Seawind 1000XL2 User manual

Owners Handbook 1

Seawind 1000XL2

Owners Manual

November 2013

Owners Handbook 2

TOPIC Page

INDEX 2

INTRODUCTION 3

SPECIFICATIONS 4

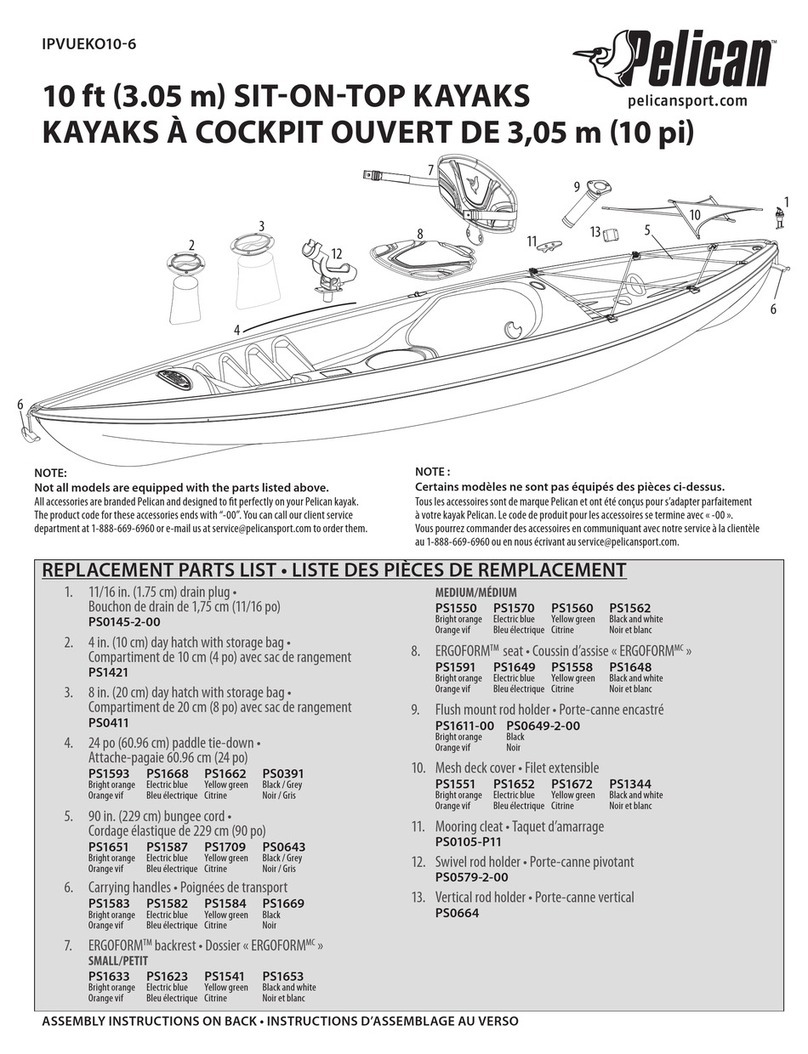

EXTERIOR 5

INTERIOR 6

MAST, BOOM, RIGGING 6

PLUMBING 8

SEA WATER SYSTEM 9

LP GAS & WATER HEATER 10

ANTIFOULING 12

DECK AND DECK HARDWARE 13

FUEL TANKS 14

MOTORS 14

ELECTRICAL 15

REFRIGERATION 17

SLIPPING 21

ANCHORING 22

INSTRUMENTATION 23

NOTES ON SAILING 25

SAIL PLAN 27

CONCLUSION 28

WARRANTY POLICY 29

WARRANTY NOTIFICATION FORM

Owners Handbook 3

INTRODUCTION:

Dear Seawind Owner:

You have just received delivery of your new Seawind 1000XL2. We would like to

thank you for showing confidence in our product by choosing a Seawind. We are

sure you will enjoy your boat for many years to come.

The Seawind family is made to last. For your boat to perform reliably, it is of utmost

importance that a careful maintenance program is followed. This will benefit you in

the form of safety, as well as protecting your investment and other waterway users.

Your Seawind dealer is at your disposal to give you help and sound advice for all

aspects of maintenance. Nevertheless, you are the “captain of your ship”. The sea

must never be underestimated. It must be taken seriously at all times.

