Semtic NERS-B3Y Owner's manual

SWIMMING POOL HEAT PUMP

Contents

I. Security and prevention----------------------------------

1. Notice---------------------------------------------------------------------------

2. Warning -----------------------------------------------------------------------

II. Advantage ----------------------------------------------------

--------------------------------------------------------------1. Compressor-----

2 --------------------------------------------------------. Digital controller-----

3-----------------------------------

Heat exchanger-----

4 --------------------------------------------------. Heat&cool capability-----

5 --------------------------------------------------------. Hot gas defrost-----

III. Specification -------------------------------------------------

1. Model Nomenclature-------------------------------------------------------

2. Parameter --------------------------------------------------------------------

3. The installation dimensions-----------------------------------------------

IV. Installation-----------------------------------------------------

1. Positioning you swimming pool heat pump---------------------------

2. Unit installation position----------------------------------------------------

3. Installation requirement ----------------------------------------------------

4 --------------------------. Connecting your swimming pool pipe work

5. Installation drawing ---------------------------------------------------------

6. Electric wiring ---------------------------------------------------------------

7 -----------------------------------------------. Selection of electrical wire

V. Use ---------------------------------------------------------------

1. Wire controller device installation----------------------------------------

2. Uses of the remote controller----------------------------------------------

I. Maintenance -------------------------------------------------V

1. Note ---------------------------------------------------------------------------

2 --------------------. Malfunction indicating table--------------------------

3. Determine and solve malfunction by below table-------------------

VII. Wiring diagram---------------------------------------------

1. NET92033 PCB input and output port definition--------------------

2. Power phase sequence protection board setting--------------------

3. The internal structure in electrical box----------------------------------

4 ---------------------------------------. Wiring diagram------------------------

1

1

1

1

1

2

2

2

2

3

3

3

4

6

6

6

7

7

8

8

9

10

10

10

12

12

12

13

15

15

16

17

22

I. Security and prevention

1.Notice

1.1 In order to use this product better and safer, please read this instruction carefully before install

and operate it. Please pay attention to all the notice in operation and maintenance. Save all manuals

and documentation for future reference.

1.2 Swimming pool heat pump is a special appliance. Improper installation will cause damage and

danger. It should be installed and maintained by the professionals. Please contact our authorized local

service point for installation and maintenance. Please read and follow this instruction carefully before

and during installation.

Remarks:

We will not bear the responsibility for any personal injury or unit damage caused by non-Compliance

of the regulations and instruction in this manual.

1.3 Please check whether the distribution power capacity, switch and socket are compliance with the

requirements of our unit power. Details please refer to the rating label or parameter table in this

manual.

1.4 The power should be equipped with leakage protection separately. Power cable should be chosen

in accordance with the operation requirements of the unit.

1.5 The unit must be grounded safely. Do not use the unit if grounded unsafely. Do not connect the

ground line to the neutral and or tap water pipe.

1.6 The wire must be joined in compliance with the requirements of the wiring chart. Do not alternate

and or repair the unit personally.

1.7 Do not install the unit closed to inflammable, explosive and naked light spot.

1.8 To ensure the unit operate properly, please equipped with a filter in the water input when

installation.

1.9 Please contact us or our authorized service site if the unit failures. The unit can’t be used again

without technicians’ checking.

1.10 The unit parameter has been set before leave of the factory. The parameter Can’t be adjusted

by the unprofessional.

1. Scroll Compressor

II. Advantage

2.Warning!

2.1 Do not carry devices alone.

2.2 Connect all the ground wires.

2.3 All the electrical connections should be made by a certified electrician .

2.4 When manipulating electrical equipment, make sure there is no voltage using a well calibrated

voltmeter . To avoid damaging the equipment the equipment, do not use heating or cooling devices

during the construction phase. Why? Because components can become obstructed with dirt and

debris which man damage the device.

50% fewer moving parts than standard piston-type compressors. This equates to much

improved reliability and improved efficiency. Scroll compressors are also much quieter in

operation than their piston-type counterparts. And, while all heat pumps are known for the

ir low operating noise levels.

1

2

2. Digital Controller

Digitally-based microprocessor controls water temperature to within 1℃

of set point.

Controller also permits user to predefine different pool and spa water temperatures, and to

prevent tampering by locking out controls via a

control ke

.y

3. Heat Exchanger

The heart of your heat pump is the patented

heat exchanger. One of the

primary causes of

premature heat pump demise is the failure of the heat exchanger. Ordinaryheat exchangers

are made from a cupronickel alloy

and the shell is made by PVC.

This

cupronickelmaterial is susceptible to attack from the sanitizers used in pools and spas and

from other related water chemistry conditions. Once the heat exchanger fails, the heat pumpis

ruined.And

The PVC is can't bear too high pressure and temperature, and exit the risk ofburst

and leak.

