6

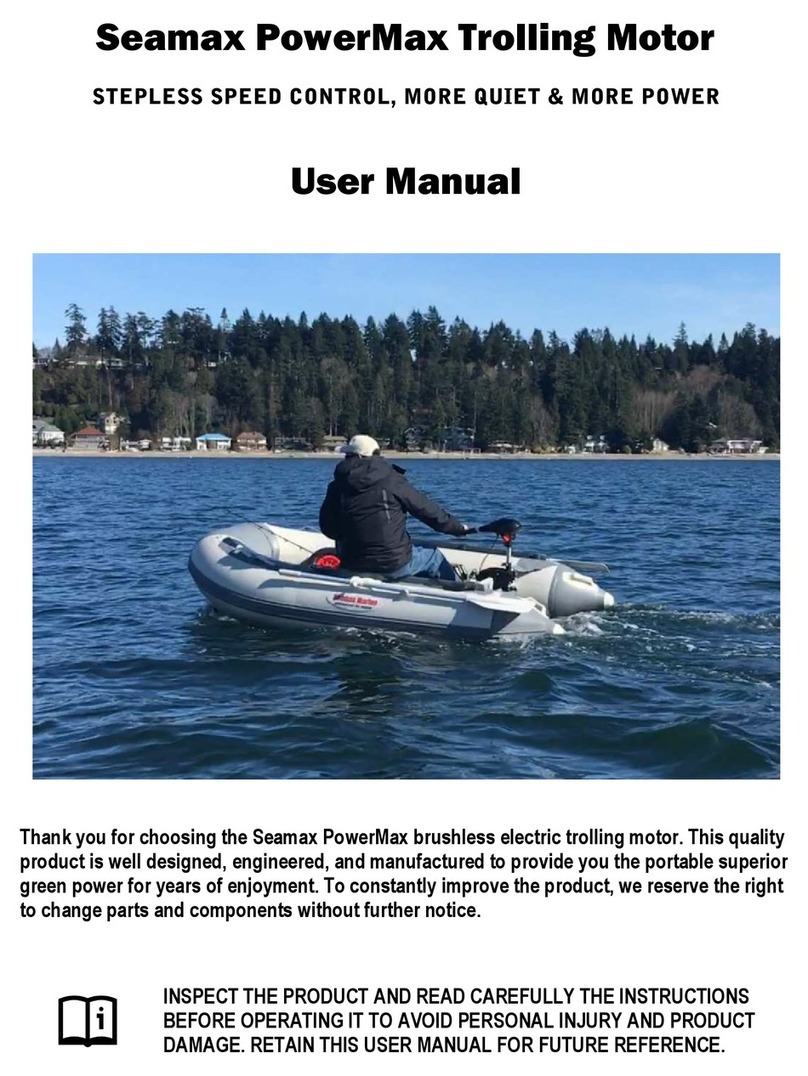

A spinning propeller, a moving boat, or any solid device attached to the boat can

cause serious injury or death to swimmers. Stop the trolling motor immediately

whenever anyone in the water is near your boat.

Whenever the boat is in motion, observe the location of all passengers. A sudden reduction in boat speed, such as a

sharp change of boat direction, could throw them off the boat. In order to safely enjoy the waterways, familiarize

yourself with local and other governmental boating regulations and restrictions, and consider the following

suggestions.

▪Use flotation devices. It is the law to have an approved personal flotation device of suitable size for each

person aboard and have it readily accessible.

▪Do not overload your boat. Most boats are rated and certified for maximum load (weight) capacities, refer to

your boat capacity plate. If in doubt, contact your dealer or the boat's manufacturer.

▪Perform safety checks and required maintenance. Follow a regular schedule and ensure all repairs are made

properly.

▪Never be under the influence of alcohol or drugs while boating (it is the law). Alcohol or drug use impairs

your judgment and greatly reduces your ability to react quickly.

▪Passenger boarding. Stop the trolling motor whenever passengers are boarding or unloading.

▪Be alert. The operator of the boat is responsible by law to maintain a proper lookout by sight and hearing.

The operator must have an unobstructed view particularly to the front. No passengers, load, or fishing seats

should block the operators view when operating the boat.

▪Underwater hazards. Reduce speed and proceed with caution whenever navigating in shallow water.