You and only you, are responsible for checking and regularly maintaining the

condition of your boat, including all of its equipment and by practicing the rules of

good seamanship always.

This handbook is provided as a guide. While it does not cover every item, it will go

a long way toward making ownership of your new Seawind 1000 an exciting and

pleasurable experience.

Many years of happy sailing!

Seawind Catamarans.

Revision 2.04

Owners Handbook 4

SPECIFICATIONS:

LOA 10.86 mtrs 35’ 7”

LWL 10.66 mtrs 32’ 4”

BEAM OA 5.91 mtrs 19’ 5”

BEAM CL - CL 4.62 mtrs 15’ 2”

BEAM DWL 1.08 mtrs 3’ 6”

DISPLACEMENT 4,300 kgs 9 479 lbs

DRAFT 0.93 mtrs 3’

UNDERWING CLEARANCE 0.75 mtrs 2’ 5”

HEADROOM IN HULLS 1.93 mtrs 6’ 4”

MAST HEIGHT ABOVE WATER 16.00 mtrs 52’ 6”

WATER TANK CAPACITY 400 litres 106 usgal

FUEL TANK CAPACITY (2 TANKS) 120 litres 31.7 usgal

SULLAGE TANK 130 litres 34.3 usgal

GREY WATER TANK 62 litres 16.4 usgal

Owners Handbook 5

EXTERIOR MAINTENANCE:

1. GELCOAT: Your Seawind 1000XL2 gelcoat is a polyester gelcoat known as

“Isothalic NPG Gelcoat”. It has been chosen for its very high performing properties

of water resistance, UV resistance and colourfastness.

Maintenance: Like all finishes, your Seawinds’s gelcoat will suffer over time from

the harsh properties of the sun and its UV rays. All gelcoats will oxidise and fade

under constant severe sun. However, an easy maintenance program will give good

protection and ensure that your gelcoat will give many years of beautiful finish.

(a) Regularly wash down the boat to remove salt. A build up of salt crystals will

magnify the rays of the sun and intensify the heat.

(b) Polish the decks and topsides every 3 to 4 months using a non-cutting polish

with wax.

(c) Repair any gelcoat chips immediately. This can be done using any polyester or

epoxy gelcoat repair kit.

2. STAINLESS STEEL: The bow and stern rails, stanchions and Targa

Bar are all constructed from Marine Grade 316 Stainless Steel and hand finished.

All external fastenings (bolts, nuts & washers) are also Grade 316 Stainless Steel.

Maintenance: To maintain a high shine on your stainless steel, wipe over regularly

(every 3 to 4 months) with a non abrasive chrome or stainless polish or metal wax

preferably containing Oxalic acid.

Despite our endeavors to always use the best marine grade stainless steel on your

boat, some stainless will always have a higher percentage of ferrous metal and rust

staining can occur. Most polishes will remove any rust or water stains as well as

leave a durable protective coating.

3. SOLAR PANELS: The Solar Panels require regular cleaning to maintain good

output efficiency. Dirt smears or bird droppings will significantly affect the

amperage output.

4. AFT SEATS: The aft seats are slatted teak finished with “Akzo Nobel, Cetol”.

This combination provides a durable, hard-wearing finish. Depending on the

exposure to sun, rain and general wear, the seats should be inspected on a regular

basis and re-coated with Cetol as necessary. For a thorough refinish – sand down

to raw timber – apply three coats of Cetol.

5. WINDOWS:

The side windows on hull and hardtop of your Seawind1000 are made from 6mm

grey tint toughened glass. The hardtop front opening windows are 10mm grey tint

toughened glass. These can be cleaned using general purpose glass cleaner.

6. WATER INGRESSION:

On some occasions, such as hull stress from heavy weather, water ingression may

occur. These should not occur but are mostly due to a single cause such as Silastic

seal being broken around a bolt or screw. Use a water hose to identify the cause

which will most likely be a problem fastening. Retract and reseal with Silastic.

Warning: Do not tighten all fastenings in the vicinity as this will generally

cause more seals to be broken.

Owners Handbook 6

INTERIOR:

The interior of your Seawind 1000XL2 is a blend of timber with modern lightweight

materials and fabrics. General household cleaners and detergents can be used

throughout.

Timberwork - The interior timberwork is coated with two-pack polyurethane 60%

sheen to give a tough, sheen gloss surface. The only maintenance required is a

regular wipe down with a damp cloth. The occasional use of a good furniture polish

will also help to keep the timber looking its best.

