WARNING! The SM65.V2 bandsaw MUST NOT be used to cut non-metallic materials (including wood) as to do so will invalidate your

insurance cover and your warranty and may cause damage and/or personal injury.

8DO NOT wear loose or ill-fitting clothing. Remove ties, watches, rings and other jewellery. Tie up, or adequately cover, long hair.

8DO NOT start the machine until the workpiece is secure and the blade has been lowered to just above the workpiece.

8DO NOT use the bandsaw with the blade guard or pulley cover removed.

8DO NOT use damaged or deformed blades.

9Turn the saw off before raising the blade.

8DO NOT run the saw with the blade in the raised position.

8DO NOT use the machine in wet or damp locations.

8DO NOT use the machine in areas where fumes from paint, solvents, or flammable liquids pose a potential hazard. Keep all flammable

materials (including wipers or cleaning rags) away from the saw, and dispose of according to local regulations.

8DO NOT stand on the machine.

8DO NOT leave machine running unattended. Turn power switch ‘Off’ and DO NOT leave area until machine has come to a complete stop.

8DO NOT use whilst under the influence of drugs, alcohol or other intoxicating medication. DO NOT use the tool if you are tired.

2. iiiINTRODUCTION

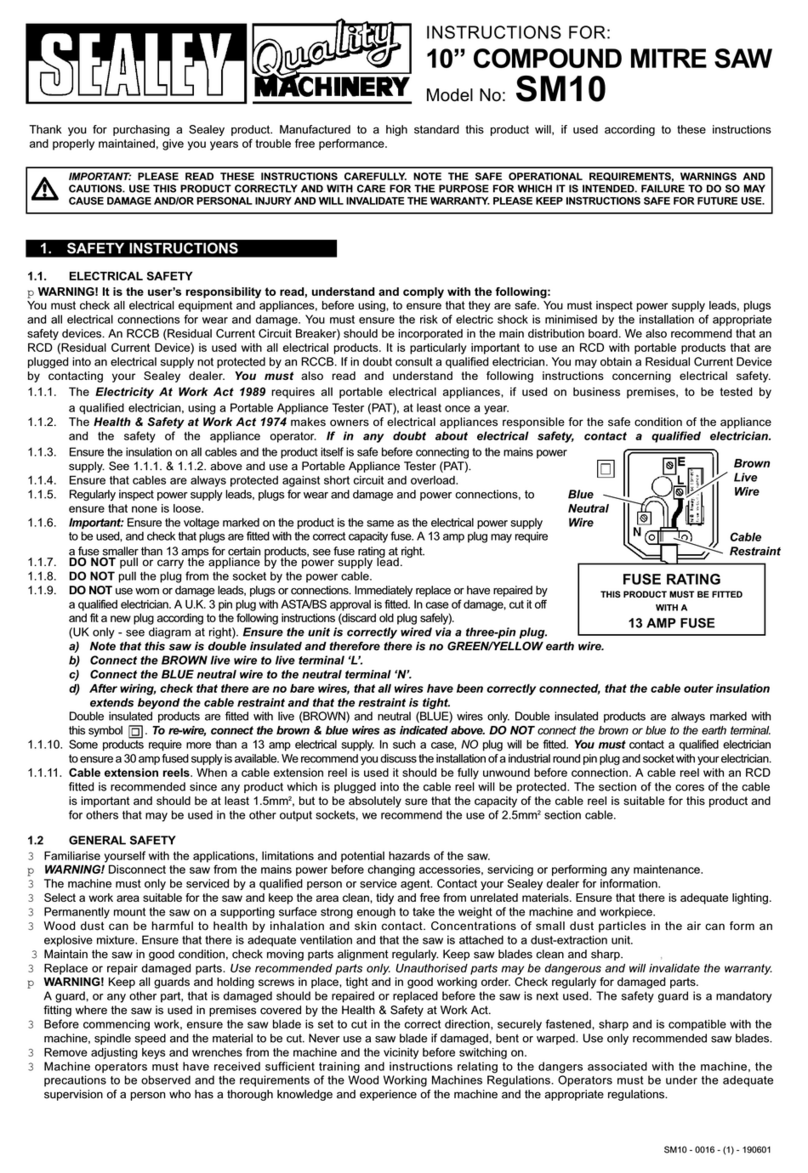

Fully guarded blade with magnetic no-load voltage switch to prevent motor re-start in the event of power failure or blade jam. Fitted

with oil-bath gearbox and life lubricated drive bearings for quiet, smooth operation. Features swivel arm facility to aid angle cutting of

long pieces of stock in confined workshop. Supplied with quick action vice - push the jaw up to the workpiece and then pull the cam

action lever to lock. Fully adjustable precision blade guides for accurate cutting and longer blade life. Supplied with anti-vibration feet and

workshop stand.

