Secutron MR-2602 User manual

INSTALLATION

MANUAL

Revision: 2 022708

Document #: LT-2015

WARNING: This manual contains information on limitations

regarding product use and function and information on the

limitations as to liability of the manufacturer. The entire

manual should be read carefully.

MR-2602

Fire Alarm Control Unit

MR-2602 Installation & Operator’s Manual

i

Table of Contents

1.0 Introduction .............................................................................................................................................. 1

1.1 The MR-2602 Fire Alarm Control Unit ............................................................................................ 1

1.2 Codes, Standards and Installation Requirements........................................................................... 1

1.3 Technical Support and General Information ................................................................................... 2

1.4 System Verification ......................................................................................................................... 2

1.5 Standby Power................................................................................................................................ 2

1.6 Battery Maintenance ....................................................................................................................... 2

2.0 Preparing to Install the MR-2602 Fire Panel ............................................................................................ 3

2.1 Unpacking the MR-2602 ................................................................................................................. 3

2.2 Optional Accessories ...................................................................................................................... 3

2.3 MR-2602 Overview ........................................................................................................................ 4

2.4 Planning Your Installation ............................................................................................................... 5

2.5 Electrical Specifications .................................................................................................................. 5

2.6 Module Current Ratings .................................................................................................................. 6

2.7 Standby Battery calculation chart ................................................................................................... 6

2.8 Calculation for Standby Battery Requirement................................................................................. 7

3.0 Installing the MR-2602 Fire Panel............................................................................................................ 8

3.1 Environmental Specifications.......................................................................................................... 8

3.2 Panel Assembly and Modules Locations ........................................................................................ 8

3.3 Mounting the MR-2602 ................................................................................................................... 9

4.0 Wiring the MR-2602 ................................................................................................................................. 10

4.1 Wiring Specifications....................................................................................................................... 10

4.2 Connecting NAC Devices (Class ‘A’ and Class ‘B’) ........................................................................ 12

5.0 Panel Operation ....................................................................................................................................... 16

5.1 Operating Sequences ..................................................................................................................... 16

5.2 General Zone Fire Alarms............................................................................................................... 16

5.3 Waterflow Alarms............................................................................................................................ 16

5.4 Supervisory Zone Alarms................................................................................................................ 17

5.5 Trouble Operation ........................................................................................................................... 17

5.6 System Reset Operation................................................................................................................. 19

5.7 Lamp Test ....................................................................................................................................... 19

5.8 Walk Test (Installer function only)................................................................................................... 20

5.9 NAC operation ................................................................................................................................ 21

5.10 Relay Function .............................................................................................................................. 21

6.0 Programming the MR-2602 System......................................................................................................... 22

6.1 How to Program the MR-2602 ........................................................................................................ 22

6.2 Programming Section Descriptions................................................................................................. 24

6.3 Viewing the Event Buffer................................................................................................................. 27

7.0 Startup of the MR-2602............................................................................................................................ 29

7.1 Prior to power up............................................................................................................................. 29

7.2 Power up sequence ........................................................................................................................ 29

7.3 Default Operation............................................................................................................................ 29

7.4 Programming the Panel .................................................................................................................. 29

7.5 Final Verification ............................................................................................................................. 29

8.0 Programming Worksheets ....................................................................................................................... 30

8.1 Entering Programming Mode .......................................................................................................... 30

8.2 Zone Programming (Section 0)....................................................................................................... 31

8.3 NAC Temporal/Steady Programming (Section 1) ........................................................................... 31

8.4 NAC Auto-silence, Strobe Programming (Section 2) ...................................................................... 31

8.5 Silence Inhibit and Walk Test Programming (Section 3)................................................................. 32

8.6 Waterflow Programming (Section 4) ............................................................................................... 32

8.7 50/60 Hz Option (Section 5)............................................................................................................ 32

MR-2602 Installation & Operator’s Manual

ii

9.0 Appendix: Table of Compatible Smoke Detectors ................................................................................... 33

9.1 Smoke Detector Bases ................................................................................................................... 35

9.2 Compatible 4-Wire Smoke Detectors.............................................................................................. 35

9.3 Compatible Horns/Strobes.............................................................................................................. 36

FCC Compliance Statement .......................................................................................................................... 38

Warranty & Warning Information.................................................................................................................... 39