The

heat exchanger tube is made from titanium, and isvirtually impervious to water

chemistry damage,

and the shell is made form a patent

secret

ingredients, it can standmore than 21kg water pressure and high temperature.

4. Heat&Cool Capability

Puts you in full control, year round... Warms your pool or spa with the reliability and efficiency

of our other heat pumps, but, with the flip of a switch, can also cool your pool or spa to

refreshing temperatures during hot summer months. For cooler climates, Heat & Cool heat

pumps offer unique advantages over passive defrost models. Please read more below...

5. Hot Gas Defrost

Hot gas defrost heat pumps are uniquely equipped for an

active

defrost cycle.

Active defrost

involves directing hot refrigerant vapor to the heat collector, melting accumulated ice away in

a matter of a few minutes... then right back to heating. Standard defrost heat pumps may

remain

“off in defrost”

for extended periods during very cold weather. Because of their

ability to continue to operate-even during freezing weather-hot gas defrost models extend the

swimming season longer than

any

standard-defrost heat pump.

PLEASE READ FURTHER

TO BECOME FAMILIAR WITH

ALL

THE FEATURES,

THE SAFE

OPERATION

2.Performance of Swimming Pool Heat Pump

3

III. Specification

NERS-G8Y

34.5

23.5

6.65

380V/3PH/50Hz

28

40

14.8

IPX4

Ⅰ

60

≤60

1360*854*1320

260

272

4.2/4.2/4.2

Model

Rated heating capacity

Rated cooling capacity

Rated input power

Power supply

Rated output water temperature

Max output water temperature

Rated circulating water flow

Refrigerant

Rated of waterproof

Rated of Elc.leakage protection

Pressure drop between inlet

and outlet water

Noise

Max Heat exchanger's pressure

Net Dimendions (L/W/H)

Net Weight

Gross Weight

KW

KW

KW

V/PH/Hz

℃

℃

3

m /h

IPX4

kPa

dB(A)

MPa

mm

kg

kg

NERS-B6Y

26.2

18.3

5.12

380V/3PH/50Hz

28

40

13

IPX4

Ⅰ

40

≤58

165

175

4.2/4.2/4.2

NERS-B5Y

22.5

15.7

4.24

380V/3PH/50Hz

28

40

8.7

IPX4

Ⅰ

40

≤55

1108*518*1257

155

162

4.2/4.2/4.2

NERS-B3Y

12.8

8.96

2.43

28

40

5

IPX4

Ⅰ

30

≤50

1108*518*904

100

105

4.2/4.2/4.2

220V/1PH/50Hz

COP

W/W

5.19

5.125.35.27

Inlet/outlet size

Compressor

R410A R410A R410A R410A

Class

1.5" 1.5" 1.5" 1.5"

Copeland Copeland Copeland Copeland

1108*518*1257

NERS-G30Y

120

91

23.5

380V/3PH/50Hz

28

40

52.5

IPX4

Ⅰ

70

≤66

2180*1000*1980

800

840

4.2/4.2/4.2

Model

Rated heating capacity

Rated cooling capacity

Rated input power

Power supply

Rated output water temperature

Max output water temperature

Rated circulating water flow

Refrigerant

Rated of waterproof

Rated of Elc.leakage protection

Pressure drop between inlet

and outlet water

Noise

Max Heat exchanger's pressure

Net Dimendions (L/W/H)

Net Weight

Gross Weight

KW

KW

KW

V/PH/Hz

℃

℃

3

m /h

IPX4

kPa

dB(A)

MPa

mm

kg

kg

NERS-G24Y

101

74.2

19.6

380V/3PH/50Hz

28

40

40.0

IPX4

Ⅰ

70

≤64.8

750

775

4.2/4.2/4.2

NERS-G12Y

53.2

37.2

10.2

380V/3PH/50Hz

28

40

20.8

IPX4

Ⅰ

60

≤60

320

340

4.2/4.2/4.2

NERS-G10Y

45

30

8.65

28

40

17.5

IPX4

Ⅰ

60

≤60

1360*854*1320

300

315

4.2/4.2/4.2

COP

W/W

5.11

5.155.225.20

Inlet/outlet size

Compressor

R410A R410A R410A R410A

Class

1.5" 1.5" 3.0" 3.0"

Copeland Copeland Copeland Copeland

2180*1000*1980

380V/3PH/50Hz

1360*854*1320

Heating:the specifications are based on DB Temperature 24C,WB Temperature 19C,Water in/out 26C/28C.

Cooling:the specifications are based on DB Temperature 35C,WB Temperature 32C,Water in/out 30C/28C.

3. The installation dimensions

4

886

903.6

1105

452

430

1108

1134.5

518

489

3.1 NERS-G3Y

3.2 NERS-G5Y, NERSG6Y

1257

1222

5

1312

1626

854

2180

1000

1980

3.3 NERS-G8Y, NERSG10Y,NERS-G12Y

3.4 NERS-G24Y, NERS-G30Y

1. Positioning Your Swimming Pool Heat Pump

1.1 For correct operation air must be free to circulate around the heat pump. Do not place the

unit in a shed, greenhouse or similar. This unit is designed to be placed outdoors only.

