Semtic BKDX30-95 User manual

1

CONTENT

I. Prologue............................................................................2

II. Main Instruction of Product....................................... 3

III. Installation......................................................................8

IV. Trial Running...............................................................13

V. Operation Panel Instruction.....................................15

VI. Maintenance & Repair..............................................22

Please read this manual carefully before installation

◆The heat pump must be installed by the professional technician.

◆Please install the heat pump and connect the water pipe in accordance with this manual strictly.

◆For safety, please make sure to recheck everything before power on.

◆If the machine has any improvement, the content is subject to change without notice.

Read the Manual before Operation

2

I. Prologue

Thanks for using heat pump water heater! Please read this manual carefully before installation and

operation! This manual contains the information about installation, commissioning, operation, and

maintenance. The following items should be focused:

1. Before installation, please confirm if your local voltage is match with the voltage showed on the

machine's nameplate and if the carrying capacity of the power supply, wires and sockets are suitable for

this machine's input power.

2. Users are not allowed to change the power cord or socket. Wiring work must be carried out by a

qualified electrician and ensure that the metal part of the machine has a good grounding. Changing the

ground mode is strictly forbidden.

3. After the completion of the construction of all wiring work, please make sure to recheck everything is

well before power on.

4. Installing the machine in the place which the combustible gas may leak is strictly forbidden.

5. Do not put your hands or foreign objects into the air outlet of heat pump unit, otherwise, it will be

dangerous to the people and equipment.

6. In order to obtain a better energy-saving effect, the unit should be installed in a place with

well-ventilated.

ATTENTIONS:

1. Please make sure the water systems should be filled with water before the machine start working.

2. When the machine is operating, all the valves of the water systems must be in the open position.

3. If without inlet water or stop using for a long time, when re-boot the machine, please according to the

item of attentons 1.

4. A removable filter must be installed at the water inlet and please clean the valve periodically depend

on your locate water quality (every 2 or 3 months).

5. The maximum water temperature is 55C .When you use the water, please adjust the water

temperature to a appropriate temperature (The most comfortable water temperature for shower is

38~42 , if the water temperature above 50C , there will be danger of burns!)

6. The maintenance of the machine must be carried out by the professional personnel.

7. If the unit power off,please discharge all the water inside.Otherwise,the heat exchanger will be frozen

in winter.

