Sentencia Volumo User manual

© 2016erie watertreatment TM-EN-Sentencia-Rev2016.01

Technical Manual

WATER SOFTENER

TABLE OF CONTENT

Page 2

Table of content...................................................................................................................Page 2

Warning & Safety instructions..............................................................................................Page 3

Operating conditions & Requirements .................................................................................Page 4

Installation...........................................................................................................................Page 5

Start-up................................................................................................................................Page 6

Electronic control panel.......................................................................................................Page 7

Maintenance........................................................................................................................Page 11

Hydraulic flow diagrams - Volumo........................................................................................Page 12

Hydraulic flow diagrams - Volumo+......................................................................................Page 13

Troubleshooting...................................................................................................................Page 14

Electrical wiring diagrams ....................................................................................................Page 16

Default parameter settings ..................................................................................................Page 17

Exploded view -System .......................................................................................................Page 18

Exploded view -Cover assembly ..........................................................................................Page 20

Exploded view - Valve body assembly - Volumo...................................................................Page 22

Exploded view - Valve body assembly - Volumo+..................................................................Page 24

Exploded view - Valve body assembly ..................................................................................Page 26

Technical data -Volumo.......................................................................................................Page 28

Technical data - Volumo+.....................................................................................................Page 29

WARNING & SAFETY INSTRUCTIONS

Page 3

Before you begin the installation of the water softener, we advise you

read and carefully follow the instructions contained in this manual. It

contains important information about safety, installation, use and

maintenance of the product. The actual system that you have received,

may differ from the pictures/illustrations/descriptions in this Technical

Manual.

Failure to follow the instructions could cause personal injury or damage

to the appliance or property. Only when installed, commissioned and

serviced correctly, the water softener will offer you many years of

trouble-free operation.

The water softener is intended to 'soften' the water, meaning it will

remove hardness minerals; it will not necessarily remove other

contaminants present in the water. The water softener will not purify

polluted water or make it safe to drink!

Installation of the water softener should only be undertaken by a

competent person, aware of the local codes in force. All plumbing and

electrical connections must be done in accordance with local codes.

Before setting up the water softener, make sure to check it for any

externally visible damage; do not install or use when damaged.

Use a hand truck to transport the water softener. To prevent accident or

injury, do not hoist the water softener over your shoulder. Do not lay the

water softener on its side.

Keep this Technical Manual in a safe place and ensure that new users are

familiar with the content.

The water softener is designed and manufactured in accordance with

current safety requirements and regulations. Incorrect repairs can result

inunforeseen danger for the user, forwhich the manufacturer cannot be

held responsible. Therefore repairs should only be undertaken by a

competent technician, familiar and trained for this product.

In respect of the environment, this water softener should be disposed of

in accordance with Waste Electrical and Electronic Equipment

requirements.Refertonational/locallawsandcodesforcorrectrecycling

of this water softener.

OPERATING CONDITIONS & REQUIREMENTS

Page 4

OPERATING PRESSURE: min. 1,4 / max. 8,3 bar

this system is configured to perform optimally at an operating

pressureof3bar(±½bar);incaseofalowerorhigheroperating

pressure the performance may be affected negatively!

check water pressure regularly.

take into account that night time water pressure may be

considerably higher than day time water pressure.

install a pressure reducer ahead of the water softener if

necessary.

OPERATING TEMPERATURE: min. 2 / max. 48 °C

do not install the water softener in an environment where high

ambient temperatures (e.g. unvented boiler house) or freezing

temperatures can occur.

the water softener cannot be exposed to outdoor elements,

such as direct sunlight or atmospheric precipitation.

do not install the water softener too close to a water heater;

keep at least 3 m of piping between the outlet of the water

softener and the inlet of the water heater; water heaters can

sometimes transmit heat back down the cold pipe into the

control valve; always install a check valve at the outlet of the

water softener.

ELECTRICAL CONNECTION: 230V-50Hz

this water softener only works on 24VAC; it is equipped with a

230/24V-50Hz transformer; always use it in combination with

the supplied transformer.

makesuretoplugthetransformerintoapoweroutlet,whichis

installed in a dry location, with the proper rating and over-

current protection.

INSTALLATION

Page 5

Picture 1&10

To facilitatethe installation,youmay want to remove the salt

lid and main coverfrom the water softener.

1. Remove the salt lid.

2. Remove the rivets at the rear of the main cover.

3. Carefully lift the main cover from the water softener.

INLET & OUTLET

Check the waterpressure at the place of installation of

the water softener; it should never exceed 8,3 bar.

In case of high concentration of impurities in the inlet

water, we recommend the installation of a sediment filter,

ahead of the water softener.

We strongly recommend the use of flexible hoses to

connect the water softenerto the waterdistributionsystem;

usehoseswithalargediameterinordertolimit thepressure

loss.

If the water softener is not equipped with the factory

bypass (optional), we strongly recommend to install a 3-

valve bypass system (not included with this product!) to

isolate the water softener from the water distribution

system in case of repairs. It allows to turn off the water to

the water softener, while maintaining (untreated) water

supply to the user.

WITH FACTORY BYPASS (optional)

Picture 2

= mains water supply (untreated water)

= inlet of water softener (untreated water)

= outlet of water softener (treated water)

= house/application (treated water)

1. Screw the factory bypass onto the elbow connections of

the water softener (&); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

2. Screw the connection kit with nuts onto the factory

bypass (&); make sure to install the gasket seals.

Tighten the nuts firmly byhand.

3. Connect the mains water supply to the adaptor on the

inlet port of the factory bypass ().

4. Connect the house/application to the adaptor on the

outlet port of the factorybypass ().

WITH 3-VALVE BYPASS SYSTEM (not included)

Picture 3

= mains water supply (untreated water)

= inlet of water softener (untreated water)

= outlet of water softener (treated water)

= house/application (treated water)

1. Install the 3-valve bypass system.

2. Screw the connection kit with nuts onto the elbow

connections of the water softener (&); make sure to

install the gasket seals. Tighten the nuts firmly by hand.

3. Connectthe3-valvebypasssystemtotheadaptorsonthe

in () and out () elbow connections.

