sensonor STIM202 User manual

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 1/22 Dec 2017

Table of contents:

1GENERAL DESCRIPTIONS......................................................................................................................................2

2KIT CONTENTS.........................................................................................................................................................3

3KIT FEATURES .........................................................................................................................................................3

4CONFIGURABLE AND READABLE PARAMETERS ..............................................................................................3

5SYSTEM REQUIREMENTS.......................................................................................................................................4

6GETTING STARTED..................................................................................................................................................4

6.1 INSTALLATION OF NI SERIAL DRIVER........................................................................................................................4

6.2 INSTALLATION OF PC SOFTWARE............................................................................................................................5

6.3 FIRST HARDWARE CONNECTIONS............................................................................................................................9

6.3.1 Common preparations .................................................................................................................................9

6.3.2 For preparing the PCI kit (skip this step if the USB kit is used)...................................................................9

6.3.3 For preparing the USB kit (skip this step if the PCI kit is used)...................................................................9

6.3.4 Common verifications...................................................................................................................................9

6.4 FIRST PC SOFTWARE START-UP ...........................................................................................................................10

7INTRODUCTION TO PC SOFTWARE ....................................................................................................................14

7.1 PANELS OVERVIEW ..............................................................................................................................................14

7.2 MAIN PANEL MENUS .............................................................................................................................................16

7.3 NORMAL MODE PANEL DESCRIPTIONS ...................................................................................................................17

7.4 SERVICE MODE PANEL DESCRIPTIONS...................................................................................................................17

7.5 MEASURE PANEL DESCRIPTIONS...........................................................................................................................18

7.6 LOGGING PANEL DESCRIPTIONS............................................................................................................................19

7.7 PARAMETERS PANEL DESCRIPTIONS .....................................................................................................................20

7.8 MESSAGES FROM THE PROGRAM..........................................................................................................................21

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 2/22 Dec 2017

1 General descriptions

The STIM202 evaluation kits provide measurement and configuration access to STIM202 multi-axis gyro modules.

Gyro module configuration, graphical result presentation and save data to file functions are supported. The single

voltage supply required for operation is provided from any PC or laptop USB port.

Two alternative evaluation kits are available, for either PCI or USB connectivity.

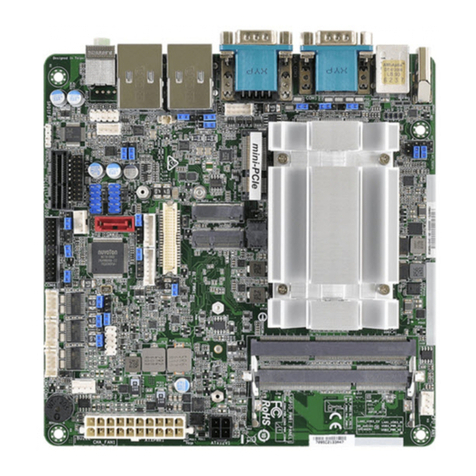

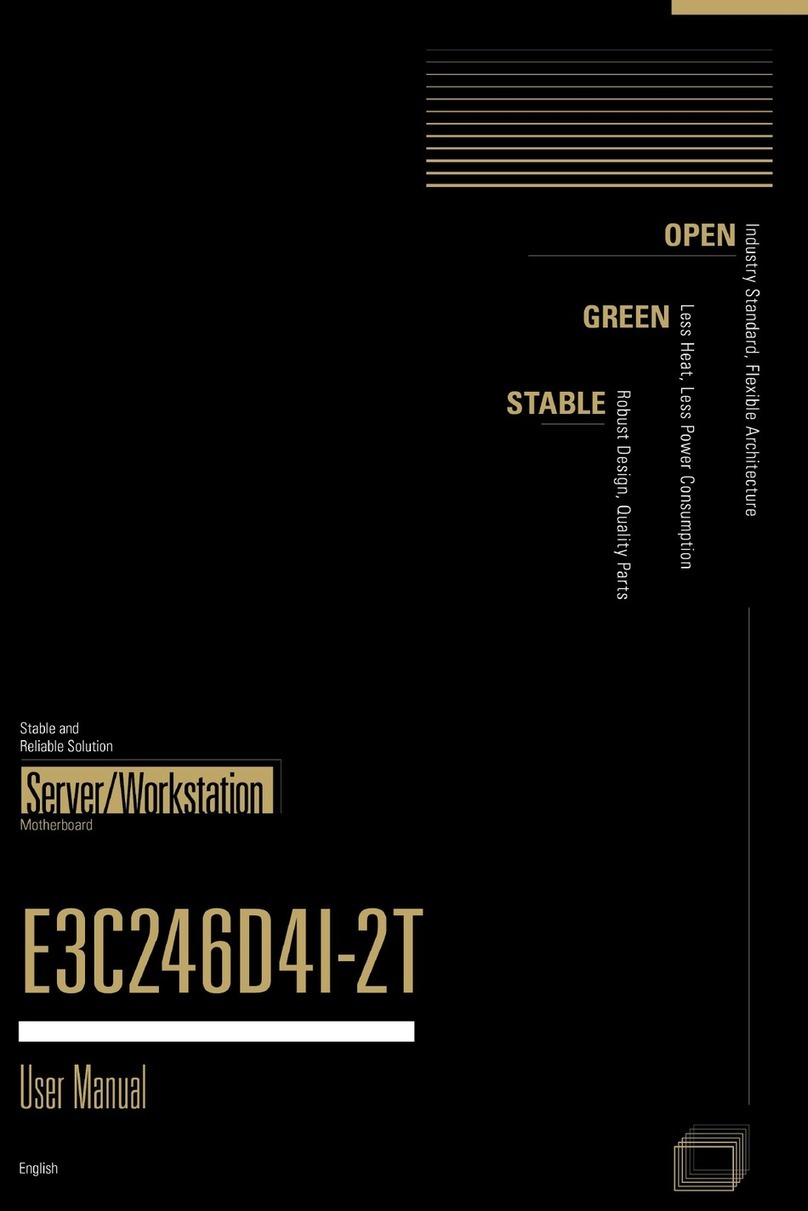

1. STIM202 EVK PCI

The evaluation kit with PCI connectivity is the recommended solution for thorough characterization. The kit is

in the following referred to as "the PCI kit"

Figure 1: STIM202 EVK PCI

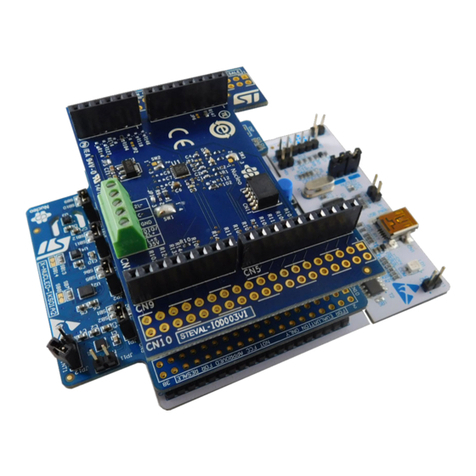

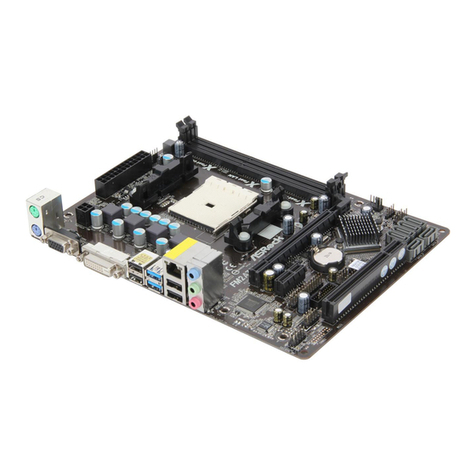

2. STIM202 EVK USB

The evaluation kit with USB connectivity provides the alternative solution, e.g. for smaller, portable laptop

setups, and is an excellent choice for gyro module configuration and shorter measurement series. The kit is in

the following referred to as "the USB kit"

Figure 2: STIM202 EVK USB

Note that the evaluation kits does not include the gyro module.