MR-2602 Installation & Operator’s Manual

iii

List of Figures

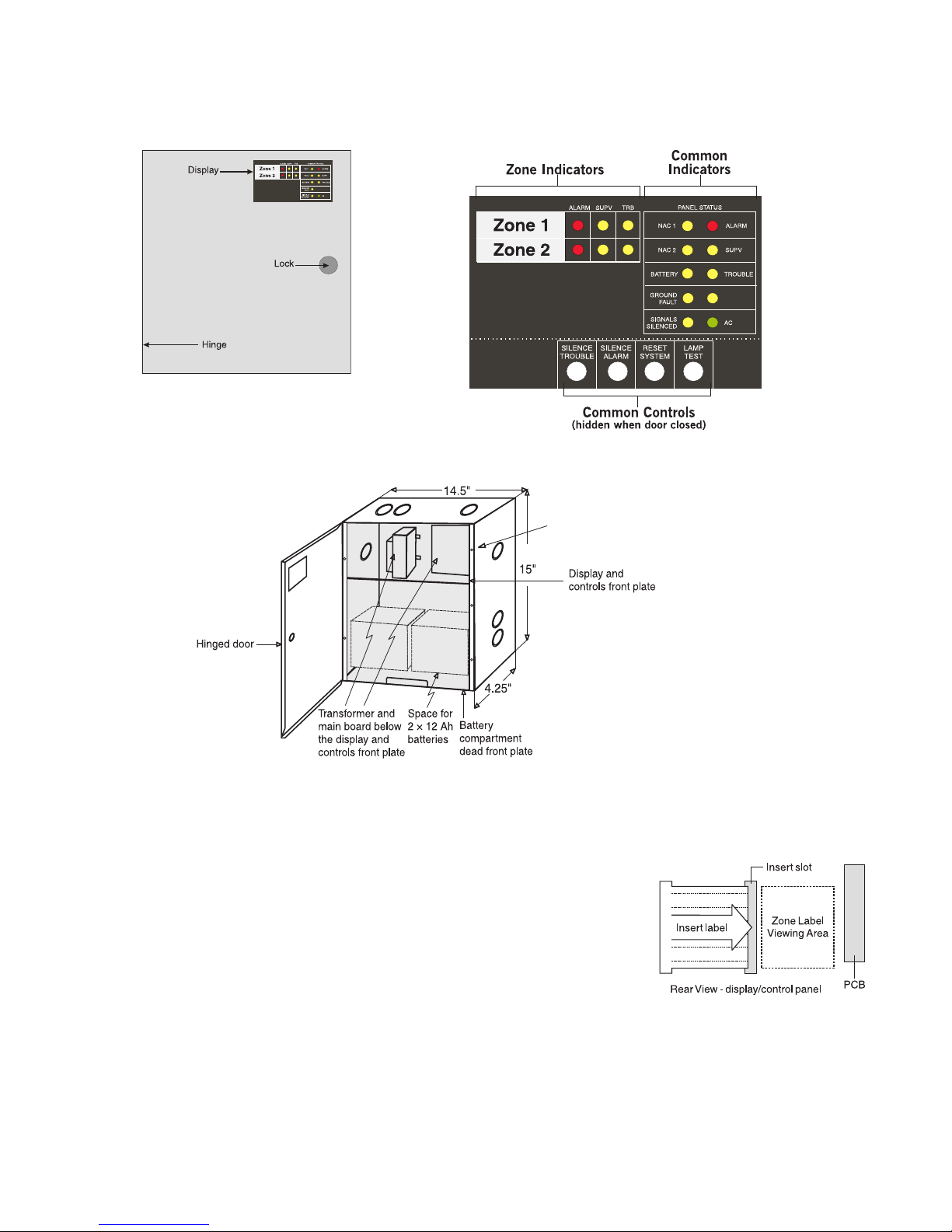

Figure 1: MR-2602 cabinet with door closed ....................................................................... 4

Figure 2: MR-2602 display and controls ............................................................................. 4

Figure 3: MR-2602 Cabinet Overview ................................................................................. 4

Figure 4: Zone Label Insert ................................................................................................. 4

Figure 5: Panel Assembly and Modules Locations ............................................................. 8

Figure 6: Mounting Dimensions .......................................................................................... 9

Figure 7: Knockout Locations .............................................................................................. 9

Figure 8: MR-2602 Terminal Descriptions ......................................................................... 10

Figure 9: Connecting 2-Wire Alarm Initiating Devices ......................................................... 11

Figure 10: Connecting 4-Wire Smoke Detectors ................................................................. 12

Figure 11: Connecting NAC Devices (Class ‘B’) ................................................................. 12

Figure 12: Connecting NAC Devices (Class ‘A’) ................................................................. 12

Figure 13: Connecting Batteries .......................................................................................... 13

Figure 14: Connecting AC Power ........................................................................................ 13

Figure 15: Connecting the Alarm and Trouble Relays ........................................................ 14

Figure 16: Connecting Optional Devices ............................................................................. 14

Figure 17: Locating the Walk Test Switch ........................................................................... 22

MR-2602 Installation & Operator’s Manual

1

1.0 Introduction

1.1 The MR-2602 Fire Alarm Control Unit

General features

•Two initiating device circuits, class B / style B

•Two notification appliance circuits, class B / style Y (Power Limited)

[can be wired as one NAC, class A / style Z]

•One common alarm-actuated relay, form ‘C’

•One common trouble-actuated relay, form ‘C’

•AUX+ power output, 500 mA max. (Power Limited)

•Unswitched common and switched common auxiliary power returns

•Integral battery charger

•Cabinet with dead-front construction

•Transformer, mounted in the cabinet

Applications

The MR-2602 two zone, fire alarm control panel is listed for use in the following applications.

•Protected Premises Fire Alarm System

•And for the following types of service:

A – automatic, M – Manual, SS – Sprinkler Supervisory, WF – Waterflow

1.2 Codes, Standards and Installation Requirements

Relevant codes and standards

The MR-2602 fire alarm control panel is designed to meet the requirements of NFPA 72, 2002 edition, UL 864

Rev 9, Control Units for Fire Protective Systems, and in Canada, CAN/ULC-S527-99, Standard for Control

Units for Fire Alarm Systems.

Information provided with this unit is intended as a guide. Installation of this equipment, optional system

components, alarm initiating devices and notification appliances must follow the manufacturer’s guidelines as

contained in their respective installation documents, all applicable codes and the instructions of the Local

Authority Having Jurisdiction.

General Installation requirements

Manufacturer’s documents

When installing the MR-2602 control panel, refer to this manual. When installing optional system components

refer to the installation documents included with those components. When installing compatible alarm initiating

devices or notification appliances, refer to the installation documents included with those products.

Field wiring

Field wiring recommendations in this document are intended as guidelines. All field wiring must be installed in

accordance with NFPA 70 National Electrical Code and in Canada with the standard for installation ULC/S

524, the most current Canadian Electrical Code, with all relevant local codes and standards, and the Authority

Having Jurisdiction.

Compatible devices

Use UL or ULC Listed smoke detectors and notification appliances that are compatible with the MR-2602 Fire

alarm control panel from the lists included in this manual.

MR-2602 Installation & Operator’s Manual

2

1.3 Technical Support and General Information

For technical support call 1-888-SECUTRON, or email techsupport@secutron.com

For general product information visit the Secutron web site: www.secutron.com.

1.4 System Verification

The complete fire alarm system must be verified for proper installation and operation when:

•the initial installation is ready for inspection by the Local Authority Having Jurisdiction;

•any system component is added, changed or deleted;

•any programming changes are made;

•system wiring has been altered or repaired;

•system failure due to external influences such as lightning, water damage or extended power outages has

occurred.

1.5 Standby Power

The MR-2602 provides standby battery support for lead-acid rechargeable batteries. The required capacity of

the standby batteries must be calculated using the charts and tables within this manual for the period as

required by national or local codes and standards. Even though the calculation table within this manual

includes a safety margin, lead-acid batteries commonly used for standby can have variable capacity as a

result of age and ambient conditions. Periodic inspection for damage and the batteries’ ability to support the

attached equipment is highly recommended.

1.6 Battery Maintenance

The two 12V sealed lead-acid batteries should be replaced after each period of 3 to 5 years of normal service.

If the Battery Trouble indicator activates, obtain required service.

MR-2602 Installation & Operator’s Manual

3

2.0 Preparing to Install the MR-2602 Fire Panel

2.1 Unpacking the MR-2602

The basic MR-2602 package includes the following components:

•Cabinet with hinged door

•Display and control plate c/w display and control printed circuit board.

