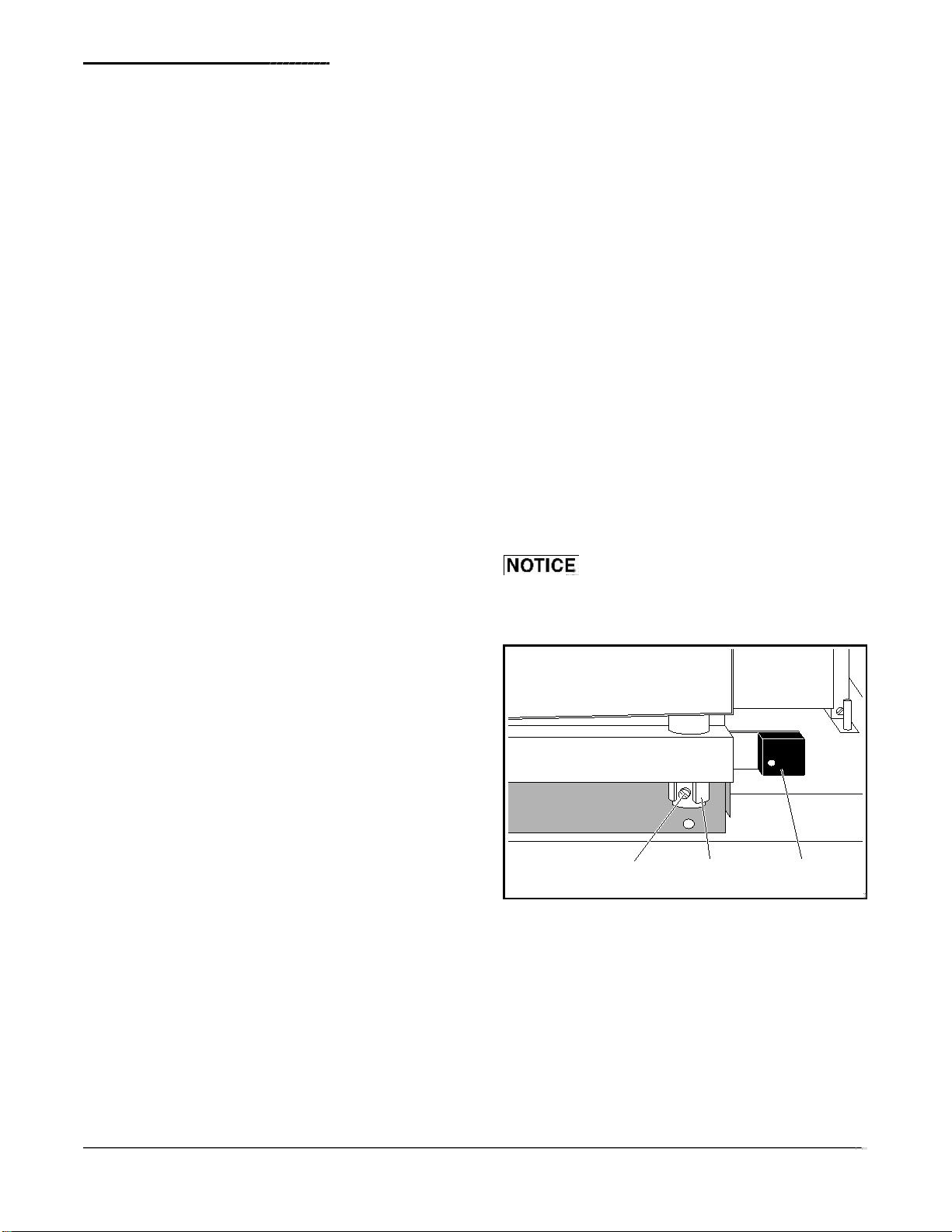

The specification plate islocated behind the lower front

panel.To access the specification plate,loosen the four

screws below the doors, and pull the panel outward.

Thespecificationplatebearingtheoven’sserialnumber

is attached to the underside of the upper ledge above

the control panel.

D. ELECTRICAL CONNECTIONS

The oven issupplied for connection to a 208V 3

PHASE grounded circuit. The electric motor, oven

lights,indicator lights andc ontrol circuits are connected

internally and require no secondary power supply.

Before making any connections to these units, check

the specification plate to assure that the voltage and

phase of the oven is compatible with the electrical

supply. When installing, all ovens must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 (in Canada – CSA Std. C22.1).

Wiring diagrams are located inthe control compartment

Ikon cannot assume liability for Loss ordamage

suffered intransit. The carrier assumes full responsibility

for delivery in good order when the shipment was

accepted. However, we are prepared to assist you in

filing your claim.

C. LOCATION OF THE OVEN

Proper planning and placement of the oven will give you

the best results in terms oflong-term user convenience

and satisfactory performance. We urge you to give

adequate thought in the placement of your oven prior

to itsarrival.