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 3/22 Dec 2017

2 Kit contents

STIM202 communication and power cable

Either of the two options for interface hardware;

oPCI to RS422 interface card, "the PCI card", for the PCI kit, supporting all gyro module transmission

bit rates (377400, 460800 and 921600 bits/s)

oUSB to RS422 interface cable, "the USB cable", for the USB kit, supporting only the default gyro

module transmission bit rate (460800 bits/s)

Memory stick with PC software and User manual

Torx screw driver for fixing connector of communication and power cable to gyro module

Hard copy of User manual

3 Kit Features

PCI or USB connectivity to PCs/ laptops

Up to 1000Hz sampling rate

Temperature measurements

Service mode access

oFull gyro module information

oFull gyro module configuration capability

oDetailed gyro module diagnostics

oHelp section

Measure panel

oData presentations and save data to file capability

oCustom scale and zoom functions

oCRC check

Logging panel

oSupport for any measurement duration (only limited by HD memory and processor capacity of PC)

oVarious stop criteria for measurement series (Manually, No of samples or Time elapsed)

Measurements on 2 gyro modules simultaneously supported (requires either one or two additional cables

depending on the kit in use)

4 Configurable and readable parameters

In addition to measurements, the evaluation kits provide access to the following gyro module user configurable

parameters:

Output format (angular rate, increment angle, etc.)

Datagram format (standard, extended, etc.)

Sampling rate (125 samples/s, 250 samples/s, etc.)

Bandwidth/ Low pass filter frequency (16Hz, 33Hz, etc.)

RS422 transmission bit rate (374400 bits/s, 460800 bits/s, etc.)

Number of stop bits in datagram (1 or 2 stop bits)

Parity bit (no parity, odd parity, even parity)

Line/ Datagram termination (on/off, None/ <CR><LF>)

The evaluation kits provide access to the following user readable gyro module parameters:

Unit part number

Serial number

Firmware revision

Hardware revision

Guro module diagonistics

Gyro module diagnostic information includes RAM and flash checks, stack handling checks, status of internal voltage

supply references, and various parameter reports for each measurement axis.

Note: External trigger functionality of STIM202 are not supported by the evaluation kits.

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 4/22 Dec 2017

5 System requirements

Windows XP SP2 (or later), Windows Vista, Windows 7 (32/ 64bit)

1 free USB port and 1 free PCI slot for the PCI kit

2 free USB ports for the USB kit

Quad core processor recommended (when simultaneously logging data from two gyro modules)

6 Getting started

Two separate software installations are required:

NI serial driver installation

PC software installation

6.1 Installation of NI serial driver

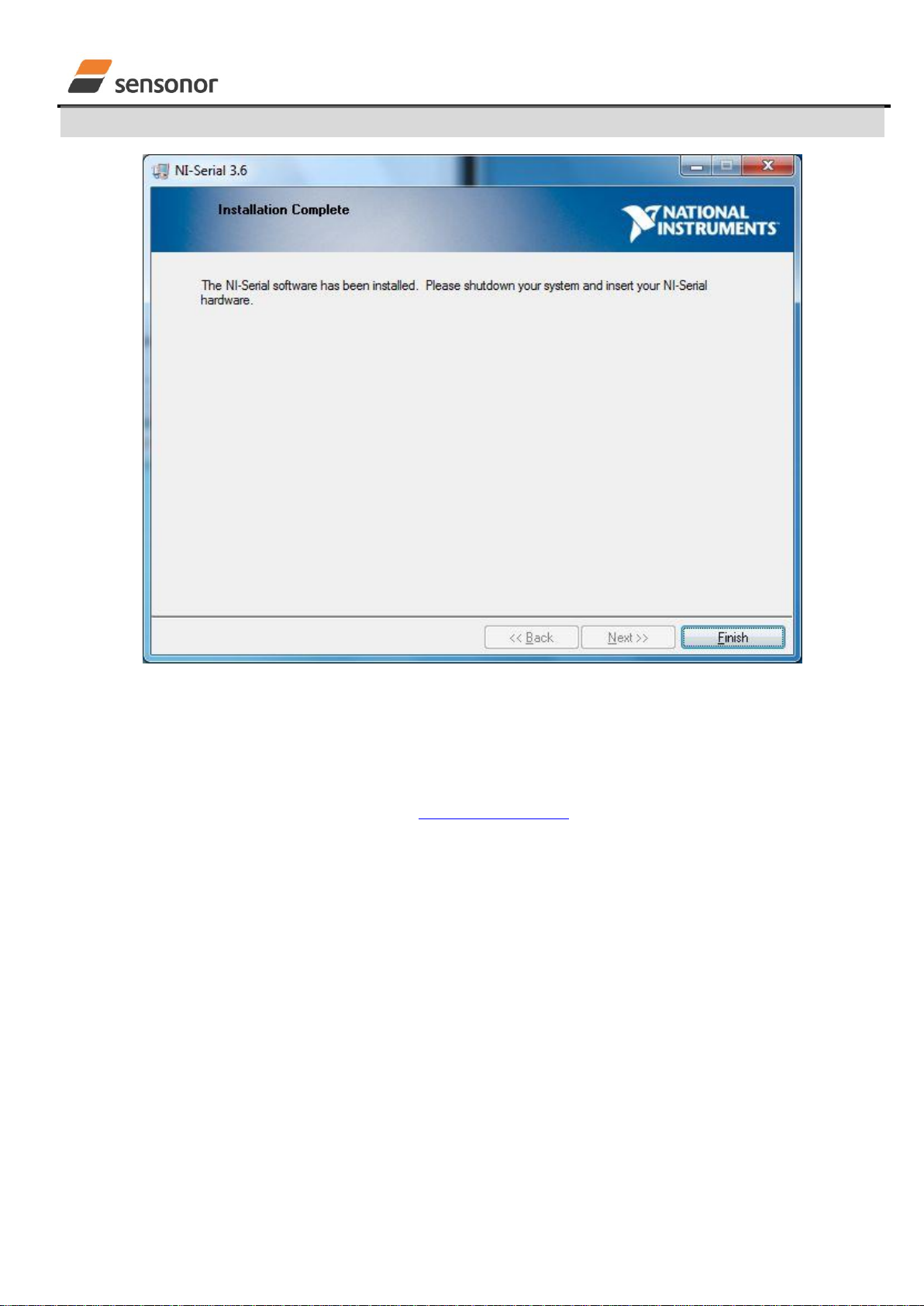

Install the National Instruments (NI) serial driver from the CD-ROM included in the kit. This process is self-instructive.

Follow the on-screen messages without doing any configuration changes.