▪Tripping hazards. To avoid a trip hazard, route all cables and wiring neatly and out of the way.

▪Report accidents. Boat operators are required by law to file a Boating Accident. Report with their state

boating law enforcement agency when their boat is involved in certain boating accidents. A boating accident

must be reported if 1) there is loss of life or probable loss of life, 2) there is personal injury requiring medical

treatment beyond first aid, 3) there is damage to boats or other property where the damage value exceeds

$500.00 or 4) there is complete loss of the boat. Seek further assistance from local law enforcement.

GENERAL PRACTICE

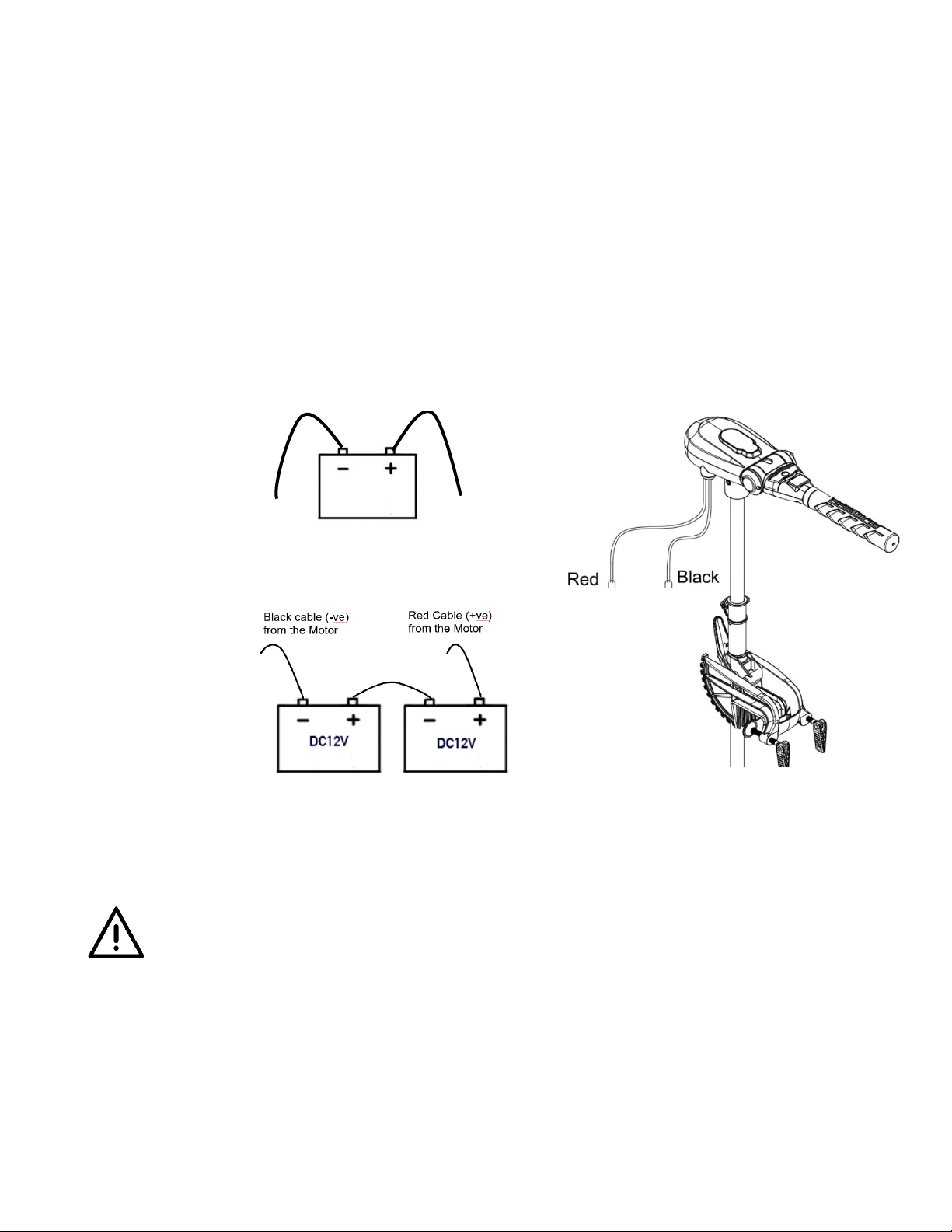

▪Not suggest to use the main engine battery to power the trolling motor. Use a

dedicated trolling motor battery or battery bank.

