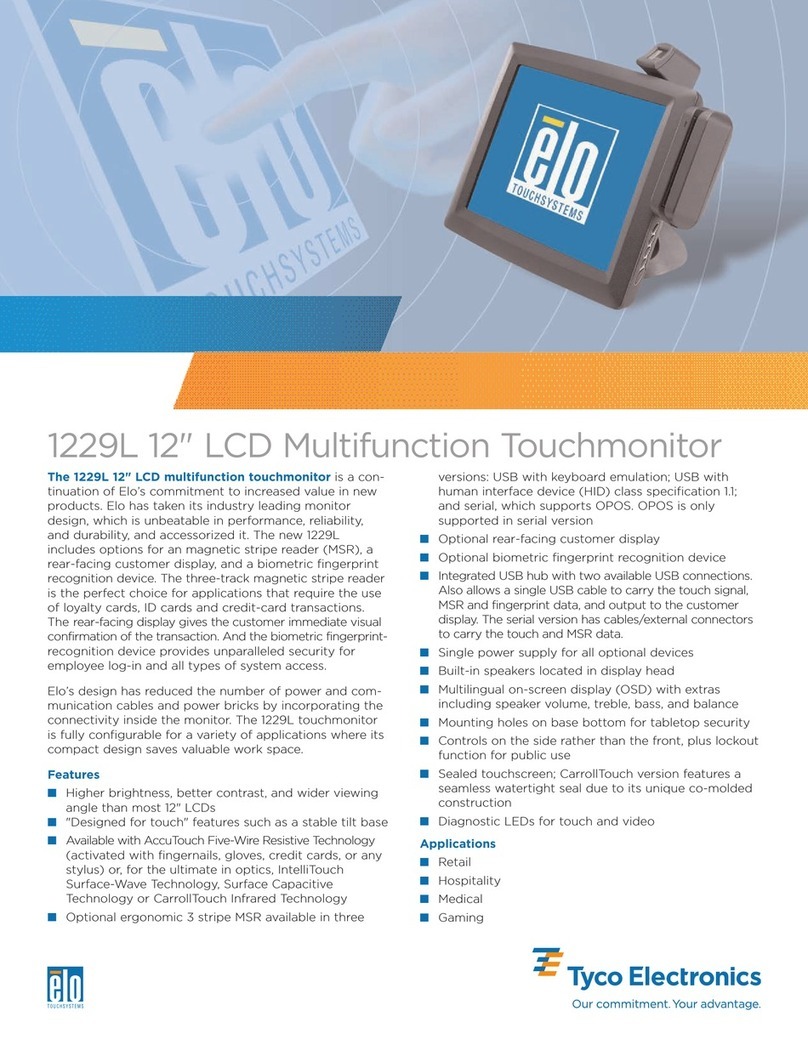

Sense PSH5-M32-ASI3.2S-Ex User manual

INSTRUCTIONS MANUAL

Installation Recommendations

Intelligent Valve Monitor

PSH5-M32-ASI3.2S-Ex

2Sense

Certification information :

The Smart Valve monitor PSH5 -M32-ASI3.2S-Ex is

certified for explosive atmospheres of gases with type

of protection increased safety and encapsulation,

intrinsically safe Ex IB in output for use with solenoid

valves Exi . Has marking Ex mb and [ib ] IIB , IIA T6 Gb

IP66 being able to be installed in zones 1 and 2.

Special Conditions of Safe Use:

Valve Signalling:

The dual sensor was designed to signal rotary valves,

which rotate 1/4 turn (90 °). The sensors in the

AS-interface network are perfect for the automation of

valves, as they allow through a single cableto transmit

the open and closed state of the valve and also receive

the command to actuate the solenoid valve.

Another advantage of the network system is the

possibility of the sensor indicate a diagnosis,

especially short-circuit or open solenoid valve.

Magnetic Sensors:

The sensor consists of two magnetic sensors mounted

in the same enclosure. The sensor detects the

magnetic targets mounted on the actuator for greater

reliability, because the sensors are polarized, ie, the

sensor 1 detects only the magnet with north pole and

sensor 2 only detects the magnet with the south pole,

thus avoiding inverted detection.

System Functioning:

The electronic sensor detects the magnetic actuator

installed on the local signaller, and sends a signal to

the network with the valve positioning.