•Zone label insert

•Battery compartment dead front plate

•Main control PCB

•Transformer

•Installation manual

•Hardware pack

-- 2 × NAC EOL resistors (4.7 K, 5%, ½ W)

-- 2× Zone EOL resistors (4.7 K, 5%, ½ W)

-- 1 × Battery jumper wire

-- 1 × EGND terminal ring

-- 1 × EGND KEP nut

• Door keys (taped to outside of cabinet)

All components described above are factory assembled into the enclosure.

2.2 Optional Accessories

Model Number Name Description

MR-2605-R3 Relay module

Provides 3 relays that are jumper programmable to activate on

common ‘alarm’, ‘supervisory’ or ‘trouble’. Mounts inside the enclosure

and plugs into the main board.

MR-2806 Dual line dialer

Communicates all alarms, supervisory and trouble conditions to a

Central Station using Contact ID, SIA or 10/20 BPS communication

formats. Programmable using the MR-2644 handheld programmer.

Mounts inside the enclosure and connects to the main panel using a

supplied 4-wire cable with connector.

MR-2644 Programmer Handheld programmer for the MR-2806 DACT.

MR-2605-T Remote trouble

indicator

Single gang plate complete with common trouble buzzer, trouble

visual indicator, ‘AC on’ visual indicator and a trouble silence / lamp

test switch. Mounts remotely to a single gang electrical box and is

connected to the main panel via the 4-wire ‘secur-bus’.

MR-2605-AT

Remote trouble

indicator and alarm

indicator

Two gang plate complete with common trouble buzzer, trouble visual

indicator, ‘AC on’ visual indicator and a trouble silence / lamp test

switch and red zone alarm visual indicators and yellow zone

supervisory indictors. Mounts to a standard 2 gang electrical box and

is connected to the panel via the 4-wire ‘secur-bus’.

MR-2605-SR EOL supervision

relay

Supervises the extended power wiring typically used for installations

that employ 4-wire smoke detectors. Mounts in the field.

MRD-EOL4.7K EOLR End-of-Line resistor for NAC and Initiating circuits. Mounts in the field.

MRD-MP400 EOLR plate Single gang plate with EOL resistor. Mounts to a single gang electrical

backbox.

MR-2602 Installation & Operator’s Manual

4

2.3 MR-2602 Overview

Zone Label Insert

A zone label insert is installed in the zone window area. Reach behind

the display/control panel and remove the blank insert. Zone designations

can be written directly on the insert or can be created using Word for

Windows, printed on Avery label #5167 and applied to the insert.

CPU

FAULT

Figure 1: MR-2602

cabinet with door closed

Note: Use Security Screw(SPAENAUR #381-064)

provided to meet UL 864 Rev 9 requirement

Figure 2: MR-2602 display and controls

Figure 3: MR-2602 Cabinet Overview

Figure 4: Zone Label

Insert

MR-2602 Installation & Operator’s Manual

5

2.4 Planning Your Installation

As a minimum, the following points should be considered to ensure that the installation will be successful and

proceed without delay.

•Consult with your local AHJ to ensure that the overall system will meet all requirements. Have your plans

reviewed and approved as required.

•Review the electrical specifications, mounting and wiring instructions in this manual and in the manuals of

all connected modules and devices.

•Using the chart in this manual, calculate the standby battery size that will meet the standby time required.

Include all components that will draw current from the standby battery when the panel is in the ‘standby’

mode.

•Determine the location of the control panel, all initiating and indicating devices and remote modules and

mark them on your system layout plan. An indicating device must be located in close proximity to the control

panel.

•Using the charts in this manual, determine the wire gauge and wire run distances for the connected

components. (initiating devices, indicating devices and ‘secur-bus’ connected components.)

•Review the programming section of this manual and determine the operating characteristics required of the

initiating zones, indicating zones and common panel features.

2.5 Electrical Specifications

Note: This system should be installed and serviced by qualified fire alarm installation professionals.

Circuit Rating

Primary AC 120 volts, 60 Hz. 1.5 Amps maximum/240 volts, 50 Hz. 1.0 Amps

maximum

AUX+ 500 mA maximum ~ Restoral of Aux Power Shorts requires removal of

all Aux Power loading

SCOM 500 mA maximum (current sink)

COM 500 mA maximum (current sink)

Relays (common alarm &

trouble) Form ‘C’ contact, 2 Amp, 30 VDC resistive, power limited source

NAC Outputs 24 volts, full-wave rectified DC, 1.5 Amps max. – Power limited. (3.0

Amps total for both NAC circuits) EOLR – 4.7K ohm, ½ W, 5%

Initiating Zone Inputs 24 VDC, 60 mA max.(in alarm) – Supervisory current: 6.0 mA – max.