3

II. Main instruction of product

1.Parameter

Model Size(L*W*H mm) Net Weight(KG) Power Source

BKDX30-95 1105×472×914 100 220V~50Hz/60Hz

BKDX50-200 1114×489×1257 145 380V~50Hz/60Hz

BKDX60-220 1114×489×1257 150 220V~50Hz/60Hz

BKDX80-280 1507×587×1556 185 380V~50Hz/60Hz

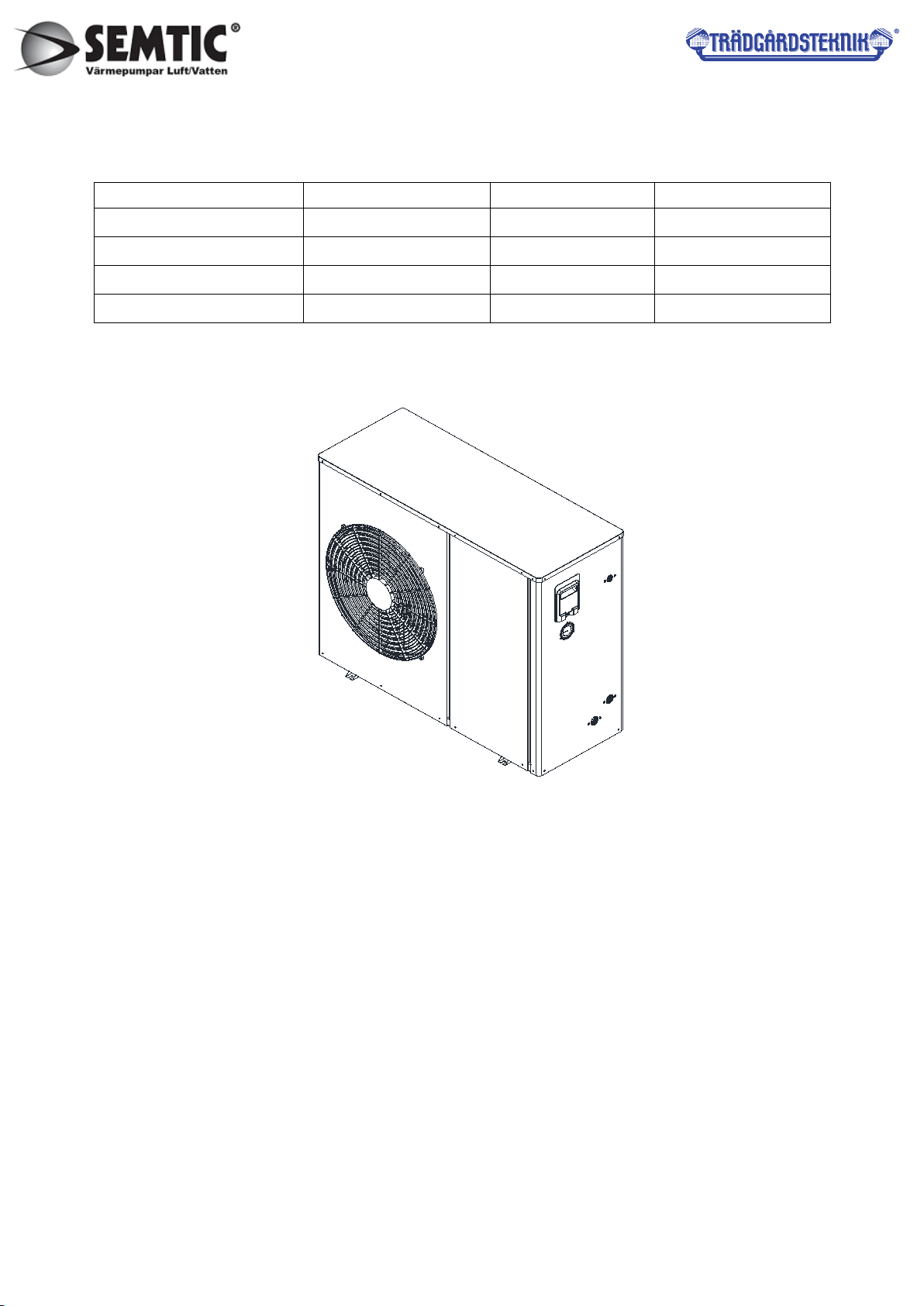

2.Appearance

BKDX30-95

4

BKDX50-200, BKDX60-220

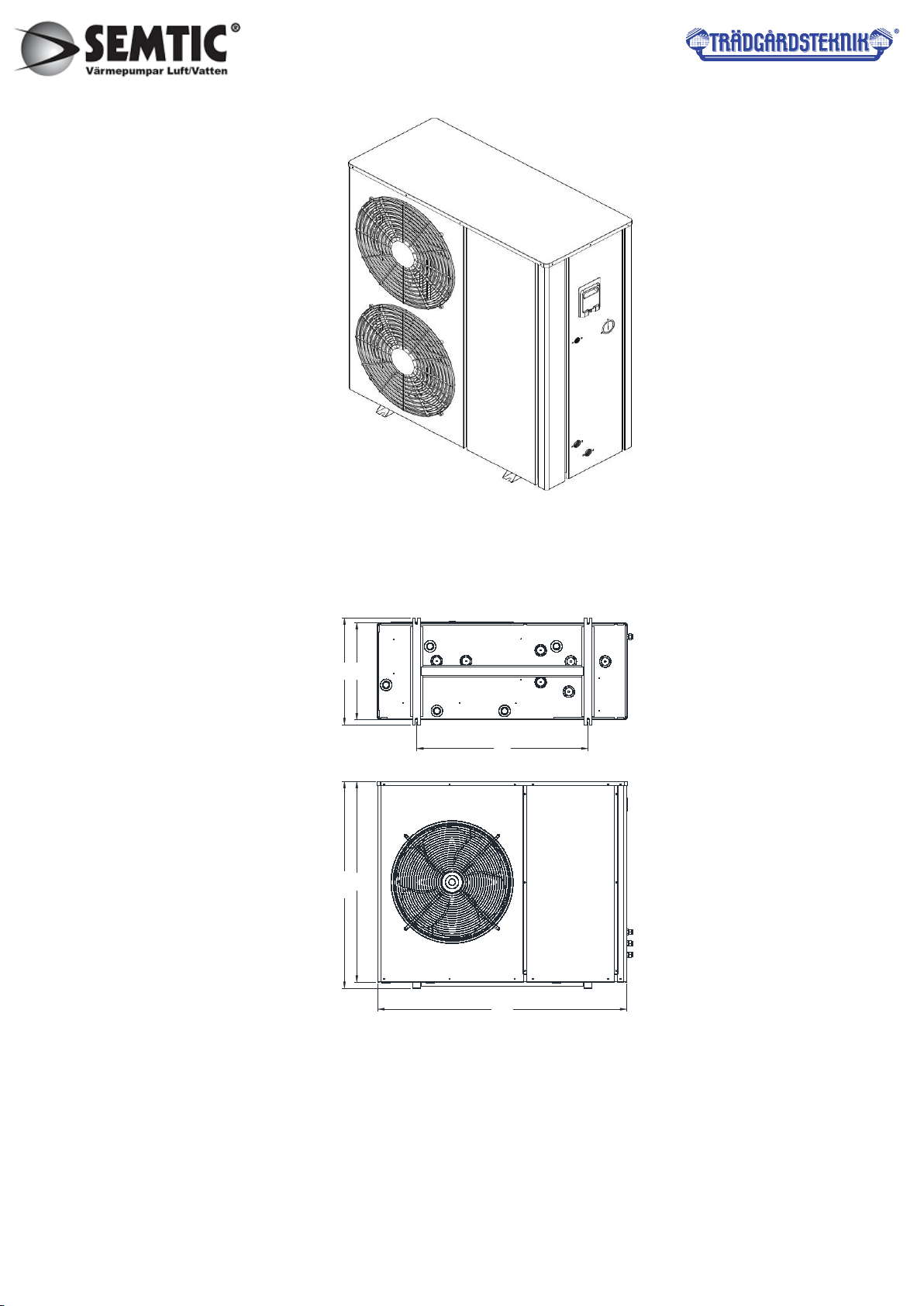

3.Appearance size

3.1 BKDX30-95

430

472

886

913.6

1105

760

3.2 BKDX50-200, BKDX60-220

5

490

1114

1256.7

509

705

1222

489

1114

G1"内 牙 接 头

G1"内 牙 接 头

G3/4"内 牙 接 头

高 压 表

抽 手

489

BKDX80-280

6

比例

1521.5

1556.5

587

592

620

104.2 964.6

出水口G1.5寸

进水口G1.5寸

62

1507

591.8

1052

7

Unit Low temperature DC Inverter monoblock heat pump

Model BKDX30-95 BKDX50-200 BKDX60-220 BKDX80-280

Waterproofing

grade

IPX4

Leakage

protection

ⅠClass

Power source

220V

~

1N/50Hz/60Hz 380V

~

3N/50Hz/60Hz

380V~3N/50HZ

Rated water

supply

165L/h 385L/h 392L/h 535L/h

Rated heating

capacity

9000W 19000W 21000W 30000W

Hot water

capacity

2200-9200W 4000-19400W 5200-21500W 6950-29200W

Heating

capacity

2600-9500W 4500-20000W 5600-22000W 5850-30000W

Cooling

heating

2500-7000W 4500-11000W 5200-13500W 7200-16600W

Heating input

power

1000-3000W 2000-5500W 2500-6600W 2660-8000W

Hot water

input power

1000-3000W 2000-5500W 2500-6600W 2660-8000W

Cooling input

power

1000-3000W 2000-5500W 2500-6600W 2660-8000W

Electrical

heating power

3000W 3000W 3000W /

Electrical

heating

14A 14A 14A /

Rated input

power

2370W 5080W 5660W 6050W

Rated current 10.5A 7.3A 26.1A 9.2A

Max current 27.1A 15.2A 45A 12A

Max input

power

5960W 8080W 8660W 8850W

Max hot water

temperature

55℃55℃55℃55℃

Rated water

flow

1.8m3/h 3.5m3/h 4.0m3/h 5.1m3/h

Refrigerant R410A/1500g R410A/2200g R410A/2700g R410A/3500g

Net weight 100kg 145kg 150kg 185kg

Noise ≤48dB(A) ≤52dB(A) ≤55dB(A) ≤60dB(A)