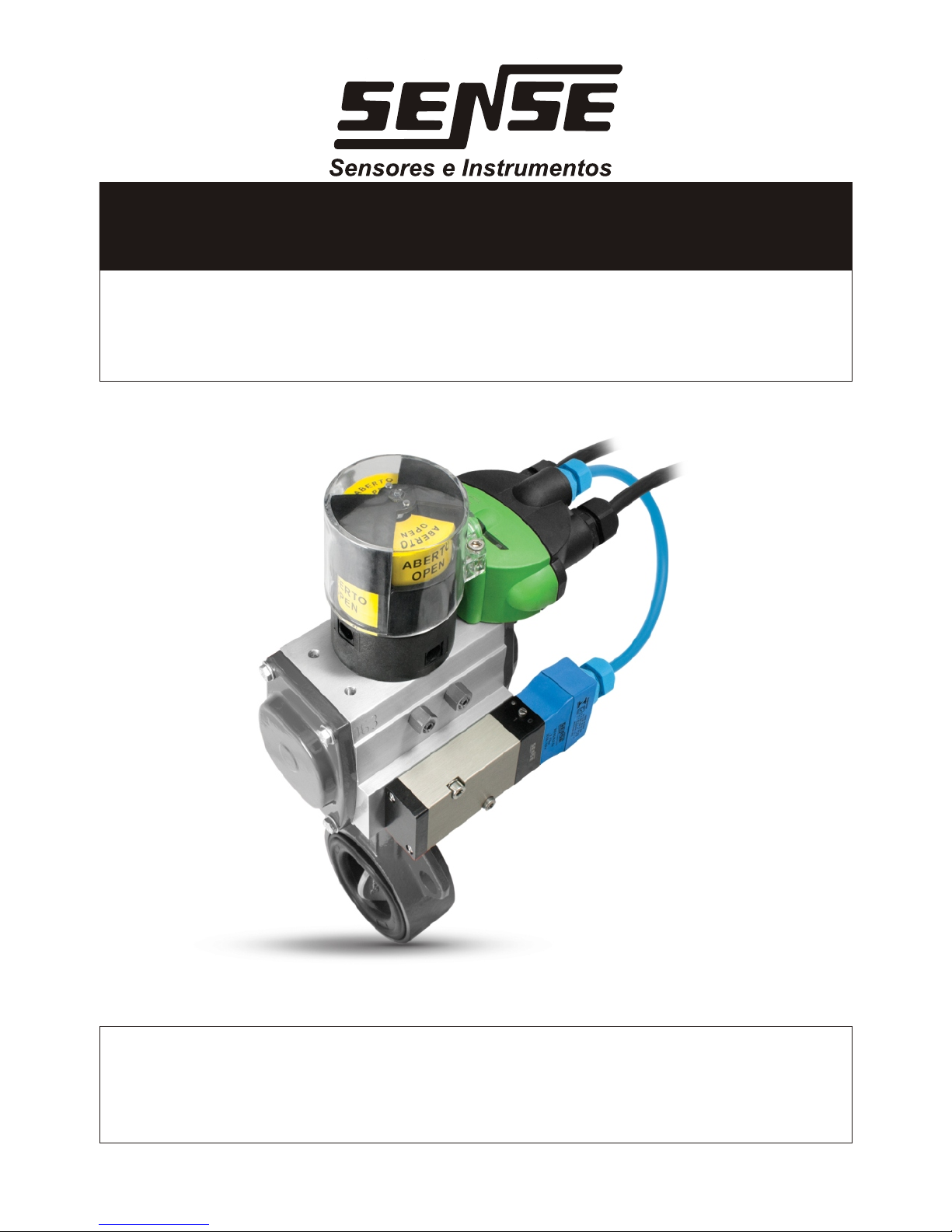

Trigger with Open/ Closed Local Signalling:

The activation kit

consists of local

indicator and its two

magnetic actuators.

The set also includes 1

distancing disc and

screws: M6x40 for fixing

the local actuator to the

shaft and the 2 screws

for fixing the M5x55

sensor.

