Seen IRIS 860 Sensor User manual

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 1

INSTALLATION GUIDE

SEEN IRIS 860 sensor

SEEN IRIS 860 Cab Box

SEEN IRIS-i camera

This guide contains instructions and

information to support the installation of

SEEN System products, including the IRIS

860 sensor and IRIS-i camera.

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 2

Contents

Installation Instructions

IRIS 860 sensor

Introduction 5

Mounting 7

Sensor wiring 9

Testing 10

Troubleshooting 11

IRIS 860 Cab Box

Introduction 13

Wiring 14

Testing 15

Troubleshooting 15

IRIS 860 Weather Shield 17

IRIS-i camera

Introduction 19

Serial Number Record 20

Installation 21

Antenna 23

LED indications 23

IRIS 860 accessories

Bluetooth Dongle 24

Buzzer Cap 25

Machine templates

Introduction 26

Sit-down Counterbalance Forklift 27

Stand-up Counterbalance Forklift 28

Reach Truck 29

Sensor settings

Sensor settings 30

How to change the settings 31

Technical reference resources

Using a DC/DC converter 33

Connect a third party accessory 35

Sensor internal self check function 37

Changing settings via Cab Box Sensor Cable 38

Cab Box cable shortening and threading 39

IRIS-i camera Internal memory 40

Product Specifications

IRIS 860 sensor 42

IRIS 860 Cab Box 44

IRIS-i camera 46

General

Warranties 48

Maintenance 49

Support 49

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 3

IMPORTANT

SEEN IRIS 860 sensors can provide collision warning assistance to the operator but do not

replace the need for proper operator training and best practice safe operating procedure.

While IRIS 860 sensors can alert the machine operator to a potential collision, the operator

is always fully responsible for the safe operation of the equipment. IRIS 860 sensors do not

comply with the regulatory standards required for devices which are intended to directly

control vehicle or machine safety functions. Using the sensor accessory port to control a

vehicle or machine function is entirely at your own risk. Detection can never be guaranteed.

IRIS 860 sensors are a CLASS I LASER PRODUCT. Disassembly or modification of this device

may result in hazardous radiation exposure.

IRIS 860 sensors and accessories have no user serviceable parts. Opening the enclosure will

void the warranty.

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 4

SEEN IRIS 860 sensor

INSTALLATION GUIDE

For additional resources about the

SEEN Safety system, please refer to

www.seensafety.com/resources.

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 5

Introduction

IRIS 860 sensor

SEEN IRIS 860 sensors are designed for use on heavy mobile

equipment like forklifts and wheel loaders. The sensor uses

non-visible infrared laser light to detect the presence of retro-

reflective material, such as the reflective tape found on day/

night high visibility PPE and markers. Detection is indicated

by an audible alert.

The detection zone and alert volume can be changed to suit

the operating environment.

Before you start installation

1. Read the installation instructions in full before starting.

2. Ask the customer for their Machine template, which

specifies where the sensor should be installed on the

machine, and how it should be set up.

If the customer doesn’t have a template, please refer to

SEEN’s generic Machine Templates on page 26, which

outline recommended mounting specifications for a

variety of common machine types.

3. Before going on-site, ensure you have an exact plan

of how you will mount the sensor(s) and any custom

mounting attachments, if required.

Related section

Sensor mounting location - Pg. 7

Machine Templates - Pg. 26

Check the vehicle’s power supply voltage against the IRIS

860 sensor maximum voltage rating sticker and use a DC/

DC converter if necessary.

Related section

Using a DC/DC voltage converter - Pg. 33

4. Check with the customer whether any additional

accessories need to be installed. These may include a

Weather Shield, Cab Box, and IRIS-i camera.

