Tayana 37 Manual

Chapter I

OPERATIONS

AND

MAINTENANCE

MANUAL

Chapter 1

I-1

TAYANA 37

OPERATIONS

AND

MAINTENANCE

MANUAL

Originally prepared by Southern Offshore Yachts.

Converted to digital format by Harvey J. Karten August 1998. Current update: 1/10/02

Many thanks to Ed Potter, Tom Beard and Mauro Migliorelli

I-2

TABLE OF CONTENTS

I. INTRODUCTION .

II. SPECIFICATIONS

II-A. General Design Specifications

II-B. Serial Numbers

II-C. Materials

II-D. Construction

II-E. Importer's Documents

II-F. Procedures & Data For Documentation .

III. COMMISSIONING AND DECOMMISSIONING

III-A. Initial Commissioning

III-B. Owner Commissioning

III-C. Decommissioning for Storage

III-D. Recommissioning After Lay-Up

IV. OPERATING PROCEDURES

IV-A. Sailing The Tayana 37 Cutter

IV-B. Sailing The Tayana 37 Ketch

IV-C. Tuning The Spars And Rigging

IV-D. Tuning Under Sail

IV-E. Handling Under Power

IV-F. Fuel System

IV-G. Electrical Systems

IV-H. The Plumbing Systems

I-3

V. MAINTENANCE & MAINTENANCE PROCEDURES

V-A. The Hull

V-B. The Deck And Cabin Top

V-C. Interior Woodwork

V-D. Spars, Rigging, And Sails

V-E. Auxiliary Engines & Related Systems

V-F. Electrical Systems

V-G. Plumbing and Sanitation Systems

LIST OF ILLUSTRATIONS AND TABLES

Drawing

Tayana 37 Cutter Sail Plan

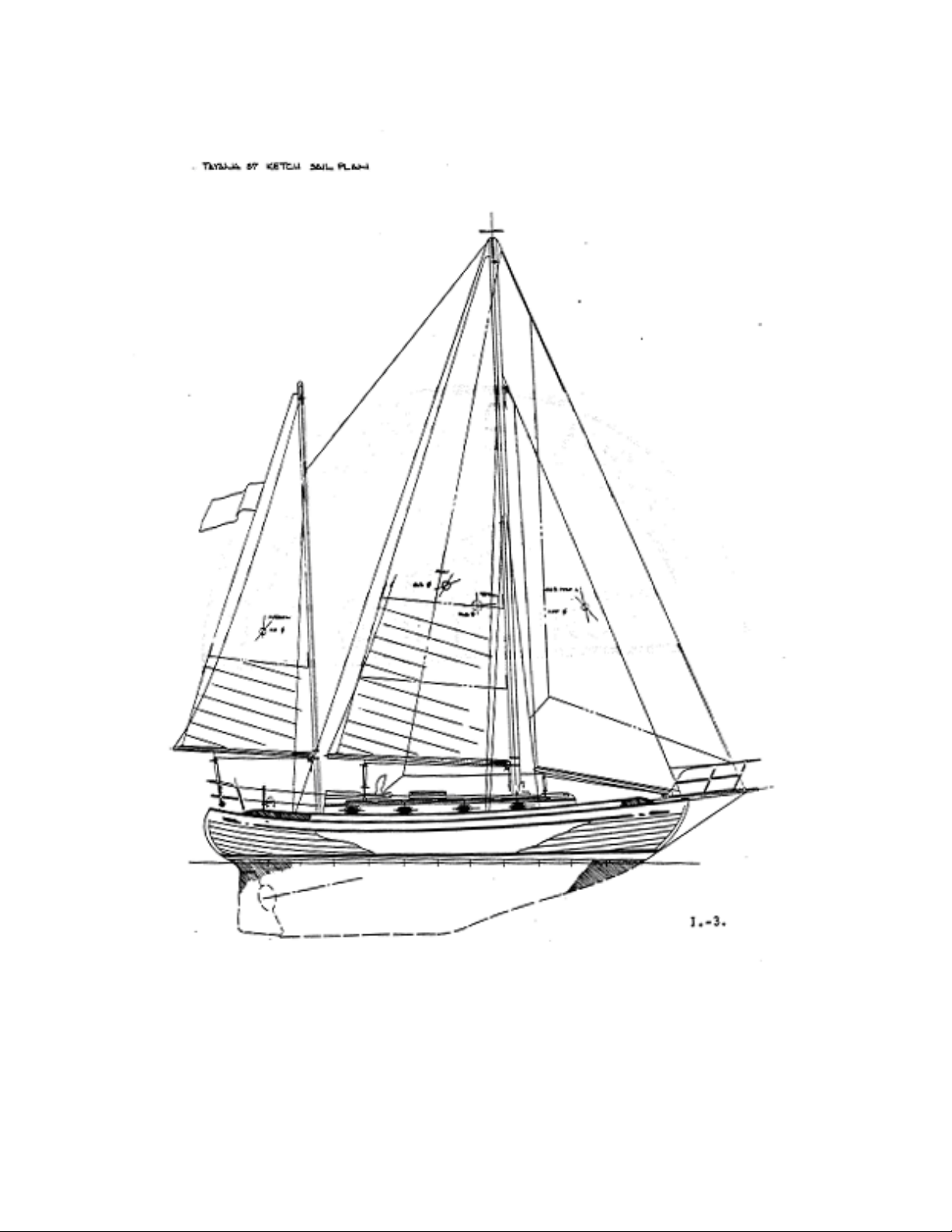

Tayana 37 Ketch Sail Plan

Tayana 37 Deck Plan

Tables

ELECTRICAL SYSTEMS/The Energy Audit System

(Table IV.-1)

ELECTRICAL SYSTEMS/The 12 Volt System

(Electric Wire Number & color Codes-Table V.-1.)

Figure

CONSTRUCTION. Thiokol Joints (Figure II.-l.)

FUEL SYSTEM - (Figure IV.-1.)

FRESH HOT AND COLD WATER SYSTEM - (Figure

IV.-2.)

AUXILIARY ENGINES/Installation

Exhaust And Engine Mounting -(Figure V.-1.)

ELECTRICAL SYSTEMS/The 12 Volt D.C. System

(Figure V.-2.)

PLUMBING AND SANITATION SYSTEMS/Bilge Pumping

Systems - (Figure V.3.)

I-4

ANNEX I ............................................................................................... Winch Assemblies