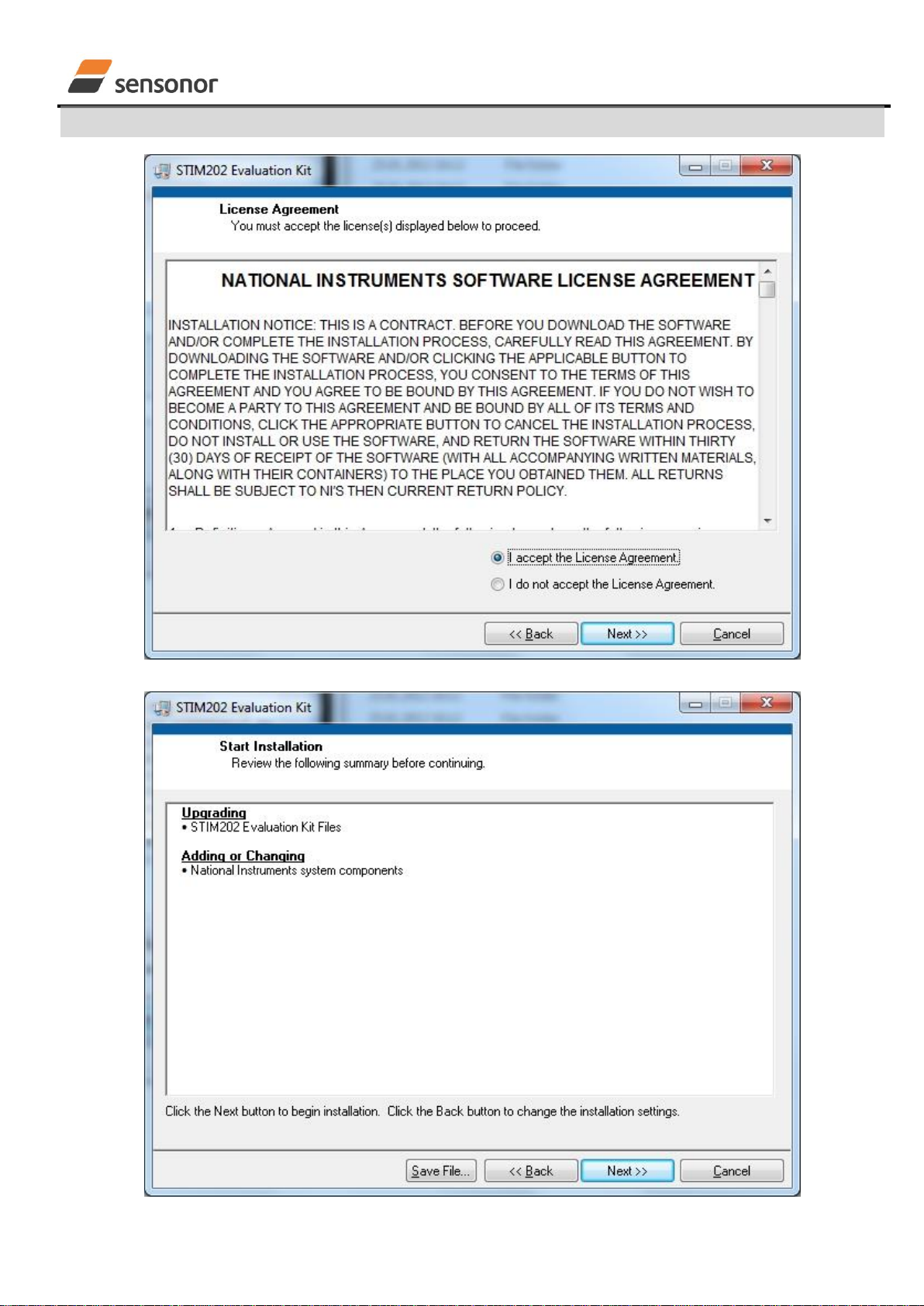

Figure 3 and Figure 4 show two of the messages that appear during serial driver installation.

The NI serial driver can also be found from the Sensonor support site. Use this site to regularly check for updates.

Figure 3: NI serial driver installation. Start Installation

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 5/22 Dec 2017

Figure 4: NI serial driver installation. Installation complete

6.2 Installation of PC software

Install the PC software by running "setup.exe" found on the included memory-stick. Follow the on-screen instructions

to complete the installation. See Figure 5 through Figure 10 for guidance.

The PC software can also be downloaded from the Sensonor support site. Use this site regularly to check for updates.

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 6/22 Dec 2017

Figure 5: PC software installation (1 of 6). Installer initialization

Figure 6: PC software installation (2 of 6)

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 7/22 Dec 2017

Figure 7: PC software installation (3 of 6)

Figure 8: PC software installation (4 of 6)

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 8/22 Dec 2017

Figure 9: PC software installation (5 of 6)

Figure 10: PC software installation (6 of 6). Installation complete

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 9/22 Dec 2017

6.3 First hardware connections

6.3.1 Common preparations

1. Connect a gyro module to the Micro-D connector of the STIM202 communication and power cable. Use the T6

Screw driver (included) for tightening the fixing screws of the connector to gyro module

6.3.2 For preparing the PCI kit (skip this step if the USB kit is used)

2. Install the PCI card into a free PCI slot of the PC cabinett

3. Connect the 9 pin D-SUB connector of the STIM202 communication and power cable to either PORT 1 or

PORT 2 of the PCI card. Tighten the screws of the D-SUB connector to ensure a good electrical connection

6.3.3 For preparing the USB kit (skip this step if the PCI kit is used)

2. Connect the 9 pin D-SUB connector of the STIM202 communication and power cable to the USB cable.

Tighten the screws of the STIM202 communication and power cable to ensure a good electrical connection.

See Figure 2 to identify two cables if necessary. (The USB cable is the black one with blue connectors.)

3. Connect the (blue) USB connector of the USB cable into a free USB port of the laptop/ PC

6.3.4 Common verifications

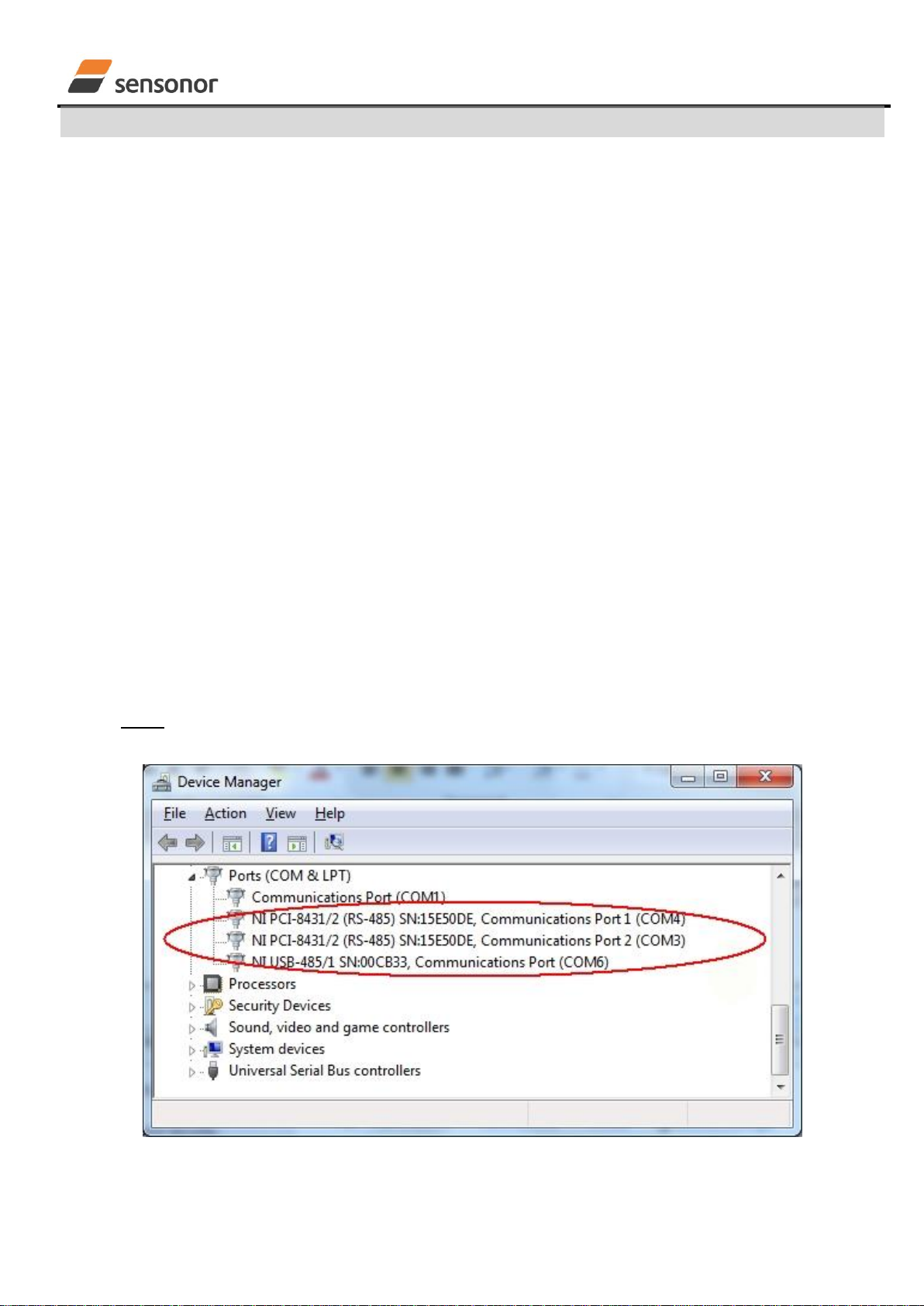

4. Verify that the NI serial driver installation has completed successfully in the Device Manager. See Control

Panel -> Hardware and Sound, or similar path, to locate this. An example for Device Manager in Windows 7 is