1.2 Refer to the drawing below for required clearance.

1.3 You should position the heat pump so that the control panel does not face directly towards

the sun.

1.4 The heat pump must be upright.

1.5 The distance between the heat pump and the pool / plant room should be as short as

practically possible to reduce pressure and heat loss in the pipe work.

1.6 Insulating the pipe work will assist with the prevention of heat losses.

1.7 An isolator switch should be installed (by a qualified electrician) near the heat pump.

1.8 The electrical supply to the heat pump must be protected by a 30mA RCD.

1.9 The air inlets and outlets must not be obstructed or blocked.

1.10 Even though the heat pump is low noise, it must be positioned so as to be considerate

to neighbours.

1.11 Your heat pump must be placed on a solid base.

1.12 Avoid the condensation will drip from underneath the heat pump, the base must be able

to tolerate this.

IV. Installation

2. Unit installation position

To avoid ventilation short, the r unit discharged air should not return when installation.

Please keep enough space around the unit for repair. Right and wrong means as below:

Wrong Right

!

NOTICE:

1. To get enough air for ventilation of the unit, the installation position should be with good

ventilation.

2. The installation position can hold the outdoor unit without noise and shake.

3. No sunlight to the unit. Set an awning if necessary.

4. The water from rain and defrosting can be discharged in the installation position.

5. The unit will not be covered by snow in the installation position.

6. The discharged air will not face strong air in the installation position.

7. Assure the noise caused by the unit ventilation and operation will not affect the

neighbour.

8. The installation position will not be affected by garbage, oil and mist.

9. The unit will be damaged under the condition with oil(engine oil), salt(sea area) and

sulfide air(near thermal spring and refining factory).

6

3. Installation requirement

3.1 The unit can be installed in the balcony, roof, floor or any other convenient place and reliable

load-bearing.

3.2 Airiness place.

3.3 No heat radiation or other heat source place

3.4 Should be set up shed against the snow in winter.

3.5 Barrier-free at the air inlet or outlet place.

3.6 Outlet against strong winds blowing place.

3.7 There should be drainage channels around the machine in order to rule out the condensate.

3.8 Control Panel, do not install in the bathroom, so as not to affect the unit work by wet.

3.9 Should leave enough space around the machine. As shown below.

4. Connecting Your Swimming Pool Pipe Work

4.1 The pool water is fed through the heat pump by a swimming pool pump.

4.2 The heat pump must be installed after (down stream) the swimming pool filter so clean,

filtered water passes through it.

4.3 Double union ball valves must be fitted just before the heat pump inlet and just after the

outlet to aid servicing and winterising.

4.4 Each heat pump has a maximum water flow rate. If the flow via the pool pump is higher

than this then a by-pass should be installed. Consult your supplying dealer.

4.5 Each heat pump also has a minimum flow rate, below this the heat pump will not operate.

Consult your supplying dealer.

4.6 Pipe work of less than 1-1/2” diameter should not be used.

4.7 Fit a union nut onto each pipe.

4.8 Push the gasket over the pipe until the gasket is about 5 -10mm from the edge of the pipe.

You may need to lubricate the gasket.

4.9 Insert the pipe into the heat pump and tighten the union nut.

4.10 The union must only be hand tightened.

≥700mm

≥400mm

≥600mm

≥1000mm

≥700mm

≥400mm

≥400mm

≥1000mm

≥2000mm

Bolt

fix

4.11 If the swimming pool is equipped with a chlorinator, brominator, or possibly chemical

control with acid and chlorine pumps, these must be in the return pipe work after the heat

pump and a non-return valve used. Any dosing system must be the final equipment before

the water returns to the swimming pool. Damage caused to the heat pump by chemical dosing

units is not covered by warranty.

4.12 Any heat exchanger or electric heater fitted as auxiliary heating must be installed after

(down stream from) the heat pump so as to avoid pre-heating the pool water before it enters

the heat pump.

7

5.Installation Drawing

6.1 Unit supply cable must be used copper. Power supply voltage in line with theshould be

rated voltage and the rated current.

6.2 The unit, power supply circuit must have a grounding wire, and the power supply ground

wire must with the external grounding wire, and an external grounding wire to beconnect to

effective.

6.3 W must be installed by professional technicians carried out in accordance iring installation

with circuit.

6.4 S up a good leakage protection devices etting and in accordance with the relevant national

technical standards.

6.5 Power line and signal line layout should be neat, rational, strong and weak lines separating

cable and Can not interfere with each other, without contact with the connecting pipe and valve.

6.6 he construction of all wiring is completed, carefully check the correct order to connect After t

the power.

6.7 Unit electric wire connection: connect to the appropriate terminals according to wiring

diagram, and fix it by the pressure line of board in the electrical box.