ANNEX II.............................................................................................. Warranty

ANNEX III ............................................................................................ Miscellaneous Info

PHRF Rating

Rigging (P, I, J and E Values) of Cutter

Fuel Tank Depth vs. Volume

I-5

INTRODUCTION

You are to be congratulated on your selection of the TAYANA 37 cruising yacht. There is

no better yacht in her size range on the market. With care and proper maintenance she will

not only prove to be an excellent investment, she will take you cruising anywhere in the

world safely and comfortably. This is being proven almost daily. Ocean crossings by

TAYANA 37's are routine. Circumnavigations have been reported. By the same token, over

100 of these yachts are the primary homes of their owners.

The object of this handbook is to help you to know your yacht and to guide you in

providing proper care and maintenance. And really, it isn't very hard- in fact, it can be a lot

of fun. Your TAYANA 37 has been designed and built with maintenance in mind.

Machinery, pumps, glands, seacocks, etc. have been installed to insure full and easy access.

Where simplicity and adequate function do not conflict, the simpler equipment has been

chosen. In a few cases, custom interiors have complicated some equipment installations, but

you will find that adequate access and straight-forward installation have alleviated the

potential for problems.

In the various sections which follow, you will find discussions of materials and

construction, hull maintenance, rigging and sails, machinery-electrical systems and

plumbing. But remember, this is a TAYANA 37 manual. It is not a general maintenance

manual. It is not designed to take the place of your manufacturer's equipment manuals. In

fact, should you find conflicts between this manual and that published by the manufacturer

of any piece of equipment, the manufacturer's recommendations should be followed.

