Schweitzer Engineering Laboratories, Inc. SEL-2414 Data Sheet

5

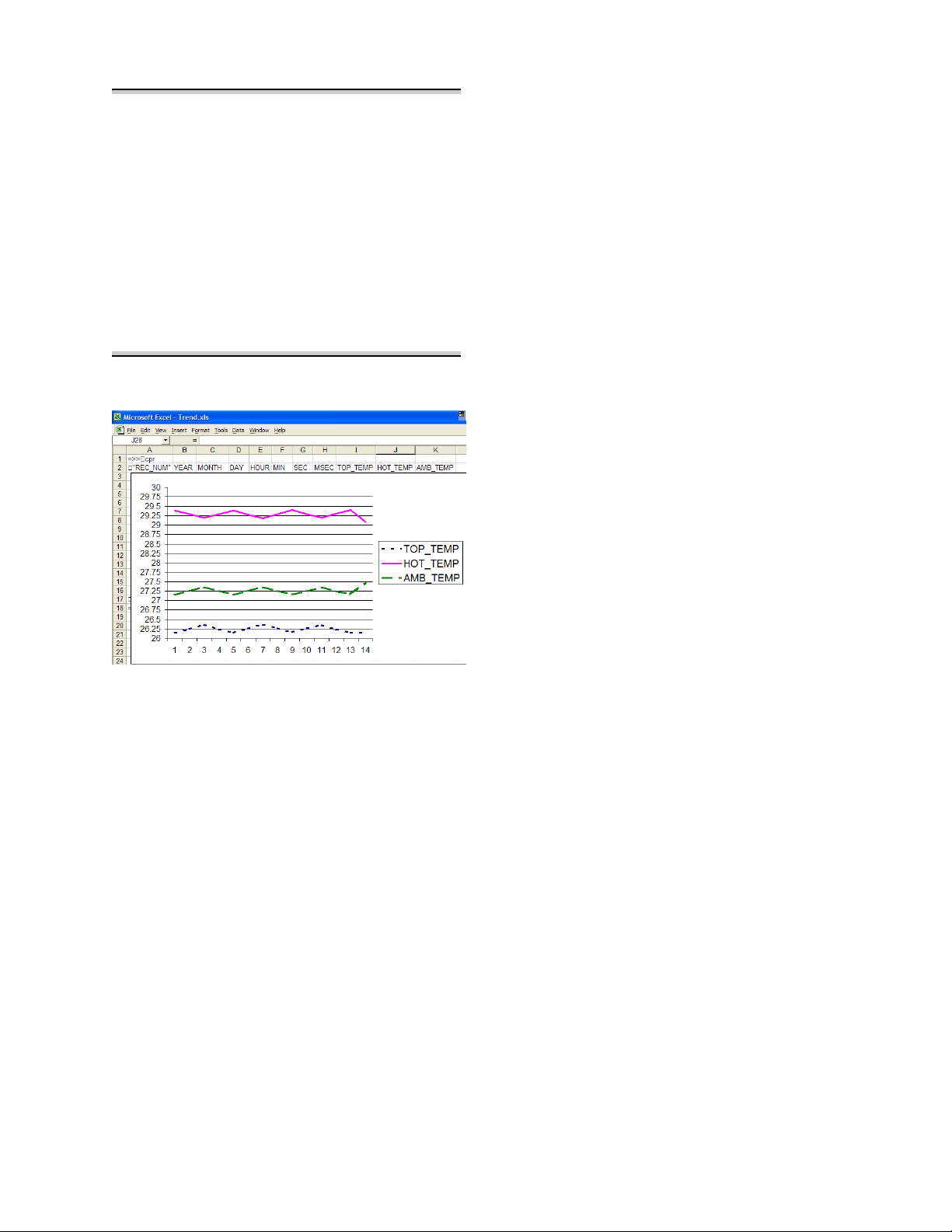

Figure 5 Comma-Separated File Format for Easy

Display, Analysis, and Archiving

Figure 6 Excel Graph of Trend Data

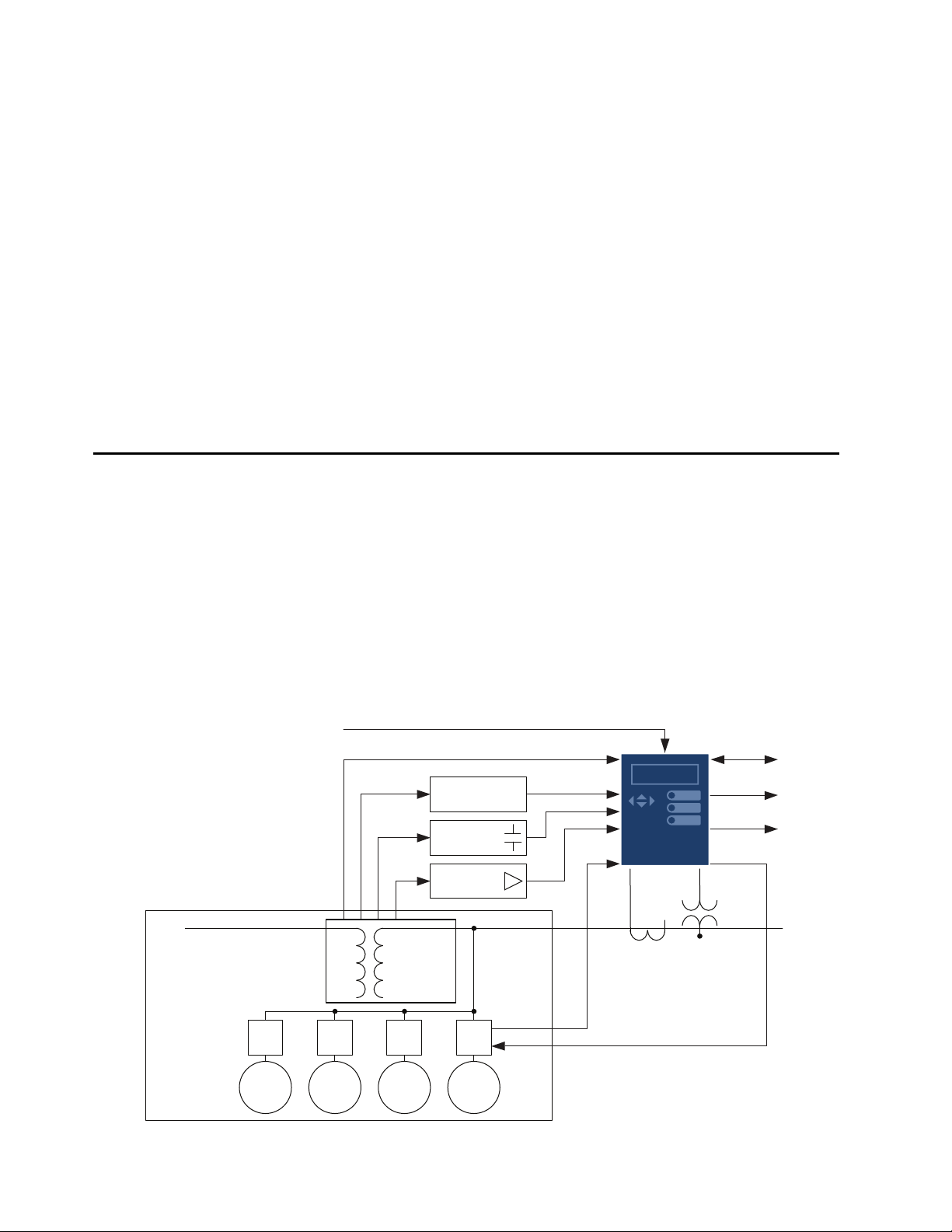

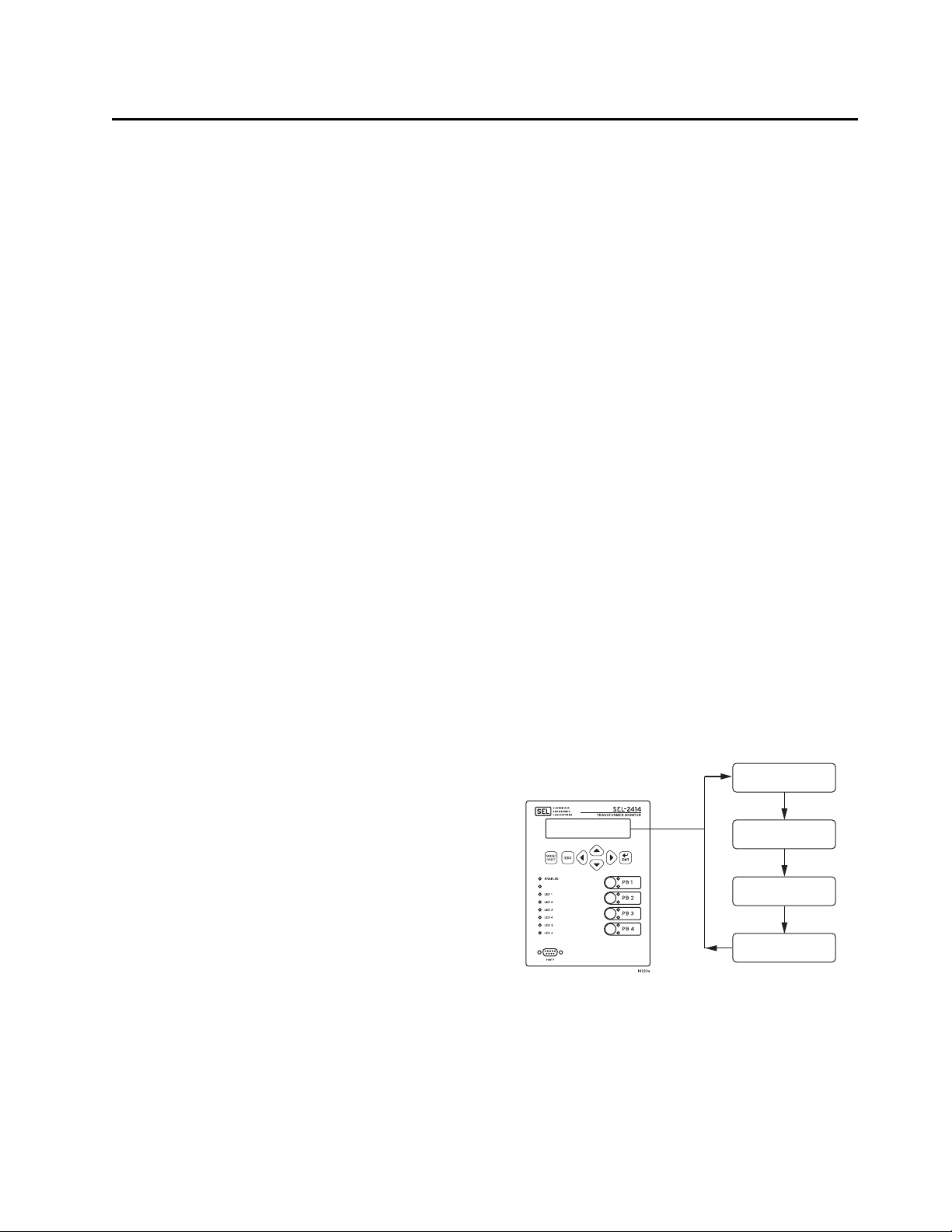

Transformer Thermal Monitoring

Transformer thermal modeling, per IEEE C57.91-2011

or the IEC 60076-7:2018 Ed. 2, is a standard feature in

the SEL-2414. Specify the SEL-2414 to provide this

capability for monitoring and protection of a single

three-phase transformer, a three-phase transformer with

tertiary windings (three-winding mode with separate CT

ratios), or three independent single-phase units. Use the

thermal element to activate a control action or issue a

warning or alarm when your transformer overheats or is

in danger of excessive insulation aging or loss-of-life.