6.8 All the wiring construction is completed, can be plugged in only after careful examination

correctly.

6.9 Unit control board fuse parameters: 3.15A.

6. Electric wiring

Unit electric box

(380V/3ph/50Hz)

PCB

Power input

(380VAC/3PH/50Hz)

R S T N

Wire controller

6. 10 lectric wiring installation drawingUnit's e

L1 L2 L3

Connect to the swimming

pool side water pump

(380VAC/3PH/50Hz)

CN9

ROO M

SET

MAUX

8

Water cycle pump

7. Selection of Electrical Wire

7.3 Caution of Ground The internal motor protector does not protect the compressor against

all possible conditions Please be sure that the system utilizes the ground connection when

installed in the field.

7.1 Voltage drop may occur due to the large current draw during compressor starting, and

may be result in the compressor is difficult to stat. So we recommend selecting the wire

specification from the table below.

7.2 Specification Table of Electrical Wire

7.4 Warning: To avoid fire, electric shock and other accidents, keep in mind about these tips:

A: Only use power supply voltage indicated on the label, if you do not know the family of

voltage, contact the dealer or local power company.

B: When you use the unit by the maximum current please view the specifications, so make

sure our home's power supply (current, voltage and cable) to meet the machine's normal load

requirements.

Host PowerMode: Phase line Zero line Ground line Circuit break

C: To protect the power lines. Power lines should be fixed, so that people will not be trip over

or the lines damaged by other things. Paying particular attention to plugs, which should be

easily plug into the socket, careful the plug position.

D: Do not overload wall plugs or extension the cable. Line overload can cause fire or electric

shock.

E: To ensure your safety, you must plug the power lines into the socket with a grounded

three-phase, and check to ensure your socket is accurate and reliable grounding.

9

NERS-G12Y

380V/3PH/50Hz 2

6.0mm 2

4.0mm Capacity:40A specification: <30mA <0.1sec

2

6.0mm

NERS-G24Y

380V/3PH/50Hz 2

10.0mm 2

6.0mm Capacity:80A specification: <30mA <0.1sec

2

10.0mm

Unit electric box

(220V/1ph/50Hz)

PCB

Power input

(220VAC/1PH/50Hz)

Wire controller

L N PE

Connect to the swimming

pool side water pump

(220VAC/1PH/50Hz)

CN9

ROO M

SET

MAUX

L N PE

NERS-G4Y/G3Y

220V/1PH/50Hz 2

6.0mm 2

4.0mm Capacity:21A specification: <30mA <0.1sec

2

6.0mm

NERS-G6Y

380V/3PH/50Hz 2

4.0mm 2

2.5mm Capacity:18A specification: <30mA <0.1sec

2

4.0mm

V. Use

1.Wire controller device installation

2.Use of wire controller

The remote controller is designed and employed standard electrical box dimensions

(86*86,fixed hole distance 60mm). The electrical box and three core can be built in the

wall before decoration, which makes the interior decoration more perfect. The

illustration shows as below:

Cover the face covering in the reverse procedures

as shown in Illustration 2 and Illustration 1 to

complete the mounting of the remote controller.

Put the remote controller in the electrician base .

box and tighten the two setscrews.

Illustration 3

Illustration 4

Illustration 1

Illustration 2

Use flat screwdriver to press down the two back-off

and lift open the face covering.

Remove the top covering leftwards to disengage

two top back-off.

2.1 The user interface and function shows as below:

10

I N

R O O M

SET

M

A B CD E

G

F

H

I

R

Q

P

O N M L K J

NO. Symbol Means

A

B

Automatic mode icon

Cooling mode icon

C

D

E

F

G

Water outlet temp. icon

Ambient temp. icon

Auxiliary electric heater icon

Temperature display area

R O O M

H

I

J

K

L

M

M

Timer on icon

Timer off icon

Timer /auxiliary electric heater

button setting

Clock setting button

O

P

Q

R

Down setting button

Up setting button

Model select setting button

Unit turn on/off button

Time and parameter display area

Button lock icon

Inlet temperature icon

I N

SET

M

SET

OUT

AUX

O U T

Heating mode icon

N

AUX

T E M P

N O.

S

T

T

S

The number of parameter

The icon of measure temperature

N O.

T E M P

1

2

U

V

U

V

The first period of timer icon

1

2

The secondperiod of timer icon

11

2.2 Turn on/off the unit.

Press“ ” button to turn on turn off the unit. When the unit is under the turn off status.

The interface display the mode icon, and the ambient temperature,like the picture 1.when the

unit is under the turn on status,the interface display the mode icon, the inlet and outlet

temperature,like the picture 2.

2.3 Mode selection.

Press“ ” this button to choose “ ”cooling and heating mode “ ”cooling

mode or “ ” heating mode.