I-6

I-7

I-10

I-11

BARIENT WINCH #22

WINCH ASSEMBLY

I-12

Volume in Fuel Tank in Bow of older Tayana 37 as a function of height of fuel in tank. As

the tank is shaped in the form of a polyhedron, the exact relationship of fuel level to total

volume is non-linear and difficult to assess. Based on data provided by Tom Beard in TOG

News.

Fuel Tayana 37 Bow Tank

0

5

10

15

20

25

0 102030405060708090100

Gallons

Depth

II-1

Chapter II SPECIFICATIONS ...............................................................................................II-1

A. General Design Specifications......................................................................................II-1

B. Serial Numbers...............................................................................................................II-2

C. MATERIALS ................................................................................................................II-4

D. CONSTRUCTION........................................................................................................II-5

E. IMPORTER’S DOCUMENTS (No information provided in manual)..........................II-8

F. PROCEDURES AND DATA FOR DOCUMENTATION...........................................II-8

Procedure ........................................................................................................................II-8

Chapter II SPECIFICATIONS

A. General Design Specifications

Length Overall 42' 2"

Length on Deck 36' 8"

Length Waterline 30' 10"

Beam 11' 6"

Draft 5' 8"

Displacement 22,500 lbs. (dry)

Ballast (Internal) 7,340 lbs.

D/L (Displacement/Length) 337

SA/D (Sail Area/Displacement) for Cutter 17.3

B/D (Ballast/Displacement) 33%

Sail Area

Cutter 864 square feet (total)

Main 342 sq. ft.

Jib 292 sq. ft

Staysail 230 sq. ft

Rigging Values:.

I = 51.0 (Length from top of mast to deck) – May vary – confirm on your boat.

J = 19.25 (Length from Forestay to mast )

P = 44.0 (Length of Luff of Mainsail)

E = 15.25 (Length of Boom)

Calculated length of forestay based on I and J values = 54.5'

Approx. area of 110% Genoa = 470 Square Feet

Source of Data: DESIGNER'S SAILPLAN – obtained from SailRite Webpage

PHRF Rating of Tayana 37, Cutter Rig = 180

Ketch 786 square feet (total)

Main 263 sq. ft

Jib 209 sq. ft.

Staysail 156 sq. ft.

Mizzen 140 sq. ft.

II-2

Standard Engine Depending upon year of construction and original owner’s choice:

Perkins 4-108 Diesel or YANMAR 3QM30 Diesel

Fuel Tankage may vary 100 gallons (U.S.)

Water Tankage may vary 100 gallons (U.S.)

Vertical Clearance 55feet (Verify on your particular vessel)

Non-Dimensional Values:

Hull Speed 7.46

Comfort Index 40.78

Capsize Ratio 1.63

Pounds/Inch 1,274

(Pounds per Inch Immersion: The weight required to sink the yacht one inch.

If the boat is in fresh water multiply the result by 0.975. If you know the beam

at the waterline (BWL) multipy the result by BWL/Beam. )

