SENKO SP12C7 User manual

MODEL: SP12C7

(Portable 4 gas detector)

Operating Manual

Guarantee and Repair

Guarantee

and

Repair

Senko Co., Ltd. guarantees the products of SP series for 24 months from the

shipping date and repairs or replaces the defected product during warranty

period at no cost. Nevertheless, Senko is not responsible for the following

cases and would not repair or replace the product at no cost, such cases as the

product has been purchased through the route that Senko does not approve or

product

has

been

purchased

through

the

route

that

Senko

does

not

approve

,

or

as the product has been damaged or deformed mechanically by misuse of the

user, or as the product has not been calibrated or replaced the parts according

to processes in the operating manual.

In the event that any defect or issue of the product occurred during warranty

period, Senko will cover all the expenses except transportation fee. After the

period of warranty the expenses of repair or replacement of the product and

period

of

warranty

,

the

expenses

of

repair

or

replacement

of

the

product

and

transportation will be in principle borne by the user. Senko will not be

responsible for any indirect occurrence or accident and/or damage during the

use of the product, and the guarantee shall be limited to the replacement of

parts and product. The guarantee is applied only to the users who purchased

the product at Senko’s authorized dealers or agents, and the guarantied repair is

to be

p

erformed b

y

the ex

p

ert en

g

ineers of Senko’s authorized aftercare center.

pypg

Introduction

SP12C7 is 4 Gases Alarm Detector that is required to protect users’ safety at

dangerous work environments where an explosion accident can occur. The

apparatus can indicate simultaneously the concentration of 4 gases (Oxygen,

Inflammable Gas, Carbon Monoxide and Hydrogen Sulfide) on a digital LCD

monitor, and the methods of operation and calibration are easy and convenient.

Thi i t t l t t l th l i t t t d

Thi

s

i

ns

t

rumen

t

a

l

er

t

s accura

t

e

l

y

th

e a

l

arm c

i

rcums

t

ances

t

o opera

t

ors an

d

workers for their safety with its functions of loud alarm sound and vibration,

when higher gas concentration than normality is detected. Besides, it is

available for users to check upon occasion and adjust the value of alarm to the

work environment on demand, since it has the function of indicating minimal

and maximal concentration of the gases. It is also possible to prevent in

advance workers from the danger of exposing for a definite period of time to

advance

workers

from

the

danger

of

exposing

for

a

definite

period

of

time

to

such toxic gases as Hydrogen Sulfide (H2S) and Carbon Monoxide (CO) by its

function of STEL (Short Term Exposure Limit) and TWA (Time Weighted Average).

1

Contents of Operating Manual

Product Specification ---------------------------------- 3

Names and Functions of Exterior --------------------- 4

Start of O

p

eration -------------------------------------- 5

p

Operation Method ------------------------------------- 6

Calibration ---------------------------------------------- 7

Method of Alarm Set and Display ------------------- 10

Applicable Battery and External Pump ------------- 15

B&S l

16

B

attery

&

S

ensor rep

l

acement ------------------------

16

Operation Flow Chart --------------------------------- 17

Notice for User -----------------------------------------18

2

Product Specification

MODEL SP12C7

Detecting Gas O2 CO H2S EX

Detecting Range 0~30% 0~500ppm

0~1,000ppm

0~100ppm

0~200ppm 0~100%LEL

Product

Specification

Sensor Type Galvanic Electrochemical Electrochemical Catalytic

Sampling Method Diffusion

Display Digital LCD

Audible Alarm 90dB

Visual

Alarm

Red

LED & White

back light

Visual

Alarm

Red

LED

&

White

back

light

Vibrator Alarm Vibrator

Power Alkaline battery 2ea, Rechargeable NI-MH battery pack

Operating

temp. & Humi. -20℃ ~ +50℃, : 10% ~ 95% RH (non-condensing)

Explosion

proof

EEx

ia

IIC T4 / IP67

Explosion

proof

EEx

ia

IIC

T4

/

IP67

Case Clear polycarbonate with thermal-plasticelastic (TPE) overmold.