4. Connectthemainswatersupplytotheinletofthe3-valve

bypass system().

5. Connectthehouse/applicationtotheoutletofthe3-valve

bypass system().

DRAIN

We recommend the useof a stand pipe with air trap.

To prevent backflow from the sewerage system into the

water softener, always make sure to have an air gap

betweenthe end ofthedrain hose andthe sewerage system

itself; as a rule of thumb, the air gap should be minimum 2x

the diameter of thedrain hose.

Always use separate drain hoses for the control valve

(evacuation of rinse water) and the softener cabinet's

overflow.

Lay-out the drain hosesin such a waythat pressure loss

is minimized; avoid kinks and unnecessary elevations.

Make sure that the sewerage system is suitable for the

rinse water flow rateof the water softener.

Picture 4

1. Connecta13mmhosetothedrainsolenoidofthecontrol

valve (); secure it by means of a clamp.

2. Run the drain hose to the sewerage system and connect

it to the stand pipe assuring sufficient air gap. This drain

lineoperatesunderpressure,soitmaybeinstalledhigher

than the water softener.

3. Connect a 13 mm hose to the cabinet overflow elbow,

located at the back side of the water softener; secure it

by means of a clamp.

4. Run the drain hose to the sewerage system and connect

it to the stand pipe assuring sufficient air gap. This drain

line does NOT operate under pressure, so it may NOT be

installed higher than the water softener.

ELECTRICAL

Picture 5

1. Plug the transformers output lead into the socket on the

water softeners power cord; secure it by means of the

TwistLock clamp.

2. Plug the transformer into an electrical outlet.

START-UP

Page 6

PRESSURIZING

1. Make sure the bypass system is in 'bypass' position.

2. Make sure the electronic controller of the water softener

is in service mode.

3. Open the mains water supply.

4. Open a cold treated water faucet nearby the water

softener and let the water run for a few minutes until all

air is purged and all foreign material that may have

resultedfromtheinstallationiswashedout;closethetap.

5. Gently pressurize the water softener, by putting it into

service:

factorybypass:

1. open the 'outlet' valve;

2. slowly open the 'inlet' valve.

3-valvebypass:

1. close the 'bypass' valve;

2. open the 'outlet' valve;

3. slowly open the 'inlet' valve.

6. After 2-3 minutes, open a cold treated water faucet

nearby the water softener andlet the water runfor afew

minutesuntilallairispurgedfromtheinstallationandthe

resinbedis rinsed(itis normalfortherinsewatertoshow

some discoloration!); close the tap.

7. Check the water softener and all hydraulic connections

for leaks.

After the first regenerations of the water softener,some

slight discoloration of the treated water might occur. This is

totally harmless and will disappear rapidly!

BRINE CABINET

8. Add water conditioner salt to the brine cabinet.

ELECTRONIC CONTROL PANEL

9. Program the electronic controller.

ADJUSTMENT RESIDUAL HARDNESS

WITH FACTORY BYPASS (optional)

Picture 6

10. Adjust the residual hardness of the water that leaves the

softener, by means of the adjusting screw, incorporated

in the ‘outlet’ valve of the factory bypass:

to raisethe residualhardness: turn the screwcounter

clockwise; usually 1 turn corresponds to a residual

hardness of ±4 °f (±2 °d), 2 turns to ±8 °f (±4 °d).

to reduce the residual hardness: turn the screw

clockwise.

PERFORM REGENERATION

11. Manuallyinitiate a regeneration, bypressing the scroll

button repeatedly until the display shows:

12. Leave the water softener in this position;the countdown

timer will countdown to 0 sec and start a regeneration.

Regen in 10 sec

ELECTRONIC CONTROL PANEL

Page 7

Picture 7

symbol

button

function

SCROLL

to advance to the next

parameter

UP

to increase the value of the

parameter

DOWN

to decrease the value of the

parameter

POWER-UP

After power-up, the display will show the installed software

version for 5 seconds, f.e.:

Afterwards it will automatically revert back to the service

display.

POWER FAILURE

In the event of a power failure, the program will remain

stored in the NOVRAM®duringan undefined period, while an

incorporated SuperCap (capacitor) will maintain the correct

time of dayduring a period ofseveral hours; consequently, in

case of prolonged powerfailure,the timeof day might not be

maintained; if this happens, the time of day will be reset to

8:00 when the power supply is re-established, while the

indication will flash, indicating that the time of day needs to

be set.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will immediately

return to the service position; when the power supply is re-

established, the control valve will stay in the service position

for 60 sec. and restart a complete regeneration from the

beginning.

TIMER FAILURE

In the event of a timer failure, the display will show the

message:

In such case, entering one of the programming levels can

possibly solve the problem. However if the problem persists,

professional service is required.

SERVICE MODE

In service mode the display shows the time of day, the

remaining capacity and the water usage indicator:

REGENERATION MODE

In regeneration mode the display shows the actual

regeneration cycle and, where relevant, the total remaining

regeneration time and remaining cycle time:

The control valve can be reset to service mode at any timeby

pressing the scroll button, as such manually advancing it

through the regeneration cycles.

CHECKING THE FLOW METER

In case of water usage, the remaining capacity counter in the

service displaywill count back per unit, i.e. per litre. This way

the correct functioning of the water meter can be verified.

MANUAL REGENERATION

It is possible to manually initiate a regeneration.

1. Press the scroll button repeatedly until the display

shows:

If the control valve is left in this position, the

countdown timer will countdown to 0 sec and start a

regeneration.

To cancel this mode, press the scrollbuttonbefore

the countdown timer has reached 0 sec; the control

valve will return to the service mode.

2. Press the scroll button again if you want to manually

advance the control valve to the next regeneration cycle.

E3DIR4d LGP2 r16

8:00 1000L -

Service Required

20:51 1000L -

Rgn:XXX CycY:ZZZ

Regen in 10 sec

ELECTRONIC CONTROL PANEL

Page 8

PROGRAMMING INSTRUCTIONS -

INSTALLER

Beforeenteringtheprogramming mode, make sure that

the control valve is in the service mode.