shown in Figure 11

5. Notice the assigned COM port(s) as this information is needed later for connecting to gyro module(s) from PC

software

Figure 11: COM port assignments for PCI card and USB cable in Windows 7

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 10/22 Dec 2017

6.4 First PC software start-up

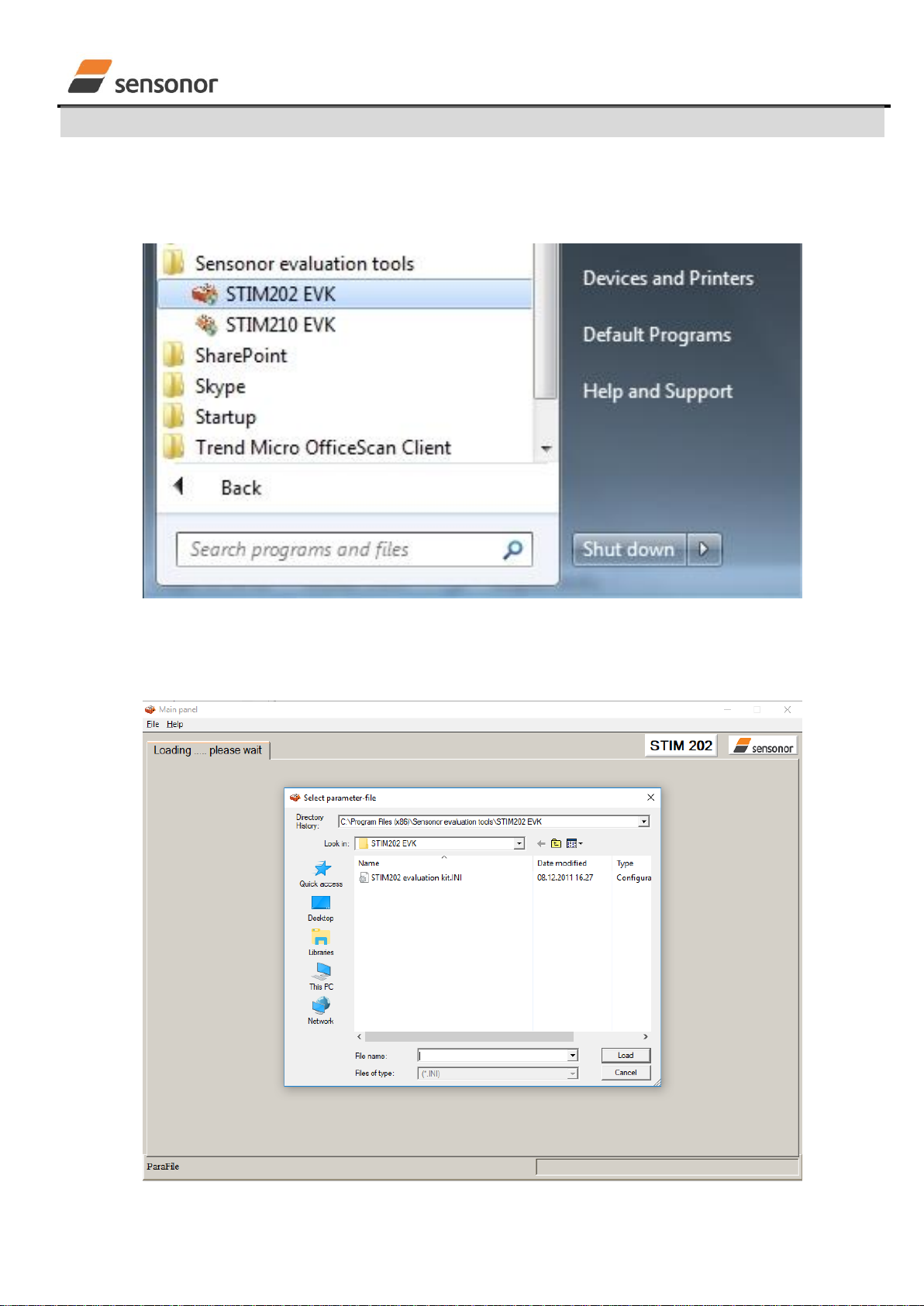

1. Navigate to the ‘Sensonor evaluation tools’folder from Windows start menu. Click on the shortcut named

"STIM202 EVK" to start the PC software. For full functionality; run program as administrator

Figure 12: Starting PC software from Windows 7 start menu

2. A pop-up box appears, asking for a parameter (.INI) file. Select the INI-file available in the installation folder

and click "Load"

Figure 13: INI-file selection

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 11/22 Dec 2017

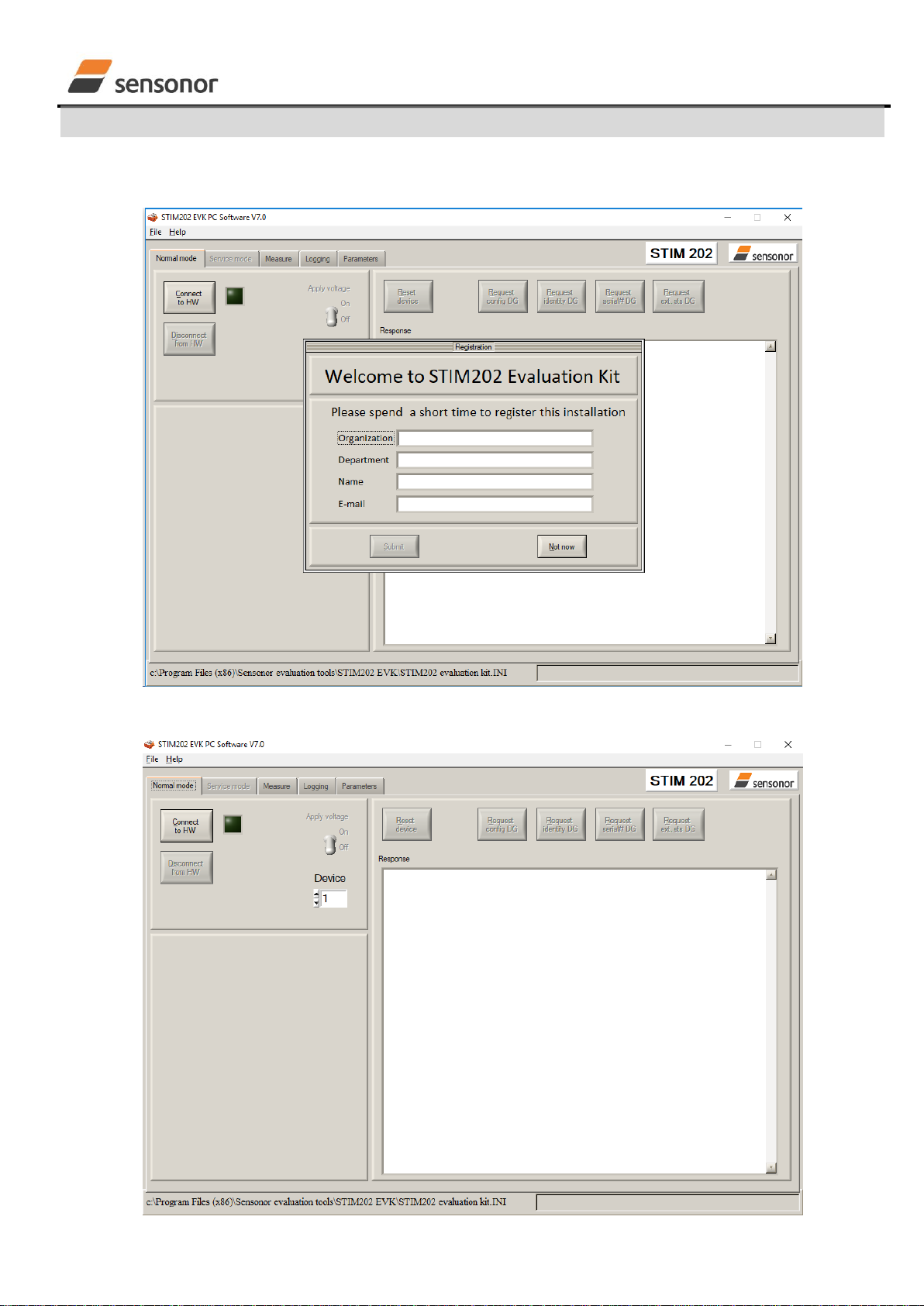

3. A pop-up box for software registration appears. Fill in the four open fields and click "Submit". The default email

client opens. Press "Send" in order to complete this step (and the user information is sent back to Sensonor)

