See Water Water Smart WSS12 Setup guide

Water Smart® SCS Switch (Model #WSS12 or WSS24)

Sing

#

www.seewaterinc.com

or www.oilsmart.org

951.487.8073 • 888.733.9283

Email: info@seewaterinc.com

121 North Dillon Street • San Jacinto, CA 92583

P.O. Box 1269 • San Jacinto, CA 92581

Fail-Safe Technology since 1995.

©Copyright 2009 See Water, Inc. All Rights Reserved.

Installation and Operator's Manual

Water Smart®Switch:

The Water Smart® SCS Bilge Pump Switch is

designed for use as an electronic bilge pump switch in

boats. An upgrade from the original “Water Smart

Switch”, the SCS now features microprocessor

memory for constant self-calibration to adapt to any

environment for reliability. Installation of the Water

Smart Switch allows you to comply with State and

Federal regulations while reducing the risk of adverse

publicity, fines and expensive cleanup costs from a

large Oil Spill.

Model Description Volts Amps

WSS12 Water Smart SCS Bilge Pump Switch 12VDC 12A

WSS24 Water Smart SCS Bilge Pump Switch 24VDC 12A

Features:

• No Moving Parts. Patent Pending Electronic Water

Smart® Pump Switch

• Outlasts any other bilge pump switch through Self

Calibrating Sensor (SCS) technology.

• After each cycle, the switch recalibrates to its

original settings compensating for any

environmental changes.

• Environmentally Responsive: Prevents major oil

spills. Oil will not activate the switch

• Small enough switch to not overcrowd the bilge

and can be placed at any predetermined level.

• Incorporates a pump on level sense point, an

eight (8-10) second time delay allowing for

maximum water elimination as well as the

elimination of pump cycling for prolonged pump

life. Includes backup sensor with its own pump

down time-delay for ultimate “pump on”

protection

• Solid state circuitry - no moving parts

• Defined trip point-Oil/fuel spills will not activate

pump

• Performance is not hampered by accumulated oil

and grease

• Extended sensors allow the switch to be mounted

high above the contaminated water

• UL 508 Marine Listed "Electrical Industrial

Control Equipment" and NFPA 302

• UL Listed in accordance with ISO 8846-

Protection against ignition of surrounding

flammable gases

Water Smart Bilge Installation:

I. Disconnect voltage source, route and secure

all wires as high as possible above the water

level.

II. Mount switch in the vertical only, do not

mount horizontally on bottom of bilge.

Complete Mounting Hardware included.

III. Be sure the bottom of switch sensor (turn on

level) is aligned high enough above the

pump impeller (1 to 4 inches) for proper

turn off and turn on.

IV. For maximum efficiency of the eight (8-10)

second delay the switch should be placed

high enough that when the switch detects

water, the switch turns on and runs for 8-10

seconds after it no longer detects water. At

this time the water would be eliminated at

the same time the pump turns off.

V. If the switch is installed too low,the proper

dead span (amount of distance between on

and off) will not be achieved, the pump will

continue to run pumping any oil/fuel that

might be floating on the surface of water.

Water Smart® SCS Switch (Model #WSS12 or WSS24)

Water Smart Switch Wiring:

I. Connect the switch positive (+) red wire to

the (+) source with a 12Amp maximum

fuse within 2’ of switch location, failure to

install fuse protection will void warranty

and may damage the boat.

II. Connect the switch and the negative (-)

black wire to the (-) negative source.

III. Connect the positive (+) brown wire from

switch to the positive (+) wire of pump and

pump manual wire if equipped, reconnect

voltage source.

IV. The switches shall be installed where the

water intrusion will not directly contact or

splash the white plastic case.

V. Mud or other conductive materials left on

the body of the switches will hamper its

operation; take effort to clean the switch

prior to initial installation.

VI. Mount with enclosed screws.

Note: Keep sensors at least 2” clear of any

metallic material.

Wiring Diagram:

Source DC

- + Water

Smart

Switch PUMP

Red

Black - Black -

Brown +

Red or Brown

+ Manual Switch

(If Equipped)

Testing:

• Place finger on stainless steel sensor of long sensor

and the pump will turn on. Remove finger from

sensor and the pump will remain on for an

additional 8-10 seconds. To test the backup sensor,

touch finger to short sensor and the pump will turn

on for 8-10 seconds after finger is removed.

Troubleshooting:

Problem Possible Cause and Solution

No Water

Pumped.