Inlet/outlet

gas max

4.2MPa 4.2MPa 4.2MPa 4.2MPa

High/low

pressure max

4.2MPa 4.2MPa 4.2MPa 4.2MPa

Heat

exchanger

4.2MPa 4.2MPa 4.2MPa 4.2MPa

8

4.Specifications

III. Installation

1.Heat pump installation

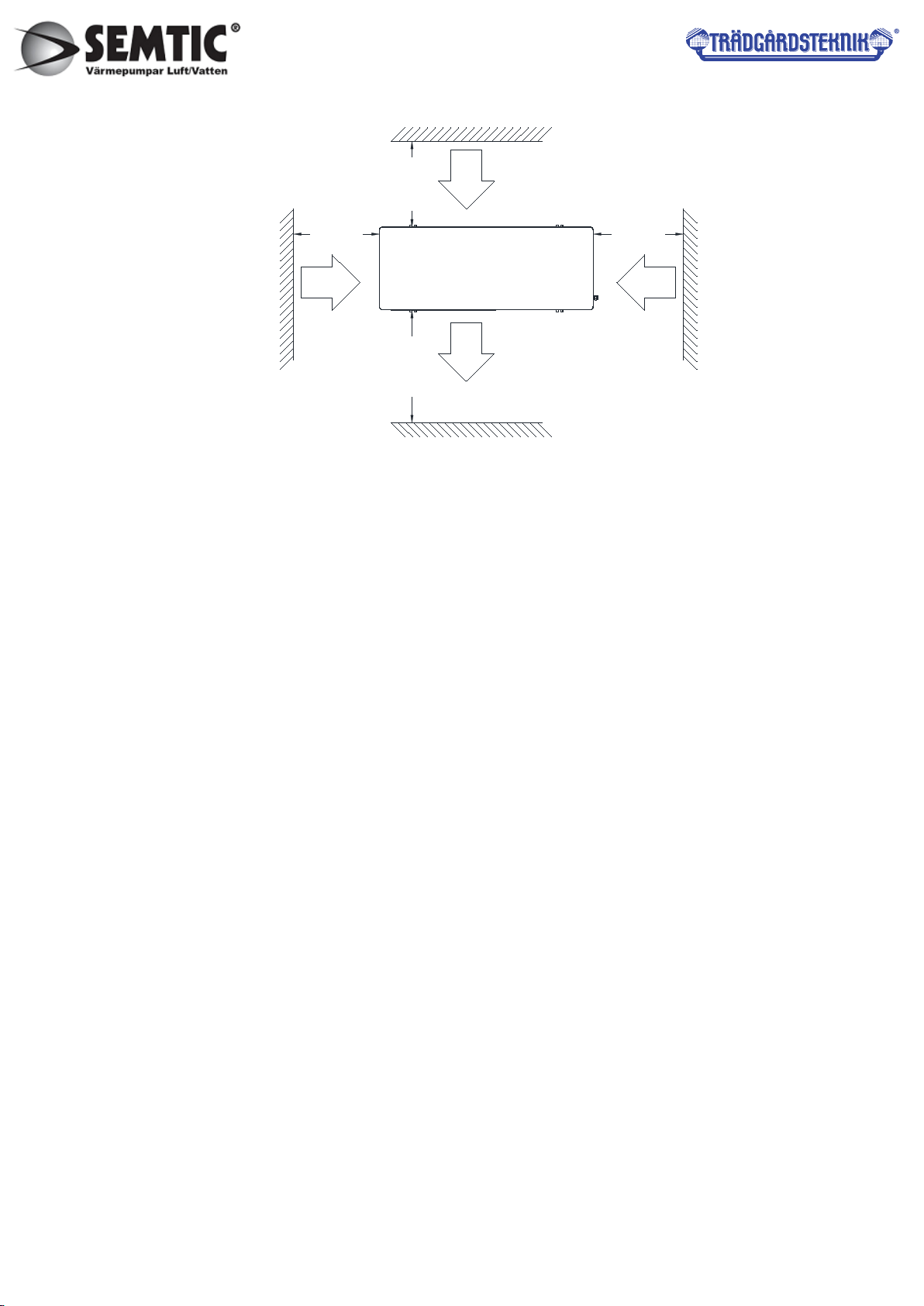

(1).Installation location

◆Provide sufficient space for installation and maintenance.

◆Inlet and outlet accessibility, strong wind cannot reach

◆Unit installed in ventilation place where can bear the weight of the unit, can mount the

unit horizontally, also will not increase the mechanical noise and vibration.

◆Exhausting air won’t affect the neighbors, no combustible gas leakage.

◆Should have the snow shed in winter.

◆Around the unit need drainage channel to drain condensate out.

◆Installation location should be easy to install, repair and connect.

◆If installed on the roof, it needs to increase measures against typhoons and lightning.

◆Do not install the control panel in the bathroom, in order to avoid moisture to affect the unit

Operation.

(2).Installed in the following locations may cause the machine to malfunction.

◆Places such as cutting oil and other mineral oils.

◆Places with salted air near the sea.

