5

ELECTRICITY WARNING

It includes information about a possible electricity shock danger. Observations mistakes may cause

equipment damages and/or serious injury or even death.

HOT SURFACE WARNING

It includes information about contact with equipment and parts. Failure of compliance may cause body

injury.

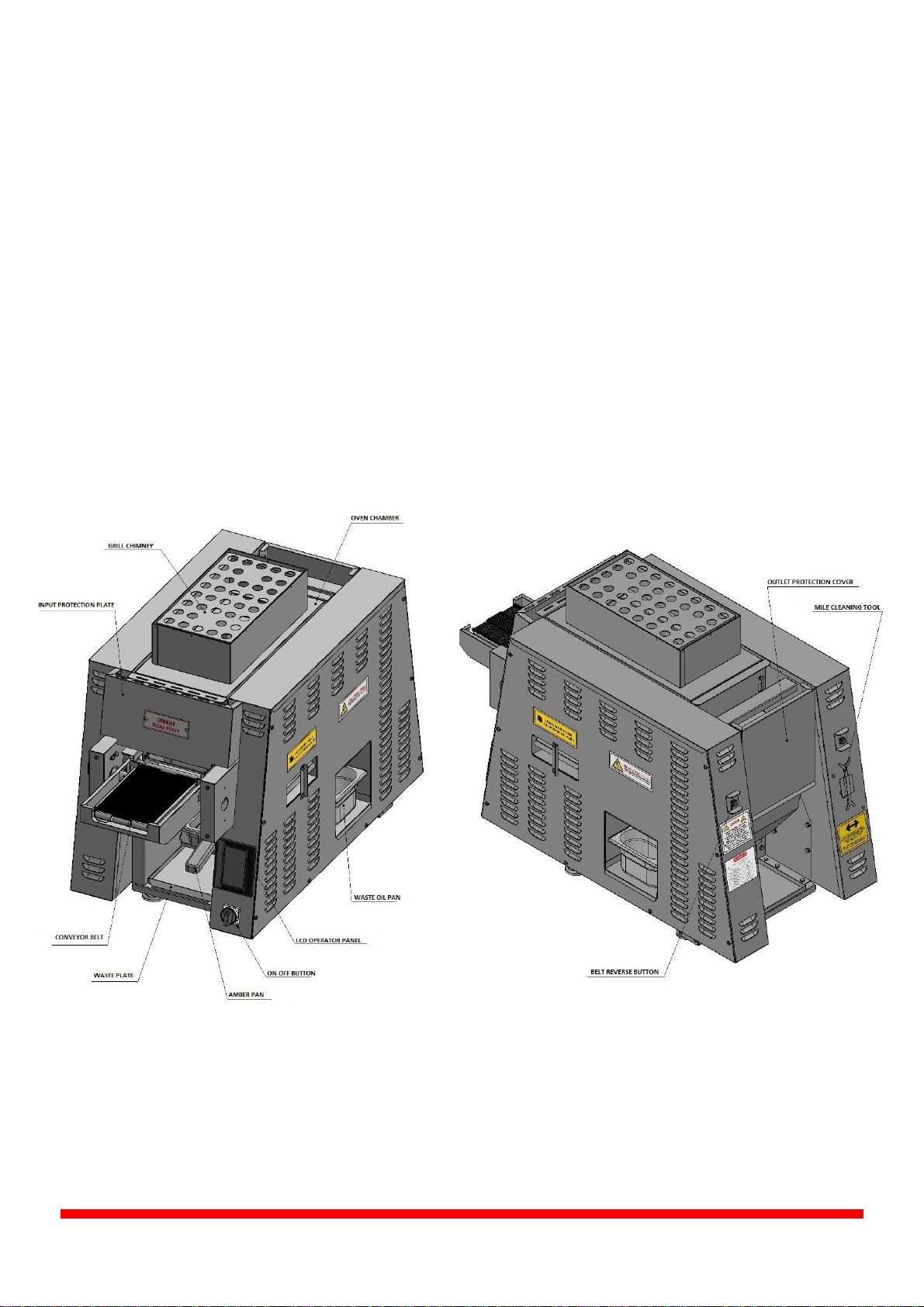

The broiler should be placed under a ventilation cover or a hood. Make sure that the broiler is sufficiently

aerated and the ventilation is adequate.

Make sure that the broiler is adequately distanced from walls and any other incombustible stuff. The

minimum required distances are to be found in the following sections.