You will need a SEEN Bluetooth Dongle (P/n SI-138)

to apply the sensor settings specified in the Machine

Template.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 6

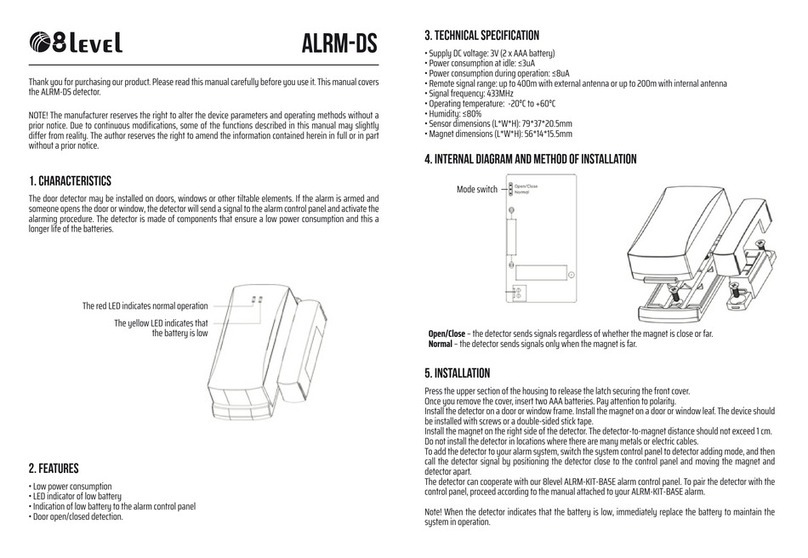

Accessory socket

Power socket

Alert buzzer

IRIS 860 sensor front IRIS 860 sensor back

IRIS 860 sensor mounted in bracket with power cable

attached.

Sensor box contents

• 1 x IRIS 860 sensor

• 1 x stainless steel mounting bracket

• 1 x power cable 4m (13ft)

• 4 x stainless screws (M6)

LED light

IRIS 860 sensor parts

Sensor box contents

IRIS 860 sensor

Sensor maximum

voltage rating sticker

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 7

Mounting

1. Sensor mounting location

The sensor’s mounting location, angle, and settings should be

specified by the customer in a Machine Template.

If one is not available, please refer to SEEN’s generic Machine

Templates on page 26. These detail the recommended IRIS

860 mounting specifications for a variety of common machine

types.

Related section

Machine Templates - Pg. 26

Make sure that the sensor is protected against impact. If the

forklift works inside containers, ensure the sensor does not

protrude above the highest point of the frame.

A custom mounting attachment may be needed to attach

the IRIS 860 mounting bracket in the desired position.

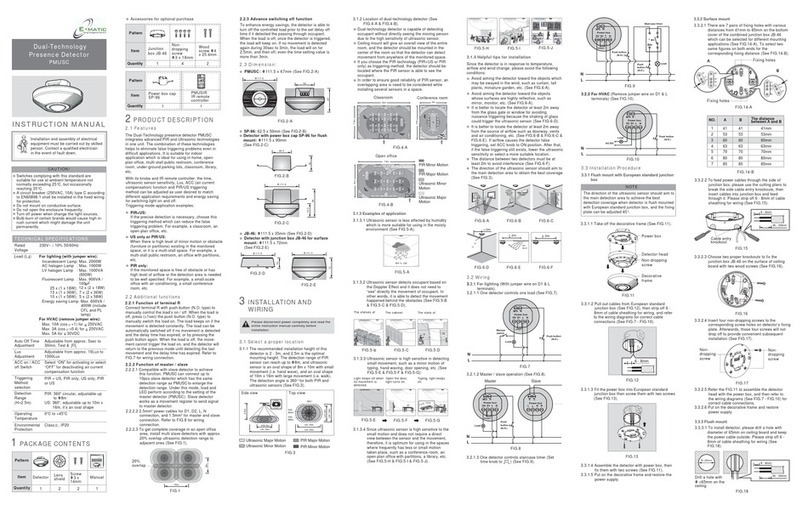

35mm

130mm

70mm

Sensor mounting bracket

UnderOver Vertical

2. Sensor bracket orientation

The supplied mounting bracket can be used on horizontal,

vertical, or angled surfaces. Select the bracket orientation that

best suits the installation requirements.

3. Attach the mounting bracket to the

machine

Securely bolt the mounting bracket to a solid surface using at

least two appropriate M6 fasteners.

WARNING. Do not drill into any roll-over or falling-

object protection structure (ROPS / FOPS) as this may

compromise the strength of the structure and void the

machine warranty.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 8

4. Mount the sensor in the bracket

If a Weather Shield is used, it needs to be installed at this

stage.

Related section

Weather Shield installation - Pg. 17

Machine Templates - Pg. 26

• Align the sensor’s four mounting holes with the slots in

the mounting bracket.