1. Press the scroll button; the display will show:

Press the up or down button to set the

language.

2. Press the scroll button again; the display will show:

Press the up or down button to set the time of

day.

3. Press the scroll button again; the display will show:

Presstheupordownbutton tosetthehardness

of the incoming untreated water.

Language:English

Set time: 20:51

Set hardn.: XX°f

ELECTRONIC CONTROL PANEL

Page 9

PROGRAMMING INSTRUCTIONS -

PARAMETER SET LEVEL

Allconfigurationparametersonthiswatersoftenerhave

been pre-programmed in the factory, to offer optimal

performance ina wide range of applicationsand situations.

See table at the end of this manual for default factory

parameter settings. Nevertheless it may be necessary or

desirable to change any of these parameters, to further

optimize the water softeners performance or to adapt it to

the specific requirements of the installation.

Beforeenteringtheprogramming mode, make sure that

the control valve is in the service mode.

1. Press the scroll button and hold it for 5 sec until the

displayshows:

2. Within 10 sec, press the up button; the display will

show:

Presstheupordownbuttontosetthehardness

unit. Make sure to also adjust/convert the exchange

capacity!

3. Press the scroll button again; the display will show:

Press the up or down button to set the

exchange capacity perlitreof resin.

4. Press the scroll button again; the display will show:

Press the up or down button to set the volume

of resin.

5. Press the scroll button again; the display will show:

Press the up or down button to set thenumber

of days between regenerations.

6. Press the scroll button again; the display will show:

Press the up or down button to set the length

of the regeneration cycle.

Pressthescrollbuttonagaintoadvancetothenext

regeneration cycle.

Eco

Eco

+

Backwash

/

Cycle 1

Brine draw/slowrinse

Cycle

1

Cycle 2

Fast rinse

/

Cycle 3

Refill

Cycle 2

Cycle 4

7. Press the scroll button again; the display will show:

Press the up or down button to set the type of

water meter sensor.

8. Press the scroll button again; the display will show:

Press the up or down button to set the

regeneration mode:

Dlyd/Immd: when the remaining capacity equals

the reserve capacity, a delayed regeneration is

started at the programmed time of regeneration;

however when the remaining capacity equals 0

before the programmed time of regeneration is

reached, an immediateregeneration is started.

Immediate: when the remaining capacity equals

0, an immediate regeneration is started.

Delayed: when the remaining capacity equals the

reserve capacity, a delayed regeneration is

started.

9. Press the scroll button again; the display will show

(onlywhentheregenerationmodewassetto'Delayed'or

'Dlyd/Immd'):

Press the up or down button to set the time of

regeneration.

10. Press the scroll button again; the display will show

(only when the regeneration mode was set to 'Dlyd' or

'Dlyd/Immd'):

Press the up or down button to set the reserve

capacity:

Variable: the reserve capacity is calculated

automatically,basedontheregistereddailywater

usage.

Fxd:pressthescrollbuttonagainandpressthe

up or down button to set the reserve

capacity to a fixed amount.

11. Press the scroll button again; the display will show:

Press the up or down button to save the

program into the NOVRAM® and exit the

programming level.

Cycle 1: XX min

System Check

Regen @ 2:00

Exit

HardUnit:°f

Resin:XXX liters

ExCap:5.1°f M3/L

Override: 7 days

Regen:Dlyd/Immd

2:00

Rsrv Variable

MTR:SNAP SENSOR

ELECTRONIC CONTROL PANEL

Page 10

DIAGNOSTICS LEVEL

Besides of all programming parameters, a series of operating

parameters can be consulted in the diagnostics level;

particularly during a service intervention, these parameters

can be helpful to identify the cause of a problem or

malfunction

Beforeenteringtheprogramming mode, make sure that

the control valve is in the service mode.

Accessing the Diagnostics level

1. Press the scroll button and hold it for 5 sec until the

displayshows:

2. Within 10 sec, press the down button; the display will

show:

You are now in the Diagnostics level.

Press the scroll button to advance to the next

diagnostics parameter.

Available diagnostics parameters

Regen X days ago: display shows number of days since

last regeneration of the system.

In Srvc: display shows total number of days that the

system is in service.

# of Regens: display shows the total number of

regenerations that have taken place since installation.

TotVol: display shows the total water usage through the

system since installation.

LastRgn@:display shows thewater usage at the moment

of the last regeneration.

InstFlow: display shows the instantaneous flow rate.

AvgVol: display shows the average daily water usage.

Capacity: display shows the calculated volume of

softened water between regenerations.

Hardness: display shows the setting of the water

hardness.

Rsrv:display shows the setting of the reserve capacity.

Regen @: display shows the setting of the time of

regeneration.

Override:displayshowsthesettingofthenumberofdays

between regenerations.

Cycle X: display shows the setting of the length of the

corresponding regeneration cycle.

Units: display shows that control is programmed for

Metricunits.

MTR: display shows the setting of the water meter.

Capacity: display shows that control is programmed for

hardness setting.

Regen: display shows the setting of the regeneration

mode.

Valve Type: display shows the valvetype setting.

MP Resets: display shows the number of resets of the

microprocessor(for factory purpose only).

Memory Reset: display shows the number of corrupt

memory start-ups (forfactorypurposeonly).

EZ3P5e EZ3PB r11: display shows the software version

(forfactorypurposeonly).

CapToUse: display shows the remaining capacity.

Fill: display shows the refill time used for the previous

regeneration.

Reserve: display shows the calculated reserve capacity.

Exiting the Diagnostics level

1. If no button is pressed within 5 minutes, the

microprocessor will exit the diagnostics level end return

to the service mode.

2. Press the scroll button repeatedly until the display

shows:

Press the up or down button to exit the

diagnostics level.

Exit

Regen XXdays ago

System Check

MAINTENANCE

Page 11

ROUTINE CHECKS

Regularlytheusershouldperformabasicchecktoverifyifthe

water softener is functioning correctly, on the basis of the

following control points:

1. Check settings of electronic control panel.

2. Measure water hardness before/after water softener.

3. Check drain line from control valve; there shouldn’t be

any waterflow (unless water softeneris in regeneration).