Benchtops - The benchtops are made from scratch resistant Laminex. These can

be cleaned by non abrasive household cleaners.

Galley cupboard doors - These are made from acrylic and are transparent. Any

solvents or harsh detergents must not be used, as they will permanently mark the

doors.

Fabrics - The fabrics in your Seawind 1000 vary from boat to boat. When cleaning

these materials, general household fabric cleaners should be used. It is advisable to

first try any new cleaner on a small patch of material that will not be noticed should

the cleaner mark the fabric.

MAST, BOOM AND RIGGING:

General

The rig on your Seawind 1000XL2 is designed to be efficient and easily handled by

one person. It features a roller furling headsail and single line slab reef mainsail

with lazy jacks and boom cover.

All Yacht Spars manufactured the mast using their own extrusion that has been

anodized. It is a single spreader nested diamond rig arrangement that is stepped

on a hinged mast base allowing the mast to be lowered on the boat. Each mast is

fitted with one 2:1 (53m) main halyard 8mm and (31m) jib halyard made from 10mm

Spectra, one (33m) spinnaker halyard made from 10mm Double Braid rope and a

8mm (35m) double braid topping lift.

The mainsail features full-length fiberglass battens with adjustable end caps and

optional roller bearing batten cars.

The standing rigging consists of a forestay and side stays - both 3/8 (10mm) 1 x 19

wire, and diamonds - 5/16 (8mm) 1 x 19 wire. When your boat was first launched

the mast was stepped and the rig was adjusted to the correct tension. During the

first month or so of sailing however the wire rigging will stretch a small amount. This

is quite normal and any slack can be taken out by simply tightening up the

turnbuckles (ensure tension is balanced).

Rig Tension

The rigging must be examined a month or so after the initial launch. After this

period of sailing, the wires will have stretched & will require re-tensioning & tuning.

After this initial “bedding down” period, the mast wires should not change too much

and examination on a six monthly basis should be sufficient.

Owners Handbook 7

The outer diamond wires control the mast pre-bend aft and ensure that it cannot

bend sideways. The mast is initially set up with approximately 235mm of pre-bend

(ie the mast has a gentle bend along its length so that at mid-length it has an aft

bend of approximately 235mm from an imaginary straight line between each end of

the mast). This is achieved through tensioning the outer diamond wires with the

forward spreader wires completely loose. With the correct pre-bend achieved,

tighten the inner diamond wires until they are firm (these do not need to be as tight

as the outers as they are not used to induce pre-bend. Now adjust the lowers until

the mast bend has been reduced to approximately 115mm. At this stage, the

diamond wires should be very tight. (“guitar string” tight).

Having the mast properly set up you now need to look at the stay tension. The

forestay length has been determined to allow the mast to have an aft rake of

approx. 400mm (15 inches). This means that the mast-head will be further aft than

the mast foot by 400mm. Next tighten the side stays on both sides. These should

feel tight but without over-tensioning. Achieve this by firstly hand tightening and

then, using a wrench, further tighten four full turns or until they feel firm. Do not over

tighten, as all you will do is bend the actual boat. A good guide as to whether the

correct tension has been achieved, is to try to move the stay with your hand at

approximately shoulder height from the deck. You should be able to move the stay

through a circle with a 75mm (3”) diameter (but no more).

Now go sailing. The correct rig tension for the Seawind 1000XL2 can best be tested

with the boat at sea. In a reasonable sail to windward (say, in 15 knots or more),

the lee stay will slacken. This is normal & acceptable. However, it should only go

slack & not “flop” around. If it does “flop” around – tighten it to take out the slack

(count the number of turns). Tack and take up the same amount on the opposite

side so as to balance the tension on each side.

Once you have completed all the above steps, the rig should be well set up &

should not need adjusting again. However, one last check is worthwhile. When

sailing hard to windward (say in 20 knots), go to the base of the mast & look up its

length. It should be perfectly straight in its side-ways plane all the way up until the

jib halyard exit. Above this point, the mast is unsupported & it is normal that this top

part will fall away to leeward. In a fore & aft plane, the mast will be bending slightly

aft but not pumping.

Owners Handbook 8

PLUMBING:

Owners Handbook 9

The Fresh Water System.