Loop resistance: 100 ohms max. – EOLR: 4.7 K ohm, ½ W, 5%

Battery Charging Current 270mA maximum

Low Battery Trouble

Low Battery Trouble: 22.0 VDC

Low Battery Trouble Restore: 23.0 VDC

Critical Shutdown: 19±0.5 VDC

MR-2602 Installation & Operator’s Manual

6

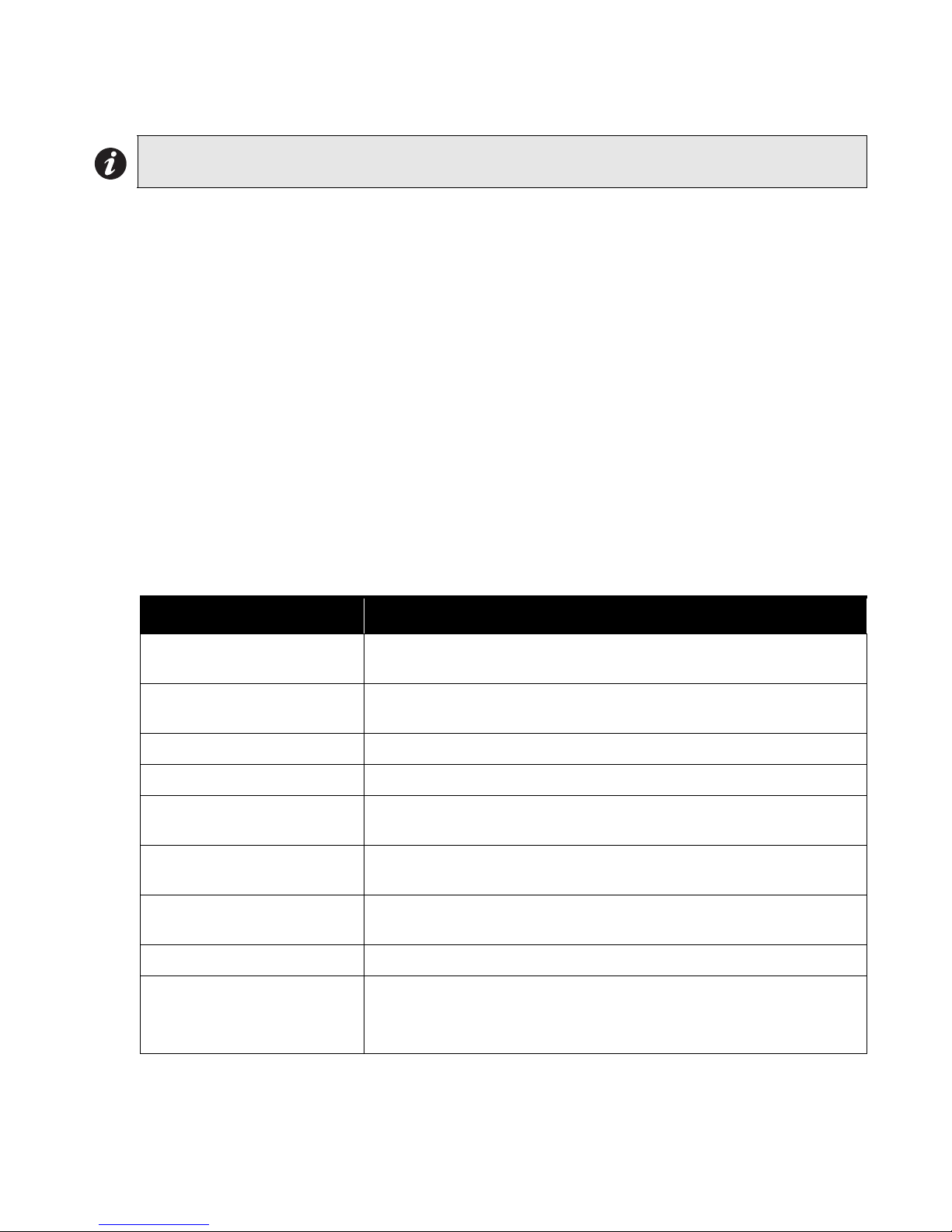

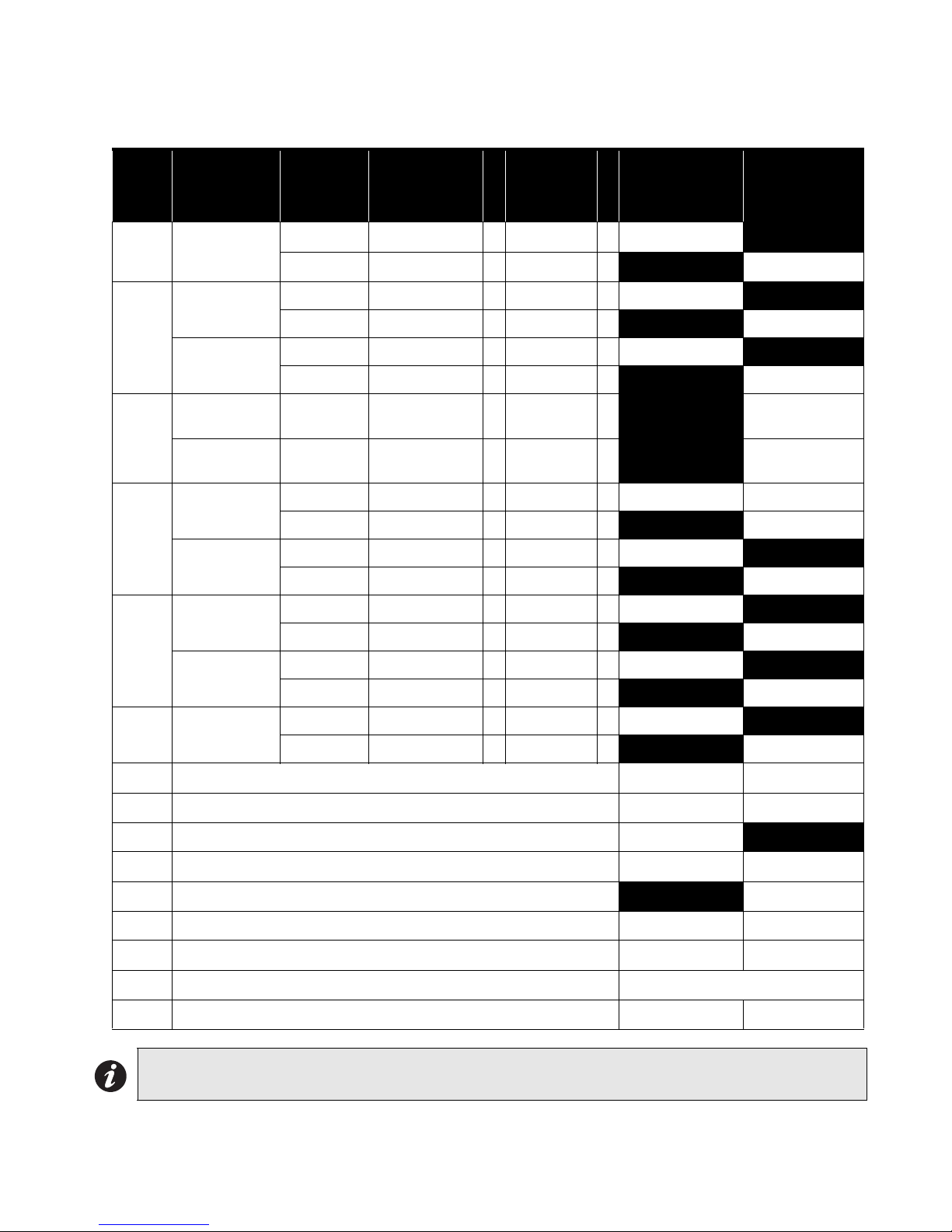

2.6 Module Current Ratings

2.7 Standby Battery calculation chart

All components that draw current from the panel while it is in the ‘standby’ mode (AC OFF) must be

considered for the standby battery calculation. All components that draw current while in the ‘Alarm’ mode

must be considered for the alarm battery calculation.

1. The control panel will always draw the currents as shown in the chart.

2. Typically the alarm current is calculated assuming only one initiating zone is in alarm. If it is required that

more than one zone be considered, add 60 mA per zone in the Alarm column. Consult the smoke detector

manufacture’s installation sheet to determine the standby current of these devices. Write that number in

the ‘current per device’ column then multiply that number by the number of devices on the zone. Repeat for

each zone.