• Insert each M6 screw (supplied) and finger-tighten.

• Adjust the sensor to the correct angle. The figure on the

alignment sticker should be upright.*

• Tighten the four M6 mounting screws to 10Nm.

CHECK. Check that the sensor is the right way up and that

the figure on the alignment sticker in upright*.

*If the sensor is mounted higher than approximately 2m (6.5ft)

It may need to be angled slightly further towards the ground. *

80V max

The alignment sticker is found on the

side of the sensor.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 9

M12 connectors.

Finger tighten only.

Do not use tools.

Wiring

If a Cab Box is being installed (required for closed-cab

machines), skip to Cab Box installation on page 13.

Related sections

Cab Box installation - Pg. 13

Using a DC/DC voltage converter - Pg. 33

Troubleshooting - Pg. 11

1. Check the sensor voltage

Check the sensor’s maximum voltage rating sticker. It will

either be 24V or 80V.

If the vehicle’s power supply exceeds the maximum voltage

indicated on the sticker, a DC/DC voltage converter must be

used.

2. Wire in the Sensor Power Cable

IMPORTANT. Ensure the vehicle is turned o before

starting work.

The 4-PIN, 4m (13ft) Sensor Power Cable must be connected

to the vehicle’s electrical power supply. The following three

wires must be connected:

BROWN (Power)

The Brown wire must continuously receive DC power

when the vehicle is on. A DC/DC voltage converter may

be needed.

BLACK (Direction signal) DC 3.5-100V 1mA

The Black wire must be connected to the vehicle’s

direction signal (in most cases the reverse signal). The

reverse signal must be continuous (not pulsed) while

the vehicle is in reverse gear. Ensure the voltage on the

Black wire is less than +1V when the direction signal is

not high.

3. BLUE (Ground)

The Blue wire must be connected to the vehicle’s

ground.

Once the Sensor Power Cable is wired to the vehicle, carefully

connect the M12 plug connector to the sensor’s 5-PIN M12

power socket. Finger-tighten only.

80V max

80V max

The sensor’s maximum

voltage rating sticker

will be either 24V or

80V.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 10

Testing

Related sections

Troubleshooting - Pg. 11

Sensor settings - Pg. 30

Once installed the sensor must be tested to ensure it works

correctly.

SAFETY FIRST. For your safety ensure the vehicle engine

is o and the park-brake is on at all times.

Check the mounting angle

Check that the face of the sensor is angled down correctly,

and that the figure on the alignment sticker is upright.

Test the power supply

Switch the vehicle on. The sensor should have a steady

green LED while the machine is switched on.

Test the reverse signal connection*

Note. If the factory default settings have been changed,

the functionality may dier from that described below.

Test Method:

1. Place a retro-reflective safety vest (or similar) in the

sensor’s detection zone (approximately 2-3 meters

from the sensor). The sensor should not alert.

2. Now, put the vehicle in reverse and repeat the test.

This time the sensor should alert.

When the sensor alerts, the LED will turn red and the

sensor will emit a loud audible tone.

*By default IRIS 860 sensors are factory pre-set so they

can only alert while receiving a direction signal (usually the

reverse signal) from the vehicle. This setting can be changed

using the Sensor Setup App and SEEN’s Bluetooth Dongle.

Related section

How to change the sensor settings - Pg. 31

The sensor LED should be green while

the vehicle is powered on.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 11

Troubleshooting

1. The sensor LED is green, but the sensor will not

alert.

Possible cause: No reverse signal present. By default

sensors are set so they can only alert while receiving a

direction signal (usually reverse) from the machine. Check

the black wire is connected to the vehicle’s reverse signal.

Possible cause: The retro-reflective material is too close

to the sensor. Move further back. Detection starts 0.8m

/2.6ft from the sensor face.

Possible cause: The retro-reflective material is worn out

or is of insuicient size to enable detection.

Related Resources

seensafety.com/resources/reflective-tape-requirements

2. A sensor that is set so that it can only alert during

reverse, will alert when the vehicle is not in reverse.

Possible cause: The reverse signal input wire (black) is

twisted together with the power wire, meaning the reverse

signal is always high. Connect the black wire to the reverse

signal.