2.5 Clock setting.

Press “ ” button for 5 second, and the bit hour is flicking, press “ ”to adjust

the setting of hour.Press “ ” button again. the bit minute is flicking. Press“ ”

buttons to adjust the setting of minute. Press “ ” button again to complete and exit the

clock setting mode.

2.4 Water inlet temp. Setting.

On standby or power on status, press“ ”button,enter the parameter setting interface.

Press the“ ” button to adjust the setting of water inlet temp.

(The parameter of “ 00 ” is cooing mode setting temperature,the parameter of “ 01 ” is

heating mode setting temperature.).

R O O M

SET

MAUX

picture 1 picture 2

I N

SET

M

OUT

AUX

M

SET

SET

SET

SET

2.6 Unit turn on /turn off timer setting.

Press “ ” button for 5 second, the of place hour, minutes and timing 1 ON symbol

keep display. And the place of hour keep flicking, then, press the button of “ ”

to adjust the setting of the hour. Press“ ”button again, and the bit minute flicks. Press

“ ”buttons to adjust the setting of minute; Press“ ”button again and the

place of hour and timing 1 OFF symbol display. And the place of hour keep flicking, press

“ ”button to adjust the setting of hour. Press“ ”button again, and the bit

minute flickers. Press“ ”buttons to adjust the setting of minute. Press“ ”

button again,the of place hour, minutes and timing 2 ON symbol keep display, the second

period of timer setting like the first period timer setting, when you finish the timer setting,press

Press“ ”button complete the timer setting and exit the timer setting interface.

(Note:if you want to cancel the timer,setting the time on is 00:00 and the time off is 00:00 too )

AUX

AUX

AUX

AUX

AUX

AUX

2.7 Button Lock.

Press“ ”and“ ”button at the same time for 5s, symbol“ ”comes out, it

means all buttons on the display are locked, but it can be unlocked after pressing both

“ ”and“ ”button at the same time for 5s again.

(B3Y don't have this function)

(B3Y don't have this function)

10) These settings are for Engineers only, please call if you require to change any of the Optional

Parameters.

Under the standby status, press “ ”button enter system parameter checking and setting interface.

Press“ ”button to select the parameter you need, if you want adjust the parameter data,press

“ ”and“ ”button and the same time for 5second,until you hear the sound of “ B ”,

press“ ”or“ ”button to set data you need. Parameter table as below:

Note:1 The parameter of “ 00 ”and “ 01”is user parameter.

Note:2 The controller esc automatic after staying status 8 seconds.

2.8.The checking of status parameter

Press the“ ”or“ ” button enter the running state parameter checking interface

Esc automatic after staying status 8 seconds.

.Symbol Means

Temp. icon

Inlet water temperature

Outlet water temperature

T E M P

I N

O U T

Ambient temperature

System 1 coil temperature

R O O M

P1

P2 System 2 coil temperature

2.9.The system parameter setting.

SET

SET

Water inlet temp. Setting

(cooling mode)

00

01

02

03

04

05

06

07

08

09

10

Digit meaning range default Adjust

Water inlet temp. Setting

(heating mode)

Defrost cycle

The temp. setting to enter defrost status

The temp. setting to exit defrost status

Defrosting time

The system number setting

1:single system.2:double system

Power lost memory

0:without 1: with

Unit Model selection

Working mode of water pump

Adjusted by technicians

Adjust

Adjust

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

8~28℃

15~40℃

30~90MIN

-30~0℃

2~30℃

1~12MIN

1 / 2

0 / 1

0~3

0~1

2~20℃

28℃

28℃

40 MIN

-3℃

13 ℃

8 MIN

2

1

1

0

2℃

Remarks: parameter 08

0:cooling

1:cooling&heating

2:auxiliary electric heating + heat pump (Auto mode can be selected)

3:heating +auxiliary electric heating

parameter: 09

0:always working

1:water pump starts working for 1 min before the compressor starts to work,

water pump stop working after the compressor stop working for 30 secretary.

The difference setting for compressor

restart running

12

1.6 Care the unit if the unit stops for a long time. Discharge all the water in the pump and

throughout the pipe route in case breakdown to the water pump and pipe caused by frost and

freeze. Discharge the water from the water pump and tube exchange Button drain. Check the

unit thoroughly and flood water into the system before the unit power on again.

It, the operation pressure of the refrigerant system.

1.7 To check the power supply and cable connection often, there is abnormal action or bad

smell about the electrical component. If there is, please maintain or change it in time.