The diagram included with this section will allow you to identify the main areas and

components of the Seawind 1000XL2 fresh water system.

The water tank is located under the forward seating in the central cockpit and has a

capacity of 400 litres. The tanks are integrated into the hull structure and feature

smooth surface on the inside to eliminate any fiberglass taste. The tank is filled via

the screw-on filler cap located at the base of the mast and marked “WATER”. The

tank is fitted with an overflow vent to allow air to escape whilst filling the tank.

When the tank is full, excess water will flow out of this vent.

•The water can be sterilised before use with Choloramine tablets (obtainable

from a Chemist).

•Do not fill the water tank with a hose that fits too tightly into the filler opening or

with too much hose pressure. Doing either of these may cause high pressure

within the tank and damage to the tank or its fittings.

•Ensure that the hose and your hands are clean before filling the tank. Be aware

that only very minor contamination in the tank will spoil the fresh water taste.

If the water system has been unused over an extended period of time, it may be

advisable to flush the system with fresh water a number of times before re-use.

Choloramine tablets may also be used.

The fresh water system supplies the following :

- galley sink

- shower and wash basin in heads

- transom shower

The sink and wash basin drain directly overboard. Survey vessels have a grey

water holding tank. There are no shut-off valves on these outlets because they are

well above the waterline.

SEA WATER SYSTEM:

Heads

The manual or electric toilet installed is of high marine standard and should give

years of trouble free use if used properly and according to instructions. The toilet is

flushed using salt-water supplied by a 3/4” hose leading from under the waterline

and able to be closed off with a 1/4 turn levered ball valve. The valve is open to the

sea when the 1/4 turn handle is in line with the pipe and closed when it is at right

angles.

•Always ensure that both the salt-water inlet valve and the waste outlet valve are

open before use.

•With each use, pump the manual toilet 15 to 20 times to ensure all waste matter

has been thoroughly cleared through the outlet hose. With an electric toilet

press the flush control button more than once if necessary. This is especially

important prior to leaving the boat after use. If solid waste remains in the pipe it

will dry out over time and cause blockage of the pipe.

•At regular intervals, rinse the heads system through with fresh water.

•Regularly inspect the inlet and outlet valves and to ensure that these work

smoothly grease lightly with waterproof grease. It is good seamanship to keep

wooden bungs of the right size (shaped like cones) at hand so that they can be

used to plug the inlet or outlet in the event of a valve failure.

Owners Handbook 10

Sullage Holding Tank

All new SW1000XL2’s have a 130 liter (34.3 usgal) sullage tank built into the port

hull transom above the water line. All sullage from the toilet goes directly to the

holding tank. A Y-valve on the holding tank discharge may be set to “deck” for deck

pump or “sea” for gravity flow to sea. The Y valve should normally be set to “sea”.

The sea discharge has a further stop valve to hold the sullage while in harbor or

restricted marine area. The sea discharge stop valve may be opened in an

unrestricted discharge area to flow to the sea. These valves are located through the

hatch in the compartment behind the toilet.

Grey Water Tank

All SW1000XL2 built to Survey Option from 2005 have a 62L(16.4G) Grey Water

Tank built under the port main bunk. All Galley, Shower and Vanity grey water is

pumped to this tank by operating the drain switch. To drain the Shower the plug

must be in the vanity basin. A Y-Valve under the tank selects Deck or Direct

discharge of the waste water.

Bilge Pumps

The portable manual bilge pump on a Seawind 1000XL2 is stored under the port

seat of the cockpit dinette.

Boats operating under charter are fitted with an additional pump in each hull. The

port hull pump is located in the companion way and handle under main bunk. The

starboard pump is located in the forward galley area and handle in the waste

cupboard. Regular inspection of the pumps is advised to ensure that they are in

good order. In an emergency situation these pumps are among the most important

equipment onboard your boat and should be maintained properly.

L.P. GAS & WATER HEATER:

The L.P.(Liquid Propane) Gas system in your Seawind 1000XL2 has been installed

by a licensed L.P. Gas fitter and a compliance certificate issued. A metal

compliance plate is riveted onto the rear beam as a permanent certificate. This

plate identifies the date of fitting and the licensed fitter who installed the system.

There is a 4.5 kg bottle located each side of the Targa Bar under the teak seats.