3. i SPECIFICATION

Model no:.: ....................................................................SM65

Capacity 90o - Round:..........................................Dia. 105mm

Capacity 90o - Square / Rectangular (H x W): ...105 x 150mm

Capacity 45o - Round:..........................................Dia. 100mm

Capacity 45o - Square / Rectangular (H x W): ...... 85 x 65mm

Blade Size: ............................................1638 x 13 x 0.63mm

Blade Speeds:............................................ 18, 30, 48mtr/min

Motor Power:.................................................................375W

Supply:...........................................................................230V

Weight:........................................................................... 75kg

4. ASSEMBLY

4.1. ASSEMBLY

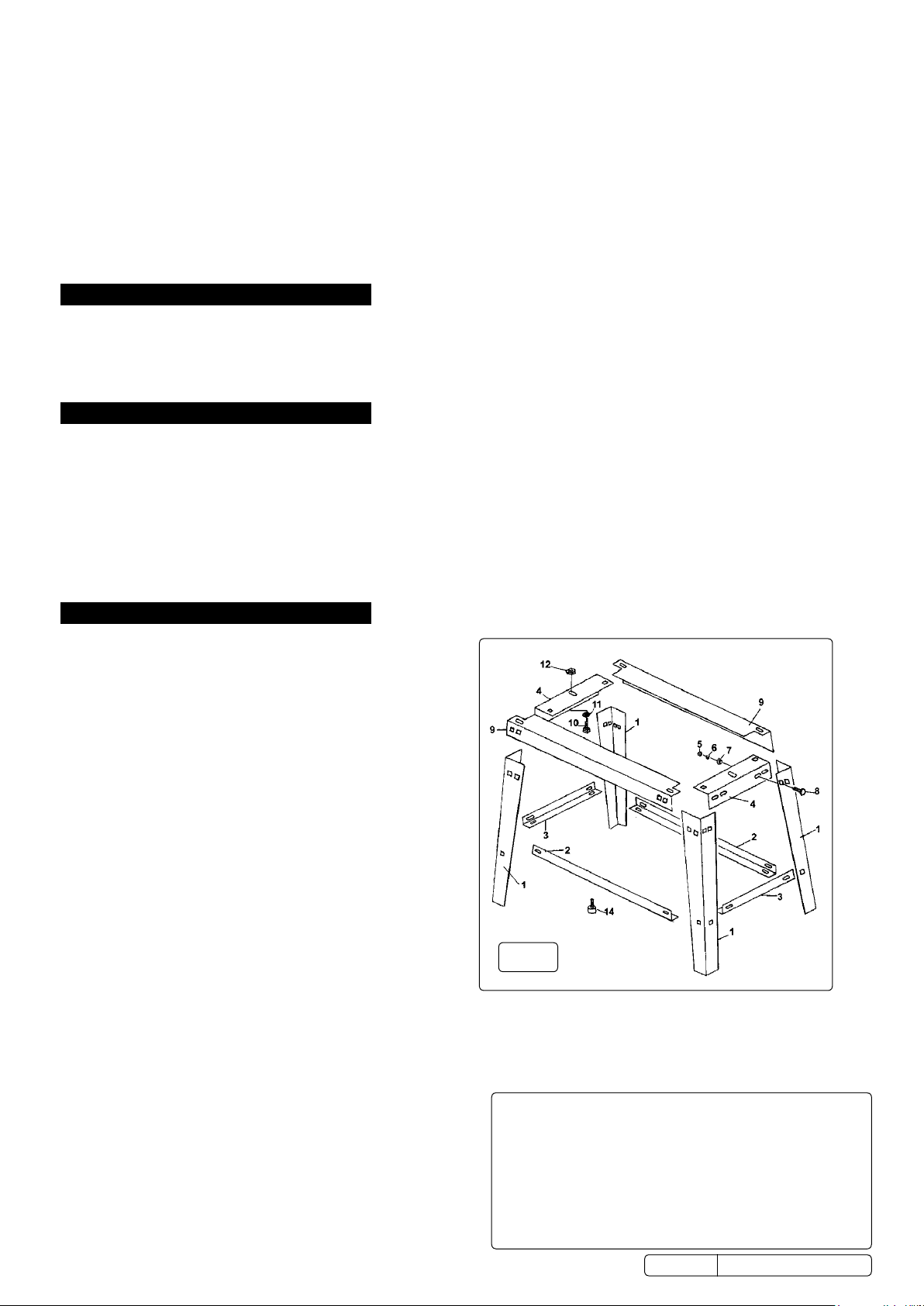

NOTE: Numbered brackets refer to Fig 1 and Parts diagram.