4. Check drain line from cabinet overflow; there shouldn’t

be any water flow.

5. Check water softener and surrounding area; there

shouldn’t be any water leakages.

BYPASSING THE WATER SOFTENER

Occasionally it may be necessary to put the water softener

hydraulically in bypass, i.e. to isolate it from the water

distribution system; f.e.:

in case of an urgent technical problem;

when it is not necessary to supply treated water to the

house/application (refill swimming pool, irrigation,...).

WITH FACTORY BYPASS (optional)

Picture 8.a

SERVICE POSITION

= inlet valve to water softener is OPEN

= outlet valve from water softener is OPEN

Picture 8.b

BYPASSPOSITION

= inlet valve to water softener is CLOSED

= outlet valve from water softener is CLOSED

Picture 8.c

MAINTENANCE POSITION

= inlet valve to water softener is OPEN

= outlet valve from water softener is CLOSED

WITH 3-VALVE BYPASS SYSTEM (not included)

Picture 9.a

SERVICE POSITION

= bypass valve is CLOSED

= inlet valve to water softener is OPEN

= outlet valve from water softener is OPEN

Picture 9.b

BYPASSPOSITION

= bypass valve is OPEN

= inlet valve to water softener is CLOSED

= outlet valve from water softener is CLOSED

Picture 9.c

MAINTENANCE POSITION

= bypass valve is OPEN

= inlet valve to water softener is OPEN

= outlet valve from water softener is CLOSED

WATER CONDITIONER SALT

Picture 10

The water softener needs 'brine' for its periodic

regenerations. This brine solution is made from water, that is

automatically dosed in the brine cabinet by the control valve,

and water conditioner salt. The user should make sure that

the brine cabinet is always kept full of water conditionersalt.

Thereforeheshouldperiodicallycheckthesaltlevelinsidethe

brine cabinet and refill it if necessary. The salt lid can be

removed completely to facilitate refilling.

Ideally the level of water conditioner salt inside the brine

cabinet is kept between 1/3 and 2/3. A lower level of water

conditioner salt can cause insufficient brine saturation,

resultinginalossofsofteningcapacity.Ahigherlevelofwater

conditioner salt can cause salt bridging (hard crust or salt

bridges in the brine cabinet). When you suspect salt bridging:

carefully pound on the outside of the brine cabinet to

break loose the salt bridges;

usingabroom(orlikeblunttool)carefullypushthesaltto

break it apart;

pour warm water over the top of the salt to dissolve it.

BRINE CABINET

To retain the appearance of the water softener, simply wipe

it with a damp cloth or clean it with a mild soap solution;

never use abrasive cleaners, ammonia or solvents.

RESIN CLEANER

Other contaminants (f.e. iron) present in the feed water can

cause the resin bed to foul up, resulting in a loss of softening

capacity. An approved resin cleaner can be used periodically

to thoroughly clean the resin bed.

SANITIZING THE WATER SOFTENER

This water softener is manufactured from premium quality

material and assembled insafe conditions toassureit is clean

and sanitary. If installed and serviced correctly, this water

softener will not infect or contaminate your water supply.

However, as in any 'device' plumbed-in in your water

distribution system, a proliferation of bacteria is possible,

especially in case of 'stagnant water'. Therefore this water

softener is equipped with a 'days override' feature, that will

automatically rinse the resin bed periodically, even in case of

low or absence of water usage.

If the power supply to the water softener is disconnected for

a longer period of time, we recommend, when the power

supply is re-established, to manually initiate a complete

regeneration.

HYDRAULIC FLOW DIAGRAMS - VOLUMO

Page 12

SERVICE BRINE DRAW SLOW RINSE REFILL

SERVICE BRINE DRAW / SLOW RINSE

REFILL PREPARATION

HYDRAULIC FLOW DIAGRAMS - VOLUMO+

Page 13

SERVICE BACKWASH BRINE DRAW SLOW RINSE FAST RINSE REFILL

SERVICE BACKWASH

BRINE DRAW/SLOW RINSE FAST RINSE

REFILL

TROUBLESHOOTING

Page 14

PROBLEM

C

AUSE

S

OLUTION

H

ard (untreated)

water

to service

Open or defective bypass

C

lose

orreplace

bypass

Water softener

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

No salt in brine

cabinet

Add salt an

d initiate regeneration manually

Salt

bridging

Break

salt

bridge(s)

an

d initiate regeneration

manually

Change in raw water hardness

Measure

the

hardness

of the incoming untreated

water and adjust programming accordingly

Water softener

fails to

start a

regenerat

ion

Refer to problem “

Water s

oftener

fails to

start a

regeneration”

Control v

alve fails to draw brine

Refer to problem “Valvefails to draw brine”

Decreasing exchange capacity of resin

Clean or replace resin bed

Loss of resin

Refer to problem “Loss of resin”

Leak at riser

tube

Verify that riser tube is seated correctly and is not

cracked

Residual hardness in

treated water

Bypass not completely closed

Close bypass

Water s

oftener fails to

start a regeneration

Faulty electrical supply

Verify electrical service (fuse,

transformer,...)

Defective flow meter

Clean and/or replace flow meter

Defective PCB

Replace PCB

Defective drain solenoid

Replace drain solenoid

Body stem assembly switches continuously

C

heck operating pressure; must be higher than 1,4

bar

Water

softener

uses

too much salt

Excessive water in brine

cabinet

Referto problem“Excessive waterin brine

cabinet

”

System

regenerates toofrequently

Verifyprogram

Excessive water in

brine cabinet

Control v

alve fails to draw brine

Refer to problem

“Control v

alvefailsto drawbrine”

Improper

re

fill time setting

Verifythat

re

fill time corresponds tothe proper salt

level and amount of resin

Missing refill flow control

Verify that

refill

flow control is installed and

properlysized

Leak from

control valve tobrine cabinet

Clean orreplace plungerand solenoid diaphragm of

refill solenoid

Salt

taste in treated

water

Excessive water in brine tank

Refer to problem “Excessive water in brine tank”

