Seametrics FT500 Series User manual

PUB -19501-0796

Page 1 of 4

SpecificationsGeneral Information

The FT500 flow computer provides rate and total flow

display, as well as additional output features. It is de-

signed for use with SeaMetrics meters, as well as many

other meters which provide a pulse-type output. Flow

rate and total are alternately shown, in user-selectable

units, on a large alphanumeric LCD display. The accu-

mulated total can be reset with a series of keystrokes.

High-flow and low-flow alarm setpoints are a standard

feature. The relay outputs of these alarms can be used

to operate a warning device such as an autodialer, or to

shut off critical equipment, such as a pump. The stan-

dard programmable pulse output is useful for metering

pump proportional feed or telemetry.

An optional analog output (0-10 V or 4-20 mA) is easily

field-calibrated. Zero and span are front-panel pro-

grammed in flow units.

The FT500 comes in a weathertight enclosure with a

hinged clear cover over the membrane front panel. Ter-

minal acccess is simplified by a separate cover. Both

12 VDC and 115 VAC versions are available.

Power 115 VAC or 12-16 VDC

(optional), 4 watts max

Temperature 32°- 130°F (0°- 55°C)

Humidity 85% non-condensing relative

Enclosure Polystyrene (NEMA 4X with

conduit connection option)

Outputs Two form C SPDT relay 120

VAC 5 A max.

Max Pulse Output 100 mA at 60 VDC (100ms)

Memory Type Battery-backed RAM

(10 year retention)

Sensor Power 12-16 VDC, 50 mA

Totalizer 8 digit (resettable)

Rate Display 5 digit (0-99999)

Engineering Units 1000 gal., cubic mtr., cubic ft.,

Imp. gal., gal., liters, 0.1 gal.,

fluid oz., cubic in., and mm.

Analog Output Optional 0-10 VDC or 4-20

mA 8-bit resolution, 500 ohm

max load

Sensor Input Max. current 25 mA at 12

VDC, Max. frequency 500 hz

Shipping Weight 5 lbs.