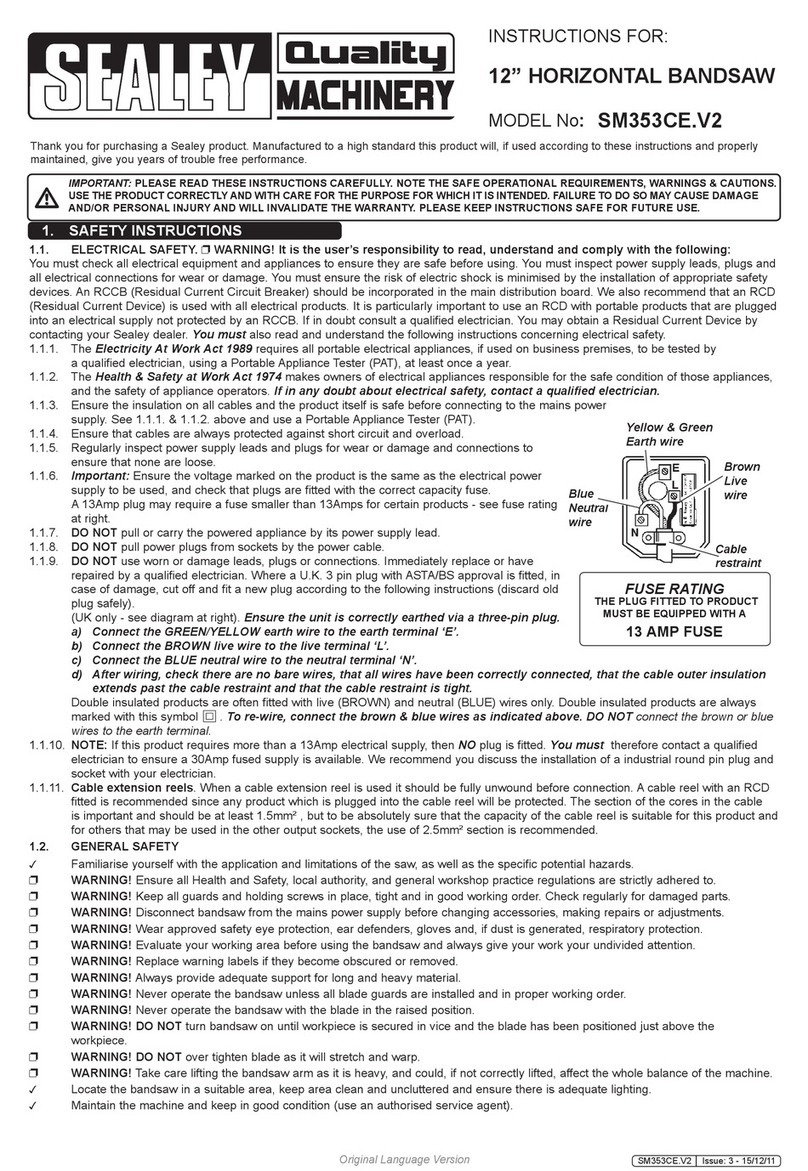

4.1.1. Assemble the floor stand as described below using the nuts

and bolts provided (refer to Fig 1).

4.1.2. Make one end frame by assembling two legs (1) to short

upper cross member (4) using four bolts (8), four washers (7),

four split washers (6) and four nuts (5). Attach lower short

cross member (3) to the inside of the legs using two bolts (8).

4.1.3. Create a second end frame using the same set of components.

Join the two end frames together using two long upper cross

members (9) using two bolts (8) at each end of each cross

member. The ends of the long cross members should pass under

the ends of the short cross members (4).

4.1.4. Attach the two lower long cross members (2) to the inside of

the frame using one bolt at the end of each.

