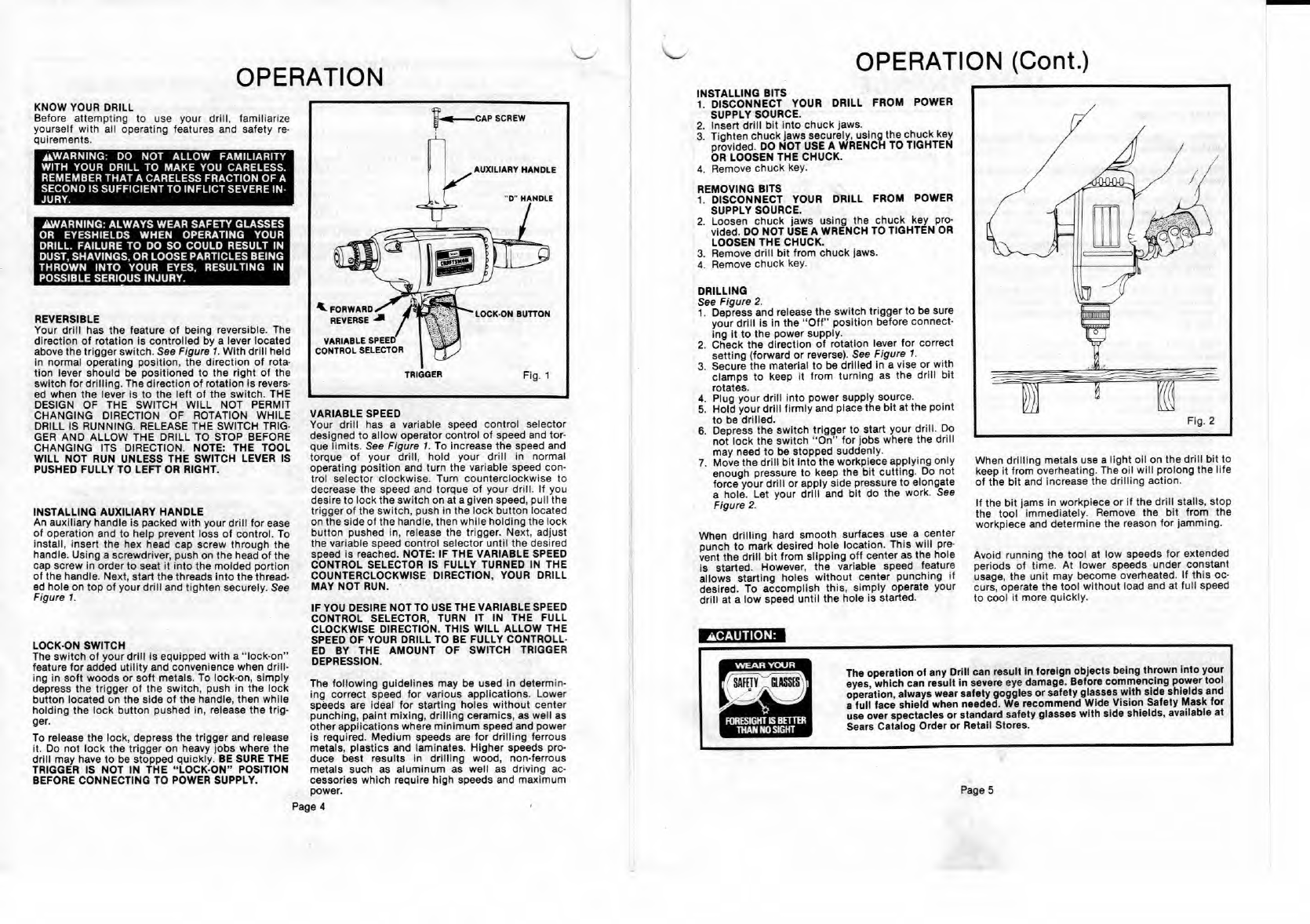

TRIGGER

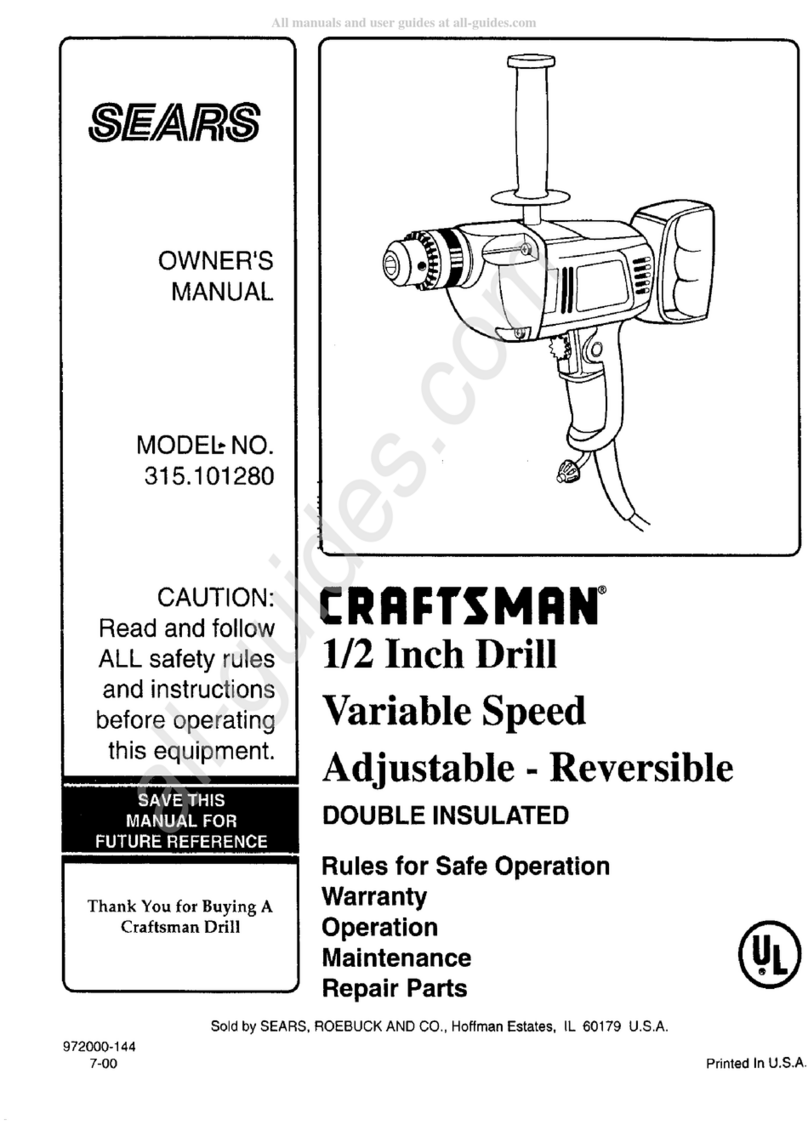

Fig. 1

..-CAP

SCREW

A

lL

FORWARD

REVERSE -

VARIABLE SPEED

CONTROL SELECTOR

AUXILIARY HANDLE

'0' HANDLE

LOCK-ON BUTTON

The operation of any Drill can result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before commencing power tool

operation, always wear safety goggles or safety glasses with Side shields and

a full face shield when needed. We recommend Wide Vision Safety Mask for

use over spectacles or standard safety glasses with side shields, available at

Sears Catalog Order or Retail Stores.

ACAUTION:

Page 5

OPERATION

OPERATION (Cont.)

KNOW YOUR DRILL

Before attempting to use your drill, familiarize

yourself with all operating features and safety re-

quirements.

WARNING: DO NOT ALLOW FAMILIARITY

WITH YOUR DRILL TO

MAKE

YOU CARELESS.

REMEMBER

THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT

SEVEREIN-

JURY.

WARNING: ALWAYS WEAR SAFETY GLASSES

OR EYESHIELDS WHEN OPERATING YOUR

DRILL. FAILURE TO DO SO COULD RESULT IN

DUST, SHAVINGS, OR LOOSE PARTICLES BEING

THROWN INTO YOUR EYES, RESULTING IN

POSSIBLE SERIOUS INJURY.

REVERSIBLE

Your drill has the feature of being reversible. The

direction of rotation is controlled by a lever located

above the trigger switch.