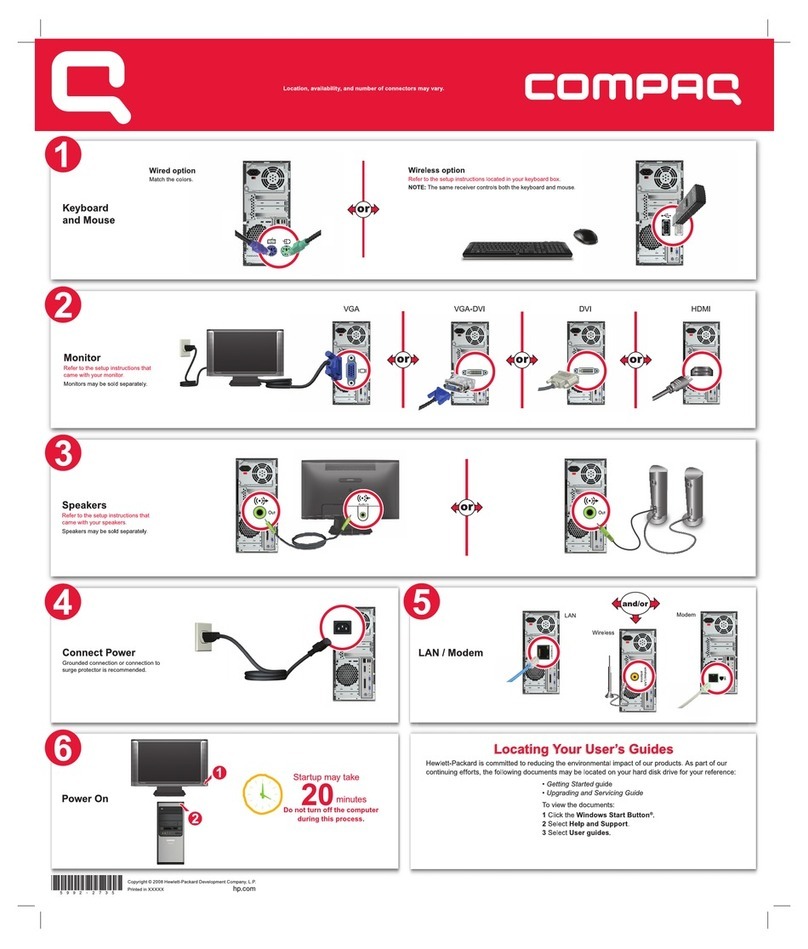

FT500 Flow Computer

Instructions

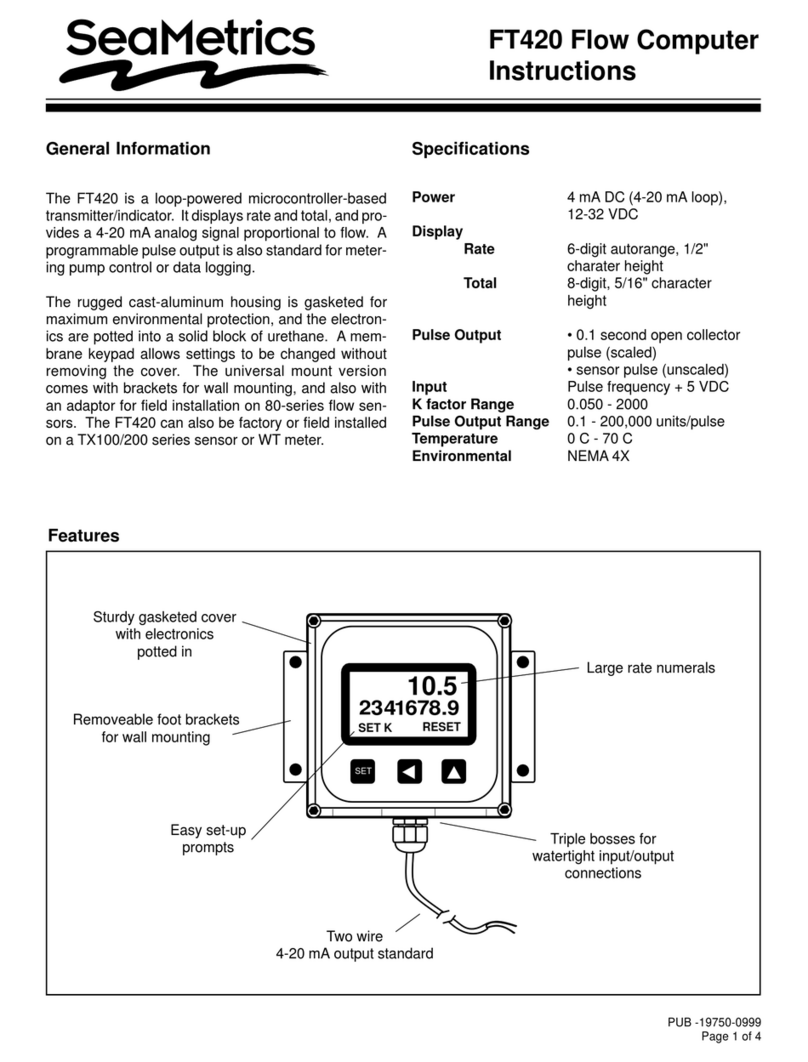

Terminal cover

removes for

easy access

High/Low flow

alarm indicators

(correspond to relays) Automatic recalculation

of units

Large, alphanumeric

display

Hinged door cover

for protection

Press to select

displayed function

Decrease

setting value

Back to

previous display

Forward to

next display

Increase setting value

FT500

FLOW COMPUTER

Installation

Caution: The FT500 like any

other electronic control can

suffer failure. If failure of the

unit could result in personal

injury or property damage,

safeguards must be installed to prevent such

injury or damage.

!

!

Caution: Always disconnect

power to the unit before open-

ing the terminal cover. Do not

reconnect power until all con-

nections have been made and

the terminal cover has been replaced.

Mounting. The FT500 enclosure can be mounted to

any secure surface with three screws. Drive the center

screw first, leaving the head protruding slightly from the

surface. Locate the center mounting lug on the back of

the control, and slide it over the shaft of the screw. Re-

move the terminal cover to expose the other two holes.

Insert screws through them and tighten.

Connections.

All connections are made with the lower terminal cover

removed. Follow the connection diagram or the termi-

nal markings on the board(s) to make connections.

Connect the meter first, then the outputs, and the power

last. Leave the other end of any outputs disconnected

until output programming is completed, since they may

activate unexpectedly and unpredictably when the un-

programmed unit is powered up.

Meter Input. Note that either powered (3-wire, typically

with Hall-effect sensors) or unpowered (2-wire, reed

switch) meters can be connected by following the con-

nections diagram. The strain relief provided with the

meter can be used with most types of meter cable. If

the FT500 is equipped with a SeaMetrics 3-pin connec-

tor, a SeaMetrics meter with mating connector can be

plugged in with no additional connection.

Pulse Output. This open-collector transistor output is

useful for proportional feed using an electronic metering

pump, for telemetry, or for remote indication. Follow the

diagram, noting the proper polarity. Cables are avail-

able from SeaMetrics for specific metering pumps, if re-

quired.