B. Serial Numbers

Hull Number (Coast Guard) _____________________

Engine Serial Number _____________________

Hot Water Heater Serial Number _____________________

Stove Serial Number _____________________

Battery Charger Serial Number _____________________

Stereo Serial Number _____________________

II-3

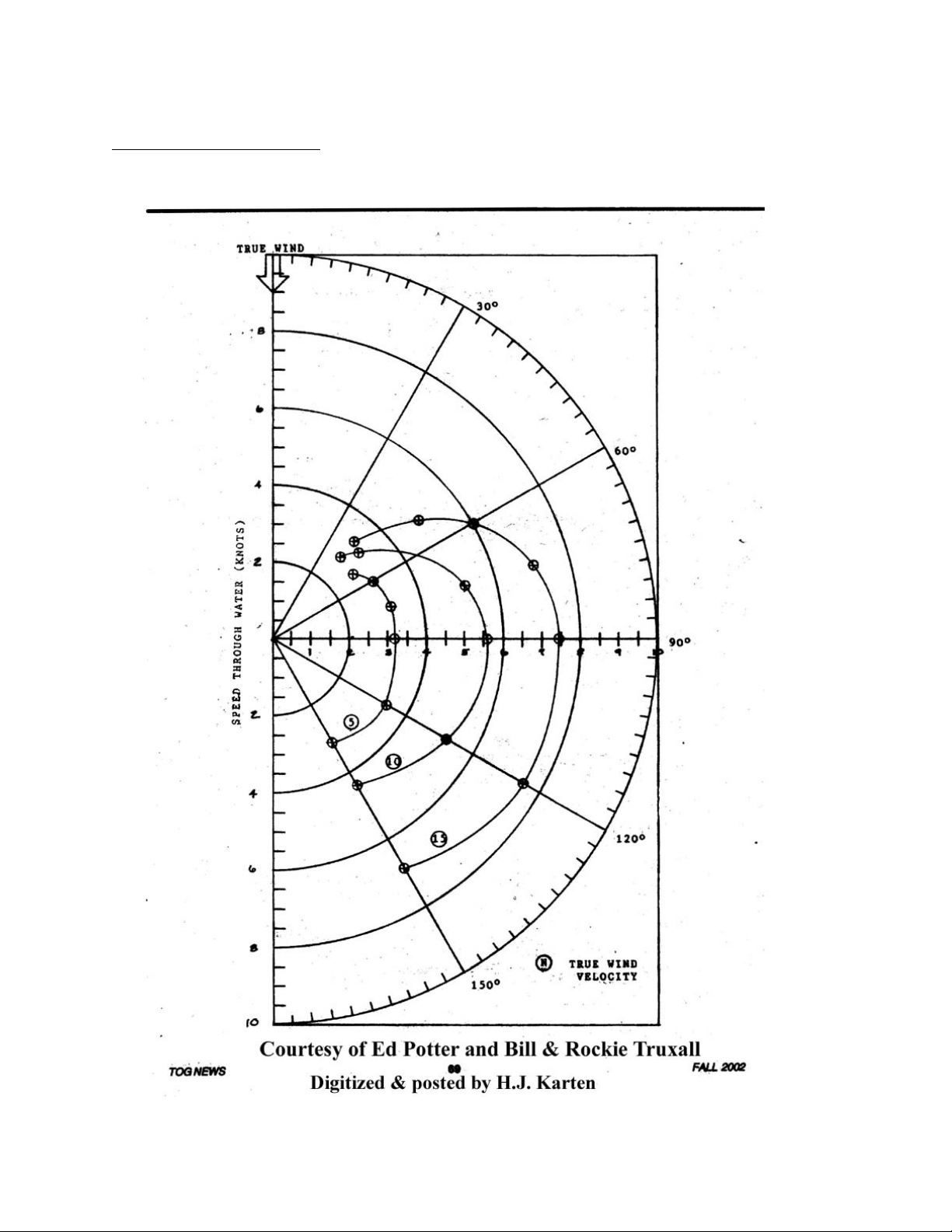

Polars for Tayana37 Cutter

II-4

C. MATERIALS

A few words about materials are called for because of the many questions people ask

about the quality of the metals, woods, and plastics used in Far East built yachts.

Resins. The resins used in the construction of TAYANA yachts are polyesters

purchased in the United States or Japan. Their quality equals or exceeds that of the

resins used in nearly any U.S. or European building yard. They are not of the fire

retardant type, however. Yachts built from late 1985 use isophthalic gel coats to resist

blistering.

Fiberglass: Fiberglass is generally purchased from the United States although some

Japanese and European glass is used. The primary glass structures are made from 1.5

ounce mat and 24 ounce woven roving.

