Seamax PowerMax Series User manual

Seamax PowerMax Trolling Motor

User Manual

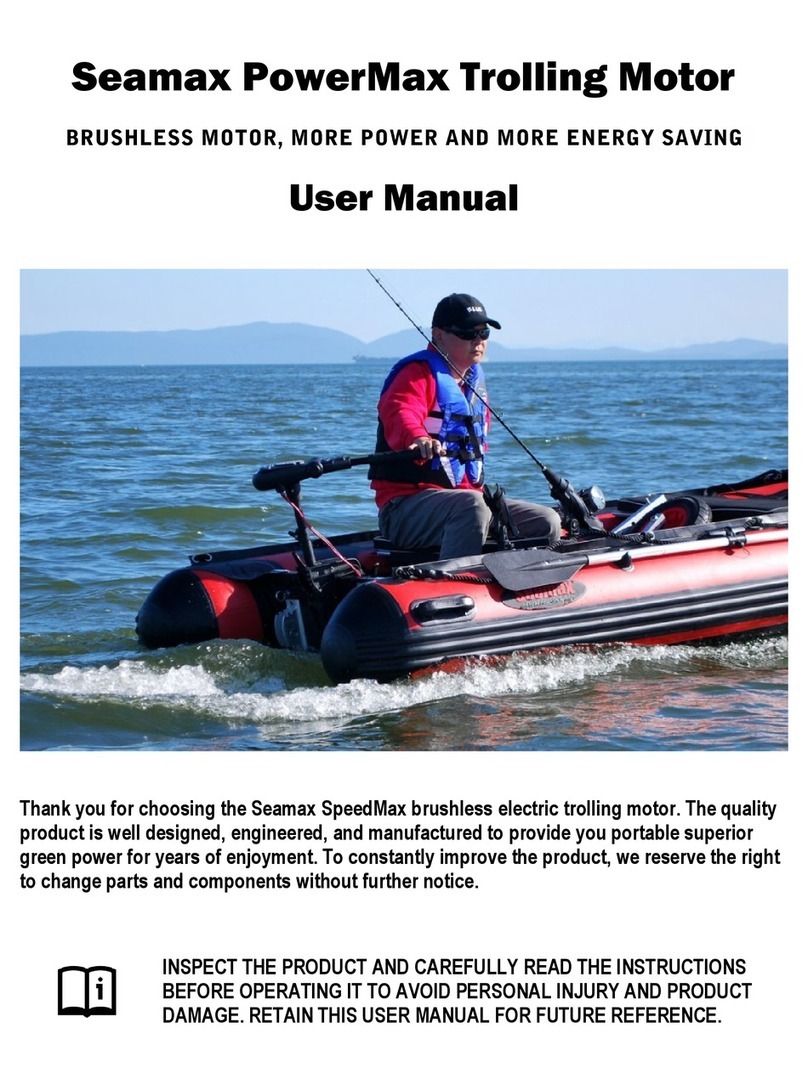

Thank you for choosing the Seamax PowerMax brushless electric trolling motor. This quality

product is well designed, engineered, and manufactured to provide you the portable superior

green power for years of enjoyment. To constantly improve the product, we reserve the right

to change parts and components without further notice.

INSPECT THE PRODUCT AND READ CAREFULLY THE INSTRUCTIONS

BEFORE OPERATING IT TO AVOID PERSONAL INJURY AND PRODUCT

DAMAGE. RETAIN THIS USER MANUAL FOR FUTURE REFERENCE.

2

PowerMax – 3x LONGER RUN TIME IN AVERAGE

DIGITAL CONTROL FOR VARIABLE SPEED

This powerful new trolling motor is equipped with stepless adjustable speed control and a safety lanyard. The digital

technology provides stepless forward and reverse speed control, and easily reaches the maximum speed. With the

benefit of the digital controller, this variable speed PowerMax trolling motor lets you dial in your requried speed, and it

delivers the exact power as you need, helping to conserve the battery for a full day of fishing or other use.

HIGH EFFICIENCY BRUSHLESS AC MOTOR

Digital speed controller saves the battery power. Motor using traditional copper resistance wire to adjust the motor

speed will waste up to 75% of power when motor running in low speed. At the mean time, the efficiency of this

brushless motor can be up to 90%, which is about 30% higer comparing with a regular DC trolling motor.

This digital controlled trolling motor is equiped with a brushless 12V or 24V AC motor, providing 3 times longer run

times in average on a single battery charge. It is excellent for propulsion of wide range of boats in different waterway.