Figure 14: Welcome message and software registration

4. The Normal mode panel is shown

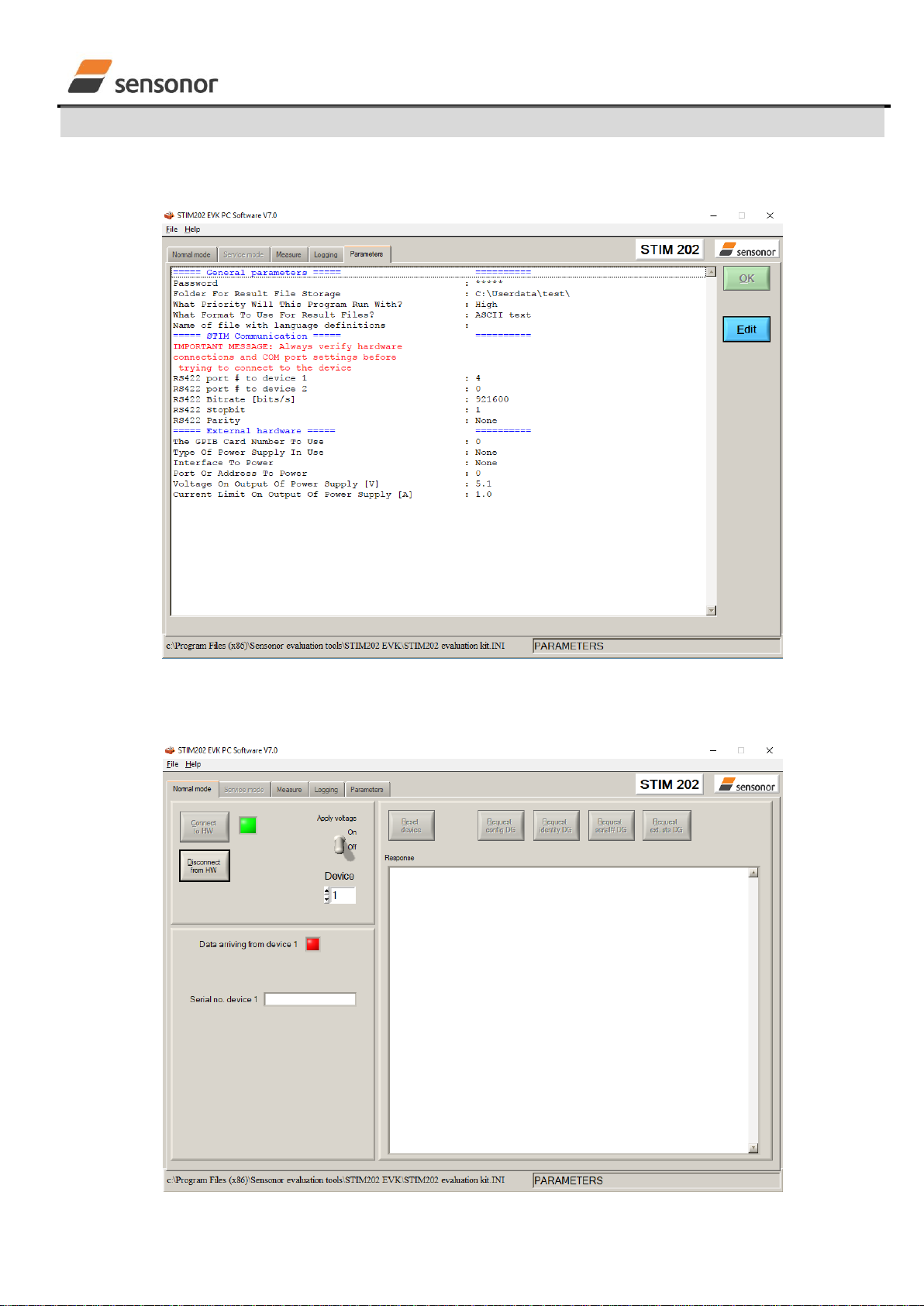

Figure 15: Normal mode panel after selecting INI-file and registration

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 12/22 Dec 2017

Verify the correct COM port settings in the Parameters view. Password to edit is ‘stim’. Click "OK" to confirm when the

correct COM port(s) is (are) selected.

Figure 16: Editing the INI-file in order to verify the correct COM port settings

5. Establish connection to module by clicking the ‘Connect to HW’ button in Normal mode panel. A green LED light

appears, indicating that the COM port(s) is (are) opened

Figure 17: Normal mode panel after first hardware connection

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 13/22 Dec 2017

6. Change the ’Apply voltage’ control switch position to ’On’. The pop-up message telling "Turn on device supply

voltage" appears. Do this by inserting the USB connector of the STIM202 communication and power cable into

a free USB port of the PC/ laptop. Confirm the supply voltage applied by clicking ‘OK’ on the pop-up message

Figure 18: Normal mode panel when USB connector of STIM202 communication and power cable is to be inserted

7. Verify the connection to module by clicking on the ‘Request config DG’ button. An example of such a result is

shown in Figure 19. (The kit is now ready for use)