Flow Alarm Outputs. If you are using the high-flow or

low-flow alarms, connect to the K1 or K2 relay termi-

nals, following the diagram. The relays energize when

their respective flow rate setpoints are reached. You

can use the normally-open contacts (they close when

thesetpointisreached)ornormally-closedcontacts(they

open when the setpoint is reached).

Analog Output. If the optional analog board has been

specified, it will be present on the right hand side of the

terminal compartment. There are two sets of terminals

on the board, one pair for 4-20 mA and one pair for 0-10

V. The board is factory-configured for one output or the

other, and is marked accordingly in the appropriate box.

Connect following the diagram. Note that the standard

internal power source for the 4-20 mA current loop will

drive up to a 500 Ohms load. If your load exceeds this

amount, it is necessary to connect an external power

source in series to drive it.

Programming

Run/Program Key. Pressing this key switches back

and forth between RUN and PROGRAM. Normal op-

erationisinRUN. ChangestosettingsaremadeinPRO-

GRAM.

Arrow Keys. Either key may be used at any time. The

forward key brings up the next display, and the back

arrow returns to the last one.

Increase/Decrease (▲/ ) Keys. Any setting which is

being displayed is increased by the (▲) key and de-

creased by the ( ) key. The longer a key is held down,

the faster the setting changes. If the desired setting is

overshot, use the other key to go back to it.

Select Key (*). When this key is pressed it selects the

option displayed. For example, pressing this key when

the display reads “ * for OUTPUT change” brings up the

first of the output settings.

!

Caution: When the control is

powered up, relay or analog

outputs may be present. If this

could be a hazard, wait to make

external connections until pro-

gramming is complete.

2 of 4

▲

▲

Displays

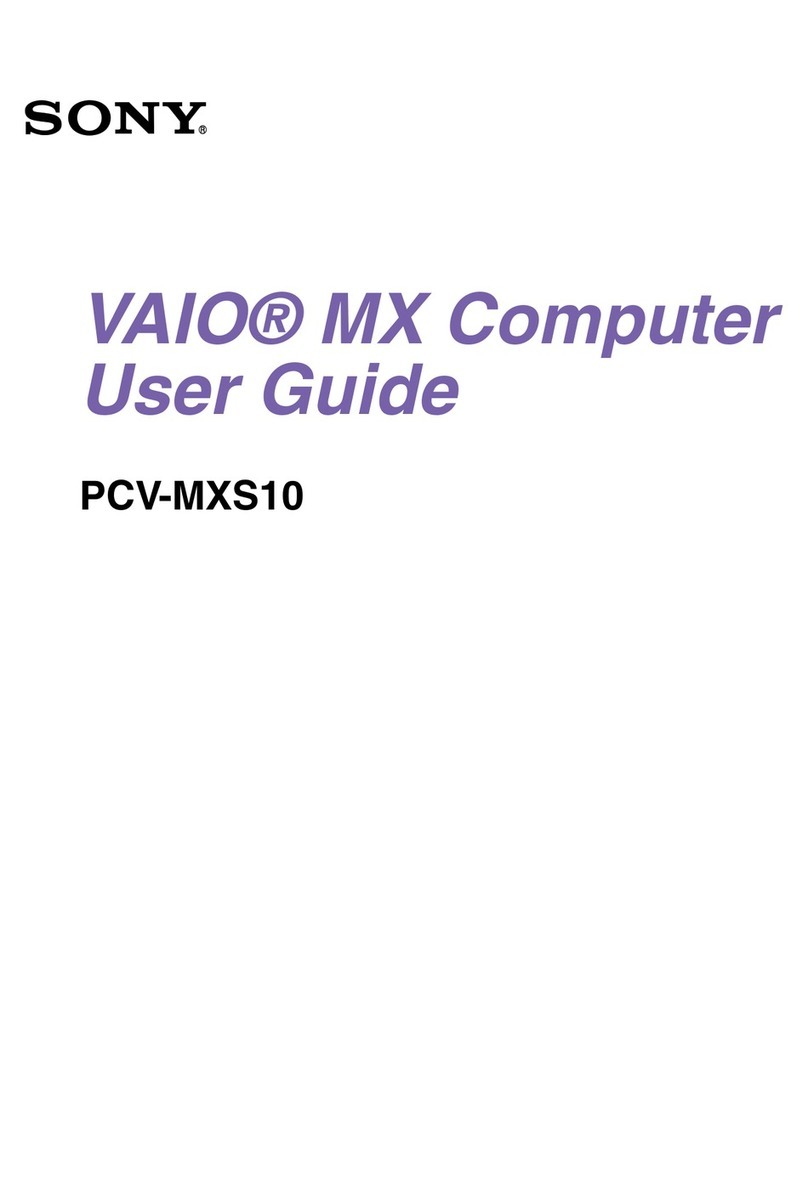

Connections

GND

+12VDC

POWER SUPPLY INPUT

- (BLACK)

+ (RED)

GND (BLACK)

INPUT SIGNAL (WHITE)

+12VDC {RED}

}

}

}

TO FLOW METER

SCALED OUTPUT PULSE

TO METERING PUMP

N.O.