Standard

Accessories Belt Clip, Charger

Option Sampling pump

Dimensions

54mm(W) x 135mm(H) x36.5 mm(D)

Dimensions

54mm(W)

x

135mm(H)

x36.5

mm(D)

Weight 240g

Specification of External Pump (Optional)

Power AA size Alkaline batter

y

1ea

y

Operating time More than 5 hours

Operating temp. & Humi. -20°C ~ + 50°C, 0 to 95% RH

Sampling flowrate 0.5 liter / min

Self Checking Low flow alarm, Low battery alarm (Red LED)

Di i

34 (W) 270 (H) 47 (D)

Di

mens

i

ons

34

mm

(W)

x

270

mm

(H)

x

47

mm

(D)

Weight 200g (with battery)

3

Names and Functions of Exterior

1

2

3

6

7

8

4

5

9

10

1. Gas sensor

2. Buzzer

3. LCD display

4. On/Off Key

5. Key

6. Alarm LED

7. Fastening clip

8. Type label

9. Charging contacts

10. Battery pack

LCD display symbols

4

Instrument Power

-

On

Start of Operation

Press Power key for 3 seconds, and power is turned on displaying 3, 2, and

1 in order on the monitor. (Power won’t turned on, if pressing the Power

key is stopped before 3 seconds)

Afterwards during the instrument is being stabilized, it displays consecutively A1 & A2 set values of

LELG A1&A2tl fO2G A1tl fCOG A2tl fCOG tl f

Instrument

Power

-

On

LEL

G

as,

A1

&

A2

se

t

va

l

ues o

f

O2

G

as,

A1

se

t

va

l

ue o

f

CO

G

as,

A2

se

t

va

l

ue o

f

CO

G

as, se

t

va

l

ues o

f

STEL & TWA, A1 set value of H2S Gas, A2 set value of H2S Gas, and set values of STEL & TWA on

the monitor.

When the instrument is stabilized after the display of the above set values, it converts to Gas

Detection Mode displaying the mark At normal status, the mark disappears after 30

seconds, and the concentration of the gas detected of the moment is indicated. In the event that

stabilization of the instrument fails, it would not convert to Gas Detection Mode, blinking the

mark

with alarm sound In this case calibration of the sensor or aftercare of the instrument is

V

X

V

mark

with

alarm

sound

.

In

this

case

,

calibration

of

the

sensor

or

aftercare

of

the

instrument

is

required.

X

Instrument Power-Off

Success Fail

Press Arrow key for 3 seconds at the state of pushing Power Key

simultaneously, and power is turned off displaying 3, 2, and 1 in order on

the monitor with turning on LED Lamp and alarm.

Caution: Appropriate calibration of the instrument is always required prior to the operation at work

sites Make sure if the instrument makes the proper detection response to the pertinent gas and if

sites

.

Make

sure

if

the

instrument

makes

the

proper

detection

response

to

the

pertinent

gas

and

if

the region of the gas detection is not blocked with foreign materials that interfere with the gas

detection

LCD Back Light

At the state of Gas Detection Mode indicating the concentration of 4 kinds of

gases simultaneously, LED Backlight is turned on by the short press on Arrow

kd dffb blh

k

ey, an

d

it is turne

d

o

ff

b

y pressing again once more. It ena

bl

es t

h

e operator

to view the measured value even at dark atmosphere. Backlight will be

automatically turned off after 10 seconds unless the button works.

5

Detection Mode The instrument is converted to Gas Measure Mode as below, when power

is turned on. Gas Measure Mode indicates the concentration of gas and

the remained capacity of battery on LCD, and it displays the gas

tti fO b%Ifl blG b%LELH2S dCO

Operation Method

concen

t

ra

ti

on o

f

O

xygen

b

y

%

,

I

n

fl

amma

bl

e

G

as

b

y

%LEL

,

H2S

an

d

CO

Gas by ppm units.

In the event that the concentration of the specific gas changes, it

indicates the value of concentration in real-time. If it exceeds A1 or A2

Alarm standard (or STEL / TWA), the measured value and A1 or A2 (icon

in case of STEL / TWA) is displayed at one second interval in turn

alerting by alarm sound and vibration.

