Sentry Sample Sequencer 5 User manual

Installation, Operation and

Maintenance Manual

Sample Sequencer5

SPD 5.5.15 Rev. 0 11/11

Original Instructions

SENTRY EQUIPMENT CORP

966 Blue Ribbon Circle N

Oconomowoc, WI 53066 USA

Phone: 262.567.7256

Fax: 262.567.4523

Email: [email protected]

www.sentry-equip.com

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 i

Declaration of Conformity

Sentry Equipment Corp. declares under our sole responsibility that our Sample Sequencer 5 to

which this declaration relates is in conformity with the following standards:

Product Safety:

Certified to CAN/CSA C22.2 No. 1010.1-92 (Certificate # XXXXXXX)

Low Voltage Directive 2006/95/EC

Required Standards include:

EN 61010-1:2001/IEC 61010-1:2001

Safety requirements for electrical equipment for measurement, control, and laboratory use -

Part 1: General requirements

Electromagnetic Compatibility:

EMC Directive 2004/108/EC:

Required Standards include:

EN 61326-1:2006 / IEC 61326:1997 w\A1:1998 & A2:2001

Electrical equipment for measurement, control, and laboratory use EMC requirements - Part 1:

General requirements

Immunity:

Required tests include:

IEC 61000-4-2 ESD

IEC 61000-4-3 Radiated Susceptibility

IEC 61000-4-4 EFT

IEC 61000-4-5 Surges

IEC 61000-4-6 RF Cond.

IEC 61000-4-8 Magnetic Susceptibility

IEC 61000-4-11 Volt dips, interrupts

Emissions:

Required tests include:

EN 55011 Class A limits

EN 61000-3-2 Harmonic

EN 61000-3-3 Voltage Fluctuation (Flicker)

FCC Compliance:

FCC Part 15.107 & 15.109

Canadian Compliance:

ICES 003

RoHS Compliance:

Directive 2002/95/EC

This product complies with the RoHS Directive.

Type of Equipment: Electrical Equipment for Measurement, Control, and Laboratory Use

Part Number: 7-02690F

Year CE Mark Affixed to Product: 2011

Sentry Equipment Corp | Sample Sequencer5

ii SPD 5.5.15

TABLE OF CONTENTS

1SPECIFICATIONS.................................................................................................................1

2SAFETY PRECAUTIONS......................................................................................................3

2.1 USE OF HAZARD INFORMATION .........................................................................................3

2.2 DEFINITIONS ....................................................................................................................3

3QUICK START GUIDE..........................................................................................................5

3.1 ELECTRICAL CONNECTIONS ..............................................................................................5

3.2 CONTROL SCREEN ...........................................................................................................5

3.3 STARTING AND STOPPING THE SAMPLE SEQUENCER .........................................................5

3.4 WIDGETS SCREEN............................................................................................................5

3.5 SETTING THE SEQUENCE ..................................................................................................5

3.6 PLACING SAMPLES IN “SAMPLE/BYPASS”...........................................................................5

3.7 SETTING SAMPLE TIMERS.................................................................................................5

3.8 SETTING THE MODE .........................................................................................................6

3.9 EDITING THE SAMPLE NAMES............................................................................................6

3.10 EDITING ANALYZER NAMES...............................................................................................6

4GENERAL DESCRIPTION....................................................................................................7

4.1 MODES OF OPERATION.....................................................................................................7

4.2 INPUTS AND OUTPUTS ....................................................................................................11

4.3 OPTIONAL MANIFOLD SAMPLING VALVE ..........................................................................12

5OPERATION .......................................................................................................................13

5.1 DESCRIPTION OF CONTROLS ..........................................................................................13

5.2 SCREEN DESCRIPTIONS..................................................................................................15

5.3 OPERATING MODES........................................................................................................35

5.4 VALVE OUTPUTS ............................................................................................................38

6INSTALLATION ..................................................................................................................39

6.1 UNPACKING....................................................................................................................39