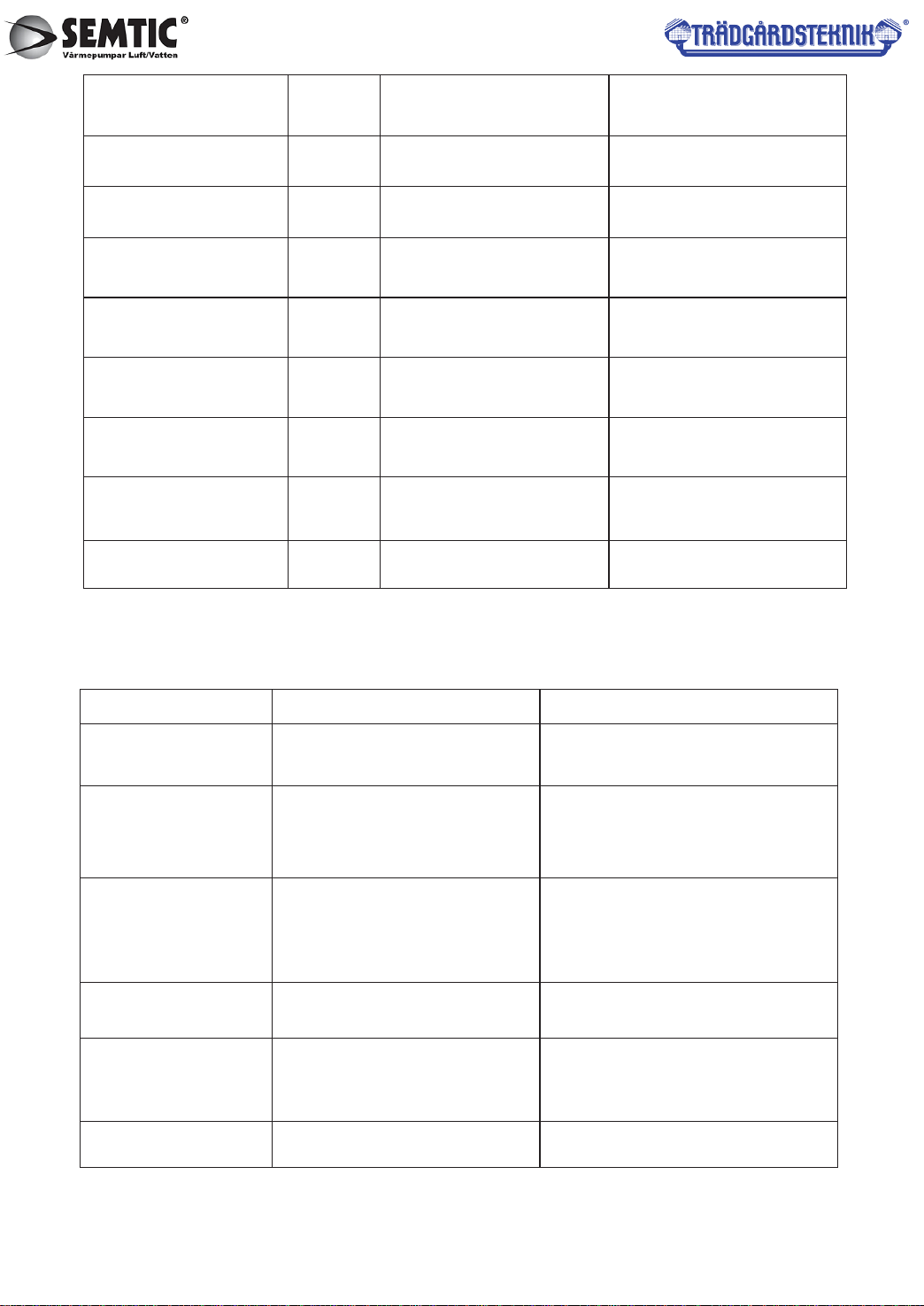

2.Malfunction indicating table

VI. Maintenance

1.Note

1.1 Check whether the exhaust equipment is normal. Avoid cutting of the water supply and or

air entering into the system, or it will influence the performance and reliability of the unit. The

water filter should be cleaned regularly. Keep the water clean in case of any damage to the

unit due to filter's dirty and jam.

1.2 Keep the unit environment dry, clean and well ventilation. Clean the side air exchanger

regularly(once per1-2 months) in order to maintain high exchange efficiency and save energy.

1.3 Often check the performance of all the parts in the unit. Check whether the working

pressure of the refrigerant system is normal. Repair and change the parts timely if there's any

abnormity .

1.4 Often check whether the wiring of the power and electric system is tightened and or

electric parts perform abnormally or smells. Repair and change the parts timely if there's any

abnormity.

1.5 To check the operation of every process in the unit, the operation pressure of the

refrigerant system.You should maintain or change it in time.

Check or change the sensor

Temp is too much different

between water-in and

water-out for cooing mode

Swimming pool side water

inlet temp. Sensor failure

The swimming pool side

antifreezing protection

under cooling mode

Check the water flow volume,

or water system is jammed or not

Check the water flow volume,

or water system is jammed or not

The sensor is open or short circuit

Not enough water flow volume &

water pressure difference is too

low for swimming pool side

Swimming pool side water flow

volume is not enough

Malfunction

Reason Resolution

Wire

Controller

PP 01

PP 06

PP 07

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Swimming pool side water

outlet temp. Sensor failure

System 1 coil temp.