As of A1, the instrument program will be converted to the original condition and starts the

operation, when the concentration value of the measured gas returns to the normal state.

(LED and LCD Backlight are displayed continuously and the alarm sound stops, if power key is

pressed during the alarm sounds. During the alarm sound, the measured value and A1 or A2

are displayed in turn on LCD.) In case of A2, power should be disconnected in order to stop

the alarm.

When the concentration value of the measured

g

as exceeds the maximum measurin

g

ran

g

e, it

ggg

is indicated as the maximum value. And LED, alarm sound and vibration applicable to A2

Alarm Standard operate together

Indication of Peak Value and TWA & STEL Value

At Gas Measure Mode, Peak value is displayed (Peak values of all 4 sensors) by pressing Arrow

ke

y

for 3 seconds, the value of TWA

(

onl

y

for CO and H2S

)

is shown b

y

p

ressin

g

it a

g

ain, and

y(y)ypgg

that of STEL (only for CO and H2S) is indicated consecutively by pressing it once more.

The program returns to Gas Measure Mode by pressing Power key at the state indicating Peak

3 sec

The

program

returns

to

Gas

Measure

Mode

by

pressing

Power

key

at

the

state

indicating

Peak

,

TWA and STEL. And it reverts automatically to Gas Measure Mode as well without using the

button for 30 seconds at the state of Peak, TWA and STEL.

6

Calibration

Caution: Senko Co., Ltd. performs the initial calibration before the shipment. Incorrectly

calibrated value can reduce the accuracy of the product, as the calibrated value is stored in the

instrument. Calibration is in general to be performed monthly or quarterly, and can be adjusted

according to frequency of the use.

Calibration

Fresh air Calibration

Press Power key for 5 seconds and input password (refer to the way of password input), and Lock icon

will blink. Then press Arrow key to make the icon blink. When Power key is pressed at the state, it

converts to Calibration mode of the standby state.

Calibration will be processed, when Power key is pressed after entering to Calibration mode of the

standby state. Calibration will be completed by 3 time blinking of 4 sorts of gas concentrations,

and the mark OK is displayed.

5 sec Password

When Power key is input at the state of OK after completing the

calibration of standby state, the program returns to the previous

Ca

li

b

r

at

i

o

n

Se

l

ect

m

ode

o

f

t

h

e

sta

n

dby

state.

I

t

r

etu

rn

s

to

Gas

M

easu

r

e

Ca b at o Se ect ode o t e sta dby state. t etu s to Gas easu e

Mode, if Arrow key is pressed twice at Calibration mode of standby

state. Please note that it reverts to Gas Measure mode through

Standard Gas mode.

7

Caution: Fresh Gas Calibration should be performed at the environment of fresh air without any

influence of other gases since the calibration is performed on the assumption that the

Standard Gas Calibration

influence

of

other

gases

,

since

the

calibration

is

performed

on

the

assumption

that

the

concentration of Oxygen is 20.9%, that of Inflammable Gas is 0%LEL, and the concentration of

Toxic Gas is 0ppm in the fresh air. Accordingly it is not recommended to perform Fresh Air

Calibration at the closed space, and it should be avoided to perform the calibration where gases

can be inhaled by operators.

Press Power key for 5 seconds and enter the password (the initial password is 000), then Lock icon

will blink. And press Arrow key to see icon blink. The icon will blink, when the operator

presses again Arrow key once more. Then it enters to Standard Gas Calibration Mode of, as Power

key is pressed.

5sec

Password

5

sec

Password

When the program is converted to Standard Gas Calibration Mode, %LEL Standard Gas

Concentration that has been initially input is displayed. And it moves to each Calibration

M

ode

r

espect

iv

e

l

y,

in

d

i

cat

in

g

t

h

e

v

a

l

ues

o

f

Sta

n

da

r

d

Gas

Co

n

ce

n

t

r

at

i

o

n

o

f

O

2

,

CO

a

n

d

H2

S

ode espect e y, d cat g t e a ues o Sta da d Gas Co ce t at o o O , CO a d S

that have been input by Arrow key.