These can be removed for re-filling by simply loosening the nut and bolt and lifting

the bottle of its base plate.

After using any L.P. Gas appliance, shut-off the supply by turning the in-line tap to

90° to the direction of the line. When leaving your boat it is advisable to turn off the

L.P. Gas supply at the bottle as well.

For boats fitted with a gas Hot Water System – there is a fan that will switch on

whenever the fresh water pump is activated. The purpose of this fan is to provide

positive pressure in the hot water compartment – thus improving the flueing of

combustion gasses.

We strongly recommend that a licensed L.P. Gas professional regularly checks the

system. Certain countries have their own specific regulations and maintenance

procedures. It is important that you familiarise yourself with these procedures.

Owners Handbook 11

Please note that L.P.Gas can be an extremely dangerous substance if not properly

installed and maintained.

Water Heater

The optional Bosh LPG Hot Water System is installed behind the panel in the port

bathroom. To operate turn on the gas at the LPG Bottle on the transom, at the

optional remote solenoid switch in the galley and at the ball valve behind the Bosh

LPG Heater itself. To light and operate the Gas Heater, Please refer to the Bosch

Operating Instructions on the following two pages.

Bosch Gas Water Operating Instructions

Owners Handbook 12

Owners Handbook 13

ANTIFOULING BOTTOM PAINT:

Prior to its first launching, your Seawind 1000XL2 was prepared for antifouling as

follows:

1. Gelcoat was sanded to remove all traces of mould release wax and to provide a

good key for the next coating.

2. One coat of Epoxy Resin.

3. Two coats of Altex No.5 ablative antifouling bottom paint.

The first antifouling coat is blue and second black so usage may be observed for

your area in the first year of operation.

Maintenance:

The bottom paint on your Seawind 1000XL2 is an ablative-type anti-fouling. This

means that the protective coat slowly dissolves as the boat sits in the water,

therefore excessive scrubbing is not required and will only shorten the life span of

your anti-foul. Under normal conditions you can expect 9 to 15 months before new

anti-foul needs to be applied. When your boat is on the slipway you should use the

opportunity to check the rudder bearings, skin fittings and general condition of the

underwater sections of the hulls. When re-applying the antifouling follow the

manufacturers instructions or if in doubt consult a professional shipwright or boat-

builder.

DECK AND DECK HARDWARE:

All deck hardware is bolted through the deck using 316 grade stainless steel bolts.

The hardware is then either tapped into aluminum backing pads or fastened using

316 stainless washers and nyloc nuts. The sealant “Sikaflex” has been used under

all fittings to prevent water leaks. Access to the washers and nuts can be made via

the various removable headlining panels. Any areas that are not accessible,

hardware has been tapped and can be removed without needing to access the

underside of the deck.

Most items of deck hardware are under significant loads and maintenance is

important. Any fittings that are damaged or become loose should be immediately

fixed or replaced. Loose or damaged deck fittings will be significantly weakened and

could break under load. If in doubt, consult a professional yacht rigger or shipwright.

Maintenance:

•Frequently scrub down decks with fresh water and a gentle liquid detergent to

remove built up dirt and salt from deck fittings. Use a soft bristled dish washing

brush to get into hard to reach areas.

•After fresh water washing and allowing to dry, lubricate any moving parts with a

silicon based lubricant such as “Ronstan Sailfast”. This applies to pulley blocks,

traveller cars, and rope jammers, rigging screws.

•Frequently check all deck fittings to ensure that they are fixed firmly to the deck

and that there are no water leaks. Fittings with any movement whatsoever must

be immediately attended to. Tightening up the bolts holding the fitting can do

this.

Owners Handbook 14

Winches:

The primary winches are on the Seawind 1000XL2 are a pair of Harken ST40.2’s.

These are two speed, self tailing winches used primarily for the headsail sheets and

all halyards.

•The winches will gradually get stiffer to use after prolonged use. This is because

of salt and dirt build-up within the winch and because of hardening of the internal

grease. At least once a year, winches must be thoroughly cleaned inside and

re-greased.

•When dismantling a winch or any deck fitting, have a bowl close at hand to put

parts into. A good practice is to circle the area with a rolled towel as a barrier to

stop any dropped parts rolling overboard. Be especially careful when

dismantling the winch as it contains small springs that, when released, can fly

overboard.