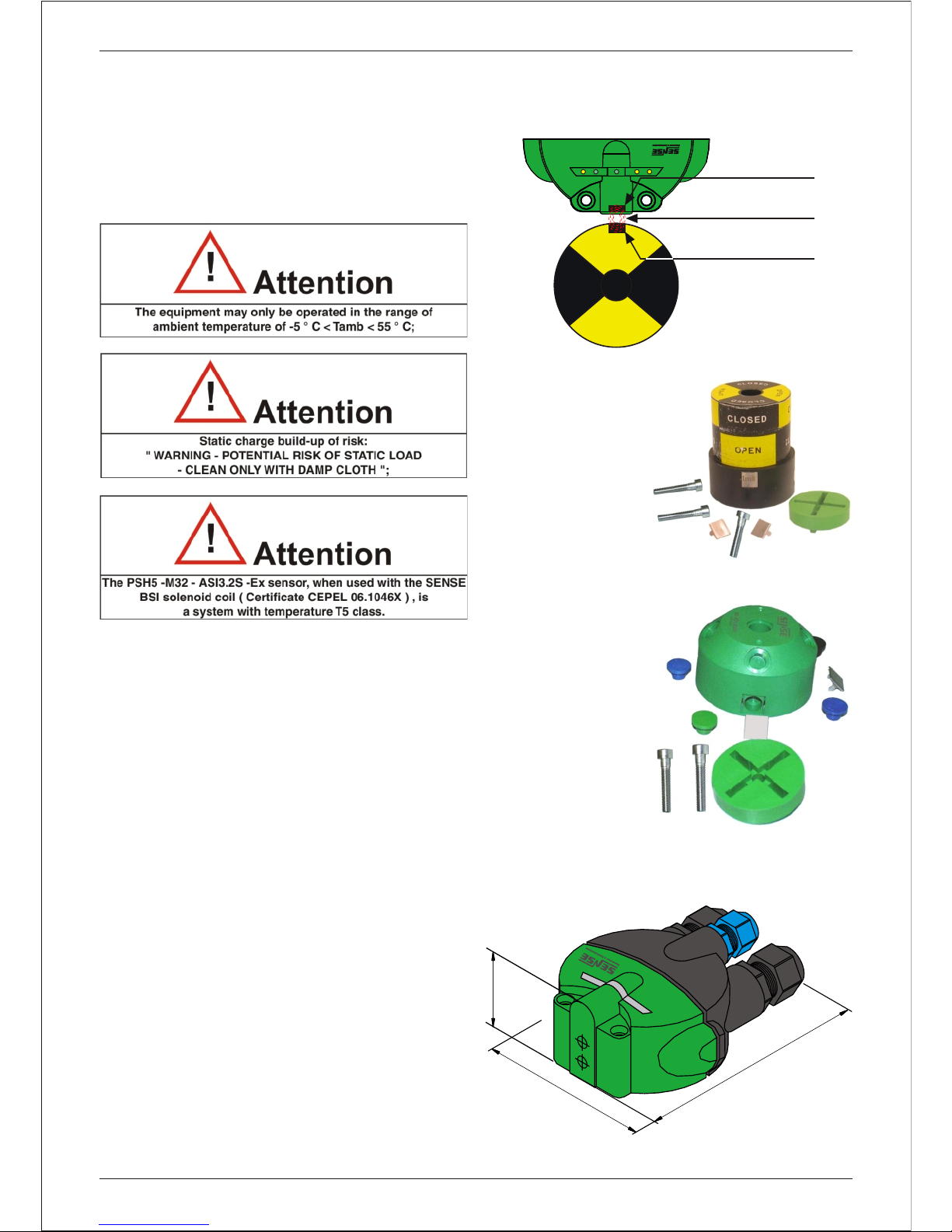

Trigger with Local Signalling by Color:

The actuation kit

consists of the "little cup"

with its magnetic

actuators.

The set also includes 2

spacer disks, 2 green

lids , 2 blue covers and 1

black cover, and apart

from that the M6x30

screws for fixing the

actuator on the actuator

shaft and 2 M5x40

screws for fixing the

sensor are also being

supplied.

Mechanical Dimensions:

Intelligent Valve Monitor

45.0

92,5

111

Sensor Magnético

Campo Magnético

Acionador Magnético

S1 S2 FAULT ASI SOL

PSH5-M32-ASI3.2S-ExPSH5-M32-ASI3.2S-Ex

N

E

P

O

O

P

E

N

Namur Standar:

In order to standardise the coupling of pneumatic

actuators with valve position signalling elements was

established the NAMUR STANDARD, which defines

four standards for pneumatic actuator, according to

the drawing below:

Types of Shaft:

For the sensor actuator to fit perfectly, this must have

the following characteristics:

Shaft Diametre:

The sensor actuator allows shafts from 11 mm to

45mm diametre.

Shaft Fitting:

The shaft must have a Tear

4mm wide and 4mm deep so the

shoulder of the actuator fits

perfectly.

Shaft Thread:

The shaft must preferably have

a threaded hole with M6 thread,

but it is believed threads M4 or

M5, however the driver is

provided with a M6x40 screw

with the actuator site and M6x30

visual signaling to the driver

without local visual cue and

shaft must have a hole deeper

than 20mm.

Shaft Height:

M32 line sensors are supplied

with 5 mm or 10 mm spacers, thus enabling the use of

actuators on shafts of different heights. The shaft

height should be adequate so that the driver does not

scrape the bottom of the actuator and not be

suspended, moving magnetic actuators from their

position in relation to the remote signalling sensor

targets.

Sense 3

Intelligent Valve Monitor

Atuador - Vista Superior

X

Y

Atuador - Vista Lateral

Z

4mm

4mm

M5

M6

Namur 1234

DIM X 80 mm 130 mm

DIM Y

DIM Z

80 mm 130 mm

30 mm 30 mm 30 mm 30 mm

20 mm 30 mm 30 mm 50 mm

M5x8 (prof.)

11

min.

45

máx.

4

4

M6x1

12mm

CLOSED

OPEN

Eixo do Atuador

Espaçador

Acionador Espaçadores

Adicionais

5mm

10mm

Cable Installation:

Follow the procedures below to install the cables:

1 - Loosen the two screws securing the junction box to

the sensor.