3

1. LIMITED WARRANTY INFORMATION

DURATION OF COVERAGE

All new Seamax SpeedMax electric trolling motors are warranted to the original purchaser to be free from defects in

material and/or workmanship for two (2) years from the date the product is sold. Warranty is NOT transferable to any

subsequent purchasers. The repair, replacement of parts, or the performance of service under this warranty does not

extend the warranty beyond its original expiry date.

HOW TO OBTAIN WARRANTY COVERAGE

To obtain warranty service, the original purchaser shall contact Seamax or authorized reseller for a return

authorization before returning the unit. The product to be returned by courier should be carefully packaged, with a

note clearly describing the nature of the problem and/or service requested, customer address, and contact phone

number in the package. A copy of the sales receipt, order form, or other proof of purchase is required with the return

of the product for warranty consideration. Warranty claims without purchase receipt will not be accepted.

Seamax or the local authorized seller will arrange for the inspection and any necessary repair. The purchaser shall

pay for all related shipping and transport charges. If the service provided is not covered by the limited warranty,

purchaser shall also pay for all related labor and materials, and any other expenses associated with that service.

CONDITIONS OF THE LIMITED WARRANTY

Warranty coverage is only available from Seamax or the authorized dealer to distribute the product in the country in

which the sale occurred. Proper routine product maintenance is required to maintain warranty coverage. Seamax

reserves the right to provide future warranty coverage only with the proof of proper maintenance.

WHAT IS NOT COVERED

Seamax reserves the right to improve the design of the model without assuming any obligation to modify any trolling

motor previously manufactured. This warranty does not apply to normal worn parts, i.e., worn cables, adjustments, or

product damage due to 1) neglect, lack of maintenance, accident, abnormal operation or improper installation or

service; 2) abuse, i.e. bent metal columns, bent armature shafts, broken control cables, etc., modifications, misuse,

excessive wear or damage caused by an owner’s failure to provide reasonable and necessary installation or care; 3)

use of an accessory or part not authorized by seller; 4) unauthorized alteration or removal of parts; 5) opening the

lower unit (motor) by anyone other than the authorized Service Center. This warranty does not apply to haul‑out,

launch, towing and storage, transportation charges and/or travel time, telephone or rental charges of any type,

inconvenience, loss of time or income, or other consequential damages.

WARRANTY COVERAGE

AC Motor Rotor Parts 2 Years Limited Warranty

Speed Controller System Parts 2 Years Limited Warranty

Water Seal Components Parts 2 Years Limited Warranty

Transom Mount and Tiller Handle Parts 2 Years Limited Warranty

Other Parts Parts 1 Years Limited Warranty

4

LIABILITY FREE CLAUSE

Seamax is not responsible for any damage caused by dropping, crashing, cuts, piercing or other man-made

behaviors; the failure of end-user to follow instruction manual; the ignorance of end-user on SEAMAX warning

information; the misplace of the motors under wet circumstances; or the use of parts or accessories that are not

genuine SEAMAX components.

TERMINATION OF COVERAGE

Warranty coverage may be terminated for repossessed product, or product purchased at auction, from a salvage

yard, from a liquidator, from an insurance company, from unauthorized marine dealers or boat builders, or other third

party entities.

2. GENERAL INFORMATION

BOATER'S RESPONSIBILITIES

Choose a good weather for your outdoor activity. Personal life-jacket is needed at all

time. The operator (driver) is responsible for the correct and safe operation of the boat

and safety of its occupants and general public. It is strongly recommended that each

operator (driver) read and understand this entire manual before operating the trolling

motor. Be sure at least one additional person on board is instructed in the basic

operation of the trolling motor in case the driver is unable to operate the boat.

PROTECTING PEOPLE IN THE WATER

It is very difficult for a person in the water to take quick action to avoid a boat heading

in their direction, even at slow speeds. While in boat trolling, always slow down and

exercise extreme caution any time you are boating in an area where there might be

people in the water. While the boat is stationary, shut off the trolling motor before

allowing people to swim or be in the water near your boat.

A spinning propeller, a moving boat, or any solid device attached to the boat can

cause serious injury or death to swimmers. Stop the trolling motor immediately

whenever anyone in the water is near your boat.