◆Places which contains gas such as sulfur, acidic or alkaline and other corrosive gases

in the spa area.

◆The place is with seriously voltage fluctuations and have strong electromagnetic waves.

◆Kitchen and other places which are full of oil odor, and oil trace.

(3).Unit infrastructure installation

Units can be installed base of concrete structures, and steel brackets can also be used to install, basic

surface is roughness (basic is designed according to the operational quality and according to the

technical performance parameters table). Under the unit, should install the vibration damping rubber, and

fix with bolts. Adjust the unit installation level, tilt <2 degrees. On the ground should have the drains for

unit's condensate.

9

Air out

≥300mm

≥2000mm ≥300mm

≥300mm

Air in

Air in

(4).Selection circulation pipeline.

Circulation pipeline of inverter heat pump can not be smaller than the inlet and outlet pipeline, circulation

pipe should use the same diameter as inlet and outlet pipes.

(5).Connection of pipeline

◆Don't let the dust and other debris into piping system.

◆Doing the plumbing work after fixing the unit firmly.

◆A removable filter (40~60mesh)must be installed at the water inlet and please regular clean the

valve depend on your local water quality.

◆Install a drain valve in the lowest point of the pipe, for convenient cleaning, Ensure smooth access

level, Can not alternately up and down, for discharge the air and draining the water in the pipe out.

◆Install the union valve at the water inlet/outlet, for convenient maintaining. Should fix the valve on

water pipe of the unit. Rotating the water pipe, water connecting can’t withstand rotation torsion directly.

◆Outlet and inlet water pipes should do thermal insulation well, the distance of outlet and inlet need to

apart, for first time to use, should add the appropriate amount of antifreeze and anti corrosive into the

warming water pipes, the input water pipe and water tank can do water replenishment according to the

actual situation.

◆Do not shut off the power in winter. If do not use for a long time, should drain off the water in the unit

and water pipes, to prevent heat exchanger or water pipe freeze and crack.

◆Select pipe material, can choose stainless steel, copper, aluminum hot water pipes, hot water PPR

pipes, etc., with pipes in national health and safety standards, heat-resistant, rust-proof, not easy to

scale.

◆Reasonable pipe layout, to minimize bending and reduce the pressure loss of the water system.

◆After the circulating water system connected, must do pipeline connection rigidity and add water

pressure inspection, and sewage, to ensure the system clean. Past the inspection,no leakage, then pack

insulation for pipeline and valves.

◆Metal pipe must use with more than 50mm thick glass fiber or high density, fire-retardant insulation

sponge. (PPR hot water pipes can be used 30mm thickness of glass fiber or high density fire-retardant

10

sponge rubber insulation.)

◆Must install thermometer and water pressure gauge on Inlet and outlet water pipes,to inspect during

operation.

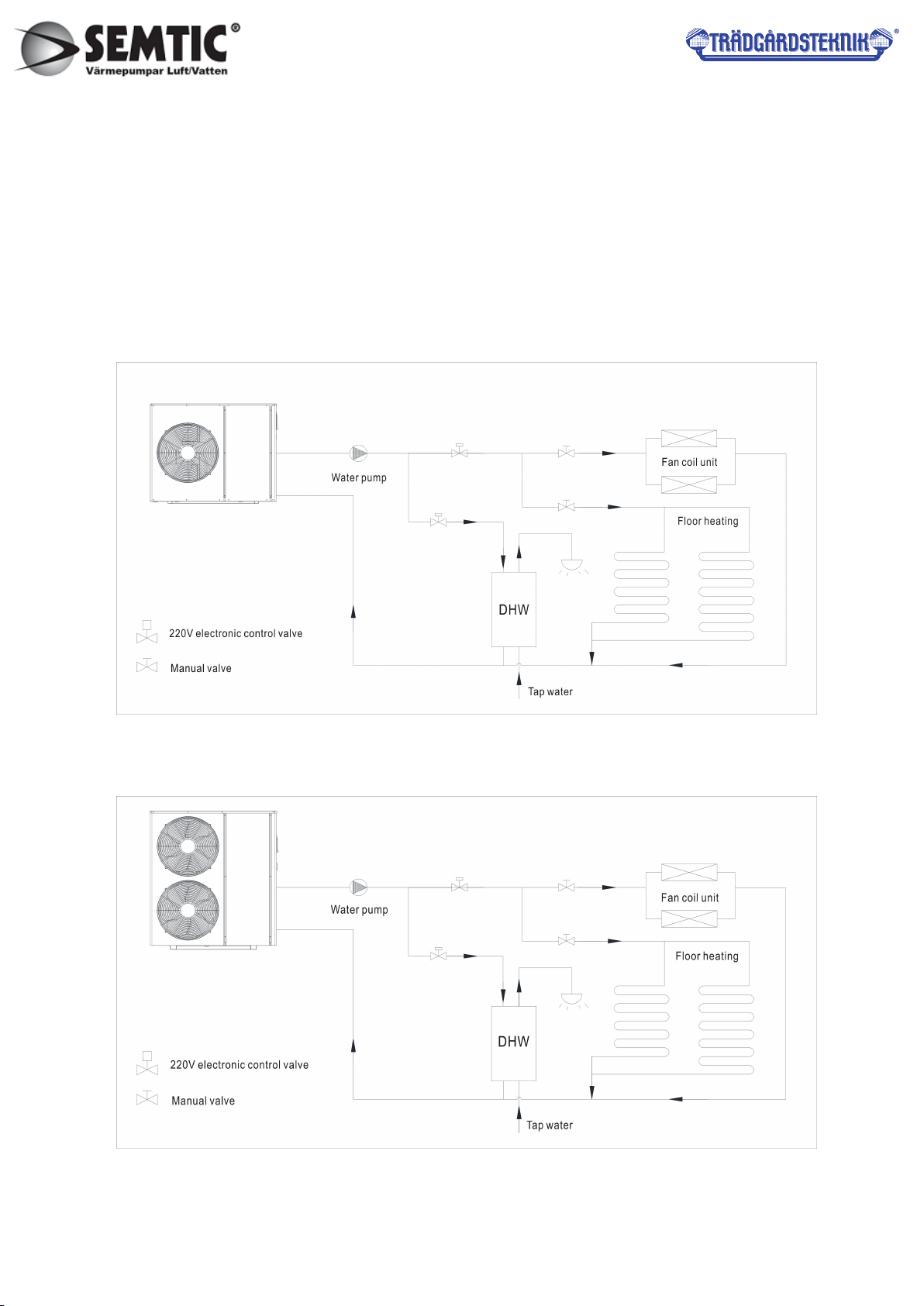

2.Connection diagram

(1)BKDX30-95

(2)BKDX50-200, BKDX60-220, BKDX80-280

11

3.Circuit connection

(1) Attentions

◆Construction wiring must be installed by a professional technician for construction in accordance with

the circuit diagram.

