1. Safety.....................................................................................................................................................................4

2. Sockets...................................................................................................................................................................5

2.1 Battery..........................................................................................................................................................5

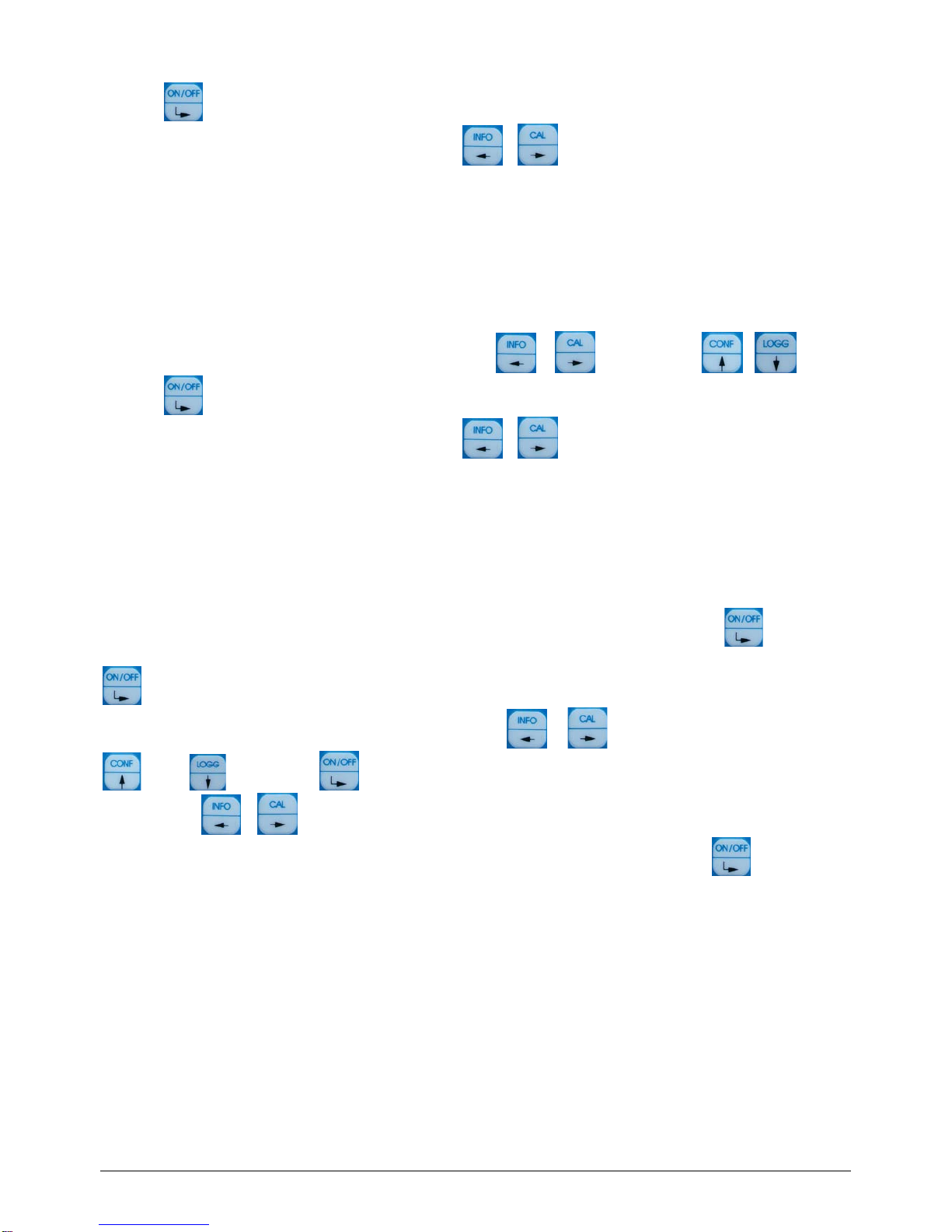

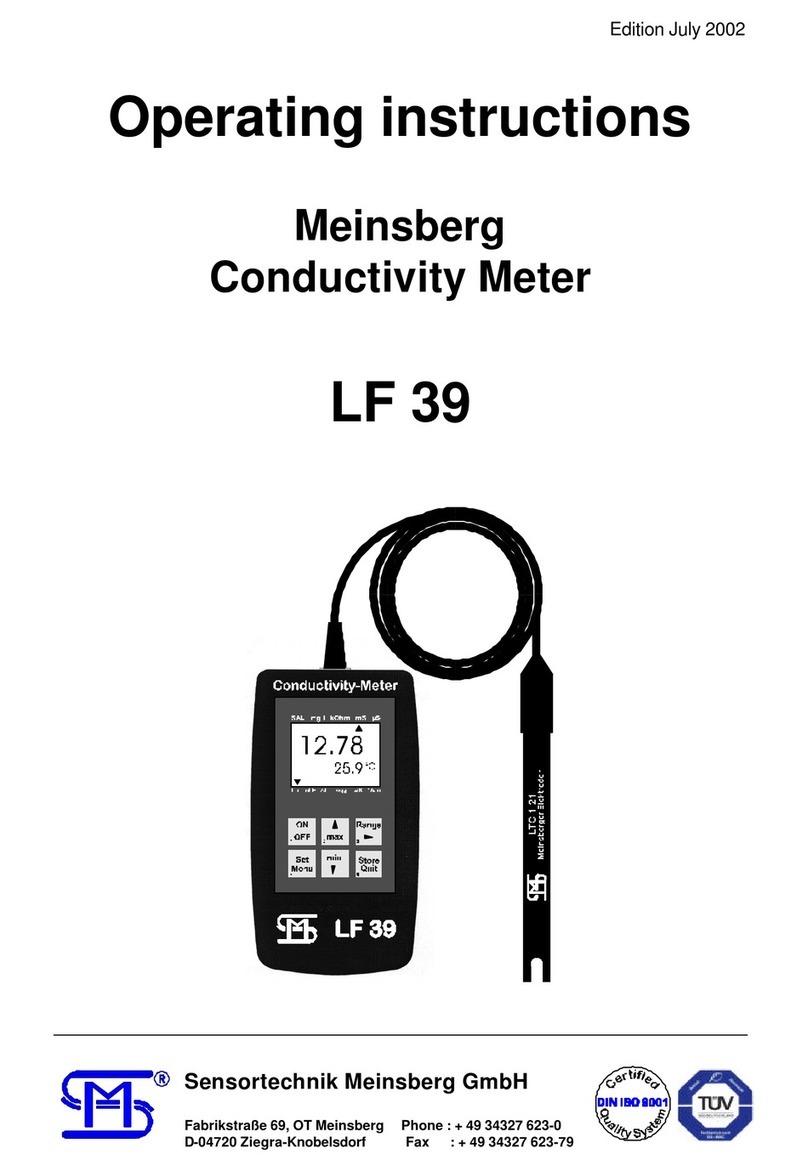

3. Button, Display, Menu structure, Password protection........................................................................................6

3.1 Operation elements.....................................................................................................................................6

4. Configuration the basic settings “General”...........................................................................................................7

4.1 Configuration Backlight...............................................................................................................................7

4.2 Configuration pass word.............................................................................................................................8

4.3 Configuration clock......................................................................................................................................8

4.4 Configuration language...............................................................................................................................8

4.5 Configuration off time..................................................................................................................................8

4.6 Data logger ..................................................................................................................................................9

5. Info........................................................................................................................................................................10

6. Interface HMG USB.............................................................................................................................................10

7. Maintenance, Disposal........................................................................................................................................10

8. TM 40...................................................................................................................................................................11

8.1Application Fields TM 40...........................................................................................................................11

8.2 Construction TM 40...................................................................................................................................11

8.3 pH-Sensor EGA 142/TM 40......................................................................................................................11