Use the thermal event report to capture current hourly

and daily data about your transformer. Operating

temperature calculations are based on load currents, type

of cooling system, and actual temperature inputs

(ambient and top-oil). Use as many as four thermal

sensor inputs: a single ambient temperature transducer

and one transducer for top-oil temperature from each of

three single-phase transformers. Temperature data are

obtained via an internal RTD/thermocouple card or from

an external SEL-2600A RTD Module. While the

SEL-2414 can receive temperature data at any rate, the

thermal element uses the temperature data once per

minute.

The thermal element operates in one of three modes,

depending upon the presence or lack of measured

temperature inputs: 1) measured ambient and top-oil

temperature inputs, 2) measured ambient temperature

only, and 3) no measured temperature inputs. If the

device receives measured ambient and top-oil

temperatures, the thermal element calculates hot-spot

temperature. When the device receives a measurement of

ambient temperature without top-oil temperature, the

thermal element calculates the top-oil temperature and

hot-spot temperature. In the absence of any measured

ambient or top-oil temperatures, the thermal element

uses a default ambient temperature setting that you select

and calculates the top-oil and hot-spot temperatures. The

device uses hot-spot temperature as a basis for

calculating the insulation aging acceleration factor

(FAA) and loss-of-life quantities. Use the thermal

element to indicate alarm conditions and/or activate

control actions when one or more of the following

exceed settable limits:

➤Top-oil temperature

➤Winding hot-spot temperature

➤Insulation aging acceleration factor (FAA)

➤Daily loss-of-life

➤Total loss-of-life

Generate a thermal monitor report that indicates the

present thermal status of the transformer. Historical

thermal event reports and profile data are stored in the

device in hourly format for the previous 24 hours and in

daily format for the previous 31 days.

The thermal model can be used even if a current card is

not installed. Current magnitude data can be received

through IEC 61850 Ed. 2 or other communications

protocols.

Through-Fault Event Monitor

A through fault is an overcurrent event external to the

differential protection zone. Though a through fault is

not an in-zone event, the currents required to feed this

external fault can cause great stress on the apparatus

inside the differential protection zone. Through-fault cur-

rents can cause transformer winding displacement lead-

ing to mechanical damage and increased transformer

thermal wear because of mechanical stress of insulation

components in the transformer. The SEL-2414 through-

fault event monitor gathers current level, duration, and

date/time for each through fault. The monitor also calcu-

lates a I2t and cumulatively stores these data per-phase.