FUEL TANKS:

There are two separate fuel tanks, each of 50 liter capacity. The tanks are

constructed from marine grade aluminum and pressure tested prior to installation to

meet Australian survey standards.

The fuel tanks are located in the central pod and are accessed through the two

opening hatches under the central cockpit table.

Each tank provides fuel to one engine only:

Forward fuel tank - Port motor

Aft fuel tank - Starboard motor

NOTE: When re-fuelling, ensure that the engines are switched off and that there are

no naked flames (including cigarettes) on the boat. Ensure that the galley stove is

not in use.

MOTORS:

A pair of 4-stroke outboard motors powers the Seawind 1000XL2. These high

thrust Yamaha 9.9 provide reliable, quiet propulsion. The engines are either locked

down or tilted up clear of the water by hydraulic rams. These rams are controlled by

momentary switches at the starboard helm.

Fuel filters are located inside each engine well and should be checked on a regular

basis to ensure that there are no blockages or leaks that could starve the motors of

fuel.

It is recommended that you check the tightness of the nuts on the engine mounts

that clamp onto the bulkheads – these will, over a period of time, require checking

and tightening. Ensure that the tightened nuts do NOT interfere with the engine

raising and lowering action.

The motors should be maintained and serviced as per the manufacturers

instructions found in the owner’s handbook.

Owners Handbook 15

ELECTRICAL:

The Seawind 1000XL2 has a 12 volt DC electrical system. Power is supplied from

three 105Ah batteries. These provide power to start the engines, as well as running

all the electrical appliances and instruments.

The batteries on your Seawind 1000XL2 are setup as two separate banks. Two

batteries under the ‘HOUSE’ bank and one engine cranking battery under the

‘START’ bank. If the house bank runs flat or extra power is required the

‘EMERGANGY PARRALLEL’ can be used to join all 3 batteries together to form one

singular bank.

The batteries are located in the battery lockers behind the front seat of the saloon

dinette. Batteries are charged by the 2 x 125W or 175W solar panels mounted on

the targa and by the motors when they are running. Batteries are also charged by

optional charger that is mounted in starboard side locker.

NOTE: The Yamaha 9.9 Outboards only contribute around 6Amps each at full

power and can not be voltage regulated. If all batteries are fully charged with

prolonged motoring the battery banks can be overcharged and worse case acid

electrolyte lost through boiling. In this exceptional circumstance turn on additional

cabin lights while the motors are running to discharge excess current.

The house battery switch can be off but the engine battery switch must be on when

leaving the boat. This allows the VSR to engage and charge both batteries.

NOTE: When using the optional electric anchor winch it is essential that the motors

are running so as to provide additional charging capacity to the batteries. Also it is

advisable to only run the winch continuously for no more than 15 seconds – give it a

break for 30 seconds then run again for 15 seconds if required (depending on how

much chain is out). Doing this, will increase the life of the solenoid.

Owners Handbook 16

Owners Handbook 17

REFRIGERATION:

The Seawind 1000XL2 is fitted with a refrigerator/freezer two compartment ICEER

105 electric eutectic unit.

NOTE: When switched on, the fan will run at varying speeds as well as

stopping and starting. This is normal operation.

NOTE: There are no operation controls i.e. thermostat. Cabinet temperature is

controlled by the electronic ICEER control system. Because EUTECTIC fluid is

employed in ICEER fridges, the initial first cycle will be longer (up to 16 hours).

CARE AND CLEANING

Defrosting

At least once a year, or when the frost layer exceeds 3mm (1/8”):

(1) Switch off power.

(2) Remove frozen food and drawers, wrap food in a blanket or newspaper to

prevent thawing.

(3) Tip a container of warm water in to the freezer. The ice will start thawing which

will enable most of it to be removed by gently scraping with a soft plastic

or rubber spatula. Collecting the ice in a bowl while it is still solid will speed

up the defrosting process.

(4) Melted ice should be mopped up with a clean cloth or sponge. Use the

opportunity to clean the cabinet interior.

(5) When defrosting and cleaning are complete, dry thoroughly, switch power on

and replace food.

Cleaning

To maintain freshness and hygiene, the inside of the freezer should be washed

periodically. Use lukewarm water to which a little baking soda has been added

(1 teaspoonful to 1 litre water). Always rinse using a cloth dipped in clean warm water.

Thoroughly dry all surfaces.