Sensor failure

Ambient temp. Sensor failure

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

PP 02

PP 03

PP 04

PP 05

13

System 2 coil temp.

Sensor failure

PP 07

The system recover automatically

after running antifreeze process.

The ambient temp.and the water

outlet temp. is too low under

standby status.

The swimming pool side

automatic antifreezing

protection in winter

Malfunction of system 1

low pressure protection

3 times of excessive temp.

Differentials of inlet water

and outlet water in 30 minutes

EE 02

EE 05

System 1 low pressure switch

protection

No water/little water flow

volume too small in water

system.

Water flow volume not

enough, water pressure

difference is too low

Check whether the pressure

switch and refrigerant is miss

or not.

Check the water flow volume,

water pump is failure or not.

Check the water flow volume,

or water system is jammed

or not.

Phase lack or phase

sequence error of power

supply

Phase lack or phase error

of power supply(only for three

phase unit)

Check power supply(only for

three phase unit)

EE 01

System 1 high pressure

switch protection

Check whether the pressure

switch and water cycle system.

Malfunction of system 1

high pressure protection

Wire controller and The

PCB connection failure.

Communication failure EE 08 Check the wire connection

Swimming pool side water

flow switch failure

EE 03

EE 04

EE 06

EE 07

3.Determine and solve malfunction by below table:

The unit can't run

1.Check the water supplement equipment and

supply water into the system.

2.Discharge the air from the water system

3.Clean the water filter or exhaust the air from

system

1. The water system is lack of water

2. There's air in the system.

3. The water system valve doesn't open

entirely

4. The water filter is dirty and jam

The water pump can run but

can't circulate and is noisy

The heating capacity is too

low and the compressor works

continuously without pause.

1.Check the leakage and add refrigerant.

2.Enhance the thermal insulation of the pipe

route.

3.Clean the exchanger and improve the

condensation condition.

4. Clean the water filter.

1. Refrigerant is insufficient.

2. Thermal insulation of the water system

is poor.

3. Thermal discharge of the exchange is

poor.

4. Water flow volume is insufficient.

1. Shut down and check the power

2.Check the reason and repair

3.Check and change the power fuse

1. Power failures

2. The unit wire loses

3. The unit power fuse burns out.

Malfunction Reason Solution

14

System 2 high pressure

switch protection

Check whether the pressure

switch and water cycle system.

Malfunction of system 2

high pressure protection

Malfunction of system 2

low pressure protection

System 2 low pressure switch

protection

Check whether the pressure

switch and refrigerant is miss

or not.

1. Discharge surplus refrigerant

2. Clean the exchanger and improve the

condensation condition

1.Too much refrigerant

2.Thermal discharge of the exchange

is poor

1.Check the reason and solve the malfunction.

2.Change the compressor.

1.Refrigerant enter into the compressor.

2.Compressor damaged.

Compressor noisy.

The compressor exhausted

pressure is too high

1.Check the leakage and add refrigerant.

2.Change the capillary tube or filter.

3.Clean the exchanger and improve the

condensation condition.

4.Change the expansion valve.

1. Refrigerant is insufficient.

2. The filter and or capillary tube jam.

3. Water flow volume is insufficient.

4. Capillary tube of expansion valve

sensor bulb breakdown.

The compressor suction

pressure is too low.

15

1.Check the leakage and add refrigerant

2.Check the reason and change the plate

exchanger.

3.Change the compressor.

1. The refrigerant leak out

2. Plate exchanger freezes

3. Compressor failure

The compressor run but no

refrigeration.

1.Clean the water filter and exhaust the air

from the system.

2.Change the flow switch.

Few water flow volume

protection to the unit.

1.Water flow volume is insufficient.

2.Flow switch.

Compressor can't work

1. Power failure.

2.The compressor capacitance is

damaged.

3. Compressor Control damaged.

4. Wire loses.

5. Compressor overload protection.

6. Return water temperature setting

incorrect.

7. Water flow volume is insufficient.

1.Check the power and solve the malfunction.

2.Change the compressor capacitance.

3.Change Control.

4.Check loose reason and repair.

5. Compressor overload protection.

6. Reset the return water temperature.

7. Clean the water filer and exhaust the air

from the system.

AC- N

GND

L4

L5

OUT8

OUT7

OUT6

OUT5

OUT4

OUT3

OUT2

OUT1

OUT9

L6

CN4

CN3

CN1

CN7

CN6

CN5

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

VII. Wiring diagram

1. NET92033 PCB input and output port definition

Symbol

Meaning

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

Unit turn on/off switch

Power phase sequence protection switch

Water flow protection switch

System 1 high pressure protection switch

System 1 low pressure protection switch

System 2 high pressure protection switch

System 2 low pressure protection switch

GND

GND

Ambient temp.

Water inlet temp.

Water outlet temp.

System 1 coil temp.