◆Appliance installation wiring should be installed in accordance with national wiring rules.

◆Before installation, please confirm whether your local voltage is match with the voltage showed on the

machine’s nameplate and whether the carrying capacity of the power supply, wires and sockets are

suitable for this machine’s input power.

◆The power source wire diameter is selected by the nameplate maximum current.

◆The regulation of insurance tube: according to the reality.

◆Users are not allowed to change the power cord, wiring work must be carried out by qualified

electricians, and to ensure that the machine metal parts has a good connection with grounding, the

machine shall not be allowed to change the grounding method.

◆The power connection must be equipped with the unit matching and at least 3mm contact with the

power from the all-pole disconnect device and leakage protection device.

◆If the power soft wire is damaged, it must be replaced by the manufacturer, its service department, or

similar professional to avoid danger.

◆Do not insert hands or foreign objects into the outlet of the unit, which will lead to the danger of

personnel and equipment.

◆The remote controller is fixed by screw and installed indoor with the height above 1.5M. It is forbidden

to install in the environment where the humidity, rain, acidity, corrosivity and light illuminate directly.

◆The water quality of the unit must meet the national standard of domestic water consumption,

otherwise it will cause the machine damage, the company does not bear any responsibility.

12

4.Circuit diagram

(1)BKDX30-95

(2) BKDX50-200, BKDX60-220

M

Power input

(380V/3PH/50Hz)

FM1FM2

PE4

PE5

1 2 3 4 5 6

P P P P

N1

N1 N1

L1

L2

L2

N2

N2

D1 D2 D3

R1

D+

PE

KA1

FR

FR

N3

L2 L2

L1

OUT10

N10

N4

P

PE6

PE2

RSTN

W

V

U

PE3

COM

NR S T

L1

S1 T1

R1

S1

T1

D+ D-

D-

I2

I1

U

V

W

D1 D2 D3

N1

Notice: please connect external contactor

when circulation pump power

large than 600W.

1 2:Circulating water pump.

3 4:Hot water solenoid valve.

5 6:Heating/cooling solenoid valve.

Ambient temp..(Yellow)

Coil temp..(Blue)

Exhaust gas temp..(Red)

Return gas temp..(Green)

Output water temp..(Black)

Return water temp..(White)

Water tank temp..(White)

Red Red Red

Red

Yellow

Green

Blue

Red

Yellow/Green

Blue

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

Red

Blue

Red

Blue

Red Red

Red Green

Red Yellow

Green

Inductor

5mH/20A

Yellow

Yellow

Wired controller

Electronic expansion valve

Red

Yellow

Green

Blue

Blue Blue

Blue

Blue

Red

Red

Pipeline herter

Four-way valve

Crankshaft heater

Chassis heater

Black

White

Red

Orange

Red

Orange

Black

White

Red Red Red

High pressure switch

Low pressure switch

Circulating water side

water flow switch

Linked switch

(short-circuit)

Antifreeze switch

(short-circuit)

CN607

I1

I2

DC+

DC-

R

S

T

V

U

W

DC-DC+

N1

GND

NRST

R1 S1 T1

N' R' S' T'

N1' S1' T1' COM_D

COM_L

DISP

SW2

CN26

NL

OUT4

N8 N7 N4

N2

OUT3 OUT1

TS5

N1

OUT5OUT6OUT7OUT8

TH1 TH2 TH3 TH4 TH5 TH6 TH7

TS3

TS4

TS1

TS2

SW1

TH8 TH9

OUT2

N9N10

OUT9

OUT10

CN2

Cooling valve

13

(3) BKDX80-280

M

COM_D

COM_L

DISP

SW2

CN26

NL

OUT4

N8 N7 N4

N2

OUT3 OUT1

TS5

N1

OUT5OUT6OUT7OUT8

OUT9

TH1 TH2 TH3 TH4 TH5 TH6 TH7

TS3

TS4

TS1

TS2

SW1

OUT10

P P P P

ST N

S1 T1

S1 T1

S1T1N1N2 N1

N2

(380V/50HZ)

1 2 3 4 5 6 PE1

W

V

U

PE3

COM

FM2FM1

PE4PE5

PE2

RST N

RST N

N1

L1

L2

N2

L2

N2 L1

N1N1N1

D1 D2 D3

D1 D2 D3

R1 S2 T3

R1

S1

T1

U

V

W

U V W

DC+ DC-

I2

I1

1 2:Circulating water pump.

3 4:Hot water solenoid valve.

5 6:Heating/cooling solenoid valve.

Power input

Notice: please connect external contactor when

circulation pump power large than 600W.

Red Red Red Red

Yellow

Green

Blue

Yellow/Green

Yellow/Green

Black

White

Crankshaft heater

Chassis heater

Four-way valve

Black Black

White

White

Red

Orange

Red

Orange

Red

Yellow

Green

Red

Yellow

Green

Red

Yellow

Green

Yellow

Inductor

Blue

Black

White

High pressure switch

Low pressure switch

Circulating water side

water flow switch

Linked switch

(short-circuit)

Antifreeze switch (short-circuit)

Wired controller

Electronic

expansion

valve

P

Ambient temp..(Yellow)

Coil temp..(Blue)

Exhaust gas temp..(Red)

Return gas temp..(Green)

Output water temp..(Black)

Return water temp..(White)

Water tank temp..(White)

IV. Trial running

1.Trial running must after all the installation completed.