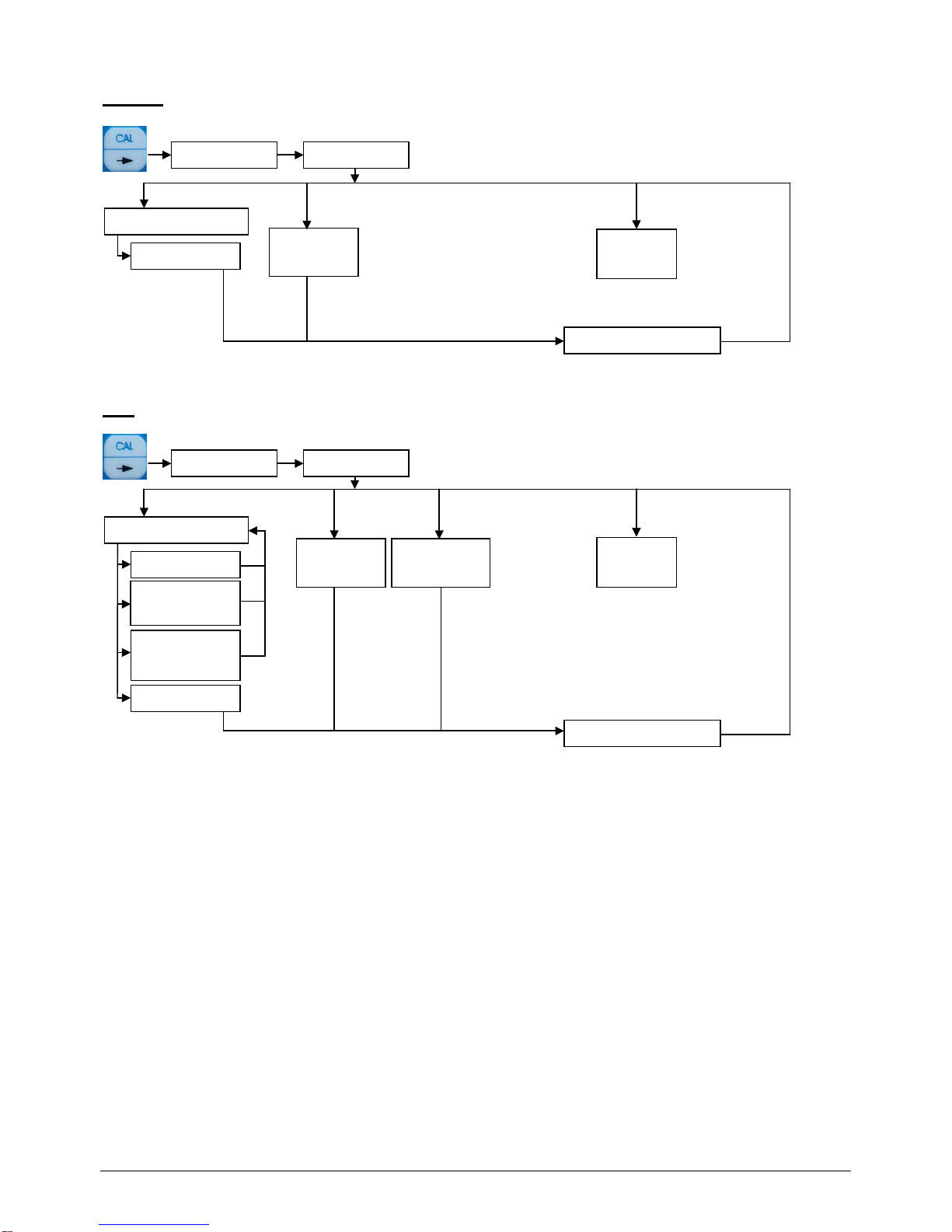

8.4 Menu structure TM 40...............................................................................................................................11

8.5 Calibration pH............................................................................................................................................13

8.5.1 Data input..................................................................................................................................... 13

8.5.2 Settings of the temperature offset............................................................................................... 14

8.5.3 Two-point-Calibration “two point“................................................................................................ 14

8.5.4 Automatic Calibration.................................................................................................................. 14

8.5.5 Calibration error........................................................................................................................... 15

8.6 Calibration Redox......................................................................................................................................15

8.6.1 Data input..................................................................................................................................... 15

8.6.2 Setting of the temperature offset................................................................................................ 15

8.7 Calibration ISE...........................................................................................................................................15

8.7.1 Data input..................................................................................................................................... 15

8.7.2 Settings of the temperature offset............................................................................................... 15

8.7.3 Two-point Calibration „Two point“............................................................................................... 16

8.8 Configuration TM 40..................................................................................................................................16

8.8.1 Configuration of the fix temperature........................................................................................... 16

8.8.2 Configuration of the sensor type.................................................................................................17