Core materials. Various core materials are used. If a cored hull has been ordered the

core material is Airex (TM). This plastic material is light and highly resistant to

moisture. It also is an excellent insulator. The decks of TaYang yachts are generally

cored with wood blocks cut into two inch squares and formed into core "mats" much as

Balsa is used. It is heavier than either Balsa or Airex, but it is cheaper than either and

tolerates fastenings better. Where there is to be a heavy installation of some type, such

as a winch or windlass, the core material is usually a solid plywood sheet covered on

both sides by a heavy fiberglass laminate.

Teak. Teak is obtained from several sources. The most common, at this writing, appears

to be Indonesia. The demand for Teak is sufficiently high that properly cured Teak is

virtually impossible to find. It has been reported to us that the Teak obtained by TaYang

is generally two to three years old when purchased. This Teak is then cut into planks and

stored in a drying yard for a period of months. It is dried further in a kiln before it is

used on a yacht. Optimally, Teak would be aged for seven to eight years before use and

kilns would not be used.

Curing cracks have occasionally been a problem in yachts with solid Teak table or desk

tops. Where this has occurred, the tops have been replaced. On the whole, however, the

Teak has been surprisingly good and, in applications such as ceiling and decks, it is

almost problem free.

* SEE SECTION V. FOR PROPER MAINTENANCE CARE.

Plywood Plywood is the core material used in interior bulkheads, soles, and tops as well

as for certain structural applications. TaYang does use marine plywood. The glues used

II-5

between the plys is waterproof. There have been few plywood problems when owner

maintenance has been reasonable.

Stainless Steel Type 304 stainless steel is most common in yachts whether built in the

Far East or elsewhere, and that is what TaYang generally uses. Type 316 stainless steel

is the best for yacht application. but it is considerably more expensive than type 304.

There is little difference in strength between them, but type 304 can tend to show

corrosion which while generally-harmless, is irritating

Bronze Bronze fittings used on TAYANA yachts are made in Taiwan. Tests by an

independent laboratory showed that the bronze used is of good marine alloy and grade.

The bronze castings are C86800 (55Cu, 37Zn, 3Ni, 2Fe, 3Mn alloy while such items as

turnbuckle barrels are C19000 alloy (98-7Cu, 1.1Ni, 0.25P) .

Iron TaYang uses iron in fuel tanks and ballast. This is important because iron is less

susceptible to corrosion than is the mild steel that is occasionally used by some builders

in place of iron. TaYang does paint the iron with a good quality red lead primer to help

extend the life of the tank.

D. CONSTRUCTION

Your TAYANA 37 has been constructed of the finest materials, using the best

techniques, and it exceeds the specifications laid down by any of the most accepted

standard-setting agencies. The fiberglass schedule for the hull is shown in figure II-1.

and Table II.-1. Layup is done in a single mold by hand using polyester resin.

The large female mold is separated longitudinally for cleaning and mold preparation.

The gelcoat is sprayed in and the first glass layer is laid up. The mold is then joined

and all the remaining layups are done in the assembled mold. While the hull is still in

the mold, bulkheads are installed and the hull is allowed to cure. The deck is laid up in

much the same way except that a core of wood is used in those deck areas which will

generally be required to support loads such as decks and cabin top.

Ballast is made of a single casting of Black Iron. The ballast casting is lowered into

the keel cavity and is fully encapsulated to become part of the hull. The deck and hull

are joined by one of the strongest methods in the industry. A diagram of the deck to

hull joint is shown in figure II-1. Assembling the hull and deck is one of the most

critical operations in the yacht's construction. The deck is lifted by a crane above the

hull. The joint is prepared with 5200 epoxy compound and the deck is then-set onto

the hull. The joint is -then bolted together using stainless steel-bolts on varying centers

depending on the curve of the hull at the various points. Once the joining has been

accomplished, the joint is fiberglassed as shown in the figure. The result is a single

piece, extremely strong hull with a rigidly curved hollow beam in the form of a

bulwark running nearly the entire length of the yacht.