2 - Detach the sensor terminal box by pulling it by

hand.

3 - Locate the three screws holding the connectors in

the junction box.

4 - With the aid of a suitable screwdriver, loosen the

three screws from the terminal box to gain access to

the connectors.

5 - Disengage the cover holding the connectors to the

terminal box.

6 - Remove the locking nut and seal rubber from the

cable gland nº 1.

7 - Prepare the cable by baring its outer cover by

maximum 40 mm.

8 - We also recommend the use of pre-insulated

terminals at the ends of the wires, to avoid problems of

poor contact or short circuit.

4Sense

Intelligent Valve Monitor

4040

55

Alicate ZA3Alicate ZA3

9 - The output cable network must be installed on the

cable gland 2. Repeat steps 6, 7 and 8 for this new

cable.

10 - The solenoid cable should be installed in cable

gland 3. Repeat steps 6, 7 and 8 for the cable. If the

solenoid is not used, replace the cable gland PG9 for a

buffer. Follow the steps below:

10.1 - Remove the cable gland # 3 with the help of a

19mm hex wrench.

10.2 - Put the plug provided with the kit terminal and

tighten with a screwdriver and wide slot.

11 - With all prepared cables, insert the nut of the

cable gland and the rubber seal on the cables that will

be used.

12 - Insert the cables through the cable gland holes

and mount them but do not overtighten.

13 - Fasten the wires to the terminals, observing the

connection diagram.

14 - Push the connector into the junction box, help

pulling cables.

15 - Put the connector cover, if necessary move the

cables so that the cover can be fitted.

16 - Tighten the three screws securing the connector

cover.

17 - Tighten the cable glands, plug the sensor in the

terminal box and tighten the two screws.

Sense 5

Intelligent Valve Monitor

6Sense

Intelligent Valve Monitor

Magnetic Actuators Assembly

The procedures below are for actuators with or without local visual indication.

01 - Place the magnet on the actuator on the top face marked inside.

02 - Place the magnet on the bottom of the actuator face checked out.

03 - Mount the metal cover over the magnet in your accommodation.

04 - Fold tabs for fixing the metal cover.

02

01

03

03

04

Dobra

Mounting on the Pneumatic Actuator - Actuator with Open/ Closed Local Signaling:

Montagem no Atuador - Acionador com Sinalização Visual por Cores:

Sense 7

Intelligent Valve Monitor

1- Mount the local indicator on the

actuator shaft , inserting the spacers

as needed , according to the height

axis.

2- Place the M6 screw for fixing the

local indicator to the actuator shaft

and tighten it with a proper key but do

not overtighten in order to enable the

adjustment of the triggers.

3- Mandatorily sensor 1 must be

triggered together with the solenoid

command. For this , adjust the local

indicator turning -o with a hand,

always observing the rotary direction

of the actuator.

4- The indicator allows the adjustment

of the Open / Close position indication

according to the actuator type (NO /

NC) . Adjust the local indicator

according your application and then

tighten the fixing screw.

5- Now place the monitor on the

actuator.

6- Place the acrylic on the trigger ,

then the two M5 screws and tighten

with a proper key, but do not

overtightening to avoid damaging the

acrylic.

1- Mount the local indicator on the

actuator shaft , inserting the spacers

as needed , according to the height

axis.

2- The trigger must be positioned in

order to sensor 1 activated together

with solenoid command. Observe the

rotary direction of the actuator.

3- Place the M6 screw for fixing the

local indicator to the actuator shaft

and tighten it with a proper key

4- Now place the monitor on the

actuator , then the two M5 screws and

tighten with a proper key.

5- Install the black cover on the trigger

fixing screw. Also Install the green and

blue covers for indicate de open and

close position of the valve.

6- The pictures below illustrate the

open and closed position of the valve.

Diagnoses:

8Sense

Intelligent Valve Monitor

The diagnostic tools aims to help users detect possible failures, ensuring the quality of operation of the actuator

assembly - valve, preventing problems of production, loss of lots or even accidents.

Valve (Opening and Closing) Cycle Time

Diagnosis:

This is a powerful tool that allows the sensor to

memorize the average time of opening and closing the

valve and generate a fault alarm if the preset time has

elapsed. This function is enabled by software, the bit 2

output and through dipswitches 1-4 you can configure

how many cycles the sensor learn the average time of

opening and closing of the valve.

Maintenance Diagnoses:

The sensor features powerful diagnostic tools that monitors the actuator opening and closing time and the

actuator set status - valve to know if preventive maintenance is necessary, i.e. maintenance that occurs before

the set fails, having reached a pre-user-defined level, considered sufficient to generate fatigue in components

of the set.