Figure 19: Result of sending ’Request config DG’ to the gyro module

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 14/22 Dec 2017

7 Introduction to PC software

7.1 Panels overview

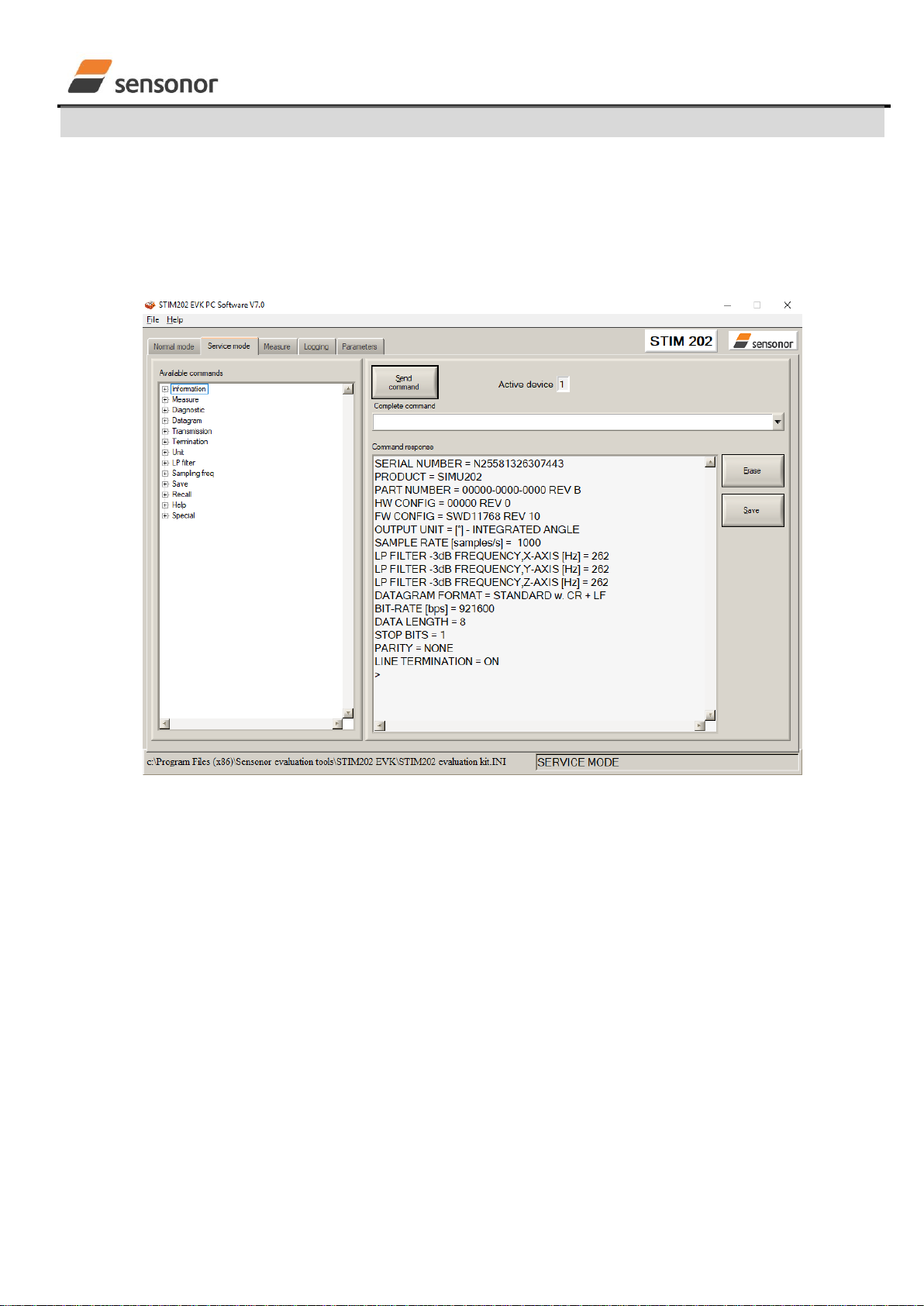

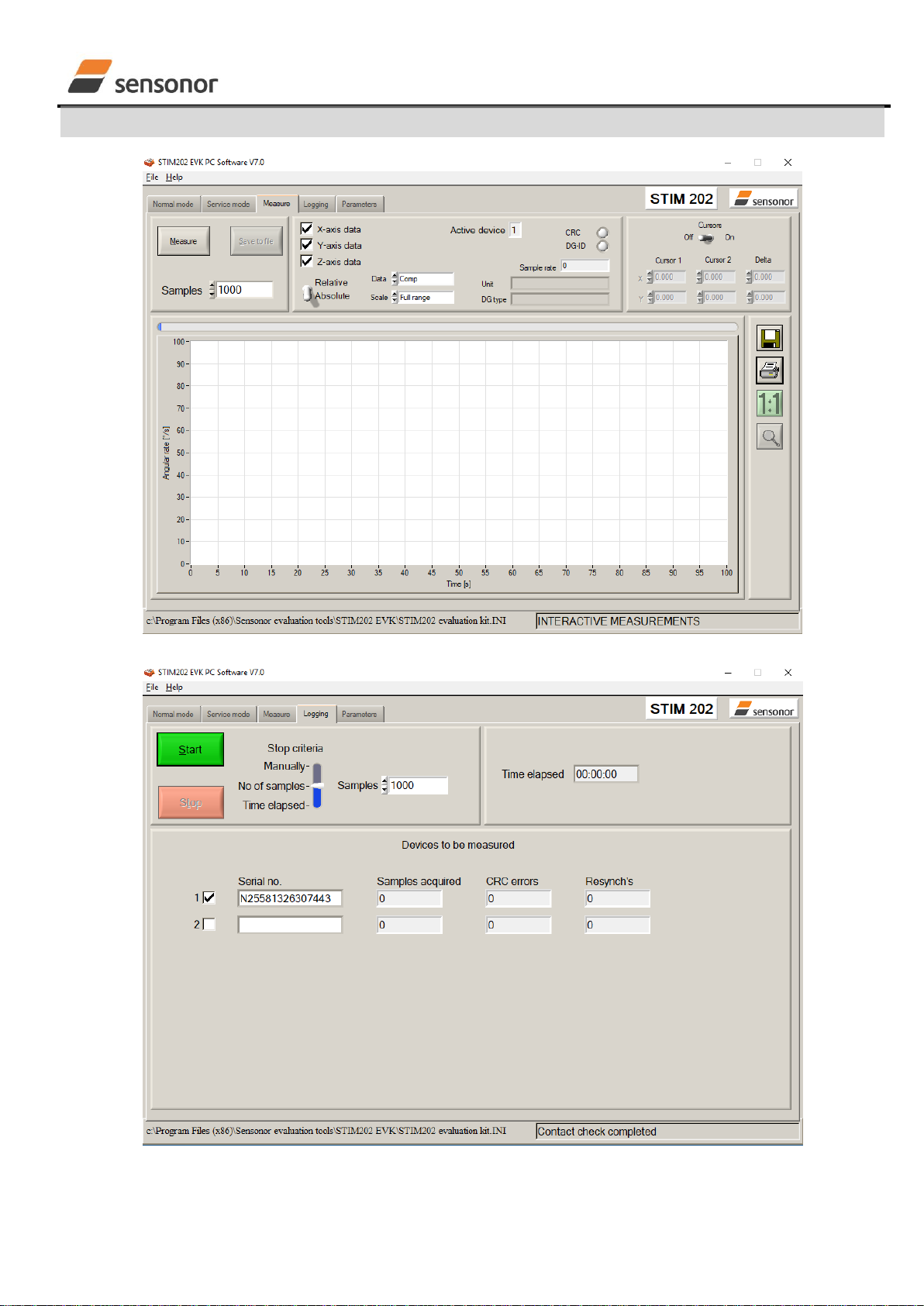

In addition to the panels already shown (Normal mode and Parameters panel), other panels are also available:

Figure 20: Service mode panel

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 15/22 Dec 2017

Figure 21: Measure panel

Figure 22: Logging panel (for saving data to file)