Concentration of Calibration Gas set at Instrument

Gas Combustible Oxygen Carbon

monoxide

Hydrogen

Sulfide

monoxide

Sulfide

Concentration 20 %LEL 0% 100 ppm 50 ppm

8

The method of Standard Gas is as below. The program enters to %LEL Calibration Mode blinking

the numbers, when Power key is pressed at %LEL Standard Gas Calibration Mode. In case that the

inflammable gas that conforms to %LEL concentration input initially at the instrument is used,

calibration is executed indicating the concentration value connected at the moment by pressing

Power key twice. In case that using Standard Gas of different concentration from that of %LEL

initially input proceed with calibration after changing the concentration to that of the required

Method of Calibration

initially

input

,

proceed

with

calibration

after

changing

the

concentration

to

that

of

the

required

Standard Gas by the same way as the input of password as shown at the diagram below. Then the

concentration value of the calibration gas connected at the moment is indicated with the

countdown of 60 seconds. If there does not occur any problem of calibration for 60 seconds, the

concentration of the calibrated gas is displayed after memorizing the concentration of calibrated

gas as the value of sensor. Methods of the calibration for the sensor of CO, O2 and H2S are to be

proceeded same as the following diagram.

Value

Gas

60 second

Count down

Failure of Calibration

In the event that Gas Calibration fails, the mark --- is displayed at the

value of calibration with the icon of Test Failure. If this occurrence

repeats, please consult a dealer or aftercare center to replace the sensor.

9

Mthd fAl St dDi l

M

e

th

o

d

o

f

Al

arm

S

e

t

up an

d

Di

sp

l

ay

Caution: The value of alarm of the instrument is set according to the alarm standard of each gas

that is required by international standard. Therefore alarm value of the relevant gas can be

changed under the responsibility and approval of the administrator of the work site where the

instrument is used.

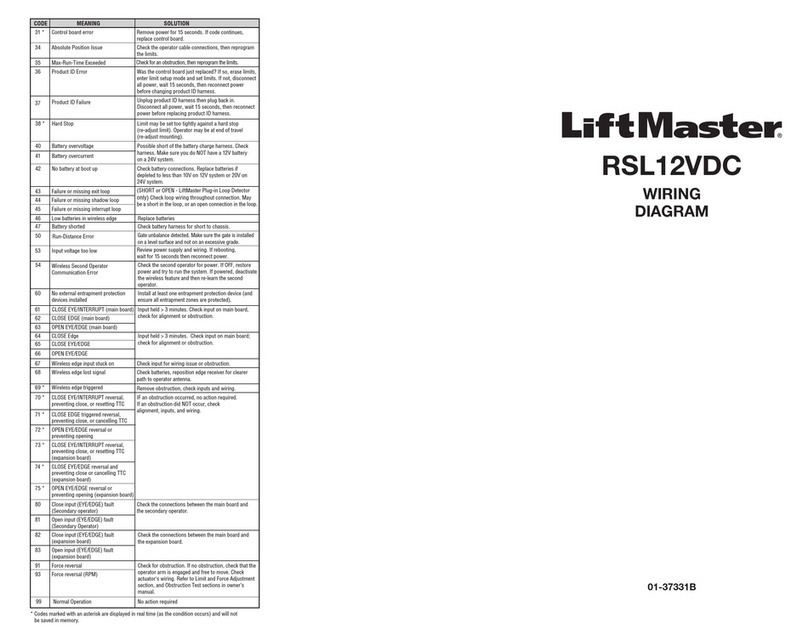

Alarm Alarm Standard LCD Display Alarm & Vibration Display

A1 In Exceeding Alarm

Value Set Primarily

Displaying

Icon A1 &

Concentration

Alarm Display

A2 In Exceeding Alarm

Value Set Secondarily

Displaying

Icon A2 &

Concentration

TWA

In Exceeding Exposure

Concentration for 8

hour

Displaying

Icon TWA &

Concentration

In Exceedin

g

Ex

p

osure Dis

p

la

y

in

g

STEL

gp

Concentration for

15 minutes

pyg

Icon STEL &

Concentration

Low

Remained Battery

Capacity is small (one

bar)

Blinking of

Test Fail re

Failure of Sensor Test Displaying

Icon Test

Buzzer

LED, LCD Backlight

Test

Fail

u

re

Failure of Calibration

Icon

Test

Failure

When A1 alarm occurs, and the operator recognizes it and presses Power key, only the sound and

vibration of alarm stop, remaining LED alarm as the operation stale.