The SEL-2414 through-fault report also provides percent

of total through-fault accumulated according to the IEEE

Guide for Liquid-Immersed Transformer Through-Fault-

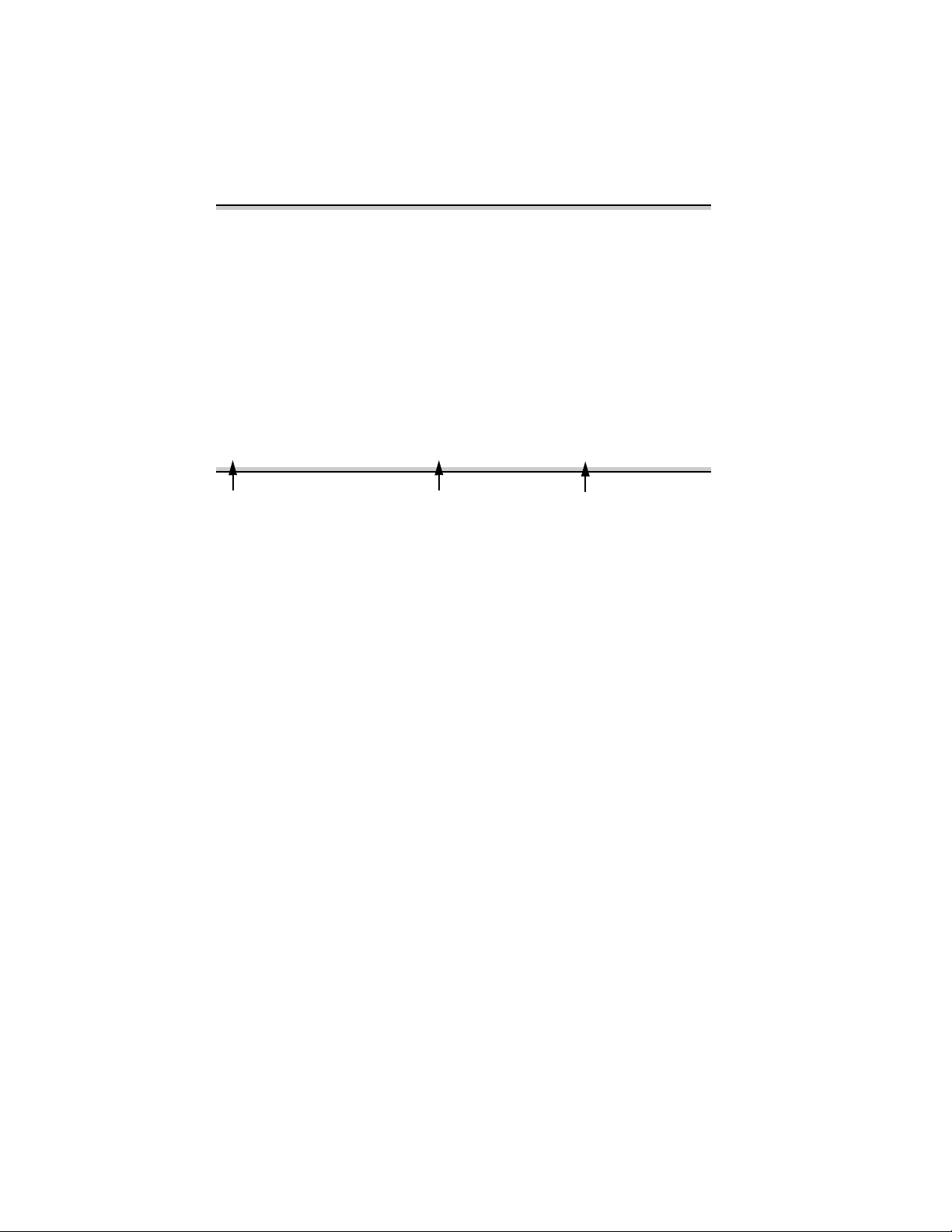

=>>CPR <Enter>

"REC_NUM","YEAR","MONTH","DAY","HOUR","MIN","SEC","MSEC","VA_MAG","VB_M

AG","VC_M

AG","AI301","AI302","AI303","AI304","AI305","AI306","1D7A"

14,2005,9,1,12,10,4,261,2092.127,2099.499,2089.107,-0.001,-0.000,

-0.001,-0.001,-

0.001,-0.001,"1190"

13,2005,9,1,12,15,3,982,2093.966,2099.176,2088.974,-0.001,-0.001,

-0.001,-0.000,-

0.001,-0.001,"11AC"

12,2005,9,1,12,20,4,82,2091.636,2099.117,2089.346,-0.001,-0.000,

-0.001,-0.001,-0

.001,-0.001,"115C"

11,2005,9,1,12,25,4,332,2092.435,2098.398,2088.487,-0.001,-0.001,

-0.001,-0.001,-

0.001,-0.001,"119C"

10,2005,9,1,12,30,4,36,2092.907,2098.208,2089.058,-0.001,-0.001,

-0.000,-0.001,-0

.001,-0.001,"115C"

9,2005,9,1,12,35,4,186,2093.153,2098.865,2089.091,-0.001,-0.000,

-0.001,-0.001,-0

.001,-0.001,"116F"

8,2005,9,1,12,40,3,978,2094.284,2098.926,2089.732,-0.001,-0.001,

-0.001,-0.001,-0

.001,-0.001,"1179"