3. Consult the Notification Appliance installation sheet to determine the current draw for each device

connected to the NAC. For each NAC, calculate the total current in alarm and put that number (mA) in the

‘Alarm’ column.

4. For each added module in the system, multiply the number of modules times the module ‘standby’ and

‘alarm’ currents and write those totals in the ‘standby’ and ‘alarm’ columns.

5. Add up all the current drawn from the AUX+ output in the standby and alarm mode and put those totals in

the ‘standby’ and ‘alarm’ columns.

6. Add up all the currents in the ‘standby’ column and the ‘Alarm’ column.

7. Convert the ‘standby’ and ‘alarm’ currents from mA to Amps. (divide mA by 1000)

8. Write in the ‘standby’ time required. (24 or 60 Hr.)

9. Multiply the ‘standby’ Amps times the ‘standby’ time to get the ‘standby’ Amp-Hr. required.

10.Write in the ‘alarm’ time required in hours. (5 min. =.08 Hr.; 30 min. =0.5 Hr.)

11. Multiply the ‘alarm’ Amps times the ‘alarm’ time to get the ‘alarm’ Amp-Hr required.

12.Add the ‘standby’ Amp-Hr. to the ‘alarm’ Amp-Hr. for the total Amp-Hr. required.

13.Multiply the total Amp-Hr. times 1.20 for the minimum Amp-Hr. battery required to support the system for

the selected ‘standby time and the selected ‘alarm’ time.

Module Standby Current

(mA) DC

Alarm Current

(mA) DC

Max. Alarm

Current (mA)

DC

MR-2602 Control panel 90 425(*) 485

MR-2605-T Remote trouble

indicator 15 15 15

MR-2605-AT R.T.I. and remote

5 zone annunciator 15 20(*) 40

MR-2806 DACT 45 60 60

MR-2605-R3 Relay module(**) 0 24 24

Note: *Current noted assumes ONE initiating zone is in alarm. The “Max. Alarm Current” assumes all

zones are in alarm.

**Values shown are for all relays set for activation on ‘Alarm’. Each relay set for activation on

‘trouble’ is normally energized and on ‘AC fail’ will draw 0 mA.

Note: Each NAC can supply 1.5 Amps max.

MR-2602 Installation & Operator’s Manual

7

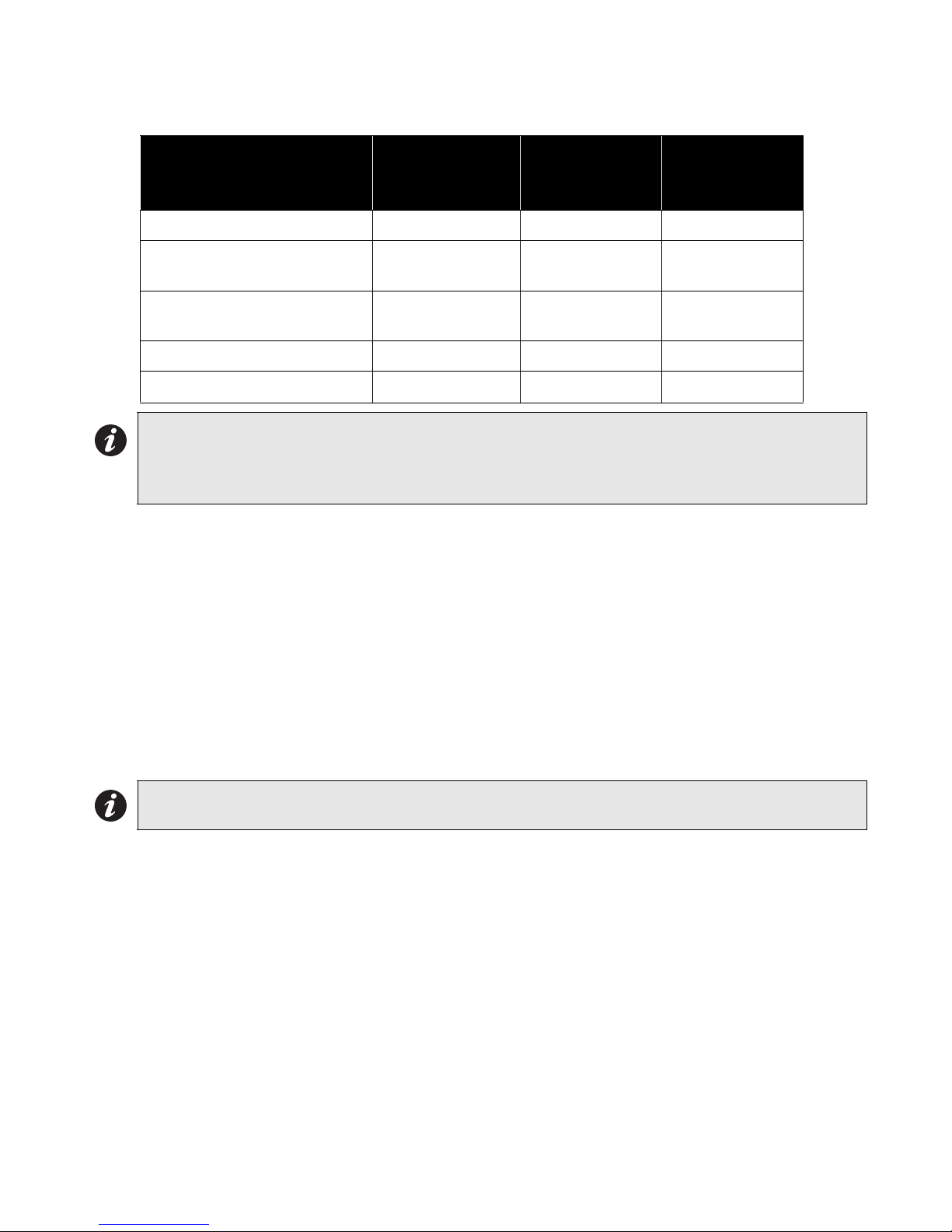

2.8 Calculation for Standby Battery Requirement

Step Device Current per

device (mA)

Number

of device

Total

Standby

Current (mA)

Total Alarm

Current

(mA)

1 MR-2602

Standby: 90 x1 =90

Alarm: 365 x1 = 365

2

Zone 1

Standby: x =

Alarm: 69 x 1 = 69

Zone 2

Standby: x =

Alarm: 69 x 1 =

3

NAC 1 Alarm: x =

NAC 2 Alarm: x =

4

MR-2605-T

Standby: 15 x

Alarm: 15 x

MR-2605-AT

Standby: 15 x

Alarm: 25 x

MR-2806

Standby: 45 x

Alarm: 60 x

MR-2605-R3

Standby: 0 x =

Alarm: 24 x

5AUX+

Standby: x =

Alarm: x =

6Total ‘standby’ and ‘alarm’ current: mA mA

7Divide ‘standby’ mA and ‘alarm’ mA by 1000: Amp Amp

8Select ‘standby’ time required (24 or 60 Hr.): Hr.