6.2 MOUNTING .....................................................................................................................39

6.3 ELECTRICAL CONNECTIONS ............................................................................................43

6.4 SEQUENCER BOARD CONNECTIONS................................................................................46

6.5 ALTERNATE SEQUENCER BOARD CONNECTIONS .............................................................47

6.6 STARTING UP THE SAMPLE SEQUENCER .........................................................................50

7MAINTENANCE ..................................................................................................................51

7.1 CLEANING ......................................................................................................................51

7.2 RECHARGEABLE BATTERY ..............................................................................................51

7.3 DISASSEMBLY ................................................................................................................51

7.4 CALIBRATION..................................................................................................................51

8TROUBLESHOOTING GUIDE............................................................................................53

9FACTORY ASSISTANCE ...................................................................................................54

10 SPARE PARTS LIST ..........................................................................................................55

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 iii

11 ACCESSORIES...................................................................................................................55

12 WARRANTY........................................................................................................................56

APPENDIX A - RECOMMENDED PIPING.................................................................................58

APPENDIX B – USING A SEQUENCER WITH HACH SERIES 5000 ANALYZER..................59

APPENDIX C – MODBUS®REGISTERS...................................................................................63

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 1

1 SPECIFICATIONS

Specifications are subject to change without notice.

Applications: The Sample Sequencer is designed to support sample stream switching in the

batch or continuous modes.

Maximum Number of Samples: 8

Maximum Number of Analyzers: 4

Power:

Input Voltage: 100 - 240 Vac

Frequency Range: 50/60 Hz

Input Current:

1.2 A / 115 V

0.72 A / 230 V

Inputs from Analyzer:

Four analog inputs: 4-20 mA (100 load)

Four digital inputs for end-of-analysis indication.

Four digital inputs for calibration indication.

Four digital inputs for analyzer system alarm indication.

Outputs:

10base-T Ethernet supports MODBUS® TCP/IP communication and embedded web

capability.

Valve outputs (12 VDC) to control a maximum of eight solenoid valves for sample

stream switching. Individual outputs capable of handle up to 2A solenoid load. Total

solenoid load current not to exceed 5.5A @ 12VDC (Please consult factory if individual

solenoid load is greater than 1A @ 12VDC).

12 digital outputs for point number indication and replicated Analyzer Alarms.

0-40V,60mA sinking outputs

Current Outputs: Eight 4 – 20 mA outputs.

Maximum Load: 550 Ω

Nominal Accuracy:

Analog Inputs: ± 0.2% full scale

Analog Outputs: ± 0.2% full scale

Resolution:

Analog Inputs: 10 µA/LSB

Analog Outputs: 10 µA/LSB

Data Logging: Records stored on removable SD card. Storage limations based on size of SD

card.

Sentry Equipment Corp | Sample Sequencer5

2 SPD 5.5.15

User Interface: 4.3” color touch screen, 65,000 colors.

Enclosure: 304 Stainless steel, 16 GA. Designed to meet NEMA 4X (indoor), IPX0

Dimensions: 7.00” (177.8 mm) H x 8.00” (203.2 mm) W x 7.00” (177.8 mm) D

Mounting: Panel or surface.

Ambient Temperature: -5-40 C (23-104 F); Relative Humidity 5-95%

Environmental: Indoor use only

Operating Altitude: 0-2000 m (0-6562 ft.) (Consult factory for other altitudes.)

Mains supply fluctuation: -10% and +10%

Transient overvoltage: 1500Vac

Pollution degree: 2

Agency Approvals:

Shipping Weight: 15 lbs (6.80 kg)

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 3

2 SAFETY PRECAUTIONS

Please read the entire manual before attempting to unpack, set up or operate this product. Pay careful

attention to all warnings, cautions and notes. Failure to do so could result in serious personal injury or

equipment damage.

2.1 Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest hazard shall be used.