When A2 alarm happens, the operator and workers should promptly escape from the work site. The

alarm will stop when power is turned off at the place where the concentration value of gas is normal

alarm

will

stop

,

when

power

is

turned

off

at

the

place

where

the

concentration

value

of

gas

is

normal

after moving to a safe region. (If the instrument is operated again at an abnormal environment, the

warning of test failure is displayed.)

When STEL / TWA alarm occurs, it is indicated with the value of the measured concentration and alerts

alarms of the same sound of alarm and vibration as that of A2 alarm.

When STEL / TWA alarm occurs, the icon can be deleted only by Power Off.

Note: It is available to set the different alarm sound of each gas respectively by requirement of the

user. Please consult Senko Co., Ltd. for further detailed information.

10

Primary battery alarm sounds repeatedly at 5 minute intervals when only a bar of battery icon is

remained.

Alarm Set Point (TWA, STEL)

Secondary battery alarm starts right before the end of power, and the power source finishes after 10

seconds from the outbreak of alarm.

In the event of failure of test or calibration, the icon of Test Failure is displayed with the sound of

alarm.

Gas Combustible Oxygen Carbon

monoxide Hydrogen

Sulfide

A1 20 %LEL 19% 30 ppm 10 ppm

A2 40 %LEL 23% 60 ppm 20 ppm

TWA

30

ppm

10 ppm

TWA

30

ppm

10 ppm

STEL 200 ppm 15 ppm

Alarm Set

When Lock icon blinks after entering password, approach to A1 Alarm Value Set Select Mode by

p

ressin

g

Power ke

y

. Note: If Arrow ke

y

is

p

ressed durin

g

blinkin

g

of Lock icon, the

p

ro

g

ram

pg y

yp g g pg

moves to Calibration Select Mode likely Sensor Calibration Mode. Please pay attention to this

point.

A1 icon blinks, when Power key is pressed at Lock Blink Mode. It will be converted to A1 Alarm Mode

by pressing Power key, and the blinking icon will be alternated in the sequence of A2, TWL, STEL and

Password. If you want to approach to each Alarm Value Set Mode, enter it by pressing Power key.

Please use Arrow key in order to escape to Gas Calibration Mode.

A1 setting mode

Caution: Changing alarm value of TWA and STEL can be applied onl

y to Carbon Monoxide and Hydrogen Sulfide. The change of alarm

standard of TWA and STEL can cause the fatal influence to the lives

of operators and workers; therefore it must be set in accordance wit

h the regulations of the relevant country and the standard of exposu

re at work site, if it is inevitably changed.

11

Alarm Set of Each Gas

Alarm

Set

of

Each

Gas

A1 icon blinks by pressing Power key at Lock Blink Mode. And it is converted to %LEL Alarm Value Set

Mode by pressing Power key again.

After moving to %LEL Alarm Value Set Mode, Alarm Value of %LEL, that has been input initially,

blinks. And the Alarm Value can be changed by the same method as password input. Changing

sequence of Alarm Value is %LEL, %vol, Oxygen, Carbon Monoxide and Hydrogen Sulfide, and it

ttA1StMdhthh fAlVlfhi ltd

re

t

urns

t

o

A1

S

e

t

M

o

d

e w

h

en

th

e c

h

ange o

f

Al

arm

V

a

l

ue o

f

eac

h

gas

i

s comp

l

e

t

e

d

.

Note: In case of Inflammable Gas, it is determined by Alarm Set Mode to display %LEL or %VOL.