4.1.5. The anti-vibration mountings (14) can either be fitted to the base

of the saw or to the stand. For bench mounting and when the

stand is to be secured to the floor, fit the mountings to the saw

base. Where the stand is to be portable, fit the mountings to

the bottom of the legs.

4.1.6. Place the saw onto the stand and retain it at either end with

bolt (10), washer (11) and nut (12).

4.1.7. Remove transit chain (15), retain for future use.

4.1.8. Slide fence (104) into vice base (103) and tighten set screw in front face of vice to retain.

4.1.9. When the saw arm is in the down position the cutting edge of the blade should be just below the main surface of the vice in order for

the blade to cut all the way through the workpiece. If this is not the case, loosen the lock nut (37) and adjust the stop bolt (38) so that

the cutting edge of the blade is 2 to 3mm below the vice surface. Re-tighten locknut (37).

4.1.10. Adjust switch cut-off screw (17) to ensure that ‘Off’ switch is actuated when, or just before, the body frame contacts the abutment

screw (38). Tighten nut (5).

4.2. BLADE SELECTION

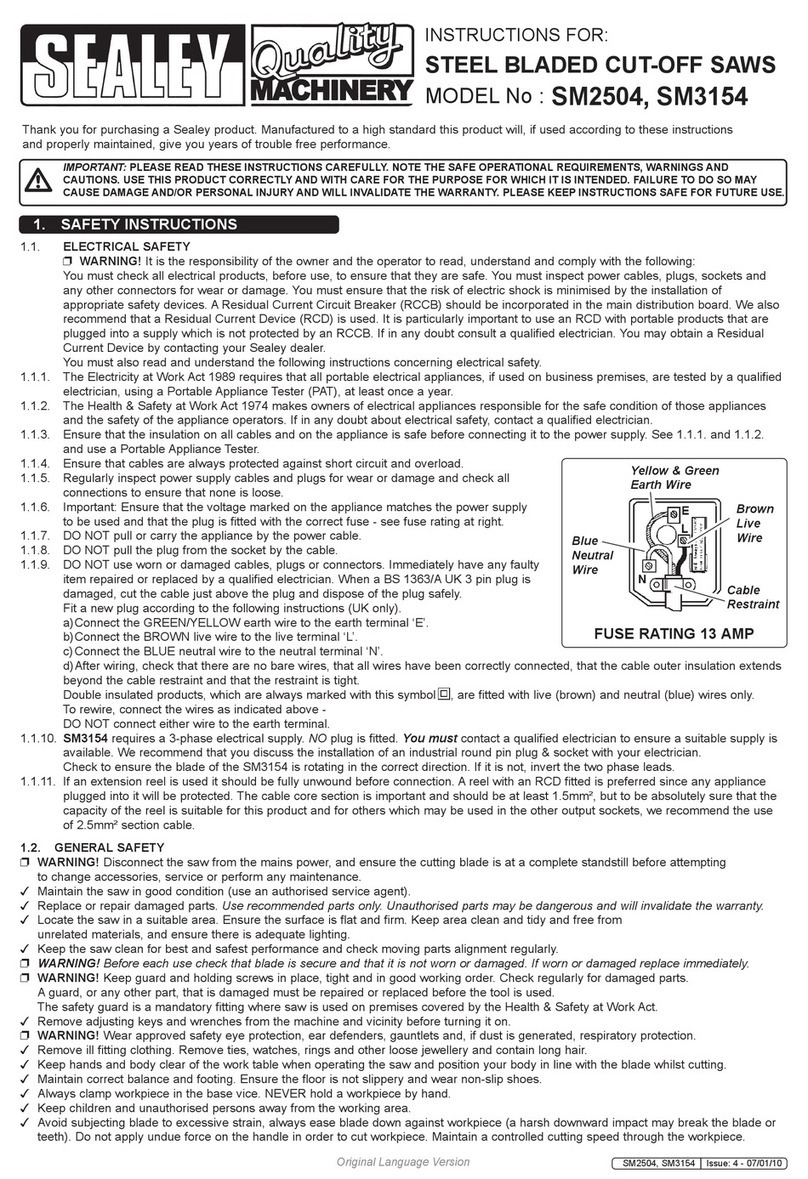

The chart at the right show the recommended setup for various

metals and cut lengths. Blades are available from your Sealey

stockist in four tooth pitches: 6, 10, 14 and 24 tpi (see parts list).