Whenever the boat is in motion, observe the location of all passengers. A sudden reduction in boat speed, or a sharp

change of boat direction, could throw them off the boat. In order to safely enjoy in the waterway, familiarize yourself

with local and other governmental boating regulations and restrictions, and consider the following suggestions.

Use flotation device - It is required by law to have an approved personal flotation device of suitable size for

each person aboard and have it readily accessible.

Do not overload your boat - Most boats are rated and certified for a maximum load (weight) capacities. Refer

to your boat capacity plate. If in doubt, contact the dealer or the boat's manufacturer.

Perform safety check and required maintenance. Follow a regular schedule and ensure all repairs are made

properly.

5

It is required by law that NEVER be under the influence of alcohol or drugs while boating. Alcohol or drug

use impairs your judgment and greatly reduces your ability to react quickly.

Passenger boarding - Stop the trolling motor whenever passengers are boarding or unloading.

Be alert - The operator of the boat is highly recommended to maintain a proper lookout by sight and hearing.

The operator must have an unobstructed view particularly to the front. No passengers, load, or fishing seats

should block the operators view when operating the boat.

Underwater hazard - Reduce speed and proceed with caution whenever navigating in shallow water.

Tripping hazard - To avoid a trip hazard, route all cables and wiring neatly and out of the way.

Report accident - Boat operators are required by law to file a boating accident. Report with their local boating

law enforcement agency when their boat is involved in certain boating accident, such as 1) there is loss of

life or probable loss of life, 2) there is personal injury requiring medical treatment beyond first aid, or 3) there

is a complete loss of the boat. Seek further assistance from local law enforcement for details.

GENERAL PRACTICE

Not suggested to use the main engine battery to power the trolling motor. Use a

dedicated trolling motor battery or battery bank.

Ensure that the batteries are enclosed and secured within a battery box to prevent

accidental shorting of the battery terminals.

Route the trolling motor wires on the opposite side of the boat from other boat wiring.

Connect boat accessories directly to the main engine battery.

Do not charge the trolling motor batteries while the trolling motor is in the deployed

(down) position.

After each use, remove sundries from the propeller and rinse the motor by fresh

water.

CIRCUIT PROTECTION

It is recommended to install a manual reset circuit breaker in line with the electric trolling motor positive leads within

1.8m (72 Inches) of the battery(s). Using a circuit breaker could extend up to 2x times of electric motor’s life time.

Please read the specification for your motor’s circuit breaker standard.

When the propeller is stuck by the weeds, small stones, fishing lines or so forth during the usage of the electric

outboard motor, the circuit breaker cuts off the power automatically to prevent the damage of the electrical parts.

When the circuit breaker cuts off the power, disconnect the battery first, then check and clean any obstacles. At last,

press the reset button on the circuit breaker and reconnect the battery, the electric outboard motor is able to continue

to work.

SPECIFICATIONS

MODEL THRUST / SHAFT

OUTPUT

EQUIVALENCE

NET WEIGHT VOLT / AMP MAX POWER

SMX2HP35 65 Lbs / 35 inch 2HP 14 Lbs 12V / 50A 600W

SMX3HP35 85 Lbs / 35 inch 3HP 15 Lbs 24V / 40A 960W

SMX2HP40 65 Lbs / 40 inch 2HP 16 Lbs 12V / 50A 600W

SMX3HP40 85 Lbs / 40 inch 3HP 17 Lbs 24V / 40A 960W

6

PACKAGE CONTENT

1x trolling motor, propeller, installation kit with spare parts, and user manual

Propeller

Propeller

Wrench

Stainless

Washers

Drive

Pins

Nuts

Jumper

Wire

Sacrificial

Anodes

User

Manual

Unplug the trolling motor after each use, and when charging the battery.

An operating or charging battery produces gas that can ignite and explode,

spraying out sulfuric acid can cause severe burns. Ventilate the area around the

battery and wear protective equipment when handling or servicing batteries.

Performing service or maintenance without first disconnecting the battery can cause

product damage, personal injury, or death due to fire, explosion, electrical shock, or

unexpected motor starting. Always disconnect the battery cables from the battery

before maintaining, servicing, installing, or removing motor components.

Do not allow children to operate the electric outboard motor.

Do not modify the unit in any way or add accessories not intended for this product.

Do not submerse the motor upper-unit controller box. If the unit is accidentally

submersed, disconnect battery right away. The motor needs a full service within 24

hours if suffered such a water damage.

Always disconnect power of the motor when replacing propeller or transport.

To prevent accidental damage of the fiberglass shaft, do not over tighten the

mounting bracket.