Keep the broiler always clean. Remove possibly incombustible substances from the broiler.

Ventilation gaps should be sufficiently dimensioned, so as to ensure proper ventilation of the broiler.

Do not block ventilation openings. Do not congest ventilation openings with foreign bodies.

Broiler shall only be used with the fuel specified on specifications’ plate fixed onto it.

Store the manual in a suitable place, considering that you may need to look at it again in the future.

Obtain a list from your gas provider which instructs you on what to do when you sense a gas smell. Hang this

list on a visible spot.

Gas won’t pass the burner when there’s no power.

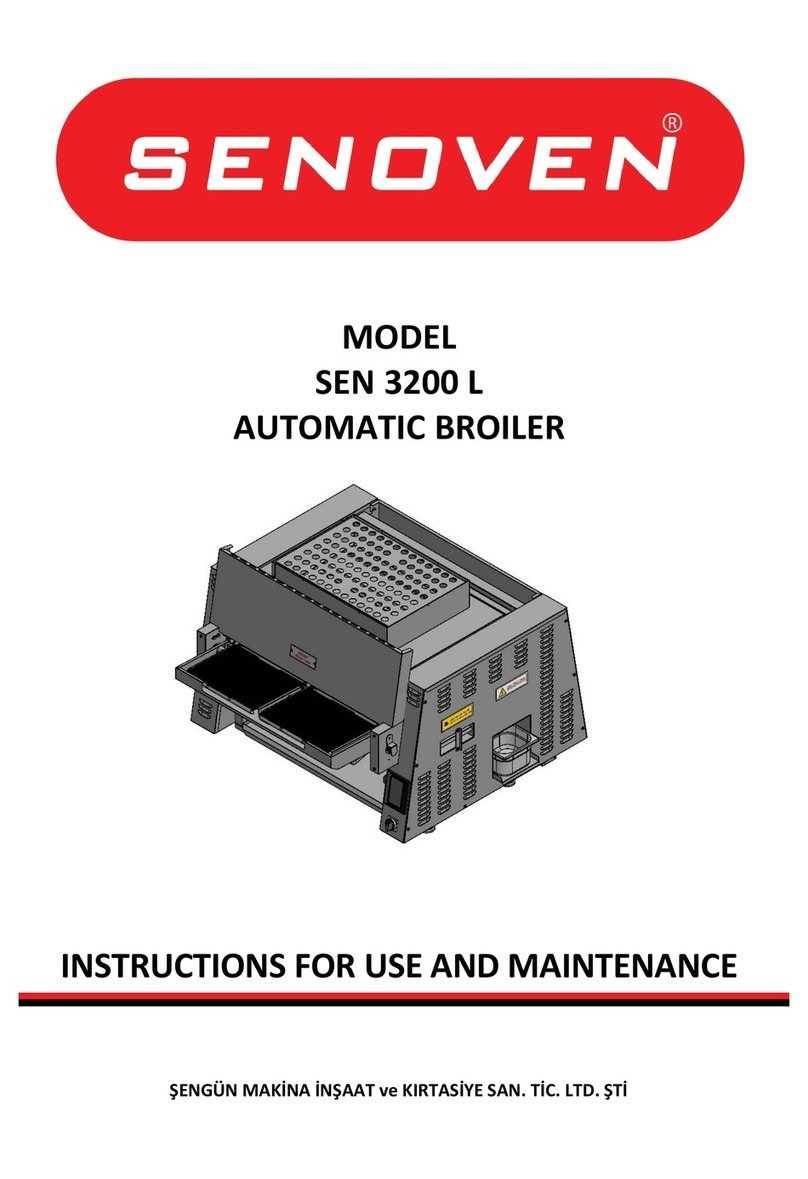

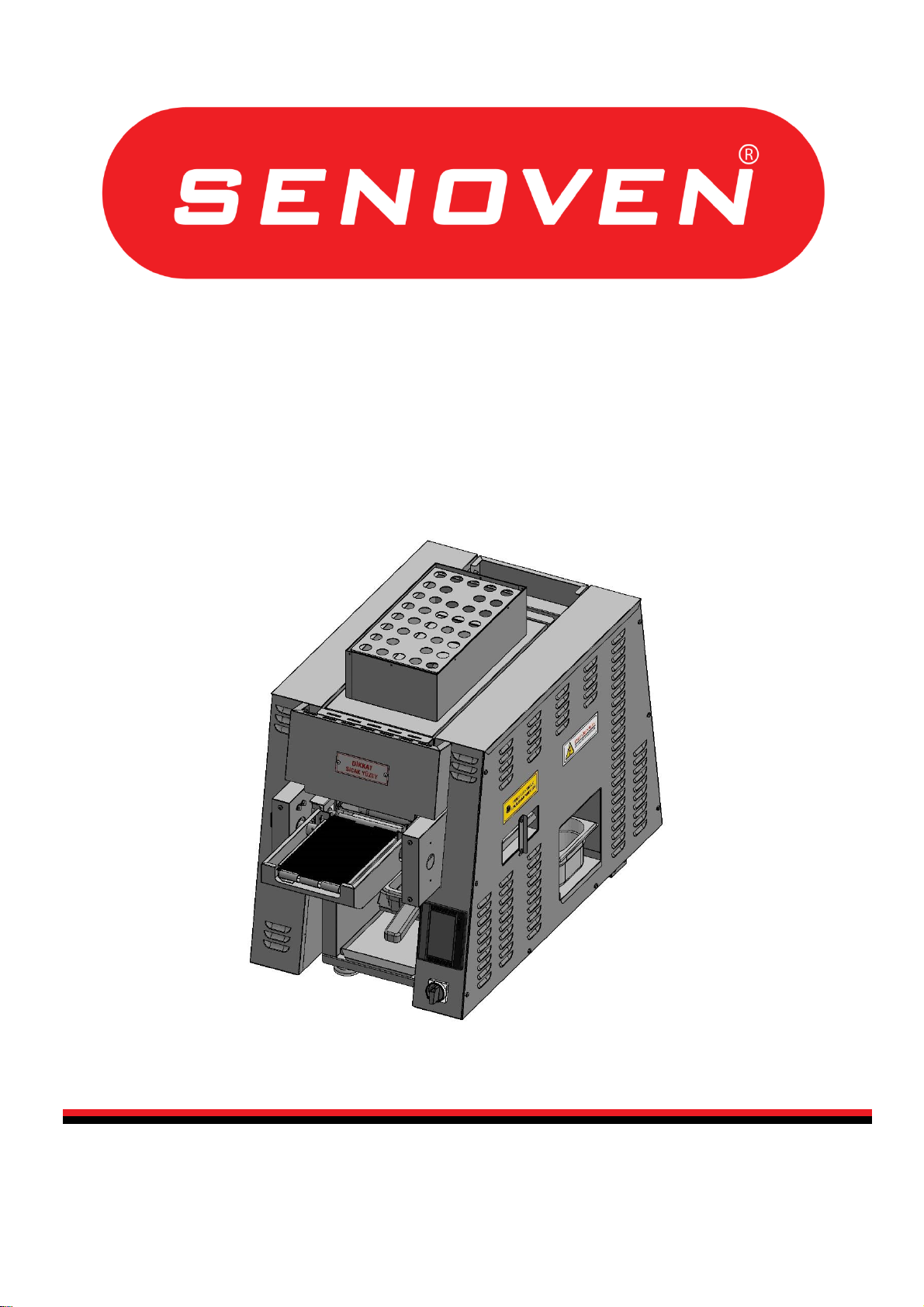

In addition to the warnings and precautions in this manual, apply the following directives for Senoven Automatic

Broiler to operate safely:

• Read and apply all the instructions before using this equipment.

• Use the broiler only for its intended use as described in this manual.

•Do not operate this device if it has a defective cable or plug or if it’s otherwise damaged.

• Only authorized personnel is allowed to carry out maintenance or repair work on this device.

Please contact your local Senoven branch.

•Please use only original Senoven spare parts for the broiler. Otherwise the guarantee becomes void and

cooking performance may be drastically impaired. Use of parts that are not produce of Senoven affects

these criteria and broiler performance may affect part service life and food health safety.

Warnings and instructions below appear throughout the manual and shall be diligently complied with:

•Shut the gas valve for turning the broiler off and unplug before any service,

maintenance or cleaning work to be done.

•Wait for the broiler to cool down completely before carrying out any service, maintenance

or cleaning. Failure to do so may cause body injuries.

•Procedures in this manual may contain references to use of chemical products. Senoven does not endorse

the use of any particular cleaning / degreasing agent. Make sure to use chemicals that are approved for use

in kitchen.

•The broiler should be grounded in accordance with the local electricity codes in order to avoid

risk of electricity shock. These fuses are protected by electric circuit breakers. Separate electricity

lines require a grounding plug.