Injectorundersized

Verifyinjectorselection

Improper brine/slow rinse time setting

Verifythatbrine/slowrinsetimecorrespondstothe

proper salt level and amount of resin

Loss of water pressure

Mineral or iron build

-

up in resin tank

Clean resin bed and control valve; increase

regeneration frequency

Plugged lowerand/or upper distributor

Verify that distributors are free of debris

Crushed lowerand/orupper distributor

Replace distributor(s)

Drain line from control

valve flows

continuously

Water softener

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

Drain solenoidstuck in openposition

Clean drain solenoid

Defective PCB

Replace PCB

Drain line from

brine

cabinet overflow flows

continuously

Excessive water in brine cabinet

Referto problem“Excessive waterin brine

cabinet

”

Leak between control valve and pressure tank

Verifysealbetween controlvalveandpressuretank

Control v

alve fails to

refill brine tank

Improper refill time setting

Verify that refill time

corresponds to salt level and

amount of resin

Plugged refill flow control

Clean

refill

flow control

Loss of resin

Lower and/or upper distributor damaged

Replace distributor(s)

Leak between riser tube and upper distributor

Verify that riser tube is seated correctly and is not

cracked

TROUBLESHOOTING

Page 15

PROBLEM

C

AUSE

S

OLUTION

Control v

alve fails to

draw brine

Low operating pressure

C

heck operating pressure; must

be higher than 1,4

bar

Drain flow adjuster closed too much

Open drain flow adjuster slowly until unit draws

brine

Plugged injector and/

orbrine restrictor

Clean injector and/

or brine restrictor

Plugged injector filter

Clean injectorfilter

Restricted drain line

Verify drain linefor kinks or restrictions

Restricted brine line

Verify brine line for kinks orrestrictions

Leak in brine line

Verify brine line and connections for air leakage

No

water in brine tank

Refer to problem

“Control v

alve fails to refill brine

tank”

Backwash solenoid remains open

Verify solenoid membrane and plunger

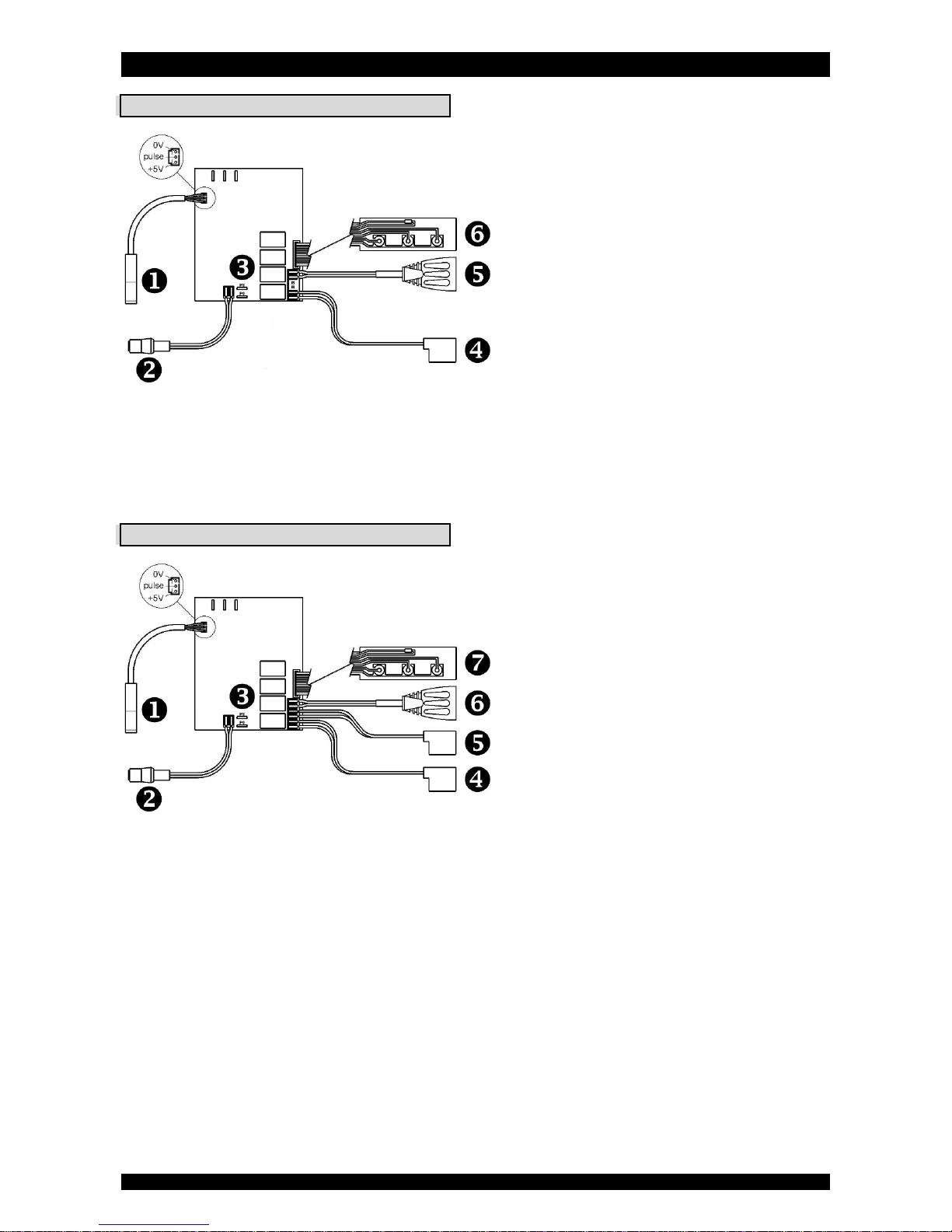

ELECTRICAL WIRING DIAGRAMS

Page 16

VOLUMO

=flow meter

= power lead

= 24VAC auxilliary contact, closed during regeneration (max. 500mA)

= refill solenoid (white)