When %LEL Alarm Value is changed, %LEL is displayed at Calibration Mode. In the event

that %VOL Alarm Value is changed, %VOL is indicated at Calibration Mode. If you don’t want

the display by %VOL, move to the next step without changing the value at %VOL Alarm Value

Chan

g

e Mode.

A1 setting mode

g

At Alarm Value Set Mode, Arrow key represents the increase (change) of

‘Number’ in lieu of Move. In other words, the number increases by

pressing Arrow key, and it moves to the next number with blinks by

pressing Power key. Program returns to the initial A1 Set Mode, after

changing A1 Alarm Values in sequence of the gases. As mentioned on

page 12 the program converts to A2 Alarm Set Mode by pressing

A1 setting mode

page

12

,

the

program

converts

to

A2

Alarm

Set

Mode

by

pressing

Arrow key at A1 Set Mode, and it approaches again to %LEL Alarm

Value Set Mode by pressing Power key. Please refer to Operation Flow

Chart for the detailed moving path.

12

Password Input

Password input screen appears by pressing Power key for 5 seconds.

Number changes from far left to the right side.

It moves upward by each 1 step and blinks by pressing Arrow key, and

the blinking 2nd number moves the position by pressing Power key. If

you press Arrow key, the number moves upward, and the 3rd number

blinks and moves the position by pressing Power key After

Password

Input

blinks

and

moves

the

position

by

pressing

Power

key

.

After

completing the change of the last number and enter the Power key,

Lock icon blinks with 0.5 second alarm sound if the password is correct.

As previously explained, the program moves to Calibration Mode by

pressing Move key, and moves to Alarm Set Mode by Power key.

If the password is incorrect, it returns to Gas Measure Mode altering

the alarm sound.

Changing Password

Caution: The initial password is set as 000. It is impossible to enter Calibration or Alarm Set

Mode, if the operator can’t remember the new password after changing it. Please be sure not

to forget the password

A1 setting mode

to

forget

the

password

.

password

When password icon blinks by moving as the above drawings, press Power key. Then the existing

password is displayed blinking from the first digit. If the new password is entered, the existing

password is deleted and the new password appears. When the same password is put repeatedly at RE,

the password will be changed and the program will return Password Change Mode where Lock icon is

blinking. If further change of password is not required, return to Gas Measure Mode by using Arrow

key.

13

Applicable Battery

Caution: It is absolutely prohibited to replace battery at potential explosion areas or dangerous

regions. And the charger should be always used at the safe place, since it is not an explosion-

proof product.

- The applicable batteries that are tested and are allowed in Ex zones are as below.

- It is a condition of safe use that the instrument should be used only with one of

the below applicable batteries.

- If the battery of other specification use, It is not permitted to use it for the

instrument at dangerous regions

Warning: Followings may cause the danger of explosion; to use the old battery and the new one

to

g

ether, to use different manufacturer’s batter

y

; or to use the batteries of different s

p

ecification.

- Disposable Alkaline Battery: Energizer No. E91, Energizer No.EN91

- Rechargeable Ni-H Battery: GP BATTERY GP210AAHCB

gyp

In order to avoid an accident, please use only the applicable batteries as specified above

Warning: Explosion can occur, when a battery is thrown into fire or disassembled with force.

Disposal of the used battery should be performed according to the guide of the pertinent

country or the work site.

When the unit is connected to battery charger, power source should be turned

off without fail before charging. The state of charging is indicated on LED

display of the charger. Red lamp indicates the state of charging, and Green

lamp shows the state of the completion of charging. Charging time of

rechargeable battery is 5 hours, and it can be used for 12 hours at the state of

general measuring.

External Pump (Optional)

key has the function of On/Off, and the state of

operation or trouble of the instrument can be

operation

or

trouble

of

the

instrument

can

be

recognized by LED lamp.

When the leakage measurement or the measurement of

concentration by inhalation of gas is required, it is

available to measure gas concentration and leakage at

the pertinent place by connecting the pump to the

instrument. Prior to use, make sure that the instrument

is tightly attached to the probe cover which is

is

tightly

attached

to

the

probe

cover

which

is

connected to the sensor.