System 2 coil temp.

Reservation

Reservation

GND

Symbol

Meaning

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

OUT9

L4

L5

L6

AC-N

CN2

CN5

CN9

Compressor crankshaft heater output

High speed fan power output

Low speed fan power output

System 1 four way valve power output

System 1 compressor signal output

System 2 four way valve power output

System 2 compressor signal output

Auxiliary electric heater signal output

Water cycle pump power output

AC-L power input

AC-L power input

AC-L power input

AC-N power input

Transformer (AC-220VAC) power input

Transformer (DC-12VAC) power output

Wire controller signal output

CN9

Cn2

NET92033

16

1 2 3 4

ON DIP

T

S

R

N

P5

P6

0057W

0057W

JK1 IC6

CON1

12V-IN 12V-OUT

L1 L4

Power

Run

2. Power phase sequence protection board setting

Power input

Power input

Power input

Power input

Protection signal output

Protection signal output

Connect transformer power(12VAC)input

power(12VAC)output

Connect transformer primary

Meaning

Symbol

NO .

R

S

T

N

P5

P6

12V-IN

12V-OUT

CN3

1

2

3

4

5

6

7

8

9

2. 1. Single system protection board NET92024 input and output port definition.

CN3

Run led display Failure indication

1flash 1 off L1 side overcurrent protection

Run led display Failure indication

2flash 1 off

3flash 1 off

4flash 1 off

5flash 1 off

L2 side overcurrent protection

L3 side overcurrent protection

L4 side overcurrent protection

Power phase sequence protection

2.4 .Power sequence, current protection board failure indication

6flash 1 off Power phase sequence protection

NERS-G24Y

Model Default

25A

2.5.Every model's factory default value of current protection .

Explaination for Power protection fault and solution:

1: when the unit occurs phase order protection,

A:Pls check if the detection power sequence is correct, whether there is phase not together.

2: when the unit occurs one side current excessive protection

A: Pls check if power supply power is too small, or the power cord is too small.

B: Pls check if the contact of compressor ac contactor is normal or not.

C: Pls check if the compressor operates normal or not.

D: Pls check if the setting of current protection is accordance with the requirements set value, whether it is

too low.

2.3. The setting of current protection value

1234

ON DIP

Symbol :0000

1 2 3 4

ON DIP

Symbol:1010

Symbol Current value

0011

1101

0101

1001

0001

1110

Symbol Current value

8A

9A

10A

11A

12A

18A

1010

0010

1100

0100

1000

0000

20A

21A

28A

29A

30A

31A

For example:

2. 2. Double system protection board NET92027 input and output port definition.

Power input

Power input

Power input

Power input

Signal output

Signal output

Connect transformer power(12VAC)input

power(12VAC)output

Connect transformer primary

Meaning

Symbol

NO .

T

S

R

N

P3

P4

TRAN-OUT1

TRAN-OUT2

TRAN-IN

1

2

3

4

5

6

7

8

9

FUSE

1 2 3 4

ON DIP

R

S

T

N

P3

P4

0057W

0057W

0057W

0057W

JK1

IC6

CON1

TRAN-OUT1

TRAN-OUT2

L1 L2 L3 L4

Power

Run

TRAN-IN

NERS-G12Y

Model Default

18A

3. The electrical box of internal structure

3.1 Model:NERS-G3Y

17

NO .

1

2

3

4

5

6

Sign

NET92033

KM

Meaning

Controller

System 1 compressor A.C.contactor

Compressor Capacitor

Water cycle pump A.C.contactor

Transformer

PCB common terminal of GND

NO .

7

8

9

10

11

12

Sign Meaning

AC-N common terminal

Water cycle pump power output

Unit power input

L N

B

A

-

+

NET92033

1 2 3 4 5 6

14/NO6/T34/T22 /T1

A2A1

13/NO5/L33/L21/L1

L N

15

4

9

8

7

6

3

2

3.2 Model:NERS-G4Y

18

1

5

L N

B

A

-

+

NET92033

2

3

4

9

6

8

7

NO .

1

2

3

4

5

6

Sign

NET92033

KM

Meaning

Controller

System 1 compressor A.C.contactor

Compressor Capacitor

Water cycle pump A.C.contactor

Transformer

PCB common terminal of GND

NO .

7

8

9

10

11

12

Sign Meaning

AC-N common terminal

Water cycle pump power output

Unit power input

This manual suits for next models

7

Table of contents

Other Semtic Heat Pump manuals

Popular Heat Pump manuals by other brands

AAF-HermanNelson

AAF-HermanNelson AEQ installation manual

Zodiac

Zodiac Z550iQ Instructions for installation and use

Bard

Bard WH611 installation instructions

Daikin

Daikin FVXD56FV2C Service manual

Carrier

Carrier 50JS Operating and maintaining guide

Mitsubishi Electric

Mitsubishi Electric EHWT17D-MHEDW installation manual