9Standby Amp-Hr. - multiply 8 × 7 = (Amps × Hr.): Amp-Hr.

10 Select ‘alarm’ time required (0.08 or 0.5):Hr.

11 Alarm Amp-Hr. - multiply 7 × 10 = (Amps × Hr.): Amp-Hr.

12 Total Amp-Hr = standby Amp-Hr (9) + alarm Amp-Hr. (11): Amp-Hr.

13 Multiply the total Amp-Hr. by the safety margin: 1.20

14 Total battery Amp-Hr required to support the system: Amp-Hr.

Note: Select a battery with an Amp-Hr. rating that is equal to or larger than the calculated minimum Amp-

Hr. battery required.

MR-2602 Installation & Operator’s Manual

8

3.0 Installing the MR-2602 Fire Panel

3.1 Environmental Specifications

Consider the following conditions when selecting a mounting location for the MR-2602 panel:

•Operating temperature: 32°F to 122°F / 0°C to 50°C

•Humidity: 95% RH non-condensing

•Close to a source of unswitched AC power

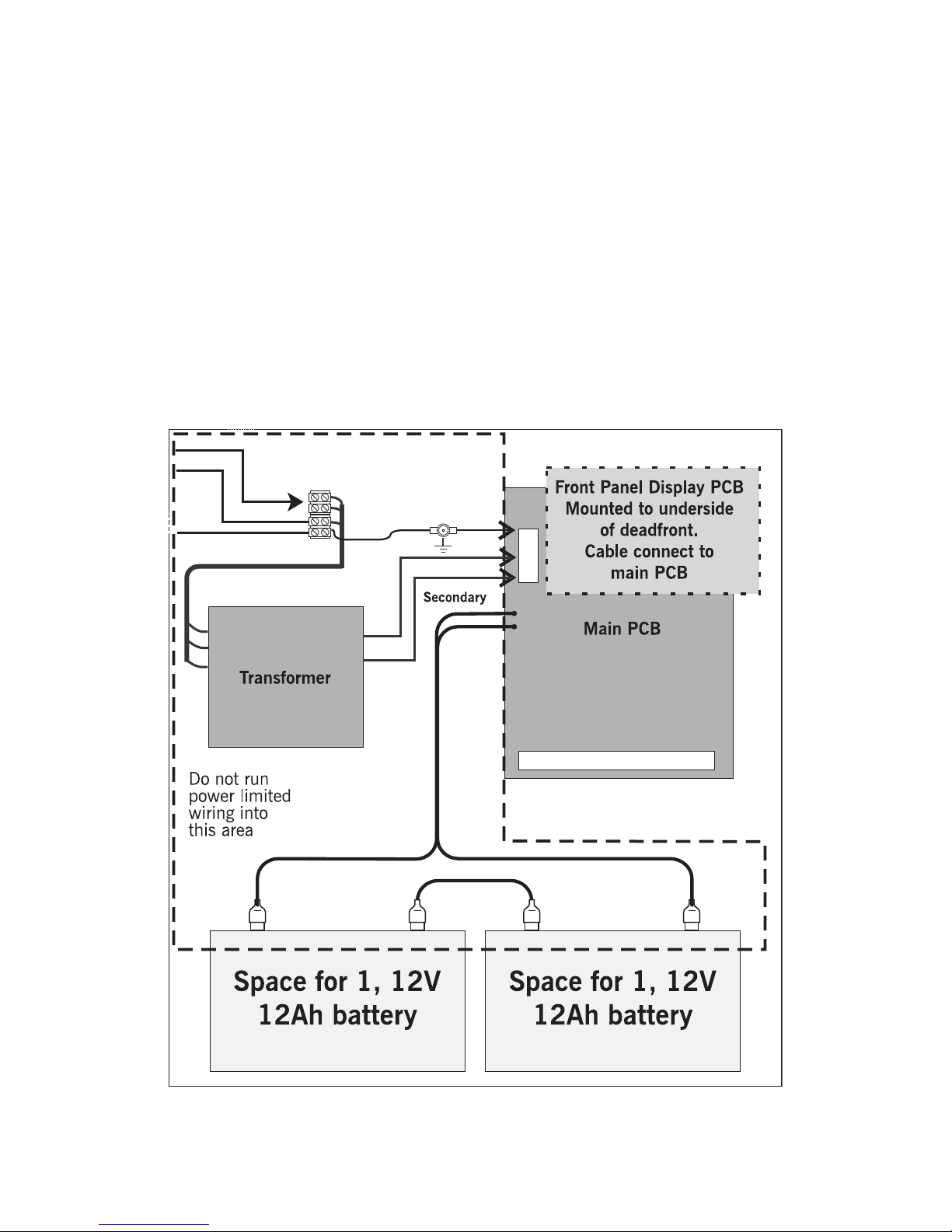

3.2 Panel Assembly and Modules Locations

The panel comes completely assembled from the factory. Remove the lower dead front for access to the

battery compartment. Remove display control panel for access to AC connections.