Possible cause: Voltage issue on the reverse signal. The

reverse signal input (black) must have no more than +1V

when it not high, and more than 3.5V when it is high.

3. The sensor is correctly wired but the sensor/s do

not behave in the expected way.

Possible cause: An electrical earthing issue on the reverse

signal. Check that the ground reference on the reverse

signal is the same as the ground reference on the sensor

power supply. Also refer to point 7.

4. The sensor repeatedly beeps and flashes with the

sequence long-short-short, long-short-short.

Cause: Blocked window. Clean the windows and the self-

check alert should cease. If the sensor is operating in a

cold-store freezer, ice on the window maybe triggering the

self checking function. Contact SEEN Support.

6. The sensor is beeping and flashing and the

sequence is NOT long-short-short, long-short-

short.

Cause: Internal fault detected. There are no user

serviceable parts. Contact your supplier.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 12

Reverse signal

(center)

Sensor Power Cable

Ignition power

Orientation slot

Ground

7. Direction signal grounding issue.

Applies to a sensor connected to a direction signal input

(usually reverse). If a DC/DC converter is used refer to

page 33.

Note: In this example the direction signal is REVERSE.

Problem: The sensor is correctly powered and connected

to the reverse signal, but the sensor does not alert even

when the reverse signal is active. The reverse signal and

sensor power supply may not share a common ground.

To check the reverse signal ground:

• Unplug the sensor power cable

• Switch the vehicle ignition ON (preferably without

starting the vehicle for safety)

• Attach a voltmeter across the ignition power pin (+)

and the ground pin (–) of the power cable. The voltage

should be between +10V and +29V. Refer to the plug

diagrams opposite.

• Next, attach the voltmeter across the reverse direction

pin and the ground pin (–). When the vehicle is NOT in

reverse, the voltage should measure between 0V and

+1V. When the vehicle IS in reverse it should measure

between +3V and +100V.

If the vehicle is in reverse and the voltage is not 3-100V

between the ground pin (–) and the reverse direction pin,

there may be a grounding issue.

IRIS 860 sensor

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 13

IRIS 860 Cab Box

INSTALLATION GUIDE

Introduction

Before you start

Check the vehicle’s power supply voltage against the Cab

Box’s maximum voltage rating and use a DC/DC converter if

necessary.

Purpose

On an enclosed cabin vehicle, the Cab Box provides an audible

alert to the operator inside the cab. Up to four sensors can be

connected to each Cab Box.

Components

• Cab Box

Installed in the driver’s cab

• Cab Box Power Cable

Connects to the vehicle’s power supply and direction

signal. (4pin cable included with each Cab Box)

• Cab Box Sensor Cable

Used to connect the sensor back to the Cab Box.

Available in lengths of 5m (16ft), 10m (33ft), 15m (50ft) or

20m (65ft).

IRIS 860 sensor

Cab Box

Cab Box Sensor

Cable

Cab Box

installation

example:

Cab Box

Sensor Cable

4-PIN Cab Box

Power Cable

Cab Box

IRIS 860 sensor

Cab Box

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 14

Wiring

1. Check the voltage

If the vehicle’s power supply exceeds 24V a DC/DC voltage

converter must be used.

Related section

Using a DC/DC Converter - Pg. 33

The Cab Box may draw up to 4.0A.

2. Connect Cab Box Power Cable

IMPORTANT. Only use the 4-PIN Cab Box Power Cable

provided with the Cab Box. Do not use the sensor 5-PIN

power cable which is not needed for Cab Box installations.

Wire the 4-PIN, 4m (13ft) Cab Box Power Cable to the vehicle:

BROWN (Power) DC 12-24V 4A

The Brown wire must continuously receive DC power

when the vehicle is switched on. A DC/DC voltage

converter may be needed.

BLACK (Direction signal) DC 3.5-100V 1mA

The Black wire must be connected to the vehicle’s

direction signal (in most cases the reverse signal). The

reverse signal must be continuous (not pulsed) while

the vehicle is in reverse gear. Ensure the voltage on the

Black wire is less than +1V when the direction signal is

not high.

BLUE (Ground)

The Blue wire must be connected to the vehicle’s

ground.