Please note that External Pump is the optional product

that can be provided by the separate order.

14

Battery & Sensor replacement

When you replace the Battery and sensors of SP12C7, you need some instrument and components as

below.

- Tool : - Phillips screw driver, Tip size : M2 x 20mm, M2 x 6mm

- wrench(hexagon) M3 x 12mm

- Battery : Energizer No.E91, EN91 or GP rechargeable Battery GP210AAHCB

- Sensors for replacement : SENKO SS series

-

Filters for replacement

Warning :

- It is a condition of safe use that the instrument should be used only with one of the applicable

batteries.

- It is absolutely prohibited to replace battery at potential explosion areas or dangerous regions.

-Unauthorized repair of this device invalidates the type of Ex protection and is prohibited by law. A

defective device should be sent to SENKO for repair or replacement.

Th id d b SENKO h ld b d f l t U it bl f ti ld b

Filters

for

replacement

-

Th

e sensors prov

id

e

d

b

y

SENKO

s

h

ou

ld

b

e use

d

f

or rep

l

acemen

t

.

U

nsu

it

a

bl

e

f

unc

ti

on cou

ld

b

e

shown if another sensors are used for replacement.

-Disassembly should be necessary only for sensors & battery replacement. After the sensor

replacement, the span gas calibration should be done.

Disassembly

- Turn off the power.

Replace the sensor and battery please refer to below drawing

2 3 456

6

7 6

-

Replace

the

sensor

and

battery

,

please

refer

to

below

drawing

.

- After replacement, check the sensor fail and battery working.

1

168

1. Label(Membrane)

2. Front Cover

3

Sensor

5. Rear Cover

6. Machine Screw

7 Belt clip

9

3

.

Sensor

4. PCB

7

.

Belt

clip

8. Bolt(hexagon)

9. Battery

15

O

p

eration Flow Chart

Calibration & Configuration Flow

16

Notice for User

Please use the instrument in the range of the applicable temperature, humidity and

pressure that are appropriate for the specification of the product. Using the

instrument beyond this range may cause malfunction or glitch of the instrument. .

Notice

for

User

Gas concentration measurement value by the sensor or the instrument can vary

Gas

concentration

measurement

value

by

the

sensor

or

the

instrument

can

vary

according to the environment at site (temperature, pressure and humidity). Therefore

the calibration of the instrument should be performed at the same or similar

environment as that of the instrument use (temperature, pressure and humidity),

If temperature changes sharply during use of the instrument (for instance, using the

instrument at places of far different temperatures between indoor and outdoor), the

value of the measured gas concentration can be changed suddenly. Please use it

after the gas concentration value is stabilized. .

Severe vibration or shock to the instrument may cause the sudden change of value

of the measured

g

as concentration. Please use it after the value of

g

as concentration

gg

is stabilized. Excessive shock to the unit can lead to trouble of the sensor or the

instrument.

18

Notes on Approval(Label)

CE marking: Electromagnetic Compatibility

(Directive 2004/108/EEC)

Explosion Protection

(Directive 94/9/EEC)

KS marking: Korean Gas Safety for Explosion

Protection

This Ex marking means that this device is an intrinsically safe apparatus of ATEX category

1 according to directive 94/9/EC, the certificate number is DNV 10 ATEX ------X. It can

be operated in non-mining locations (II) with potential explosive gas atmospheres (G) in

zone 0, 1 and 2 with gas group C, B or A. The temperature classification is T4 (135 °C) for

ambient temperatures up to +50 °C. It can not be operated in explosive dust

Protection

atmospheres.

The X in the certificate number means that there are special conditions for safe use and

that the user should check the ATEX certificate. In this case it is the following:

It is a condition of safe use that the instrument should be used only with one of the

following lithium manganese dioxide batteries: Panasonic or Duracell type CR2

S

/

N: Serial Number

/

Certificates

Other manuals for SP12C7

1

Table of contents

Other SENKO Security Sensor manuals