II-6

Once these critical operations have been finished to the satisfaction of the company

engineers, exterior trim is installed and the work on the accommodations is

undertaken. A team of the world's finest boat carpenters and finishers takes over the

yacht and frames in the interior cabinets and bunks, as shown on the plans. This work

is done with extreme care and attention to detail. Framing is actually glassed into the

hull and becomes an integral part of it. As a result, the quality and livability of the

accommodations is largely a function of how well the framers do their job. Cabinets,

doors, drawers, and the like are done by cabinet makers in a specialty shop to the order

of the production foremen. TaYang engineers closely supervise every step to insure

that dimensions are met and proper installation is made. The result is a yacht whose

strength and beauty are second to none and whose accommodations precisely fit the

needs of its new owner.

The beautiful spruce spars which come on some TAYANA 37's are made in a special

spar shop located in the factory complex. The spruce used is the finest that can be

found and truly approaches aircraft quality. It is not unusual to see grains, which are

perfectly straight for 20 feet. The spruce planks are carefully scarfed together to make

planks of the proper length and glued into the box shape using epoxy. Wires, conduits

and reinforcements are constructed into the spars as required. Final shaping and

finishing is all done by handy men who have years of experience in building fine

wood spars.

If aluminum spars are to be supplied, these are ordered from overseas suppliers-

Taiwan has no extrusion capability at this writing. Generally, the suppliers have been

ISOMET of France and YACHT SPAR out of New Zealand. ISOMET masts are

received already anodized and cannot be painted. YACHT SPARS are painted at the

yard and the color can be selected by the buyer. TaYang uses a primer and

polyurethane for this. Aluminum spars are also being imported from Japan These are

painted by the spar manufacturer.

Standing rigging is assembled at the yard using Japanese stainless steel cable and

Taiwanese-made turnbuckles and swage end fittings. A crew at the factory sets up the

spars and all of the rigging is fitted to each yacht. This is an important factor in cutting

down the number of modifications which might have to be done in the U.S. Similarly,

pulpit, lifelines, stanchions, and bowsprit are all installed to insure proper fit.

The final step is packing the yacht for shipment. Spars, rigging, and any projecting

assemblies are all disassembled and packed either in the hull, or, in the case of the

masts, into special boxes. On the shipping date, the yacht is loaded onto a lowboy and

taken to the huge port city of Kaohsiung where it is loaded aboard one of the many

container carriers which operate between Taiwan and the United States.

II-7

II-8

E. IMPORTER’S DOCUMENTS (No information provided in manual)

F. PROCEDURES AND DATA FOR DOCUMENTATION

Documentation must be accomplished with the United States Coast Guard in the

United States or with the governing agency in the country where your vessel is to

be registered. We suggest you contact the Documentation office nearest you for full

details, forms, and instructions.

The following notes and references are made for your information and convenience.

They should in no way be misconstrued as complete and detailed instructions:

Procedure

Pleasure Class Under 20 tons requires a Yacht

License. Twenty tons and over

requires a certificate of Enroll-

ment and a Yacht License.

Application for - Requires a Builder's Certificate

Admeasurement issued by the builder on the pre-

scribed Coast Guard form. This

certificate will be retained by

the Coast Guard with certified

copies available to the owner.

Admeasurement The admeasurer uses data in the Builder's

Certificate (BC) to compute net tonnage. The following

formulas are used for sailboats:

Gross Tonnage = 1/2 (LBD/100)

Net Tonnage = 0.9 (Gross Tonnage).

Where: L = Length

B = Breadth

D = Depth

Official Number - After admeasurement files your certificate of tonnage,

application is made for an official number. Title and

mortgage papers are required.

Additional Forms - Applications for number.

Declaration of Ownership and/or

II-9

Extent of interest.

Identification of Owner's or

Existing Mortgages.

Declaration of No Foreign Interest involved.

Declaration of Master of Vessel.

Declaration No freight or Commercial

Passengers to be Carried on Board.

Designated Home Port-Licensing

Office.

Designated Hailing Port-Berth

Marking Certificate

Commercial Class Contact your U.S. Coast Guard Documentation Office for

information- due to the complexity of application.

Table of contents

Other Tayana Boat manuals