Only use this product between the temperatures of -20C to +45C (-4F to +113F).

7

WIRING AND BATTERY

Route the trolling motor wires on the

opposite side of the boat from other

boat wiring. Sensitive electronics, such

as depth finders, should be connected

directly to the main engine battery.

Single battery system requires

separate connection cables.

BATTERY

12V Model: 1x 12V 105AH (Group 27) deep cycle marine battery suggested

24V Model: 2x 12V 105AH (Group 27) deep cycle marine battery suggested

To extend the running time, use a larger capacity battery or an additional battery. As a general rule, deep cycle

batteries with a higher Amp‑hour rating or reserve capacity rating provides a longer run time and better performance.

Do not power any depth sounders or fish finders from the trolling motor battery. Connecting electronic equipment to

the trolling motor batteries can cause electrical interference. Any depth sounders or fish finders must be powered

from the starting engine or accessory battery.

For better overall performance, it is recommended to fully charge the batteries after each use. Disconnect the

batteries from the motor before charging. Frequently charge the batteries to capacity to keep them in good condition.

12V DC

BATTERY

CONNECTION

24V DC

BATTERY

CONNECTION

Black cable (-ve)

from the Motor

Red cable (+ve)

from the Motor

12V DC

DEEP CYCLE

8

The red wire should connect to positive and the black wire should connect to negative. It is recommended to install a

circuit breaker in line with positive lead. The battery should always be kept in a well ventilated location.

USE DEEP CYCLE BATTERY FOR THE MOTOR. IMPROPER USE OF BATTERY

WOULD CAUSE DAMAGE. TURN ALL SWITCHES TO “OFF” BEFORE ATTEMPTING

TO CONNECT TO THE BATTERY.

3. INSTALLATION AND OPERATION

INSTALLING THE PROPELLER

Make sure the motor is disconnected from

the battery before installing or replacing

the propeller.

Use the provided propeller tool for the

installation. Use of inapproiate tool may

damage the motor and propeller.

Insert the drive pin into the shaft hole.

Align the pin with the propeller groove

horizontally. Once the propeller is in place,

install the sacrificial anode, washer, and

nut.

When it is safe, hold the propeller to

prevent it from revolving and use the

propeller tool to tighten the nut. To detach

the propeller, do the steps conversely.

MOUNTING THE MOTOR

Disconnect the motor from the battery

before mounting or dismounting the motor.

Attach the motor’s transom bracket to the

stern of the boat. Align the motor with the

boat’s center line.

Tighten both transom clamps. Do NOT

overtighten the clamps, or the bracket and

clamps may be damaged.

9

TILTING THE MOTOR

Use the mounting bracket’s tilting lever

adjust the shaft angle as needed. When

adjusting the tilt angle of the motor,

NEVER put your hands between the shaft

and the hull.

ADJUSTING THE DEPTH

The depth of the motor can be adjusted

up and down by loosening the adjustable

depth collar tension knob. Set the motor to

the desired depth, then retighten the

tension.

ADJUSTING THE STEERING RESISTANCE

To adjust the steering resistance of your

motor, simply

tighten or loosen the tension

knob. This solid 9-position bracket

features a quick-release lever lock and

reinforced composite material that resists

flexing, warping, and UV damage.

ADJUSTING THE HANDLE

The handle is tiltable and foldable.

Untighten the handle folding knob to

adjust it to a desired angle. The telescopic

handle can be extended up to 15.7 inches

for easy, comfortable, and intuitive

operation of the trolling motor

10

ADJUSTING THE SPEED

The motor is equipped with a stepless

speed controller. Motor stops at Mark

ZERO. Rotate the handle clockwise for

stepless forward speeds. Turn the handle

couterclosewise for backward speeds.

BATTERY INDICATOR

The battery indicator displays the realtime

battery level. Recharge the battery when

its power level is decreased down to 20%.

MAINTENANCE

You must disconnect the battery before maintenance.

Always thoroughly rinse your electric outboard motor with fresh water after every use. Only rinse the areas

that have been in contact with salt water, avoid getting the top cover wet as this may damage the circuitry

inside.

Check behind the propeller after each day for weeds, fishing line or other debris that may get wrapped

behind the propeller.

Lubricate all the pivot points with a non-aerosol lubricant. Never use an aerosol lubricant as many types

contain harmful propellants that causes damage to various parts of your electric motor.

Check tightness of the battery lead connections.