COMMON

N.C.

N.O.

COMMON

N.C.

K1 RELAY

LOW FLOW

ALARM

{

{

K2 RELAY

HIGH FLOW

ALARM

FOR REED SWITCH TYPE METERS

USE GND AND INPUT TERMINALS ONLY

CHART RECORDER -

CHART RECORDER +

CHART RECORDER -

CHART RECORDER +

0-10 VDC

OUTPUT 4-20mA

OUTPUT

NOTE: OUTPUT TYPE IS FACTORY SET

CONSULT FACTORY TO CHANGE

N.O.

COMMON

N.C.

N.O.

COMMON

N.C.

K1 RELAY

LOW FLOW

ALARM

{

{

{

{

{

K2 RELAY

HIGH FLOW

ALARM

110 VAC

INPUT NEUTRAL

HOT

GND

GND

INPUT

+12 VDC

GND

+ OUTPUT

TO FLOW METER

FOR REED SWITCH TYPE METERS

USE INPUT AND GND TERMINALS ONLY

SCALED OUTPUT PULSE

TO METERING PUMP

Optional 12-18 VDC Power

Standard 110 VAC Power

Optional Analog Output

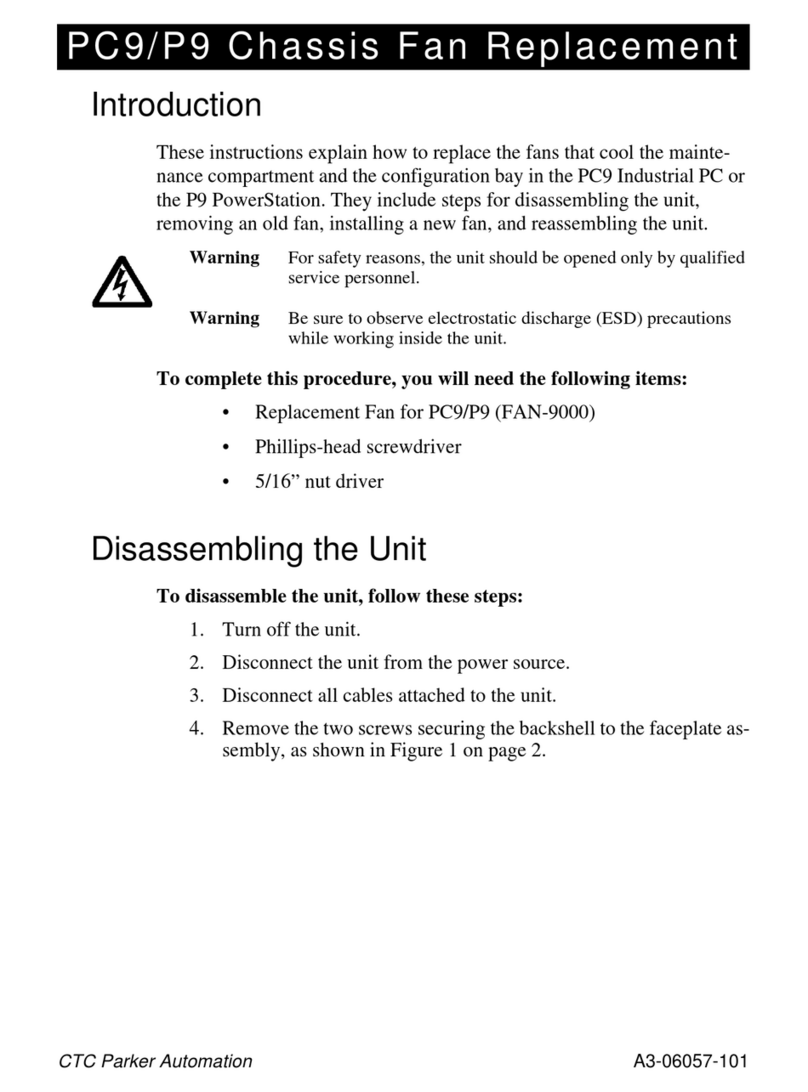

RATE 1234 GPM

TOTAL 12345678 GAL

RESETS TOTAL

AND UPDATES UNITS

UNITS = GALLONS/MIN

Dsply Contrast = 14

for 4-20ma change

K Factor 1.000 UPDATE TIME=1000ms

HI ALM 195 GPM

LO ALM 97 GPM

10 Gals. / Pulse

4mA 0 GPM

20mA 195 GPM

RUN

PROGRAM

for METER change for UPDATE change

When in PROGRAM the “ ” and “ ”