2.Please confirm the following matters before the trial operation, put “√”in the boxes after

confirmation

▲ Unit is installed correctly

▲ Power supply meets unit’s rated power source need

▲ Piping and wiring are correctly installed

▲ Unit air inlet/outlet well-ventilated

▲ Drain off water is done well

▲ Leakage protective device act effectively

▲ Pipe thermal insulation

▲ Grounding wire connected correctly

14

3.After check and ensure correct, then power on. If the control panel display nothing, that should

recheck and tight the line of control panel. The control panel should display time, setting

temperature and the current temperature.

4.Discharge the air out of the pipelines , and then press ON/OFF button, the unit work under the

setting temperature, unit’s trial running would check the following:

▲ First time to run the device, check the current normal or not;

▲ Operation panel’s function keys are normal or not;

▲ The indicator light is normal or not;

▲ The whole circulating hot water system whether has water leakage;

▲ The condensed water discharge is normal or not;

▲ System’s pressure is normal or not (according to the high water temperature or low

pressure);

▲ Whether there is abnormal sound and vibration when unit running;

▲ The wind, sound and condensed water from unit whether effect neighborhood;

▲ Whether there is leakage of refrigerant.

15

V. Operation panel instruction

1. Indoor line control panel (BKDX30-95)

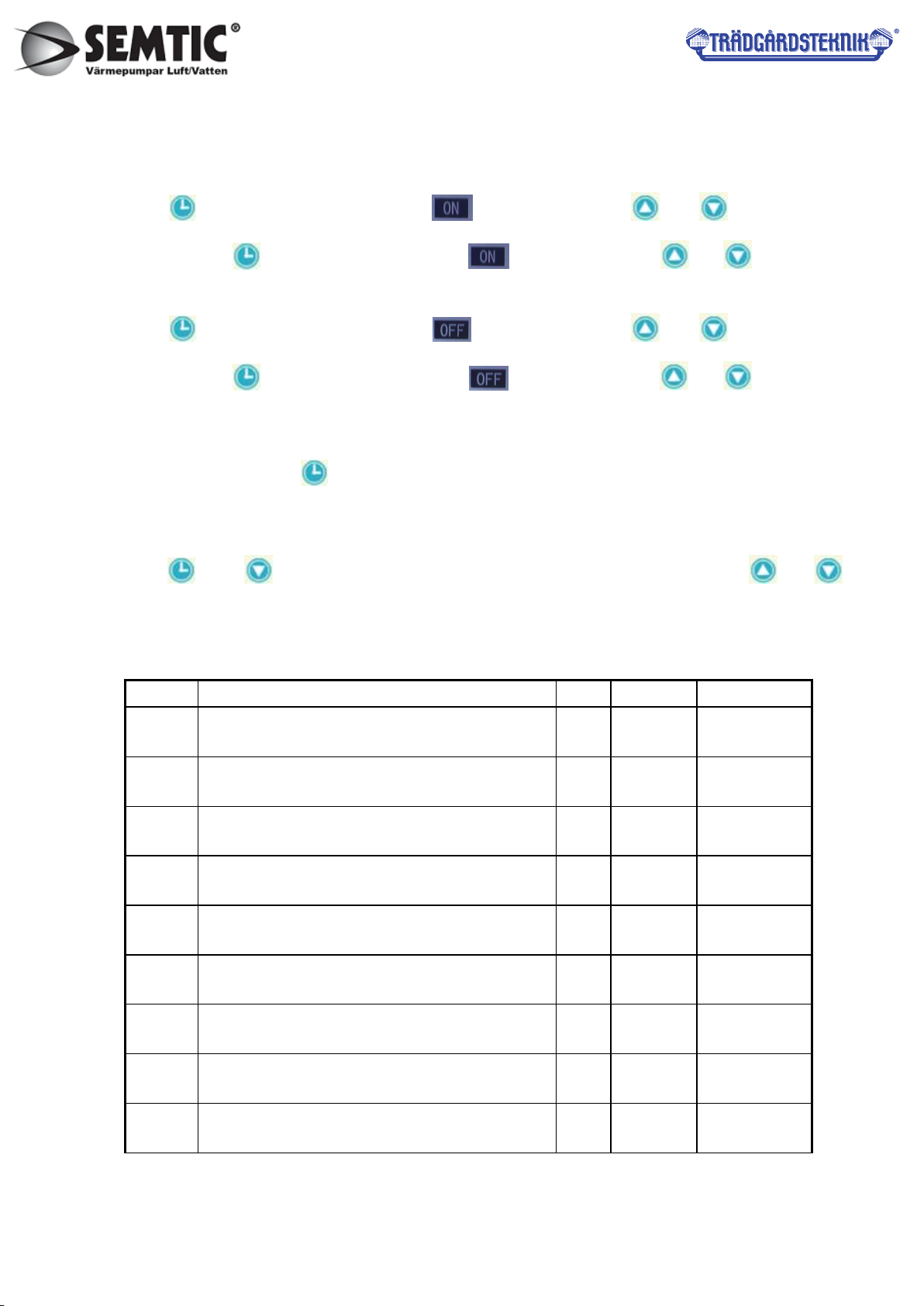

2. Button Instruction

2.1 Button lock and unlock

Press and to lock or unlock the controller.

When in lock status,the display ,when in unlock status,the hide.

2.2 On/off Button

Press to switch on/off the unit.

In power on status,in heating mode,press for 3 seconds then forced into defrost process.

2.3 Mode Button

In switch on status,press to select the working model.

In switch off status,press to for 3 seconds to forced into recycle refrigerant function.

2.4 Temperature Setting

In switch on status,press or to set the temperature,press more than 0.5 second to fast

increase or decrease.