Visually check condition of main battery cables.

Inspect for loose or corroded wiring connections.

Clean terminals with a wire brush and replace any frayed wires. Lack of maintenance may cause excessive

heat and loss of power.

Inspect for tightness of all nuts, bolts and screws.

Recharge batteries after each use. Follow the battery manufacturer’s recommendations for battery

maintenance.

Be sure to choose a well ventilated and dry location when storing the motor for long period. Never leave the

motor outside, as this may cause damaged to the magnet of the driving unit. During freezing temperatures,

when your electric motor is not being used, it should be stored in an area where it will not freeze.

11

4. TROUBLE SHOOTING

During the usage of the electric outboard motor, the propeller is possible to get stuck by weeds, fishing lines or

fishing webs. Sometimes due to the variance of the water depth, the propeller is covered by the silt. If any of those

situations stated above happens, please disconnect the battery in time and clean up the propeller. (Please DO NOT

rise steps and increase the thrust of electric outboard motor to solve the problem, it may cause permanent damages

to the electric outboard motor.)

OPERATION ERROR INDICATION

The motor has an operation indicator function, and it will automatically stop if the following error occurs.

Power indicator is off. The motor does not work. Check and make sure the power cable is well connected.

All power level lights are off. Only red light is on. Motor does not work. Check the battery voltage.

Motor internal voltage protection is on. Motor does not work. Check the battery voltage.

The speed control handle is not at the Neutral position. Turn it to the Neutral, and a “beep” will sound.

A running motor suddenly stops at the current speed. Return the speed control handle to its Neutral position

and start again.

A running motor frequently stops. Check the propeller to make sure no fishing line or weeds blocking it.

Otherwise, it may trigger the high current protection mode.

AUDIO PATTERN

AUDIO

CONDITION

3

b

eep

s

ound

System ready

,

m

otor stand by

Continuous short beep High voltage protection triggered. Low voltage protection triggered. System ready

but speed control handle is not at Netural

Continous quick short beep

Motor running with high

A

mp current condition

Continuous long beep

Motor stops

,

and waits for speed co

ntrol handle back to Netural.

LACK OF POWER

Propeller may be fouled. Remove, clean and replace the propeller.

Battery connections may be corroded.

Battery has low voltage. Check and recharge it.

Battery may be faulty. Check and recharge it.

Bad or faulty connection in boat wiring or electric motor wiring

Permanent magnet cracked or chipped. Motor will whine or grind.

HARD TO STEERING

Check if the steering tension screw is loosened.

Clean the motor shaft and apply lubricant to the fasteners and turning parts.

Make sure the underwater unit is in good condition, and not blocked by any obstacles.

12

MOTOR VIBRATION

Make sure the propeller is in good condition and properly installed.

Inspect the propeller and the drive pin’s condition. Replace it when needed.

Disconnected the battery cable and examine it by turning the propeller manually. The motor should turn

freely with a slight magnetic drag. Internal damage might occur if the motor is blocked or locked. Do NOT

use the motor when it is blocked or locked.

Bent armature. Remove propeller, set at medium speed, turn unit on and check for armature wobble.

MOTOR LOSES ONE OR MORE SPEEDS

Lose wire on rotary switch. Check wiring diagram.

Lose connection in top housing.

Rotary switch damaged.

Speed coils in lower unit may be burned.

RETURN TO SELLER

Domestic buyer can contact the original seller for the motor service. Online buyer can contact Seamax at toll free

support line: 1-877-907-7766 or email [email protected] for all any inquiries.

Pleae do not return the motor to Amazon for warranty claim. We can provide better Service!

IMPORTED & DISTRIBUTED BY:

USA: Seamax Marine USA Corp.

Canada: Seamax Marine and Outdoor International Inc.

www.seamaxmarine.com 604-277-7766

This manual suits for next models

4

Table of contents

Other Seamax Engine manuals

Popular Engine manuals by other brands

Vetus

Vetus BOW PRO Thruster BOWA0902 installation instructions

Briggs & Stratton

Briggs & Stratton Fource 21100 Operating and maintenance instructions

Briggs & Stratton

Briggs & Stratton 440000 Professional Series Operating & maintenance instructions

Leroy-Somer

Leroy-Somer X20 AC GEARLESS Installation and Maintenance

MINN KOTA

MINN KOTA Riptide 80 ST quick start guide

WinGD

WinGD WARTSILA RT-flex58T-E Maintenance manual