3. Connect Cab Box Sensor Cable

Connect each sensor to the Cab Box using the Cab Box

Sensor Cable. One end of the cable has a re-wireable plug that

can be removed to assist the threading of the cable through

the machine chassis or to shorten the cable.

Related section

Cab Box Sensor Cable shortening and threading - Pg. 39

Moulded end

(Attach to sensor)

Re-wireable plug

(Attach to Cab Box)

Cab Box Sensor Cable

5/10/15/20m length

4-PIN Cab Box Power Cable

Cab Box

M12 connectors.

Finger tighten only.

Do not use tools.

Cab Box

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 15

Testing

The Cab Box alert mirrors the LED and audible alert state of

its connected sensor/s.

• When the vehicle is first switched on the sensor will Boot,

indicated by a single beep and red LED flash followed by

a steady green LED on the sensor and Cab Box.

• While the vehicle is on the sensor and Cab Box should

have a steady green LED.

• When the sensor is detecting the sensor and Cab Box will

have an audible alert and red LED*.

*By default IRIS 860 sensors are factory pre-set to only detect

if they are receiving a direction (usually reverse) signal from

the vehicle. This setting can be changed in the Sensor Setup

App,

Related section

How to change the sensor settings - Pg. 31

Troubleshooting

1. The Cab Box is correctly wired but the connected

sensor/s do not behave in the expected way.

Possible cause: Wrong power cable. Ensure you use the

4 PIN Cab Box power cable supplied with the Cab Box. Do

not use the 5 PIN sensor power cable supplied with each

sensor.

2. Direction signal grounding issue.

Applies to a Cab Box connected to a direction signal input

(usually reverse). If a DC/DC converter is used refer to

page 33.

Note: In this example the direction signal is REVERSE.

Problem: The Cab Box is correctly powered and

connected to the reverse signal, but the sensor does not

alert even when the reverse signal is active. The reverse

signal and sensor power supply may not share a common

ground.

To check the reverse signal ground:

• Unplug the sensor or Cab Box power cable

• Switch the vehicle ignition ON (preferably without

starting the vehicle for safety)

• Attach a voltmeter across the ignition power pin (+)

and the ground pin (–) of the power cable. The voltage

should be between +10V and +29V. Refer to the plug

diagram opposite.

Cab Box Power

Cable

2 x Cab Box Sensor Cables are

shown attached. The green

LED indicates that a sensor is

attached.

Cab Box

Reverse

Signal

Cab Box Power Cable

Ignition power (+)

Orientation slot

Ground (–)

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 16

• Next, attach the voltmeter across the reverse direction

pin and the ground pin (–). When the vehicle is NOT in

reverse, the voltage should measure between 0V and

+1V. When the vehicle IS in reverse it should measure

between +3V and +100V.

If the vehicle is in reverse and the voltage is not 3-100V

between the ground pin (–) and the reverse direction pin,

there may be a grounding issue.

Related section

Troubleshooting (IRIS 860 sensor) - Pg. 11

Cab Box

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 17

IRIS 860 Weather Shield

INSTALLATION INSTRUCTIONS

Related section

Mount the sensor in the bracket - Pg. 7

A Weather Shield is recommended to protect the IRIS 860

sensor from rain, heat and UV when used outdoors.

If a Weather Shield is used, follow the installation steps below.

Insert and tighten

remaining screws

Step 1

Insert and finger tighten the two lower screws

only. Set the sensor to the correct angle.

Step 2

Fit the Weather Shield over the sensor and

bracket, so the round holes on each side

fit around each screw head.

Step 3

Insert the remaining two screws and finger

tighten. Check the alignment of the sensor

and weather shield. Evenly tighten all four

screws to 10Nm (maximum).

Lower screw

Sensor + Weather Shield

Round hole

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 18

SEEN IRIS-i camera

INSTALLATION GUIDE

This guide is intended for anyone

installing an IRIS-i camera on a

IRIS 860 sensor.

IMPORTANT

Install and test the IRIS 860 sensor before installing the IRIS-i camera.

This installation and set-up guide has been prepared with all due care and attention, however,

Seen Safety Limited cannot be held responsible for any errors or omissions in this guide or any

consequences thereof.

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 19

Introduction

• Fully install and test the IRIS 860 sensor before attaching

the IRIS-i camera.

• Read these instructions in full before starting.

• IRIS-i cameras do not record sound.