keys add or subtract from the

value displayed

The 4-20ma display only appears if

the optional AC10 board is installed.

for OUTPUT change

TO RESET TOTAL

Note:

Note:

3 of 4

Total. Theaccumulated total isshown up to99,999,999

units. To reset to zero, press the select (*) key while

total is showing on the display. Then press ( ) as in-

structed to reset.

High/Low Alarm. Whenever flow exceeds the “HI”

setpoint, an up arrow appears on the Rate display and

the appropriate relay energizes. When flow drops be-

low the “LO” setppoint, a down arrow appears and the

matching relay energizes.

Analog Output. If this option is installed, the 4-20 mA

or 0-10 V signal varies continuously with the flow, be-

tween the two programmed endpoints.

Maintenance and Repair

Repair. The circuit boards of the FT500 are not de-

signed for field repair. If the unit fails for any reason

other than a blown fuse or lack of power, it is generally

advisable to contact the distributor through whom the

unit was purchased. The distributor or factory can gen-

erally repair and return the unit quickly, for a flat fee re-

pair. Any returns to SeaMetrics must be accompanied

by an RMA (returned material authorization) number.

FrontPanelRemoval. Thefrontpanelmustberemoved

to change a fuse, or to add an analog or other acces-

sory board. To remove it, open the front (clear) cover.

Remove the two screws on the left side and the two hex

standoffs on the right. Gently loosen the panel and lift it

out. The main (display) board is attached and will come

out with the panel. This exposes the fuses, which are

on the power supply board.

Fuses. The power supply and the pulse output circuit

have fuse protection. The two fuses are on the power

supply board. If it is necessary to replace a fuse, use a

1/2AmpAGC, readily available from auto parts or elec-

tronic supply stores.

Units Setting. This determines which flow rate and

volume units will be displayed. Pressing the ▲key

changestolargerunits,andpressingthe keychanges

to smaller ones. The largest unit is 1,000 gallons, and

the smallest is milliliters.

Meter Setting. Select this setting to set the

K-factor

.

This is the number of pulses per gallon which the meter

produces. For SeaMetrics meters, this number is either

on a tag (80-Series IP, S-Series, M-Series, WTTurbine)

or in a chart for the particular pipe size (100/200-Series

IP). For other meters, it may be given as a meter factor

or as a “pulse rate”, in pulses per gallon.

Update Setting. This determines the interval at which

the flow rate display is updated. It can be set anywhere

fromone to 2,000milliseconds. Typically 1,000 to2,000

is the best range. Longer intervals stabilize the display

byaveragingmorepulses,butalsodecrease the respon-

siveness to fast fluctuations. This setting applies to rate

only, and does not effect total.

Output Settings. There are three output settings:

LO ALARM is the low-flow setpoint. When flow drops

below this setting, the LO relay energizes and a down

arrow appears in the Rate display.

HIALARMis the high-flowsetpoint. When flow exceeds

this setting, the HI relay energizes and an up arrow ap-

pears in the Rate display.

PULSEOUTPUT controls the ratio, in units perpulse, of

the open-collector transistor pulse output.

Analog Settings. This choice only appears if the op-

tionalAC10 analog output board has been installed, ei-

ther in the factory or the field. The two settings are:

4 mA = ( set in flow rate units, for example, 0 GPM)

20 mA = (again, set in units, for example, 200 GPM)

Display Contrast Setting. A number between 1 and

14 controls the contrast of the LCD display. The best

setting depends on location (high or low on the wall)

and lighting (indoor or outdoor) but typically a number

between 10 and 14 gives the best results.

Operation

Rate Display. Flow rate is displayed in the selected

units. If units are changed at any point, all of the set-

tings will recalculate themselves into the new units. To-

tal will remain in the previous units, however, until it is

reset to zero.

20419 80thAve. So., Kent WA. 98032 USA

Phone: 206-872-0284 Fax: 206-872-0285

4 of 4

▲▲

Other manuals for FT500 Series

1

Other Seametrics Desktop manuals