Valve Cycles Average Time:

It is the sum of the time that the valve completes a full

cycle (opening and closing of the valve) divided by the

number of cycles programmed to learn the sensor this

time. If the sensor is programmed to learn the average

time in cycles 4 and the sum of the times for each cycle

is equal to 60 minutes, this means that the average

time of each cycle is 15 minutes. After learning cycles,

if the average time saved is exceeded, the sensor will

indicate this anomaly.

Note: The more dense the fluid controlled by the valve,

the greater will be the number of cycles for learning

the average time.

Time Tolerance: * The failure green led flashes , indicating failure in the

mean time of opening and closing the valve.

It is possible to configure through the dipswitches 5 to 8 in a tolerance time before the fault indication can be

from 10% to 40% of the average time saved by sensor.

Dipswitch Dipswitches Function

1 2 3 4 5 6 7 8

1 0 0 0 x x x x Learns with 4 actuation cycles

0100xxxxLearns with 8 actuation cycles

0010xxxxLearns with 16 actuation cycles

0001xxxxLearns with 32 actuation cycles

xxxx1000

Tolerance of 10% in time before recognising

intelligence failure

xxxx0100Tolerance of 20% in time before recognising

intelligence failure

xxxx0010Tolerance of 30% in time before recognising

intelligence failure

Notes:

- Case: 0000xxxx ou xxxx0000 => Disables intelligence function automatically.

- "1" - switches on ON. / "0" - switches on OFF.

Possible causes for failure indication are:

- Stuck valve - valve with high air leakage.

* Actuation bit of the valve opening and closing time

diagnosis.

Sense 9

Intelligent Valve Monitor

Maneuvre Counter

The sensor has a maneuvre counter that works as a maintenance diagnostic, since it allows the user to

schedule preventive maintenance for example when the valve reach the 500 full cycles (opening and closing the

valve). You can view the number of maneuvers via software, in bits 2 and 3 input or there is the possibility of

generating an alarm (via logic programming), warning that should be taken to maintain the valve.

Input Bits

Bit 0 Bit 1 Bit 2 Bit 3

Sensor 1 Sensor 2 Parametre 1 Parametre 2 No. of

Maneuvres

000 to 499

01500 to 4.999

105.000 to

49.999

11above

50.000

Output Bitsa

Bit 0 Bit 1 Bit 2 Bit 3

solenoid Maneuvre counter and

intelligent function reset Enables intelligent function not used

0 to 499 Maneuvres 500 to 4.999 Maneuvres 5.000 to 49.999Maneuvres

Above 50.000 Maneuvres Reset Function

Input and Output Bits Table:

Energy Savings and Solenoid Increased Life Span:

If the solenoid remains activated for more than 1 minute and 30 seconds, the sensor will automatically reduce its

energy-saving voltage source and increasing the life of the solenoid.

Note:Whenever valve maintenance is performed, the output bit 1 should be activated for at least 1 second to

reset the cycle count.

IMPORTANT!

On the trigger mounting and the control logic

attention should be paid because the sensor 2

should be activated together with the solenoid

command.