fig.1

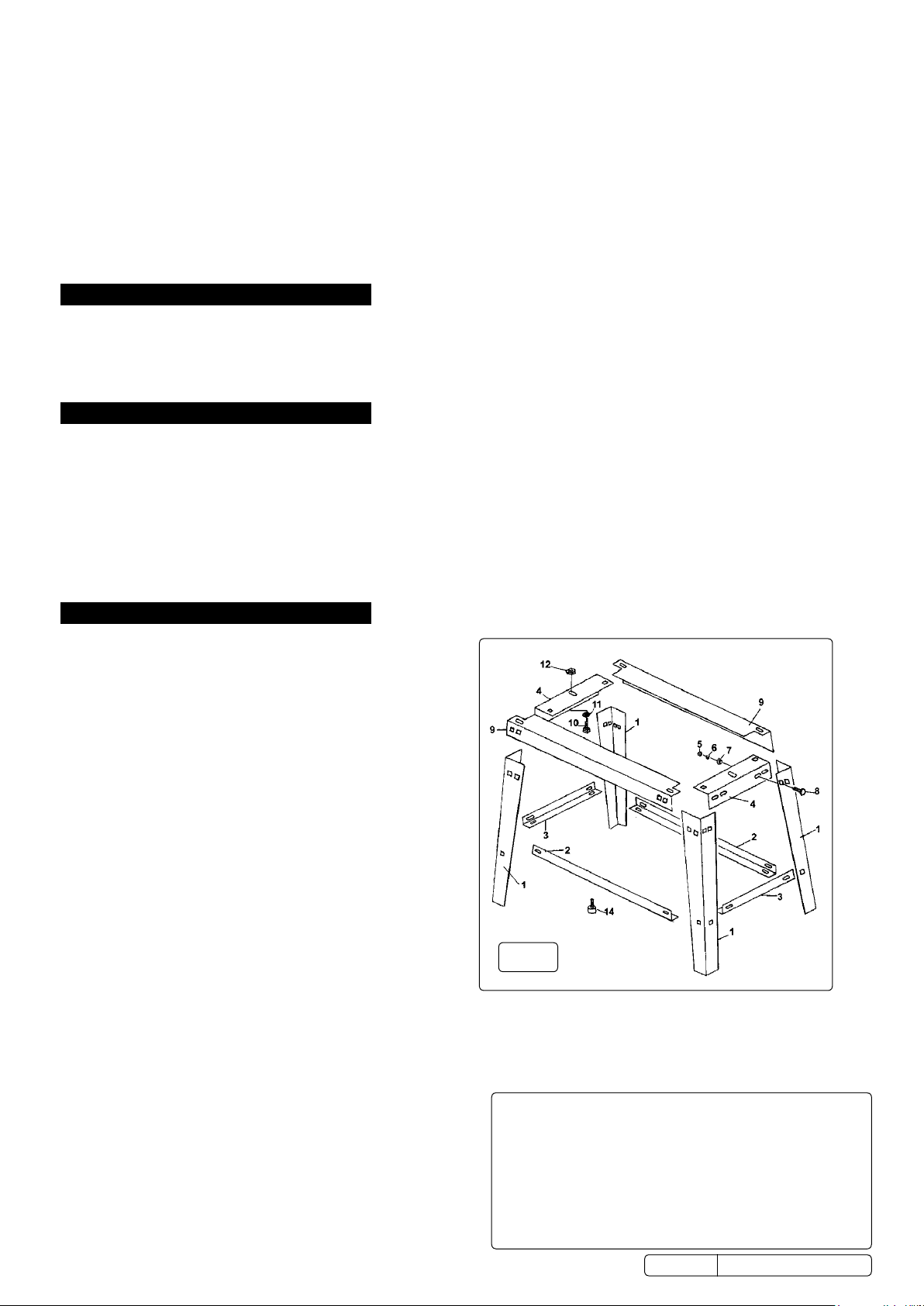

Blade Chart for Flat and Round Bar

Recommended blade teeth per inch (tpi) for nominal cut length.

Cut Length Under 8mm 4-13mm 6-16mm 8-22mm

Tpi 32 24 18 14

Cut Length 10-35mm 17-40mm 25-50mm 38-75mm

Tpi 10 8 6 4

Cut Length 50-100mm 75-150mm 114-225mm >200mm

Tpi 3 2 1.25 0.75

SM65.V2 Issue 4 (H, F) 06/02/18

Original Language Version

© Jack Sealey Limited