www.blazecut.com Page 2 of 93

technical@blazecut.com ILP CLEAN AGENT MANUAL-ILPCAM1904

BlazeCut and the BlazeCut logo are the registered trademarks of BlazeCut © 2019 BlazeCut, All rights reserved

TABLE OF CONTENT:

1. INTRODUCTION.................................................................................................................. 4

2. BASIC INFORMATION ABOUT THE SYSTEM.......................................................................... 5

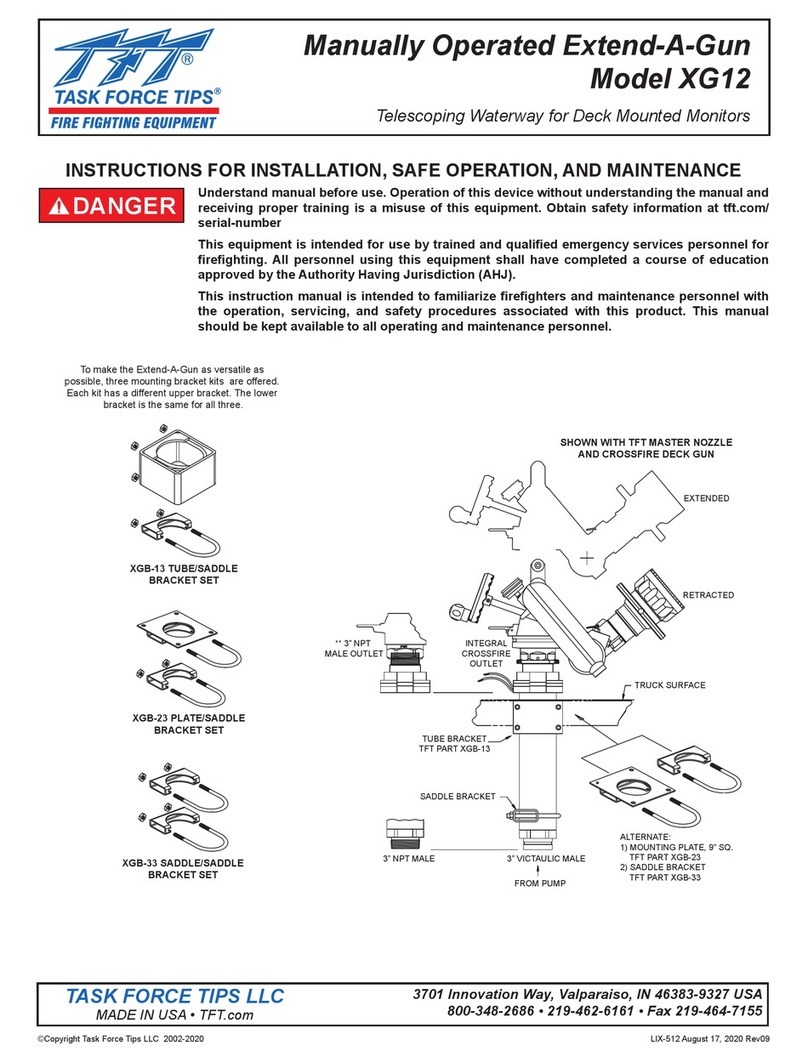

2.1. TECHNICAL SPECIFICATION AND TYPES................................................................................... 8

2.2. USE OF THE SYSTEM................................................................................................................. 8