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 16/22 Dec 2017

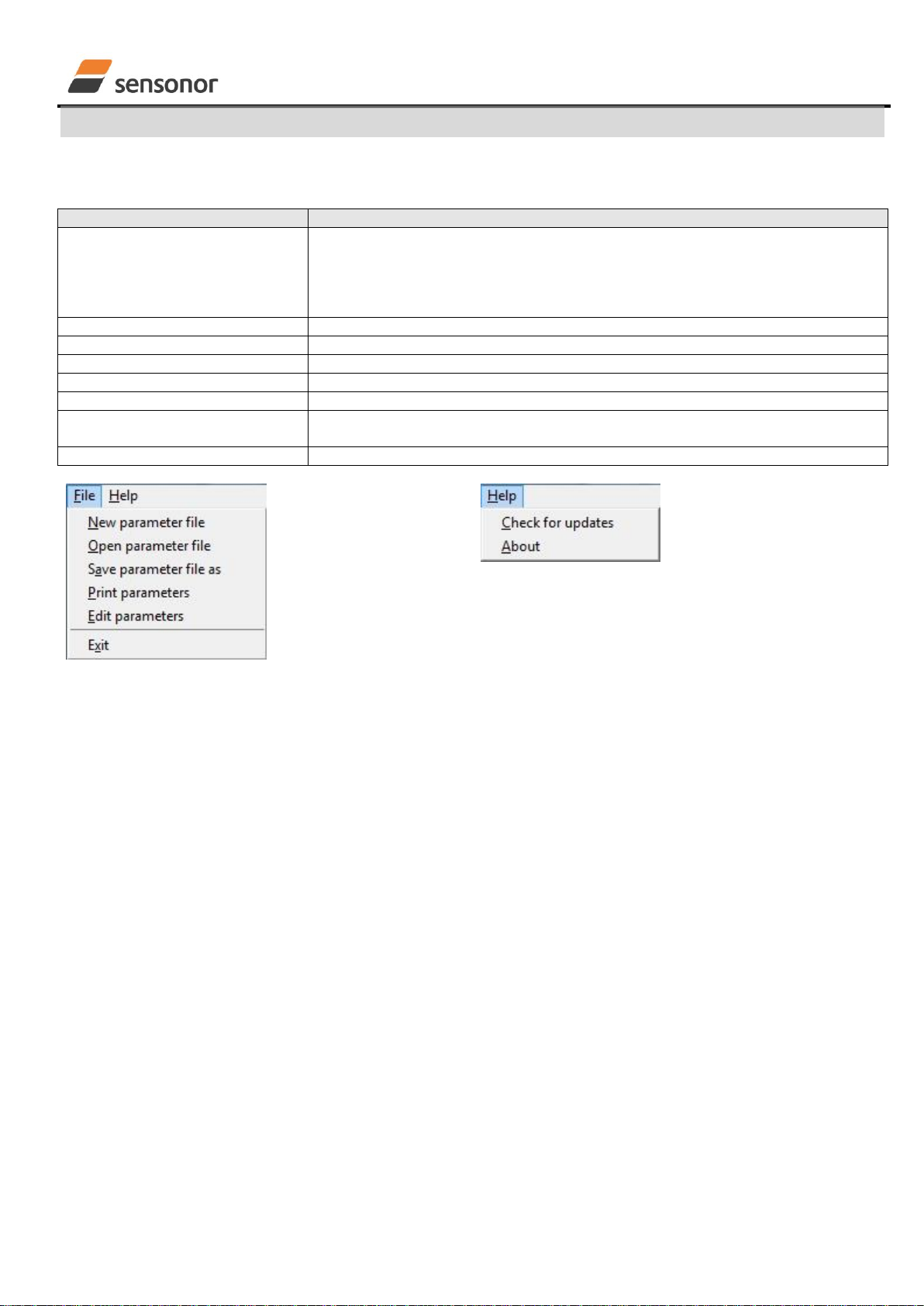

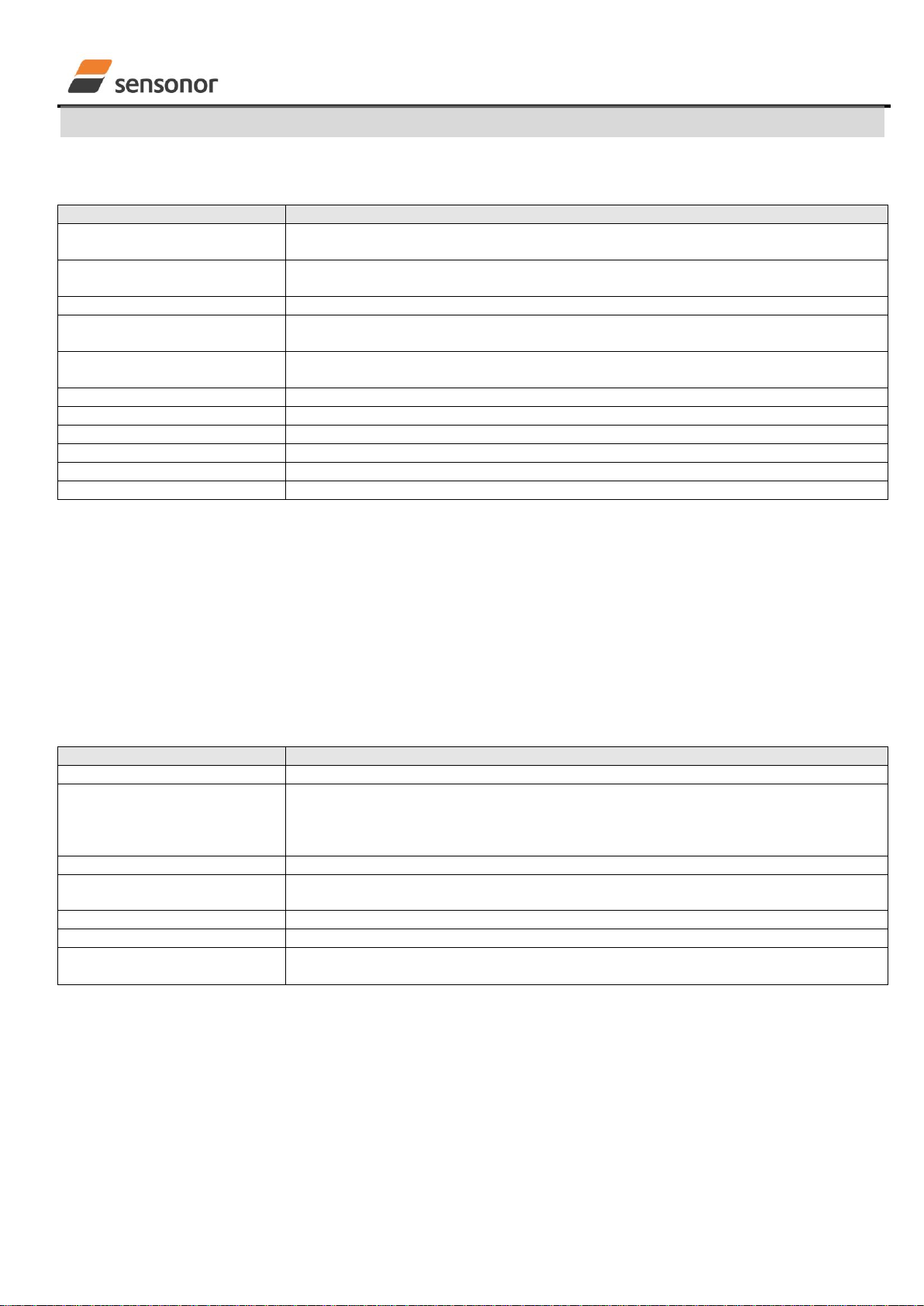

7.2 Main panel menus

Menu

Description

‘File’ →‘New parameter file’

For creating a new INI-file. Notice that this new INI-file also needs be edited by

the user before taken into use. The content is not equal to any existing INI-files.

Notice also that the Parameters view in the software is not updated with the new

INI-file content until the user clicks the “Edit”button (this triggers an update of this

view)

‘File’ →‘Open parameter file’

For opening and taking a specific INI-file into use

‘File’ → ‘Save parameter file as’

To save parameters into an INI-file

‘File’ → ‘Print parameters’

For printing the current ‘Parameters’ content at the default printer

‘File’ →‘Edit parameters’

To edit the ‘Parameters’ content

‘File’ → ‘Exit’

To exit program

‘Help’ →‘Check for updates’

Opens the Sensonor support site in a web browser. NI serial drivers, any PC

software updates and new releases of User manuals can be obtained from here

‘Help’ →‘About’

About the program (Program name, publisher and software revision number)

Figure 23: File Menu

Figure 24: Help menu

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 17/22 Dec 2017

7.3 Normal mode panel descriptions

Table 1: Normal mode panel descriptions

Panel unit

Functionality and description

Connect to HW

To connect to interface hardware. Opens PC COM port according to selections in

active parameter file

LED(s)

Indicator for hardware connection. A GREEN light indicates the corresponding COM

port is opened. If two units are connected a second LED will appear

Disconnect from HW

To Disconnect from interface hardware. Closes the corresponding COM port

Apply voltage switch (On/Off)

To be switched manually (ON or OFF) by user when asked to. Controls certain

functions of the PC software

Device box

Should hold the correct gyro module (device) number according to active parameter

file. Choice depends on which gyro module and COM port the user wants to operate

Reset device button

Resets the gyro module. Sends reset command (‘R’)

Request config DG button

Sends command (‘C’) to receive configuration datagram

Request identity DG button

Sends command (‘N’) to receive part number datagram

Request serial# DG button

Sends command (‘I’) to receive serial number datagram

Request ext. sts DG button

Sends command (‘E’) to receive extended error information datagram

Response window

Lists responses from the gyro module

7.4 Service mode panel descriptions

Service mode is used for gyro module configuration.

Service mode is entered by clicking on the Service mode tab next to the Normal mode tab. Panel units, functionalities

and descriptions are listed in Table 2. Exit from gyro module Service mode to Normal mode is done by pressing one of

the other panel tabs (Normal, Logging, Service or Parameter panel tab).

Note: Changes made for the gyro module in Service mode are only stored permanently in gyro module flash memory

when the save command (‘s’) is issued.

Table 2: Service mode panel descriptions

Panel unit

Functionality and description

Available commands window

Shows a list of available commands. See product datasheet for details

Complete command window

Contains the complete command to send. It is auto-completed by usage of the

listings in the available commands window. Left click in the complete command

window shows a list of earlier sent commands. Right click enables manual command

entry

Send command button

Sends command to the gyro module

Active device indicator

Informs about the active gyro module (device). Corresponding COM port is according

to the active parameter file

Command response window

Shows the responses from the gyro module. See product datasheet for details

Erase button

Erases the content of the command response window

Save button

Saves the content of the command response window to a text file with a detailed

date and time tag

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 18/22 Dec 2017

7.5 Measure panel descriptions

Table 3: Measure panel descriptions

Panel unit

Functionality and description

Measure button

Starts a measurement series

Samples box

Defines the number of samples to be collected (max 50 millions)

Save to file button

Saves data from a completed measurement series to a result file. The file path

defined in the active parameter file is proposed

X-, Y- and Z-axis check boxes

Selects which axis data to present in the graph area (up to 3 axes can be plotted)

Relative and absolute toggle

switch

When set to ‘Absolute’, all results are plotted as received. When set to ‘Relative’ the

curves are translated so that the first measurement is shown in the plot as zero.

Active device indicator

Informs about the active gyro module (device). Corresponding COM port is according

to the active parameter file

CRC and DG-ID LEDS

Confirms all CRC checks and DG-IDs as expected. Normally GREEN. LEDs turn

RED if checks fail

Data box

Selects which datagram content to be shown. Several options are available,

depending on the active datagram type. Use the arrows in the left side of box to

scroll between available selections. The plot updates immediately if a measurement

series has already been done.

Scale box

Enables user to select between different scales (Full range, User defined, or Auto)

Sample rate box

Informs what sample rate has been used for the measurements

Unit box

Indicated the active Output unit (Angular Rate, Incremental Angle, etc.)