2.5 Clock setting

Press for 3 seconds,minute number flashes,press or to modify the minute number.

Press again,hour number flashes,press or to modify the hour number. Press again

16

to save and exit the clock setting.

2.6 Timer Setting

Press ,minute number flashes and icon flashes,press or to modify minute

number. Press ,hour number flashes and icon flashes,press or to modify hour

number.

Press ,minute number flashes and icon flashes,press or to modify minute

number. Press ,hour number flashes and icon flashes,press or to modify hour

number.

Without operation in 10 seconds then exit timer setting.

After timer setting, press again to cancel the timer .

2.7 Parameters Checking

Press and for 3 seconds to enter into parameters checking status,touch or to

check each parameter.

Parameters table

No. Status name Unit Ranger Remark

d01 Inverter compressor current actual frequency Hz 0~150

d02 Inverter compressor operation(input) current A0~50.0

d03 Water return temperature ℃-30~999

d04 Water tank temperature ℃-30~999

d05 Water supply pipe temperature ℃-30~999

d06 Reserve ℃-30~999

d07 Exhaust gas temperature ℃-15~999

d08 Ambient temperature ℃-30~999

d09 Evaporator coil temperature ℃-30~999

17

Button instruction

Fault code and instruction table

Code No. Fault Name

E01 Outdoor unit current protection

E02 Flow switch protection

E03 EEPROM error indication (indoor board) / EEPROM error indication (operation

panel)

E04 Return water temperature over high when heating or output water temperature

over low when cooling

E05 DC link voltage is over high / low protection

E06 IPM failure

E08 Output and input water temperature different too large protection

E09 Communication error ( indoor board and outdoor board)

E10 Return water temp sensor fault

E11 Output water temp sensor fault

E12 Tank temp sensor fault

E13 Ambient temp sensor fault

E14 Evaporator temp sensor fault

E18 Compressor outlet gas temp sensor fault

E21 Compressor outlet gas temperature over high

E25 Evaporator coil temperature too high when cooling model

E31 System pressure over high protection

E32 Communication error (operation panel & indoor board)

E33 Communication error (IPM & outdoor board)