3. COMPONENTS OF THE SYSTEM AND THEIR DESCRIPTION .................................................... 9

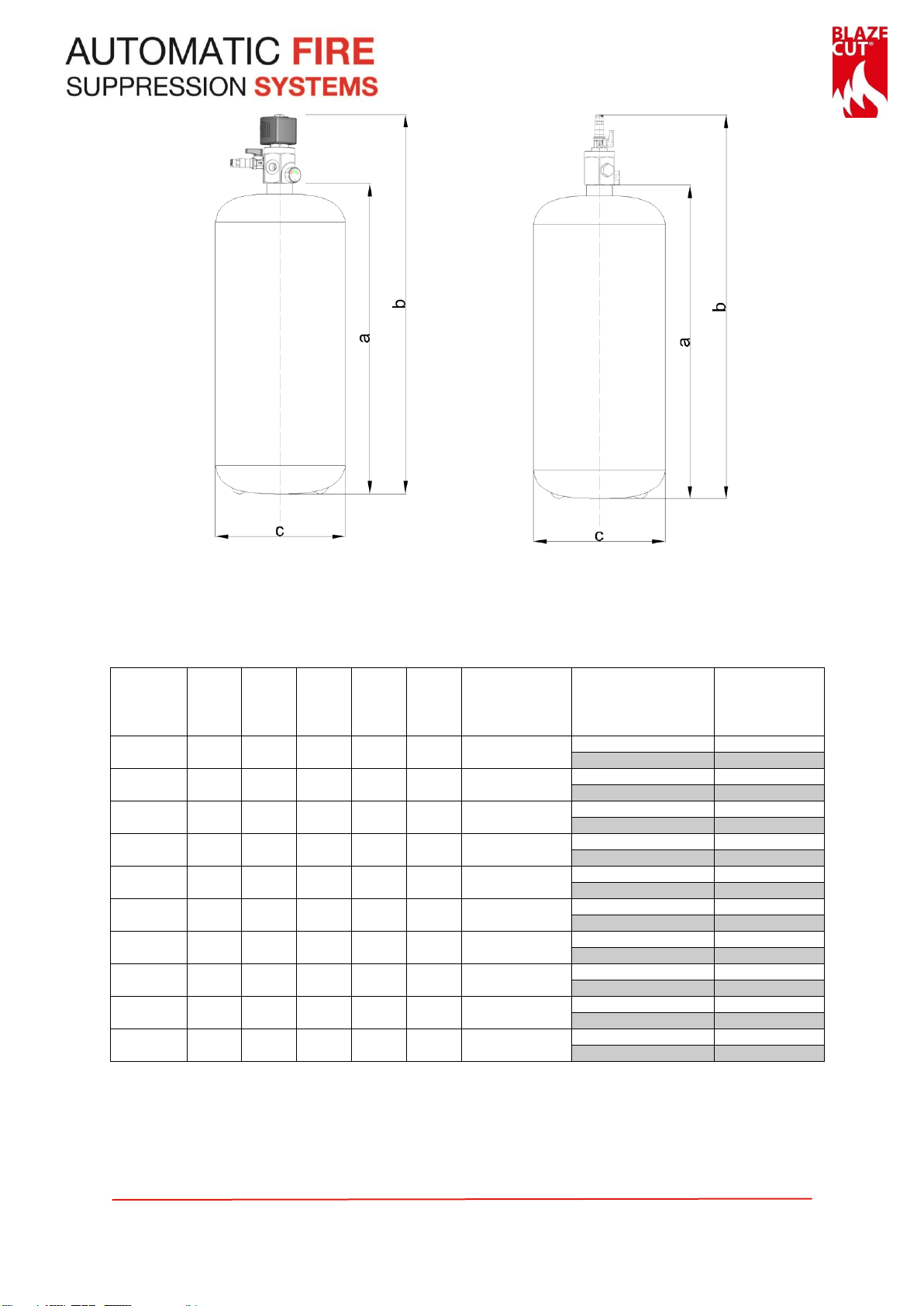

3.1. CYLINDER.................................................................................................................................. 9

3.2. VALVE OF THE CYLINDER........................................................................................................ 12

3.3. BLAZETUBE DETECTION ......................................................................................................... 18

3.4. PRESSURE GAUGE .................................................................................................................. 20

3.5. BLAZETUBE FITTINGS ............................................................................................................. 21

3.6. BLAZETUBE END OF LINE DEVICES......................................................................................... 21

3.7. BLAZEWIRE............................................................................................................................. 22

3.8. FASTENING MATERIAL ........................................................................................................... 26

3.9. LABELS.................................................................................................................................... 27

3.10. INSTALLATION OF DISTRIBUTION NETWORK......................................................................... 29

4. DEFINITION OF LEGAL REQUIREMENTS ............................................................................. 37

5. INFORMATION ON EXTINGUISHING AGENT USED.............................................................. 37

5.1. DESCRIPTION OF HFC GASES.................................................................................................. 38

5.2. DESCRIPTION OF NOVEC 1230 (FK-5-1-12)............................................................................ 38

5.3. PERMISSIBLE USES OF EXTINGUISHING AGENT..................................................................... 39

5.4. VOLUME COVERAGE .............................................................................................................. 39

5.5. SOME PHYSICAL AND CHEMICAL PROPERTIES ...................................................................... 43

5.6. IMPROPER USES OF EXTINGUISHING AGENT ........................................................................ 44

5.7. WARNINGS............................................................................................................................. 44

5.8. HANDLING HFC GASES........................................................................................................... 45

6. INSTRUCTIONS FOR INSTALLATION OF THE SYSTEM .......................................................... 46

6.1. GENERAL RULES ..................................................................................................................... 46

6.2. INSTALLATION AND PLACEMENT OF THE CYLINDER ............................................................. 47

6.3. MULTIPLE CYLINDERS CONNECTION...................................................................................... 50

6.4. INSTALLATION OF THE BLAZETUBE DETECTION .................................................................... 52

6.5. PRESSURIZATION OF THE BLAZETUBE DETECTION SYSTEM.................................................. 58

6.6. FINAL INSPECTION OF THE SYSTEM INSTALLATION............................................................... 61

7. REGULAR INSPECTION AND MAINTENANCE OF THE FIRE SUPPRESSION SYSTEM ................ 61

7.1. COMPREHENSIVE INSPECTION OF THE SYSTEM.................................................................... 62

7.2. INSPECTION OF PRESSURE IN THE SYSTEM ........................................................................... 62

7.3. PRESSURIZATION OF THE SYSTEM......................................................................................... 63

7.4. INSPECTION OF WEIGHT OF EXTINGUISHING AGENT IN SYSTEM ......................................... 67

7.5. REMOVAL OF THE SYSTEM FROM THE SERVICE .................................................................... 67

8. OPERATION OF SYSTEM BLAZECUT IN CASE OF FIRE .......................................................... 68

10. DISAMBLEMENT OF THE SYSTEM ...................................................................................... 71

11. MAINTENANCE OF THE SYSTEM, REPLACEMENT OF COMPONENTS.................................... 72

11.1. GENERAL RULES ..................................................................................................................... 72

11.2. REPLACEMENT OF THE CYLINDER.......................................................................................... 72