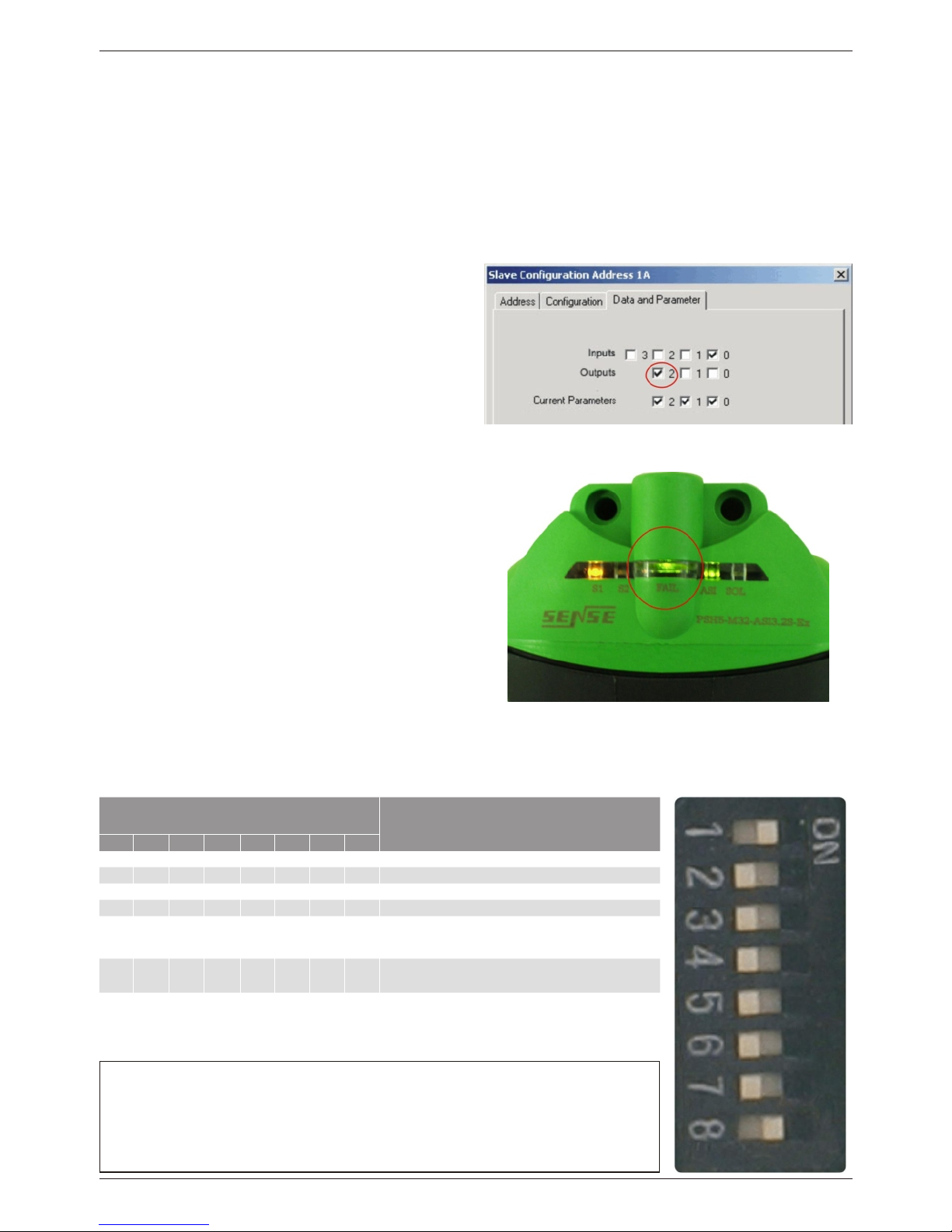

Signalling Leds:

Diagnoses via Signalling Leds:

10 Sense

Intelligent Valve Monitor

The smart sensor for valve signalling is equipped with five signaling leds, as follows:

Signalling Led

S1 yellow lights up when the sensor S1 is actuated

S2 yellow lights up when the sensor S2 is actuated

FAULT green/ red failure in cycle time, sensors or supply

ASI green/ red Peripheral or network communication failure

SOL yellow Indicates solenoid valve status

Led Sensor 1 Led Sensor 2 Led de Rede Led da solenóide

Led de Falha

LED Condition Description

Network Led

blinks green/ red A peripheral failure has occurred

on red no communication or address 00

on green communication with the network

Failure Led

blinks green Smart function failure (actuation cycle has bee exceeded)

blinks red Sensor actuation failure (stuck valve or with big air leakage)