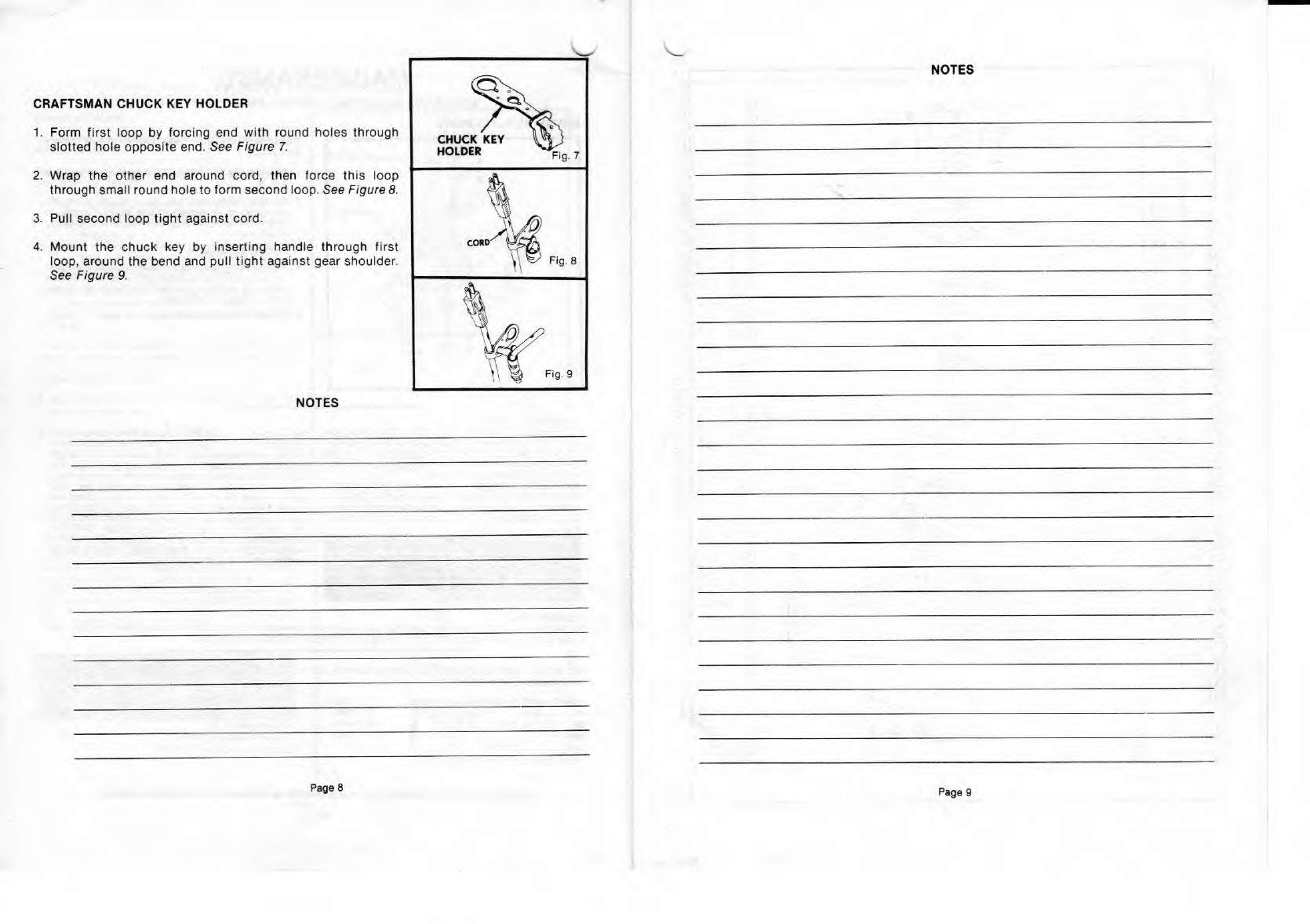

See Figure 1.

With drill held

in normal operating position, the direction of rota-

lion lever should be positioned to the right of the

switch for drilling. The direction of rotation is revers-

ed when the lever is to the left of the switch. THE

DESIGN OF THE SWITCH WILL NOT PERMIT

CHANGING DIRECTION OF ROTATION WHILE

DRILL IS RUNNING. RELEASE THE SWITCH TRIG-

GER AND ALLOW THE DRILL TO STOP BEFORE

CHANGING ITS DIRECTION. NOTE: THE TOOL

WILL NOT RUN UNLESS THE SWITCH LEVER IS

PUSHED FULLY TO LEFT OR RIGHT.

INSTALLING AUXILIARY HANDLE

An auxiliary handle is packed with your drill for ease

of operation and to help prevent loss of control. To

install, insert the hex head cap screw through the

handle. Using a screwdriver, push on the head of the

cap screw in order to seat it Into the molded portion

of the handle. Next, start the threads into the thread-

ed hole on top of your drill and tighten securely. See

Figure 1.