= drain solenoid

= key pad

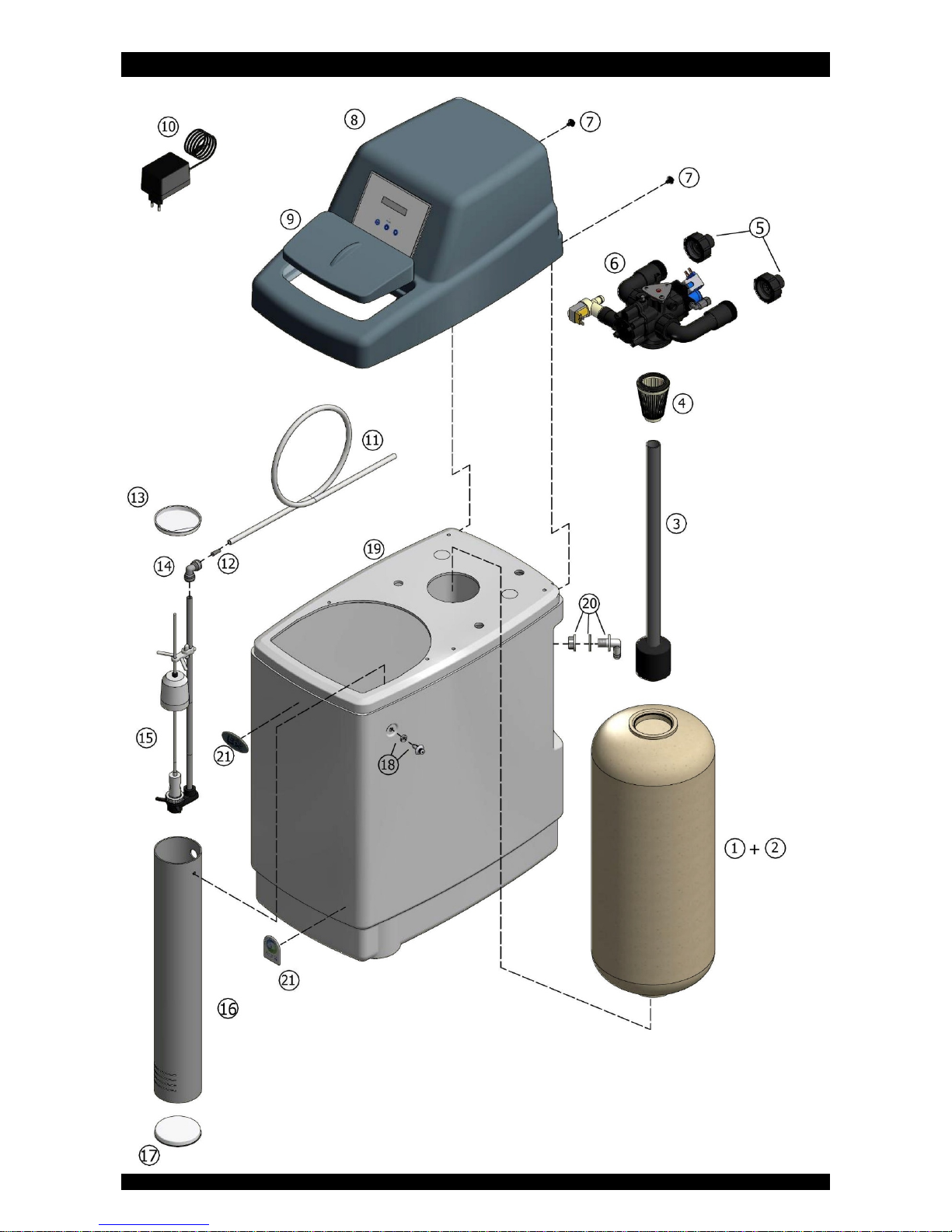

VOLUMO+

=flow meter

= power lead

= 24VAC auxilliary contact, closed during regeneration (max. 500mA)

= refill solenoid (white)

= backwash solenoid (black)