2.2 Definitions

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE

Information that requires special emphasis

SHALL

This word understood to be mandatory

SHOULD

This word understood to be advisory

Sentry Equipment Corp | Sample Sequencer5

4 SPD 5.5.15

Indique une situation imminente et dangereuse qui doit être

évité immédiatement afin d’éviter tout risque de blessures

sérieuses et qui pourrait même entraîner la mort.

AVERTISSEMENT

Indique une situation potentiellement dangereuse et qui doit

être évité immédiatement afin d’éviter tout risque de

blessures sérieuses et qui pourrait même entraîner la mort.

PRÉCAUTION

Indique une situation potentiellement dangereuse et qui doit

être évité immédiatement afin d’éviter tout risque de

blessures mineures.

PRÉCAUTION

ATTENTION une utilisation sans le symbole de sécurité

indique une situation potentiellement dangereuse et que si

elle n’est pas évité, pourrait entrainer des dommages à la

propriété.

NOTE

Informations requérant une attention spéciale

DOIT

Ce mot indique une obligation

POURRAIT

Ce mot indique un avertissement

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 5

3 QUICK START GUIDE

The following guide is intended to help you get started using the Sentry Sample Sequencer®.

This guide does not include detailed explanations and should be used in conjunction with the

remainder of this manual to build a full understanding of the Sample Sequencer.

3.1 Electrical Connections

Connect all electrical connections necessary for the application. If the analyzer being

shared is a batch type analyzer, an end of analysis signal must be connected to the

Sample Sequencer “End of Batch” input. Without this signal, the Sample Sequencer will

never advance to the next sample.

3.2 Control Screen

With the display showing the Operation Screen (see Figure 6), touch anywhere on the

screen excluding the left and right arrow areas. If prompted, enter password. This will

take you to the Control Screen (see Figure 8).

3.3 Starting and Stopping the Sample Sequencer

From the Control Screen (see Figure 8), you can start and stop any active sequence by

touching the red indicator on the screen. Once touched, the indicator will change and the

sequencer state will update.

3.4 Widgets Screen

From the Control Screen, touch the wrench button in the lower right corner of the screen.

This will take you to the first Widgets Screen (see Figure 9).

3.5 Setting the Sequence

Navigate to the first Widgets Screen. Touch the Sequences widget to take you to the

Sequences Screen (see Figure 29). Using the buttons on the screen, create the

sequences desired. Changes are saved by touching the save button in the lower right

hand corner. To exit without saving changes, touch the escape button in the lower left

hand corner.

3.6 Placing Samples in “Sample/Bypass”

Navigate to the first Widgets Screen. Touch the Bypass widget to access the Bypass

Line Screen (see Figure 12). Touch the indicator light next to the desired sample line

you wish to switch. The state of the sample line will update once indicator has been

touched. The Sample state indicates the sample point will be sampled. The Bypass state

indicates the sample point will be bypassed the next time its position is up in the

sequence. Changes are saved by touching the save button in the lower right hand

corner. To exit without saving changes, touch the escape button in the lower left hand

corner.

3.7 Setting Sample Timers

Navigate to the first Widgets Screen. Touch the Flush Times or Sample Times widget to

access the appropriate screen (see Figures 10 and 11). Touching the time on the

Sentry Equipment Corp | Sample Sequencer5

6 SPD 5.5.15

sample line you would like to update will take you to an Enter Time screen. Enter the

time desired. When finished, touch the enter button in the lower right corner. This will

bring you back to the times screen and the time you just entered will be updated. Do this

for each time you would like to update. Save changes by touching the save button in the

lower right hand corner of the screen. To exit without saving changes, touch the escape

button in the lower left hand corner.

3.8 Setting the Mode

Navigate to the first Widgets Screen. Touch the Mode widget to access the Mode

Screen (see Figure 13). Touch an indicator to toggle the sequence between the two

modes, Batch or Continuous. Make desired changes. Save changes by touching the

save button in the lower right hand corner. To exit without saving changes, touch the

escape button in the lower left hand corner.