DG type box

Shows the type of datagram received

Save to disk icon

Saves a picture of the plotted data to file

Print icon

Prints a picture of the plotted data to the default printer

1:1 icon

Resets zoom level to 1:1 (if ZOOM is active. See below)

Zoom icon

Enables a custom zoom of the presented results in the strip chart (graph area)

according to placement of available cursors

Cursors (On/Off) switch

Enables usage of cursors (default is Off)

Cursor 1

Shows the location of cursor no 1

Cursor 2

Shows the location of cursor no 1

Delta

Shows the delta between the two cursor locations (X and Y values)

Progress bar

A blue continuous line shows the measurement series progress

Lower bar on panel

Shows the INI-file in use and the active mode (NORMAL MODE)

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 19/22 Dec 2017

Save data to file from measure panel:

An example of a result file is shown in Figure 25, for a standard datagram measurement series of device # 1. A

description of each of its column of data is found in Table 4.

Figure 25: Result file example

Table 4: Result file example. (Standard datagram content written to file.)

DG-type

Col. #

Heading

Comments

Standard

1

Time[s]

Time in seconds

2

X[°/s] or X[°]

Gyro signal X-axis

3

Y[°/s] or Y[°]

Gyro signal Y-axis

4

Z[°/s] or Z[°]

Gyro signal Z-axis

5

STS

Status-byte

6

RxCRC

Received CRC

7

CalCRC

Calculated CRC

8

DG_ID

Datagram identifier

7.6 Logging panel descriptions

Table 5: Logging panel descriptions

Panel unit

Functionality and description

Start button

Starts data logging

Stop button

Stops data logging

Stop criteria slide

User selections between “manually”, “no of samples” and “Time

elapsed” for stopping a measurement series

Samples box

In use when defining a series length with “no of samples”

Time elapsed

Shows the real time for the test running

Samples acq.

Shows number of samples acquired

CRC_errors

Shows number of CRC errors (normally 0, otherwise the user should

consider to reject results data in any analysis)

Resynch’s

Increments from 0 to a number if any re-synchronisations are needed in

order to re-establish data collections from module

Log to file capability:

Quad core processor is recommended when measuring on two gyro modules simultaneously

The size of the log file is only limited by the free memory of the hard disk(s) in use

The path for result file storage is defined in the active parameter file

The program should be run as administrator to ensure the necessary rights to establish result files

USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 20/22 Dec 2017

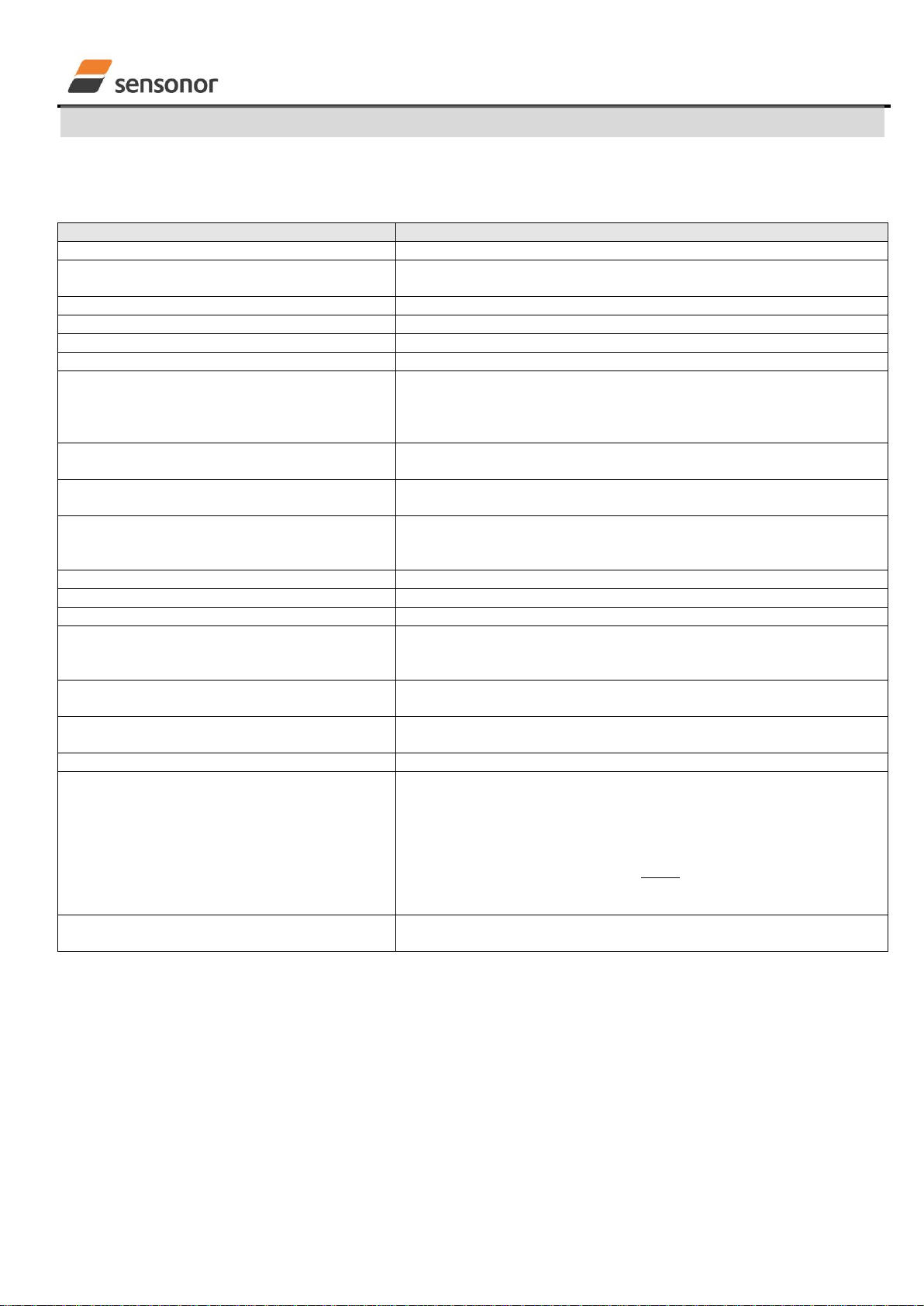

7.7 Parameters panel descriptions

Table 6: Parameters panel descriptions

Panel unit

Functionality and description

===== General parameters =====

Password

Current valid password to be able to edit the parameters list. The

password is “stim”

Folder for result-file storage

“c:\userdata\test\

What priority will this program run with

Instructs the program priority for the PC operation system

What format to use for result files

ASCII text by default. Can be changed to 8 byte binary

Name of file with language definitions

Application can be configured with language other than English

===== Device communication =====

IMPORTANT MESSAGE: Always verify

hardware connections and COM port settings

before trying to connect to the device

RS422 port # to device 1

Defining which COM port # to be assigned to gyro module (device) #

1

RS422 port # to device 2

Defining which COM port # to be assigned to gyro module (device) #

2

RS422 Bitrate [bit/s]

Manual RS422 bit rate selection. NOTE that USB cable that comes

with the USB kit, supports only the default 460800 bits/s option, while

the PCI card of the PCI kit supports all available bit rates

RS422 Stopbit

1 or 2. Default is “1”

RS422 parity

None, odd or even. Default is “None”

===== External Hardware =====

The GPIB Card Number To Use

Normally "0" (when no GPIB card in user). If card(s) are in use; the

first card will be assigned to #1, second to #2, etc. Default value is

“0”

Type Of Power Supply In Use

Normally "None" (when not in use). Agilent E3631A, E3633A and

E3644A supported. Default value is “None”

Interface To Power

Normally "None" (when not in use). RS232 (for Agilent E3631A only)

and GPIB supported. Default is “None”

Port Or Address To Power

Normally "0", when not in use. Selectable up to 31. Default is “0”

Voltage On Output Of Power Supply [V]

Default value is “5.1”. Can be neglected if not in use. Value should

be within the supply voltage range of the gyro module. Clicking on

the arrow of the control unit when editing this parameter allows for

voltages as high as 6.0V maximum. Manual entry allows even higher

values, however with a warning. Note: The entered value/ voltage

applied to the gyro module should never exceed the absolute

maximum ratings value for the supply voltage of the gyro module

(maximum 7.0V)

Current Limit On Output Of Power Supply [A]

Default value is “1.0”. To limit the current consumption from the

power source

Table of contents

Other sensonor Motherboard manuals