= drain solenoid

= key pad

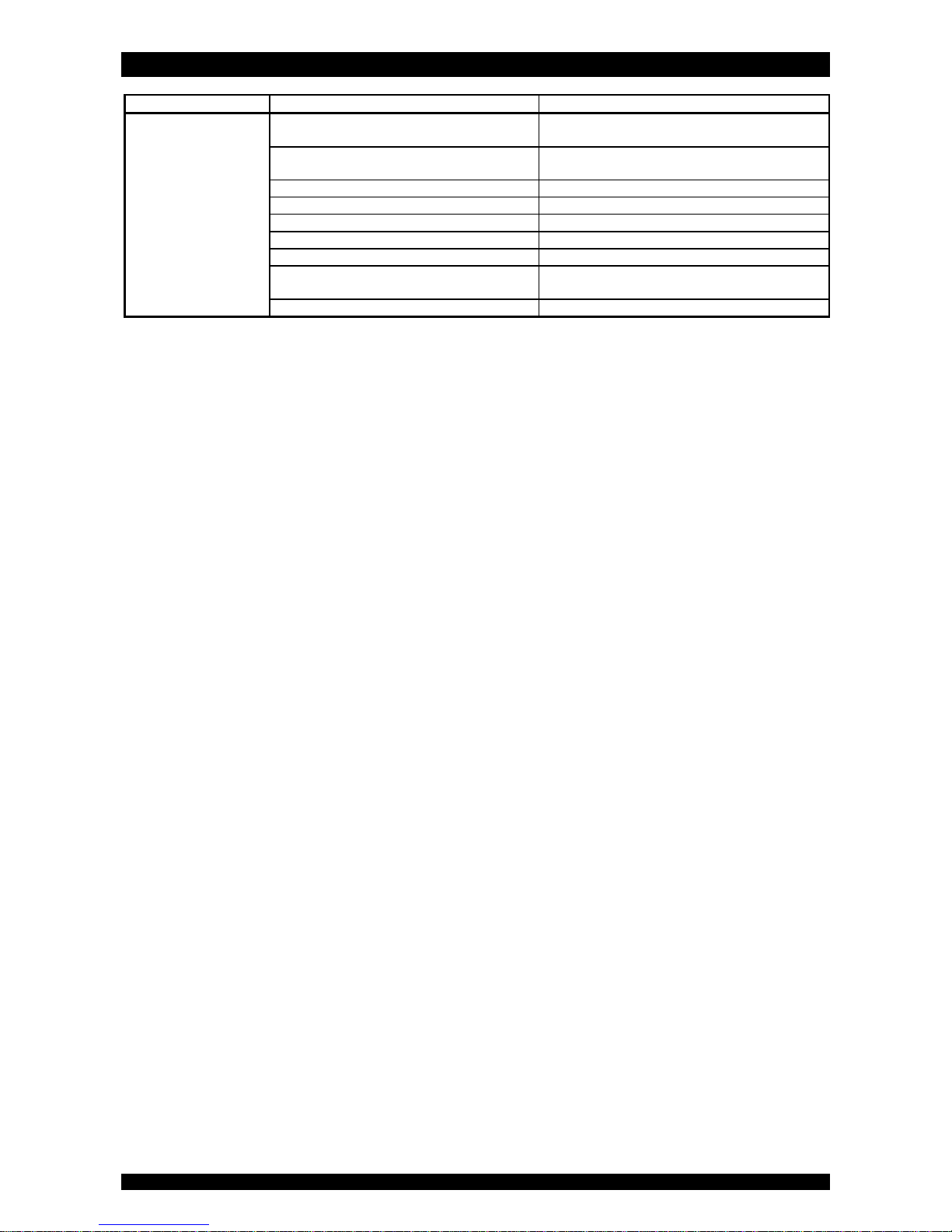

DEFAULT PARAMETER SETTINGS

Page 17

Model Volumo

Resin 11 15 20 26 32

Hardness unit (1) °f °f °f °f °f

Exchange capacity per liter resin (°f M3/L) (1) (2) 4,5 4,5 5,1 5,1 5,1

Resin(liters) 11 15 20 26 32

Override(days) 7 7 7 7 7

Cycle 1:BRINE DRAW/SLOWRINSE (min) 55 75 93 118 144

Cycle 2:REFILL (min) (2) 4 5 7 10 12

MTR SNAP SNAP SNAP SNAP SNAP

Regen Dlyd/Immd Dlyd/Immd Dlyd/Immd Dlyd/Immd Dlyd/Immd

Regen@ 2:00 2:00 2:00 2:00 2:00

Rsrv Variable Variable Variable Variable Variable

(1) When the Hardness unit is changed, the Exchange capacity per liter resin needs to be adjusted accordingly; to convert from °f to °d, multiply x 0,56.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

Model Volumo+

Resin 11 15 20 26

Hardness unit (1) °f °f °f °f

Exchange capacity per liter resin (°f M3/L) (1) (2) 4,5 4,5 5,1 5,1

Resin(liters) 11 15 20 26

Override(days) 7 7 7 7

Cycle 1:BACKWASH (min) 3 3 3 3

Cycle 2:BRINE DRAW/SLOWRINSE (min) 55 75 113 138

Cycle 3:FAST RINSE(min) 2 2 2 2

Cycle 4:REFILL (min) (2) 4 5 7 10

MTR SNAP SNAP SNAP SNAP

Regen Dlyd/Immd Dlyd/Immd Dlyd/Immd Dlyd/Immd

Regen@ 2:00 2:00 2:00 2:00

Rsrv Variable Variable Variable Variable

(1) When the Hardness unit is changed, the Exchange capacity per liter resin needs to be adjusted accordingly; to convert from °f to °d, multiply x 0,56.

(2) When the Exchange capacity per liter resin is changed, the refill cycle time needs to be adjusted accordingly.

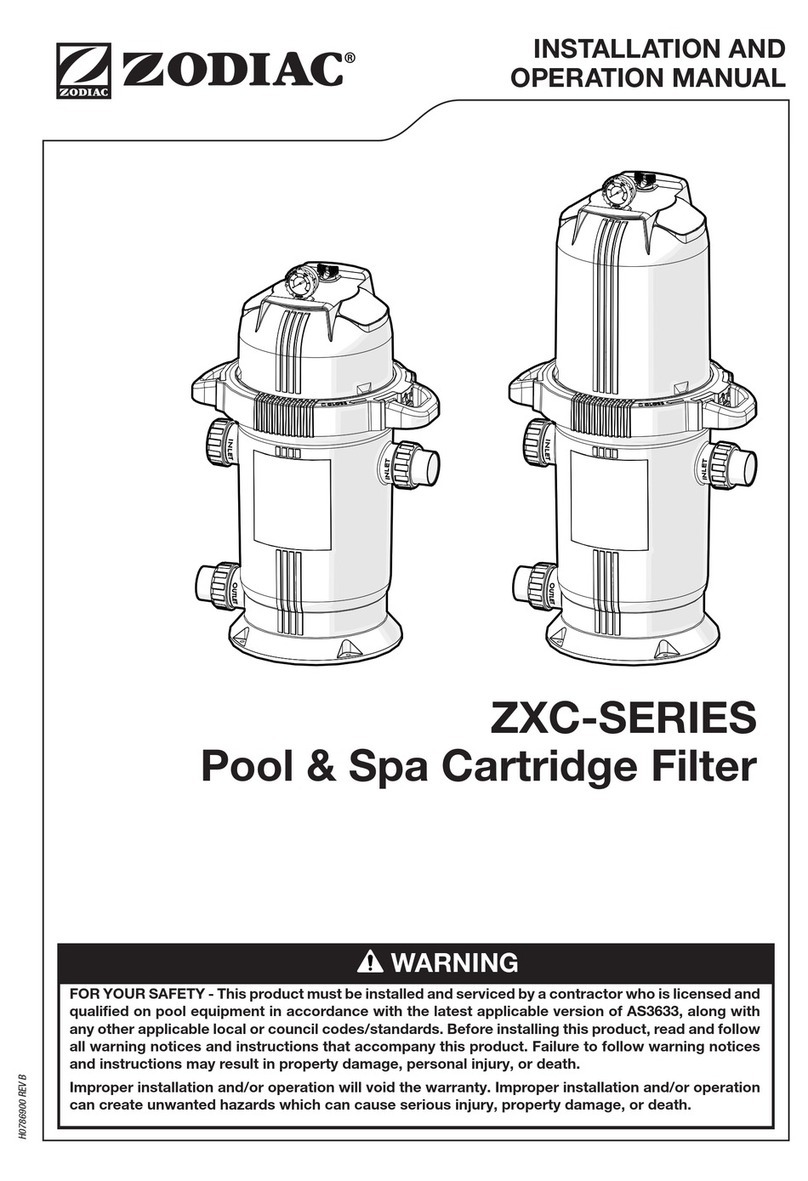

EXPLODED VIEW - SYSTEM

Page 18

EXPLODED VIEW - SYSTEM

Page 19

Item PN Description Remark (*)