on red AS-i supply < 26,5Vdc

on green no failures

Solenoid Led

off solenoid disabled

on solenoid activated

blinks yellow slowly solenoid open when activated

blinks yellow quickly solenoid in short-circuit when activated

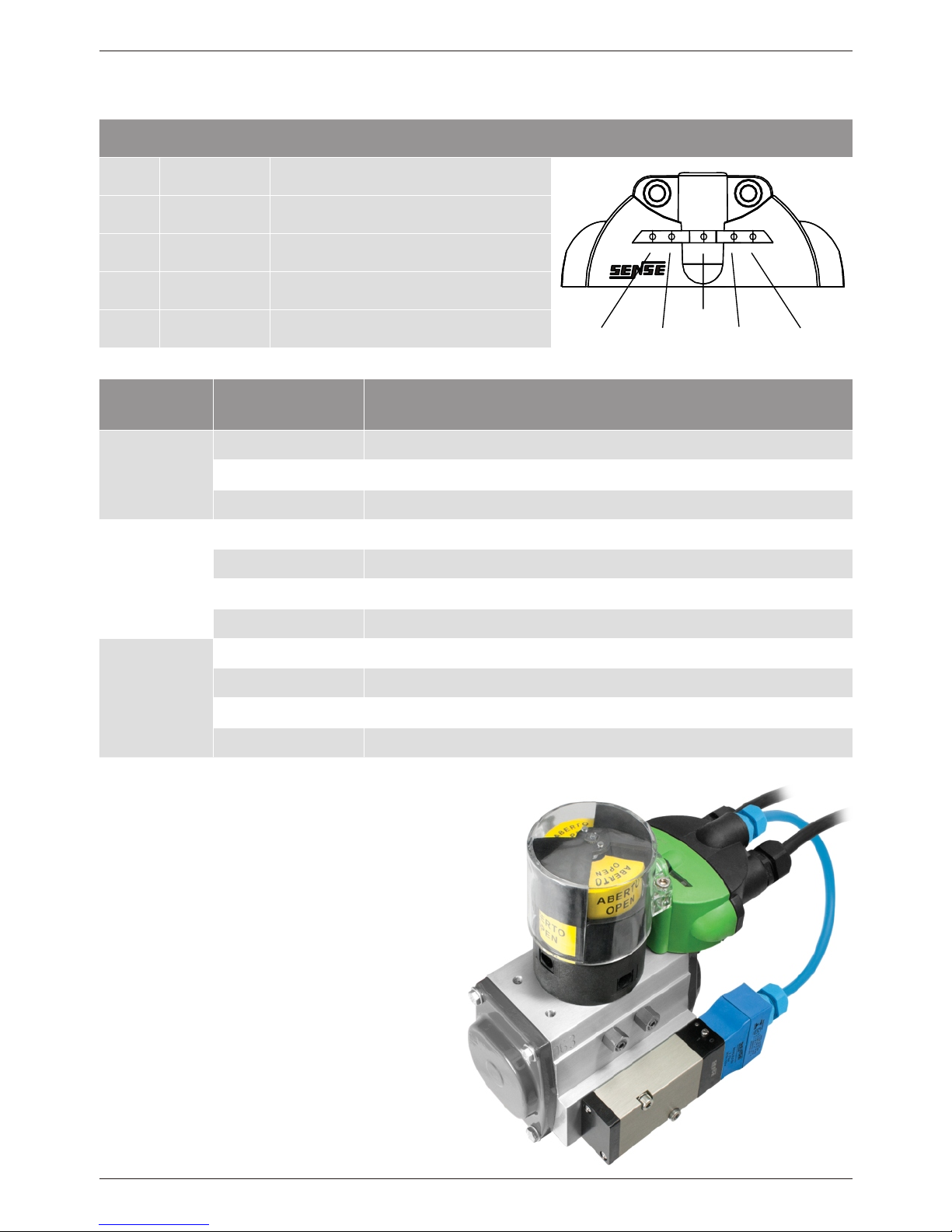

Solenoid Valve:

For the solenoid valve to be safely connected to the

valve sensor, it must be certified as Intrinsic Safety.

Sense offers sensors along with the solenoid valve,

both certificates for use in potentially explosive

atmospheres.

The valve body meets the Namur standard, which

does not require fixing accesories, as it is mounted

directly on the pneumatic actuator.

Note: Attention local indicator mounting. When the

solenoid is activated, the sensor 1 must be actuated,

otherwise it indicates a non-existent fault.

Technical Characteristics:

Connections Diagram Addressing

Sense 11

Intelligent Valve Monitor

Data PSH5-M32-ASI3.2S-Ex

Sensor Distance 5 mm

Operating Distance 5 mm

Standard Target 9 x 9 mm

Hysteresis < 3º

Repeatability < 1º

Supply voltage 30.5 Vdc via AS-Interface network

Ripple 10%

Consumption current < 40 mA

Electric Configuration AS-Interface network version 3

Maximum switching current 40 mA (Ex ib output)

Maximum switching voltage 27 Vdc

Maximum switching power 1.08 W

Maximum switching frequency 50 Hz

Output voltage drop maximum of 2 Vdc

Watch dog output de-energises upon lack of communication

Addressing 62 addresses ( 0 to 31 A or B)

Data Bits bit 0: sensor 1 ... bit 1: sensor 2

bit 2: parametre 1 ... bit 3: parametre 2

Diagnoses output shorted or open / supply out of range / failure in the

sensors or in the intelligence function

I/O and ID I/O = 7 ID = Ah ID2 = 2h

Network Signalling green / red led

Network speed 167,5 Kbps

Communication Type manchester

Network Connection screw terminal 2.5 mm² - 5 leads

Solenoid output yes

Type of solenoid low power

Solenoid Connection screw terminal 2.5mm² - 2 vias

Solenoid Signalling Yellow led

Housing PBT

Protection rate IP 66

Weight < 250 g

Operating Temperature - 25ºC to + 55ºC

ASI -ASI -

ASI +ASI +

SOL-SOL-

11

22

SOL +SOL +

++

--

The addressing on the AS-Interface network is configured

via software or manual programmer.