Figure 5: Panel Assembly and Modules Locations

240V 50Hz

120V 60Hz

GND

N

Primary AC

MR-2602 Installation & Operator’s Manual

9

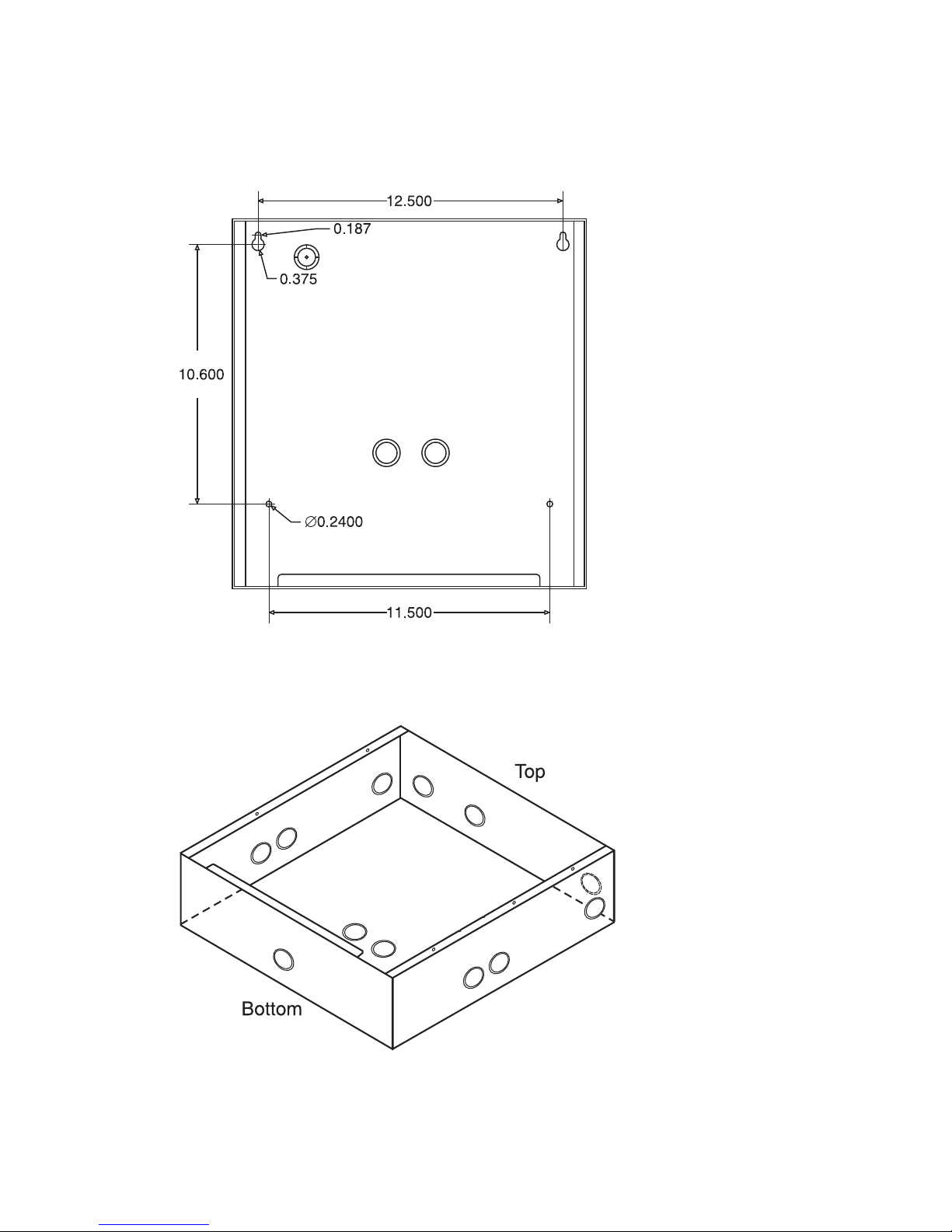

3.3 Mounting the MR-2602

Figure 6: Mounting Dimensions

Figure 7: Knockout Locations

Dimensions in inches

MR-2602 Installation & Operator’s Manual

10

4.0 Wiring the MR-2602

4.1 Wiring Specifications

Figure 8: MR-2602 Terminal Descriptions

Terminal

Label Description

NAC 1

(+, –)

Notification Appliance Circuit # 1

24 VDC, Full-Wave Rectified voltage, 1.5 Amps max.

Programmable as Steady or Temporal output on alarm.

Supervised for opens, shorts and ground fault.

Power limited.

NAC 2

(+, –)

Notification Appliance Circuit # 2

24 VDC, Full-Wave Rectified voltage, 1.5 Amps max.

Programmable as Steady or Temporal output on alarm.

Supervised for opens, shorts and ground fault.

Power limited

AUX+

Auxiliary power output

24 VDC, filtered and regulated, 500 mA max., 400 mV P-P ripple, power limited. Aux

power shorts must be restored by removing all Aux Power loading.

COM Auxiliary common power return, unswitched

24 VDC, 500 mA max.

SCOM

Auxiliary common power return, switched

(open circuit on system reset or on 4-wire smoke detector reset)

24 VDC, 500 mA max. (Please refer to Appendix A for compatible 4-wire smoke

detectors.)

DAT Data line for remote module communications

CLK Clock line for remote module communications

TRB NO Common Trouble relay, Normally Open contact

TRB C Common Trouble relay, Common contact

TRB NC

Common Trouble relay, Normally Closed contact

The Common Trouble relay is normally energized and is de-energized on trouble.

Contacts are shown in the de-energized state.

Contacts are rated 30 VDC, 2 Amps.

ALM NO Common Alarm relay, Normally Open contact

ALM C Common Alarm relay, Common contact

MR-2602 Installation & Operator’s Manual

11

Figure 9: Connecting 2-Wire Alarm Initiating Devices

Typical

1. Maximum 30 smoke detectors per zone (100 µA each standby).

2. Manual station, heat detector.

3. Maximum total loop wire resistance = 100 ohms.

4. Program zone as:

Type 1 - Smoke and contact devices instant alarm (default)

Type 2 - Smoke auto-verify and contact as instant.

ALM NC

Common Alarm relay, Normally Closed contact

The Common Alarm relay is normally de-energized.

Contact is shown in the de-energized state.

Contacts are rated 30 VDC, 2 Amps max.

Z1+ Zone 1 positive input

Z1-

Zone 1 negative input

Zone output is 24 VDC nominal to power 2-wire smoke detectors. Maximum current

draw is 60 mA in alarm and is limited by the zone circuitry. Zones may be configured to

monitor both 2-wire smoke detectors and initiating devices that employ dry contacts.

(manual stations & heat detectors)

Z2+ Same as zone 1 positive

Z2-Same as zone 1 negative

Note: For each supervised installation wire, a separate terminal must be used.