Door seals and the surface in contact with the door opening should be cleaned

with warm water and then dried. After drying wipe all around.

WARNING

DO NOT clean interior with abrasive, scented or soapy materials.

DO NOT use car cleaning or household wax or polishes on the interior.

DO NOT use sun lamps, radiators or fan heaters to defrost or dry any part of the

freezer interior or exterior.

Owners Handbook 18

Out of Use

It is desirable to keep your freezer in use throughout the year. However if is

necessary to shut the unit down, use the following important steps:

(1) Turn off power.

(2) Open the door.

(3) Empty and then thoroughly clean the interior.

(4) Leave the door open until the unit is required back in service.

Failure to observe the above may cause the interior to smell and mildew to

form.

GETTING THE BEST USE OF YOUR FREEZER

(1) If frost builds up to 3mm (1/8”) thick, defrost your freezer.

(2) Before turning on power, ensure that the interior of the freezer is completely

dry.

(3) Avoid overloading the freezer at one time.

(4) For the best results, tightly wrap items such as fish, meat and poultry in correct

freezer packing material eg freezer bags, plastic wrap etc. Ensure that all air is

removed from the package to prevent the food from drying out during storage.

(5) Small packages of food freeze and defrost more rapidly, therefore if possible

food should be packaged in meal size portions.

Owners Handbook 19

Troubleshooting

Green light not on

NO Is motor running NO Check power to fridge and wires

into on off switch

YES Try bridging terminals 7& 8 on terminal strip

YES green light faulty check voltage at danfoss controller

If no success return ICEER grey controller fo

repair

Motor running NO Bridge terminals T & C on danfoss controller Motor runs

YES YES return ICEER

grey controller for

repair

NO Try replacement

danfoss controller

Runs 10 min only and turns YES bridge terminals 5 & 6

off yellow light now on

Retest if it runs past 10 min replace

thermistor on suction line. If it still turns off

return ICEER controller for repair

NO

Leave running

after 30 min note if fan is NO

cycling

YES

Check fan can spin freely NO

YES

Is Condenser hot 47 degrees C NO

YES

Fan body is not twisted in

motor bay stopping fan or

loose wire jamming blades

Low on gas or blocked

capillary note current draw

should be low also might

be too lower motor speed

Disconnect fan wires and check directly across 12 v

dc

supply if okay reconnect fan now bridge terminals 1

&2 does fan go

Contact ICEER for further

action

YES

Replace thermistor on

condenser

NO

Return ICEER grey controller for repair

Put thermometer in empty freezer against wall away from fridge and monitor

maximum and minimum temperatures

Note freezer temperature should fall at about 4 degrees an hour untill eutectic point

where it will slow untill unit turns off expect 16 hrs for full pull down time

Freezer Temperatures should be about -11 maximum when motor starts

new cycle and pull down to -14 ~ -16 minimum degree C at end of cycle

Fridges temperatures should be about 1 maximum when motor starts

new cycle and pull down to -2 ~ -4 minimum degree C at end of cycle

To warm

Possible causes

(1) Ventilation blocked

(2) Condenser fan setting to high

(3) Suction thermistor turning off too soon

(4) Motor speed too low

To Cold

Possible causes

(1) Condenser fan setting to low

(2) Suction thermistor not turning off

(3) Low on gas 134A 100 gram

SLIPPING:

The diagrams below should be used as a reference when slipping the

Seawind 1000XL2.

The weight of the boat should be supported on its long keels. In addition to

this, props can be positioned near the bow and stern to ensure the boat does

not rock fore and aft. Care should be taken to ensure that the outboards (if

left down) and rudders do not make contact with cradle or any other object

likely to damage them.

SEAWIND 1000XL

3666

1883

5152

1487

965 540

Figure 1 Seawind 1000XL2 Slipping Diagram

Table of contents

Other Seawind Boat manuals

Popular Boat manuals by other brands

Regal

Regal 42 Fly-Grande Coupe owner's manual

Bavaria

Bavaria Cruiser 33 owner's manual

Cobalt Digital Inc

Cobalt Digital Inc 26SD owner's manual

Bancroft

Bancroft Focus II Assembly and operating manual

Pro-Line Boats

Pro-Line Boats 2012 23 Express owner's manual

Cobalt Digital Inc

Cobalt Digital Inc 220S owner's manual