Selection

IO:7 - ID:A - ID2:2

U=30,5Vdc - IL=40mA

SOL+

SOL

-

ASI -

ASI+

Not Used

Not Used

Not Used

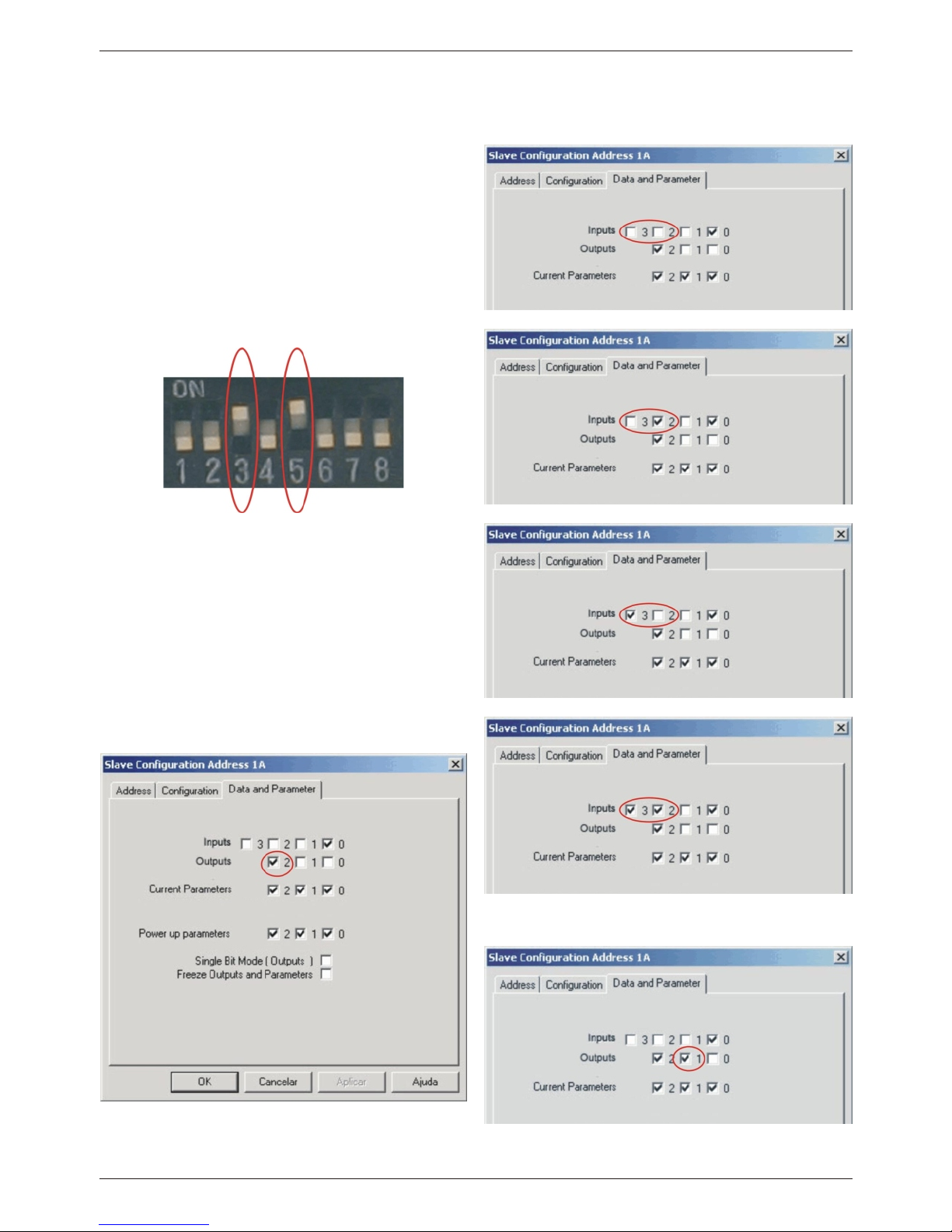

For our example we will configure the sensor to learn

that the average time for valve actuation in 16 cycles

and 10% tolerance in time before indicating failure in

the function of intelligence. For our example the

software used for configuration is the ASI-Control

Tools.

1 - Attach the sensor according to the connection

diagram and connect a PC with the ASI-Control Tools

software installed.

2 - Place the dip number 3 to "ON", the sensor will

learn it the average time of operation of the valve 16

cycles.

3 - Place the dip number 5 to "ON" so that the

tolerance in time before indicating failure is 10%.

NOTE!The other dips should all remain in the "OFF"

position.

4º - Make the setting for the sensor to be recognized

by the software.

5 - To enable the intelligence function, you must set bit

2 output for this, open the slave configuration screen

by double-clicking on it.

6 - When you open the screen click on "Data and

Parameter" tab and click on bit 2 output to enable it.

7º - The amount of maneuvering of the valve is read in

input bits 2 and 3, as the figures below:

0 to 499 Maneuvres:

500 to 4.999 Maneuvres:

5.000 to 49.000 Maneuvres:

Above 50.000 Maneuvres:

NOTE!When doing maintenance of the valve to reset

the maneuvre counter, for this, enable output bit 1 for

at least one second.

12 Sense

Intelligent Valve Monitor

Sensor Functions Configuration Example:

Rua Tuiuti, 1237 - Tatuapé - 03081-000 - São Paulo - SP - Fone: (11) 2145-0444 - Fax: (11) 2145-0404 - e-mail: vendas@sense.com.br - www.sense.com.br

We reserve the right to modify the information contained herein without notice EA3000849C - 09/2015

Table of contents