* See “9.0 Appendix: Table of Compatible Smoke Detectors” on page 33 in this manual for a list of

compatible 2-wire smoke detectors

Terminal

Label Description

MR-2602 Installation & Operator’s Manual

12

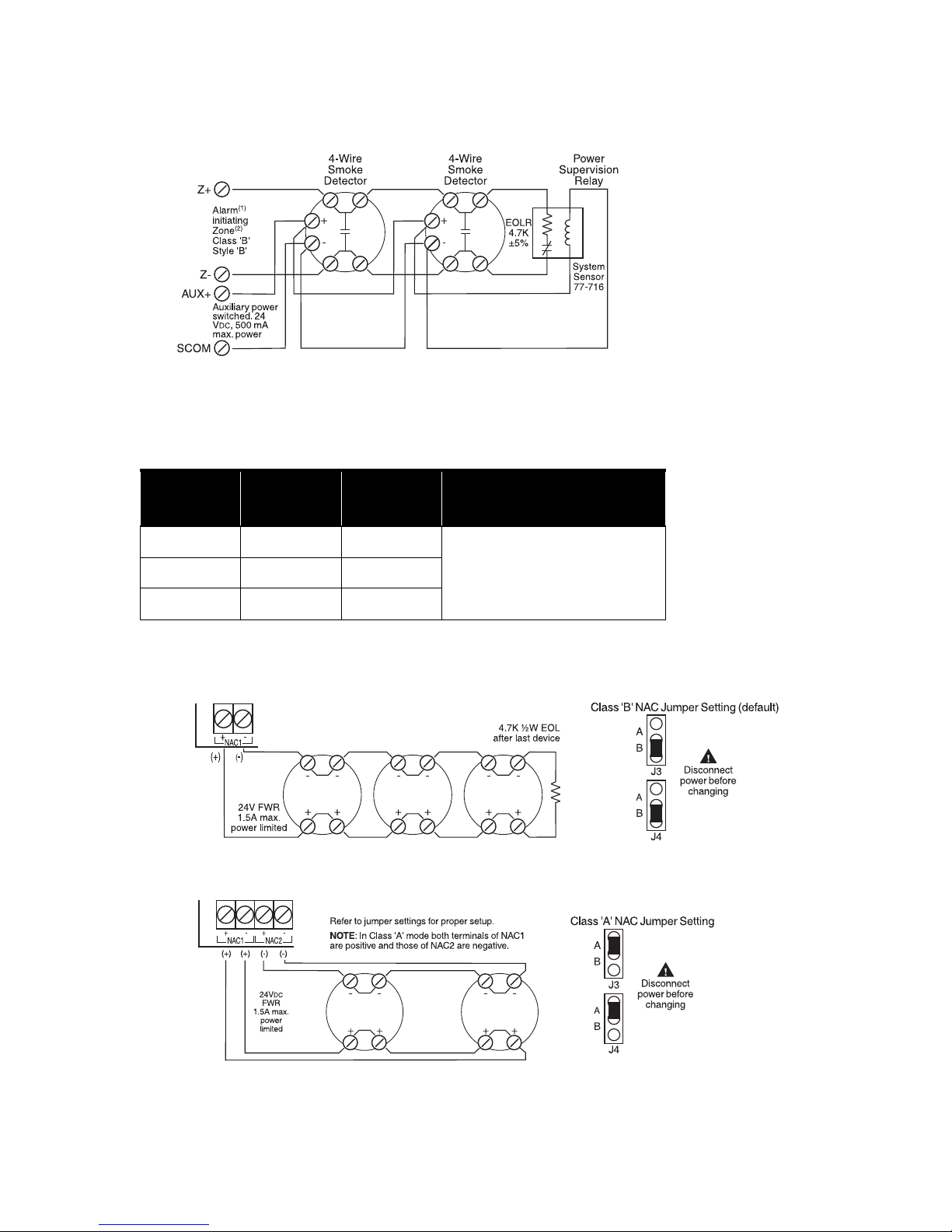

Figure 10: Connecting 4-Wire Smoke Detectors

1. Program as zone type 01, instant alarm.

2. Maximum total loop wire resistance is 100 ohms.

Zone Wiring Chart:

4.2 Connecting NAC Devices (Class ‘A’ and Class ‘B’)

Figure 11: Connecting NAC Devices (Class ‘B’)

Figure 12: Connecting NAC Devices (Class ‘A’)

Wire

(Gauge)

Distance

(feet)

Distance

(meters)

18 7,690 2,345 Maximum loop resistance is

100 ohms. Maximum current

in alarm is 60 mA.

16 12,195 3,717

14 19,230 5,861

MR-2602 Installation & Operator’s Manual

13

NAC Wiring Chart

Figure 13: Connecting Batteries

Figure 14: Connecting AC Power

Maximu

m Total

Loop

(ohms)

Maximu

m

Current

(A)

18-Awg

Wire

16-Awg

Wire

14-Awg

Wire

12-Awg

Wire

ft mft mft mft m

8.00 0.25 615 188 978 297 1,538 469 2,500 762

5.00 0.50 308 94 488 149 769 235 1,250 381

2.70 0.75 205 63 325 99 513 156 833 254

2.00 1.00 154 47 244 74 385 117 625 191

1.60 1.25 123 38 195 59 308 94 500 152

1.30 1.50 103 31 163 50 256 78 417 127

Note: This chart is based on a minimum source voltage of 22 volts and a maximum line loss

of 2 volts thus leaving a minimum of 20 volts at the last notification appliance.

240V 50Hz

120V 60Hz

GND

N

Primary AC

Note: The wire gauges must be

no less then the size required by

the Canadian Electrical Code

C22.1, Part 1, Section 32.

MR-2602 Installation & Operator’s Manual

14

Figure 15: Connecting the Alarm and Trouble Relays

Figure 16: Connecting Optional Devices

See installation sheets for the remote devices for

detailed wiring and address setup.

1. Maximum of 4 MR-2605-T per panel.

2. Maximum of 4 MR-2605-AT per panel.

Secur-bus Wiring Chart

Current

(mA)*

22-awg Wire 18-awg Wire 16-awg Wire 14-awg Wire

ft ft ft mft mft m

15 2,524 769 6,410 1,954 10,160 3,098 16,000 4,878

30 1,262 384 3,200 976 5,080 1,549 8,000 2,439

45 842 256 2,135 651 3,385 1,032 5,340 1,628

60 631 192 1,600 488 2,540 774 4,000 1,220

75 505 154 1,280 390 2,030 619 3,200 976

90 421 128 1,065 325 1,690 515 2,670 814

105 361 110 915 279 1,450 442 2,285 697

120 315 96 800 244 1,270 387 2,000 610

135 281 86 710 216 1,125 343 1,780 543

150 252 77 640 195 1,015 309 1,600 488

165 229 70 580 177 920 280 1,455 444

180 210 64 530 162 845 258 1,335 407

195 194 59 490 149 780 238 1,230 375

210 180 55 455 139 725 221 1,145 349

225 168 51 425 130 675 206 1,065 325

*See module current ratings chart for current drawn by each module attached to the secur-

bus.

Table of contents

Other Secutron Smoke Alarm manuals