d10 Gas return temperature ℃-30~999

d11 After throttling temperature ℃-30~999

d12 Opening of EXV(shown as the actual opening ) P0~500 Pulse count

18

E41 System pressure over low protection

E44 Winter unit standby antifreeze protection

E45 Return gas temp sensor fault

E46 Temp sensor fault after throttle

E47 Water tank temperature sensor abnormal protection

E48 Antifreeze switch disconnect failure

BKDX50-200, BKDX80-280

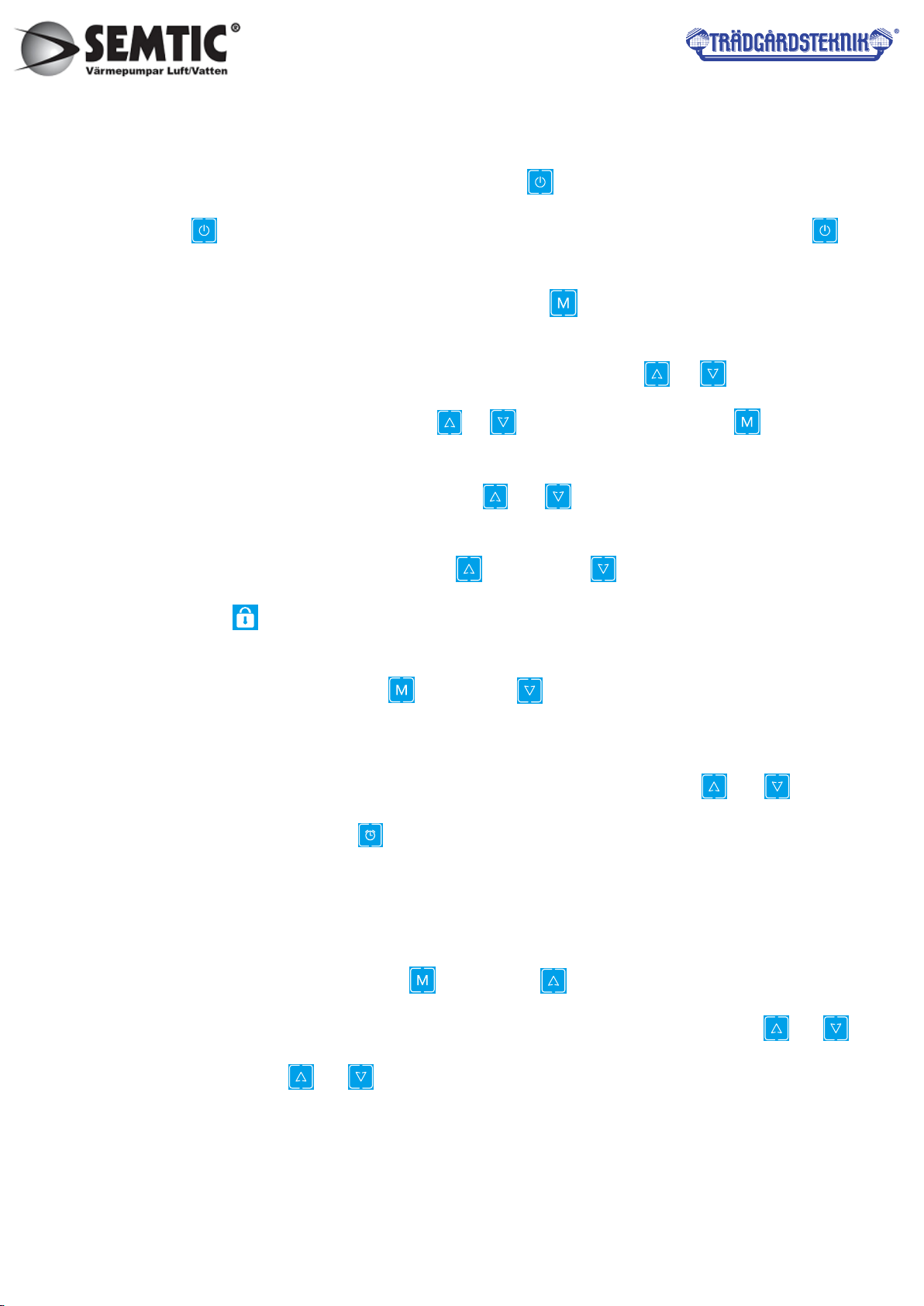

2.21. Operation illustration & displays

Symbol Definition Symbol Definition

On/Off Key Hot Water Mode Botton

Timing Setting Key Room Heating Mode

Botton

Add Botton Cooling Function Mode

Botton

Subtract Botton Defrosting Function

Botton

Mode Botton Timing Botton

2.3.1 Wired Controller Display Declaration

2.3.1.1 Temperature display area display system cock, timing, running parameters, common

parameters, alarm code related datas.Left side temperature display area display actual detect tank

temperature ,setting temperature ,parameter number etc.

Right side temperature display area display setting temperature ,parameters values etc.

2.3.1.2 Flashes of the various fields show the flashing period for 1 second; after the full power of about

3 seconds after the normal operation.

19

2.3.1.3 30 seconds without key operation, the LCD display brightness will automatically extinguished.

2.3.2 Wired Controller Operation

2.3.2.1 On/ Off Key: when heat pump shutdown, press “ ” to start up the unit ; when heat pump start

up press “ ”key to shutdown the unit. When heat pump under heating start up status, press “ ” for

more than 3s to force unit to enter defrosting function .

2.3.2.2 Mode Key: When the wired controller is on, Press“ ”to choose the operating mode, and also

for setting temperature, checking & setting parameters, etc.

2.3.2.3 Temperature Setting: When the wired controller is on, press“ ”or“ ”,the temperature

data on the screen will show up, then press “ ”or“ ”to add or reduce,

then press“ ” to confirm the

modifying, or after 20 seconds without any operation, it will automatically quit from the temperature

setting, and store the current modified data, press“ ” or “ ” without stop for over 0.5 second to start

quick adding or substracting.

2.3.2.4 Key locked function: First press “ ”, then press “ ” for 3s to enter or exit key locked

function, when “ ”symbol show up means wired controller locked.

2.3.2.5 Inquiry running parameters

2.3.5.1 Enter inquiry: first press “ ”then press “ ” for 3 s to enter parameters setting status,

temperature display area display parameter number, setting temperature area display parameters

content.

2.3.5.2 Inquiry operation and exit: after entering running parameters, press “ ”or “ ”to display

each running parameter; press “ ”to exit inquiring parameters status or if there is not any pressing

keys operation will automatically exit inquiring parameters status after 20s.

2.3.2.6 Common parameters setting

1.3.6.1 Enter setting ; first pressing “ ” then press “ ” for 3 secs,the temperature display area

display “00” and blinking display ,input the password (default password “Fb”),then press “ ”or “ ”to

add or subtract ,press “ ”or “ ” to confirm ,if the password is wrong then exit current status ; if the

password is correct then enter parameter modification status ,temperature display area display

parameters number and blinking display ,setting temperature area display parameter content ;

20

1.3.6.2 Setting operation : after entering setting parameters, the parameter number blinking

display ,press “ ”or “ ”switch line to display each setting parameters number ,then press “ ”the

parameters content blinking display ,press “ ”or “ ” to modify current content ,after finishing press

“ ” to save current modification then back to parameters number display status .

1.3.6.3 Exit setting; press “ ”to exit parameters setting status or if there is not any pressing keys

operation will automatically exit parameters setting status after 20s.

2.3.2.7 Fault display; when unit fault occurs, the fault blinking display at setting temperature area,

recycling display fault code and temperature, after fault clear the controller recover normal display.

2.3.2.8

2.3.8.1 Clock display: in unit shutdown status, long press any keys except “ ”, the temperature

display area display current time for one second.

2.3.8.2 Enter clock setting; long press “ ” for 3 secs.minutes part of clock area blinking display,

means entering clock setting status

2.3.8.3 Clock setting operation : enter clock setting status ,minutes part blinking display ,press “ ”or

“ ”to modify minute value .Then press “ ”,hours part blinking display ,press “ ”or “ ”to

modify hour value ,press “ ” to save current setting then exit or if there is not any pressing keys

operation will automatically save current setting then exit.

2.3.2.9 Setting Timing Control

2.3.9.1 There are 2 group timing units, 1 ~2 group ,each timing unit group can set as “timing

startup ”timing shutdown. Default setting is “invalid”, means timing startup and timing timing shutdown is

same.

2.3.2.9.2 Enter the setting timing: short press “ ”,symbol “1 ”、“ON ”at left bottom screen blinking

display ,minutes display area blinking means enter “1 unit timing startup ”setting status ,the minute

position blinking display ,press “ ”or “ ”to modify minute value ,then press “ ” to confirm then

enter hour setting ,the hour position blinking display , press “ ”or “ ”to modify hour value ,press

This manual suits for next models

3

Table of contents

Other Semtic Heat Pump manuals

Popular Heat Pump manuals by other brands

Panasonic

Panasonic WH-UD09HE5 operating instructions

Mitsubishi Electric

Mitsubishi Electric SLZ Series Technical & service manual

NorAire

NorAire NC-FE series Installation & operating instructions

York

York AFFINITY YZH02411 Technical guide

Trane

Trane 4WCC4036E1000B Installation and operation manual

Trane

Trane 4TWR7 Installer's guide

Panasonic

Panasonic S-80MW1E5 Installation instructions manual

Dimplex

Dimplex SIK 8 TES Installation and operating instructions

Danfoss

Danfoss DHP-iQ installation guide

CLIVET

CLIVET WSAR-MT Series Installation and use manual

ThermoTec

ThermoTec 29kw Installation instructions manual

Daikin

Daikin DP5HM installation instructions