▪Ensure that the batteries are enclosed and secured within a battery box to prevent

accidental shorting of the battery terminals.

▪Route the trolling motor wires on the opposite side of the boat from other boat wiring.

▪Connect boat accessories directly to the main engine battery.

▪Do not charge the trolling motor batteries while the trolling motor is in the deployed

(down) position.

▪After each use, remove sundries from the propeller and rinse the motor by fresh

water.

CIRCUIT PROTECTION

It is recommended to install a manual reset circuit breaker in line with the electric trolling motor positive leads within

1.8m (72 Inches) of the battery(s). Using a circuit breaker could extend up to 2x times of electric motor’s life time.

Please read the spec sheet for your motor’s circuit breaker standard.

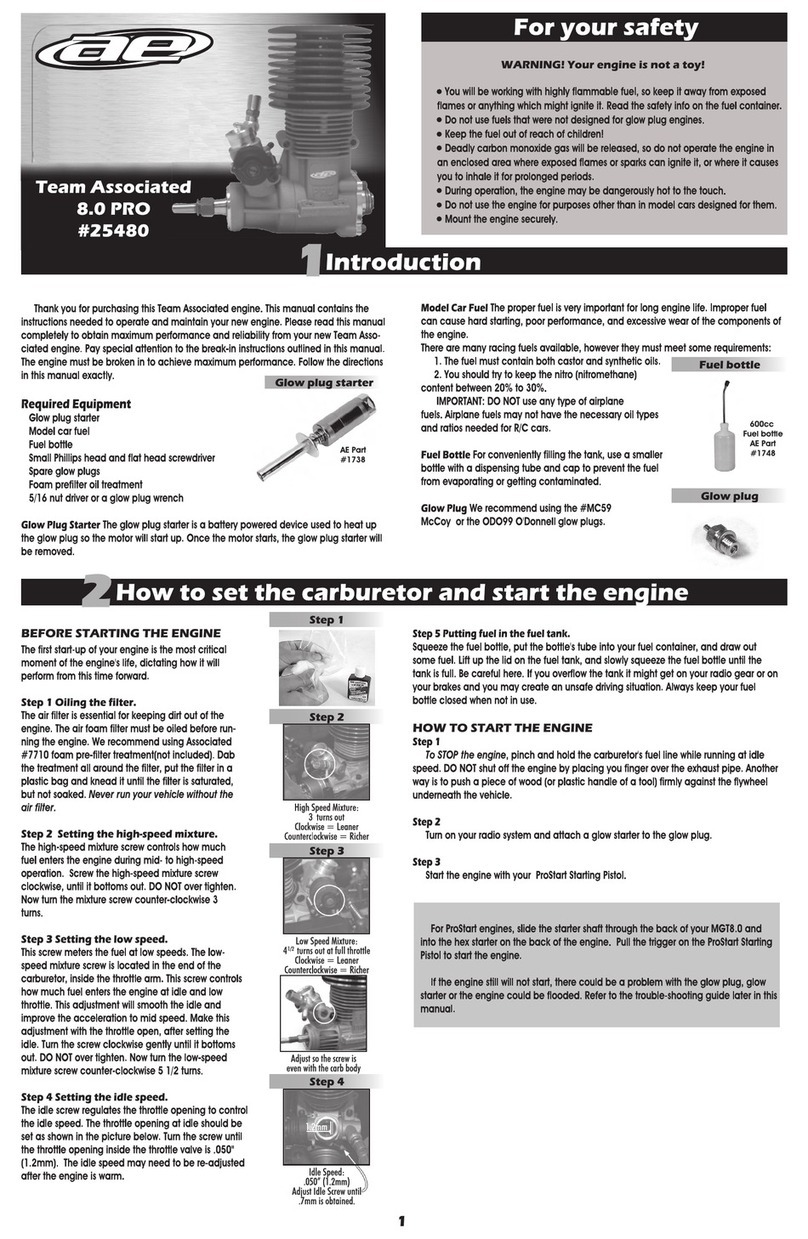

During the usage of the electric outboard motor, when the propeller is stuck by the weeds, small stones, fishing lines

or so forth, the circuit breaker will cut off the power automatically to prevent the damage of the electrical parts.