LOCK-ON SWITCH

The switch of your drill is equipped with a lock-on'

feature for added utility and convenience when drill-

ing in soft woods or soft metals. To lock-on, simply

depress the trigger of the switch, push in the lock

button located on the side of the handle, then while

holding the lock button pushed in, release the trig-

ger.

To release the lock, depress the trigger and release

it. Do not lock the trigger on heavy jobs where the

drill may have to be stopped quickly.

BE

SURE THE

TRIGGER IS NOT IN THE "LOCK-ON" POSITION

BEFORE CONNECTING TO POWER SUPPLY.

VARIABLE SPEED

Your drill has a variable speed control selector

designed to allow operator control of speed and tor-

que limits.

See Figure 1.

To increase the speed and

torque of your drill, hold your drill in normal

operating position and turn the variable speed con-

trol selector clockwise. Turn counterclockwise to

decrease the speed and torque of your drill. If you

desire to lock the switch on at a given speed, pull the

trigger of the switch, push in the lock button located

on the side of the handle, then while holding the lock

button pushed in, release the trigger. Next, adjust

the variable speed control selector until the desired

speed is reached. NOTE: IF THE VARIABLE SPEED

CONTROL SELECTOR IS FULLY TURNED IN THE

COUNTERCLOCKWISE DIRECTION, YOUR DRILL

MAY NOT RUN.

IF YOU DESIRE NOTTO USETHE VARIABLE SPEED

CONTROL SELECTOR, TURN IT IN THE FULL

CLOCKWISE DIRECTION. THIS WILL ALLOW THE

SPEED

OF YOUR DRILL TO BE FULLY CONTROLL-

ED BY THE AMOUNT OF SWITCH TRIGGER

DEPRESSION.

INSTALLING BITS

1.

DISCONNECT YOUR DRILL FROM POWER

SUPPLY SOURCE.

2.

Insert drill bit into chuck jaws.

3.

Tighten chuck jaws securely, using the chuck key

provided.

DO NOT USE A WRENCH

TO TIGHTEN

OR LOOSEN THE CHUCK.

4.

Remove chuck key.

REMOVING BITS

1.

DISCONNECT YOUR DRILL FROM POWER

SUPPLY SOURCE.

2.

Loosen chuck jaws using the chuck key pro-

vided.

DO NOT USE A WRENCH

TO TIGHTEN OR

LOOSEN THE CHUCK.

3.

Remove drill bit from chock jaws.

4.

Remove chuck key.

DRILLING

See Figure

2.

1.

Depress and release the switch trigger to be sure

your drill is in the "Off' position before connect-

ing it to the power supply.

2.

Check the direction of rotation lever for correct

setting (forward or reverse).

See Figure 1.

3.

Secure the material to be drilled in a vise or with

clamps to keep it from turning as the drill bit

rotates.

4.

Plug your drill into power supply source.

5.

Hold your drill firmly and place the bit at the point

to be drilled.

6.

Depress the switch trigger to start your drill. Do

not lock the switch "On" for jobs where the drill

may need to be stopped suddenly.

7.

Move the drill bit into the workplace applying only

enough pressure to keep the bit cutting. Do not

force your drill or apply side pressure to elongate

a hole. Let your drill and bit do the work.

See

Figure 2.

When drilling hard smooth surfaces use a center

punch to mark desired hole location. This will pre-

vent the drill bit from slipping off center as the hole

is started. However, the variable speed feature

allows starting holes without center punching if

desired. To accomplish this, simply operate your

drill at a low speed until the hole is started.

When

When drilling metals use a light oil on the drill bit to

keep it from overheating. The oil will prolong the life

of the bit and increase the drilling action.

If the bit

tams

in workpiece or if the drill stalls, stop

the tool immediately. Remove the bit from the

workplace and determine the reason for lamming.

Avoid running the tool at low speeds for extended

periods of time. At lower speeds under constant

usage, the unit may become overheated. If this oc-

curs, operate the tool without load and at full speed

to cool it more quickly.

The following guidelines may be used in determin-

ing correct speed for various applications. Lower

speeds are ideal for starting holes without center

punching, paint mixing, drilling ceramics, as well as

other applications where minimum speed and power

is required. Medium speeds are for drilling ferrous

metals, plastics and laminates. Higher speeds pro-

duce best results in drilling wood, non-ferrous

metals such as aluminum as well as driving ac-

cessories which require high speeds and maximum

power.

Page