Pump Does

Not Run

Make sure wire connections are not

corroded. Visual check is not enough --

a slight pull of each wire will tell if the

wires are still joined. Ensure wires are

not in the water

Blown Fuse

Check fuse to see that it is the correct

size recommended by manufacturer. DO

NOT exceed amp rating. If fuse size is

correct and fuse still blows, check

impeller to be sure it is not jammed or

full of debris.

Pump Control

is not

operating

properly; not

consistent or

staying on

The switch may be mounted too low for

the pump and should be reinstalled

higher. Make sure the bottom of the

switch sensor is higher than the top of

the pump impeller/ intake. Make sure

the plastic switch case is clean of soap or

soap bi-products. Clean switch case with

alcohol or oil based product: cleaning

solvent, kerosene, or WD40.

Shower Pan Installation:

I. Drill 3/8 to 1/2” hole in top of shower pan.

II. Mount switch above (outside) tank, clear of any

soapy water. Extend sensor down into tank

approximately 1-1/2”. Can be mounted

horizontally for side of tank entrance, a 45% will

work best.

III. Keep sensor in center of hole, sensor should not

contact tank material or switch will receive false

signal. If installed correctly shower pan, problems

will be a thing of the past.

©Copyright 2009 See Water, Inc. All Rights Reserved.

*Note:

• Sensor can be shortened to accommodate any size

bilge using small bolt cutters careful not to twist

sensor, may damage electrical connection.

12A Fuse

This manual suits for next models

1

Other See Water Switch manuals

Popular Switch manuals by other brands

EtherWAN

EtherWAN EX43000 series quick start guide

American Dynamics

American Dynamics AD1985A installation instructions

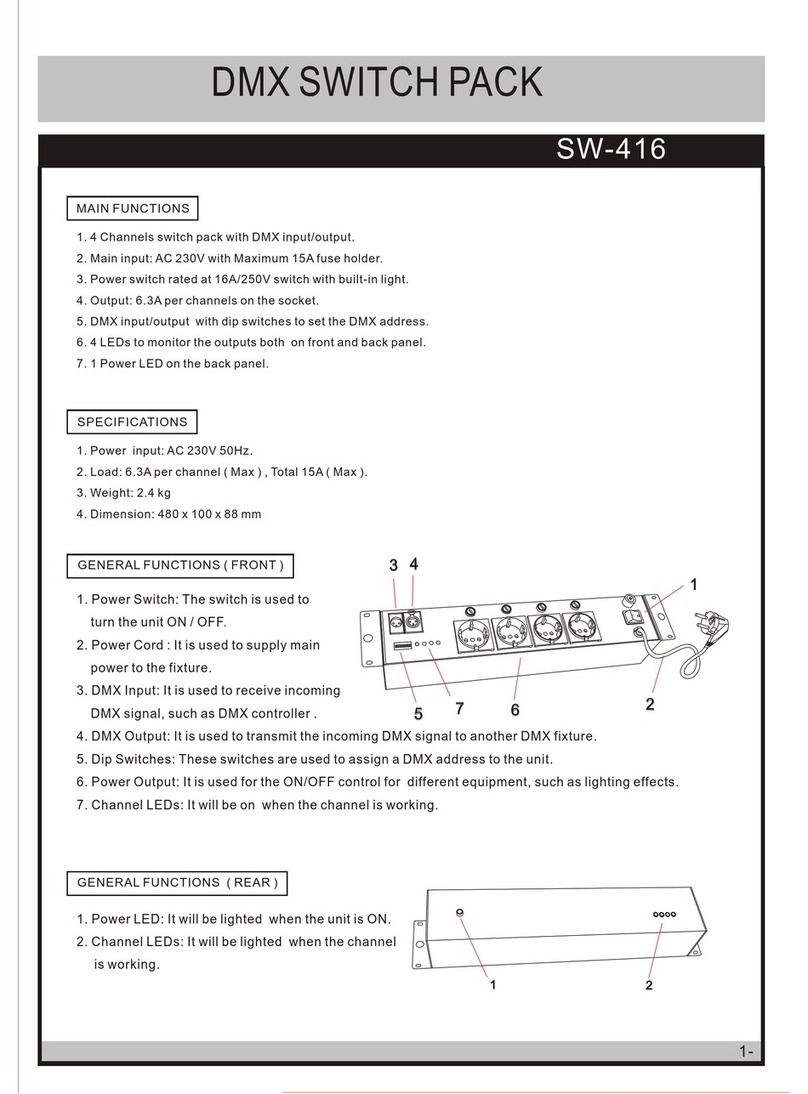

JB Systems

JB Systems SW-416 manual

NETGEAR

NETGEAR GC108P Hardware installation guide

Sygonix

Sygonix SY-4504970 operating instructions

NComputing

NComputing RX-HDX Installation and configuration