Note. Detection events are recorded and saved in the

camera memory even if the IRIS-i is not connected to the

network. These detections will be uploaded once the device

connects to the network. See page 40.

Overview

The IRIS-i camera is designed to be attached to an IRIS 860

sensor. Detection information is automatically uploaded by

IRIS-i to SEEN Insight (insight.seensafety.com).

When powered, activated IRIS-i cameras automatically

connect to the mobile data network via an embedded roaming

SIM card.

IRIS-i cameras upload the following information about each

detection event:

• A still image

• The time, date, duration, and closest distance

• Trace path through the detection zone

• Video (optional upload).

Requirements

• 3G / 4G mobile coverage

• An installed IRIS 860 sensor

In the Box

• IRIS-i camera

• 300mm M12 connector cable

• Weather shield

• Mounting bracket

• Antenna + 600mm cable

• Antenna mounting bracket

• 4 x M6 x 12mm hex head screw

• 2 x M6 x 16mm hex head screw

• 2 x M6 Nylock nut

IRIS 860 sensor and IRIS-i camera

IRIS 860 sensor and IRIS-i camera (back)

IRIS-i Camera

© Copyright 2023 Seen Safety | SEEN Safety System Installation Guide | Version 231205 | seensafety.com/resources 20

Serial number record

IMPORTANT

Please print this page and for each installation,

record the IRIS-i serial number, and the serial

number/ID of the machine it is installed on. The

customer requires this information to set up their

SEEN Insight account.

SCN0023

A0001234

The camera serial number sticker

is found on the bottom of the IRIS-i

camera. In this example the serial

number is SCN0023A0001234

TIP: The QR code can be scanned

to display the serial number.

Machine serial number / ID IRIS-i camera serial number

Please pass the completed serial number record to on-site management.

IRIS-i Camera

Other manuals for IRIS 860 Sensor

3

Popular Security Sensor manuals by other brands

Socket & See

Socket & See iVolt Instruction manual & specification

Abus

Abus FUBW50100 quick start guide

Abus

Abus SECVEST Installation instructions and user manual

C.P. Electronics

C.P. Electronics MWS1A-C-PRM-LV installation guide

Paradox

Paradox Magellan PMD75 instructions

Ceasefire

Ceasefire PRO-SENSE TI-002267 installation guide

Alarmcom

Alarmcom ADC-IS-221-LP installation guide

Multitech

Multitech RBS3010NA05BN00 user guide

C.P. Electronics

C.P. Electronics GEFL-PB-ABS installation guide

Paradox

Paradox Omnia OMN-PMD1 instructions

Paradox

Paradox NV37MR installation manual

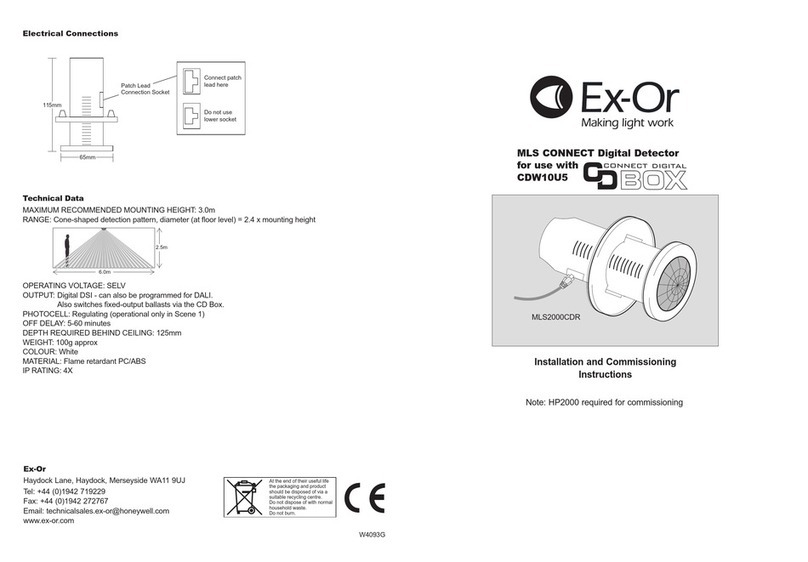

Exor

Exor MLS CONNECT MLS2000CDR Installation and commissioning instructions