1 PT/0918/CP Pressure tank, 9x18 Volumo 11L, Volumo+11L

PT/0924/CP Pressure tank, 9x24 Volumo 15L, Volumo+15L

PT/1024/CP Pressure tank, 10x24 Volumo 20L

PT/0935/CP Pressure tank, 9x35 Volumo 26L, Volumo+20L

PT/1035/CP Pressure tank, 10x35 Volumo 32L, Volumo+26L

2 E8000 Softening resin

3 38528 Riser tube assembly with deflector to be cut to length

4 287/166 Top distributor

5 568/303/6 Connection kit ¾” male

6 541NCX9B/J80 Valve body assembly Volumo

541NCX4B/J8G Valve body assembly Volumo+11L,Volumo+15L,

Volumo +20L

541NCX4B/J8J Valvebody assembly Volumo+26L

7 38540 Screw rivet, maincover (2x)

8 Cover assembly

9 38497 Saltlid

10 28/298/11 Transformer 230/24V - 50 Hz, 24VA, EuroT plug

11 H1015/2 Brine line polytube to be ordered per meter

12 38519 Brine line filter

13 H1016/2 Brine well cap, top

14 DM/A6EU6 Quick-fit elbow 3/8”

15 38530 Brine valve assembly 464 to be cut to length

16 BW3.5/0403 Brine well, 403 mm Volumo 11L, Volumo+11L

BW3.5/0538 Brine well, 538 mm Volumo 15L, Volumo 20L,

Volumo+15L

BW3.5/0823 Brine well, 823 mm Volumo 26L, Volumo 32L,

Volumo+20L, Volumo+26L

17 H1016/4 Brine well cap, bottom

18 38548 Screw rivet, brine well

19 39006 Cabinet body, mini Volumo 11L, Volumo+11L

39007 Cabinet body, midi Volumo 15L, Volumo 20L,

Volumo+15L

39008 Cabinet body, maxi Volumo 26L, Volumo 32L,

Volumo+20L, Volumo+26L

20 38532 Overflow assembly

21 39004 Dome label ‘erie water treatment’

(*) Recommended Spare Part

EXPLODED VIEW - COVER ASSEMBLY

Page 20

Other manuals for Volumo

1

Table of contents

Other Sentencia Water Dispenser manuals

Popular Water Dispenser manuals by other brands

EcoWater

EcoWater ESM9 owner's manual

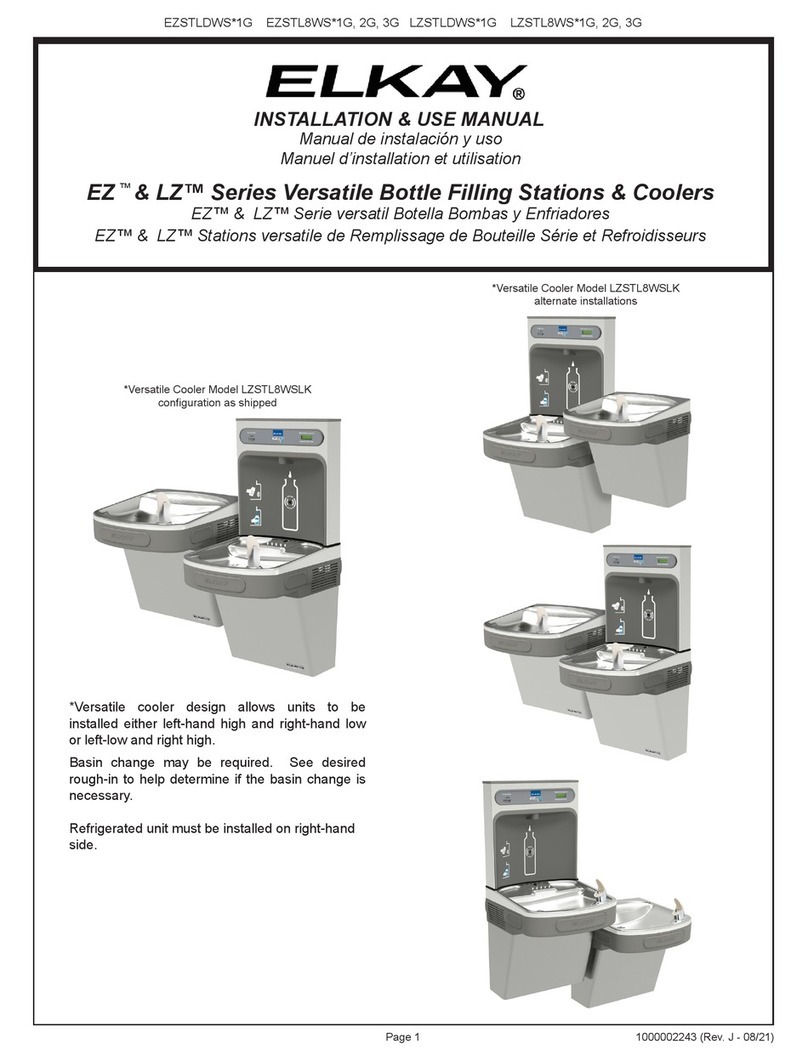

Zodiac

Zodiac ZXC Series Installation and operation manual

Zip

Zip Hydroboil Duo 310111 Installation & operating instructions

Elkay

Elkay EZSTLDWS 1G Series Installation & use manual

Elkay

Elkay 2G Installation, care & use manual

Watts Premier

Watts Premier Sof-Tek Installation, operation and maintenance manual