3.9 Editing the Sample Names

Navigate to the first Widgets Screen. Touch the Sample Names widget to access the

Sample Names Screen (see Figure 30). Touch the sample name you would like to

change to bring up the Sample Names Keypad Screen. When finished, touch the enter

button in the lower right corner. This will update the Sample Names Screen with the

name you just entered. Make any additional name changes. Save changes by touching

the save button in the lower right hand corner. To exit without saving changes, touch the

escape button in the lower left hand corner.

3.10 Editing Analyzer Names

Navigate to the first Widgets Screen. Touch the Analyzer Names widget to access the

Analyzer Names Screen (see Figure 31). Touch the analyzer name you would like to

change to bring up the Analyze Names Keypad Screen (see Figure 32). When finished,

touch the enter button in the lower right corner. This will update the Analyzer Names

Screen with the name you just entered. Make any additional name changes. Save

changes by touching the save button in the lower right hand corner. To exit without

saving changes, touch the escape button in the lower left hand corner.

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 7

4 GENERAL DESCRIPTION

The Sentry Sample Sequencer is a microprocessor-based instrument capable of electronically

switching up to eight sample streams one at a time to an analyzer and of providing signals to

recorders. If a total of eight sample streams are not needed for one process, the remaining points

may be assigned to additional analyzers, up to four in total. A Sentry manifold sampling valve

specially designed to obtain optimum representative samples is available for sample stream

switching with the Sample Sequencer. The Sample Sequencer reduces the number of required

analyzers while maintaining equivalent data accuracy. Reliable sample analysis comparison is

obtained by using a Sample Sequencer with one dedicated analyzer. In addition, significant

operating cost savings are obtained by not having to install, maintain, and service multiple

analyzers.

The Sample Sequencer is capable of operating in the continuous mode for continuous analyzers

or in the batch mode for batch analyzers. In addition, the Sample Sequencer is capable of

measuring the analyzer analog output signal and converting the analog signal to digital data to be

sent out using MODBUS®TCP/IP or Embedded web using the Ethernet communication port.

Using the MODBUS®capability, one can connect to a PC or system network via the Ethernet

cable to one or more Sequencers for remote monitoring, control, and data acquisition.

Track and Hold outputs are available to provide independent outputs for each sample point. Digital

outputs are also available to provide channel number indication as well as replicating analyzer

alarms.

Figures 1-3 illustrate a typical system arrangement for sample stream switching with the Sample

Sequencer. Customer-supplied equipment is shown for clarification.

4.1 Modes of Operation

The Sample Sequencer has two programmable modes of operation:

4.1.1 BATCH

Used for analyzers that take a sample "bite" (or batch), produce an analytical result, and then

provide a contact signal output, in typically 1-20 minutes.

4.1.2 CONTINUOUS

Used for analyzers that continuously produce an analytical result.

NOTE

If using the Sample Sequencer with a Hach analyzer, see Appendix B.

Sentry Equipment Corp | Sample Sequencer5

8 SPD 5.5.15

Figure 1: Sample Sequencer with Continuous Analyzer

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 9

Figure 2: Sample Sequencer with Batch Analyzer

Sentry Equipment Corp | Sample Sequencer5

10 SPD 5.5.15

Figure 3: Sample Sequencer with two Analyzers

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 11

4.2 Inputs and Outputs

A variety of inputs and outputs are available on the Sample Sequencer.

4.2.1 Analog Inputs:

Four analog inputs are located on the Sample Sequencer board for reading a 4–20 mA signal from

up to four different analyzers. The Sample Sequencer converts this signal into Engineering Units for

display and outputs the same signal for the Track and Hold analog outputs.

4.2.2 Analyzer Alarm Inputs:

Four analyzer alarm inputs are located on the Sample Sequencer board. These inputs are typically

used to indicate a loss of sample flow to the analyzer. An analyzer alarm will cause the analyzer

description to flash on the operation screen. An analyzer alarm will also cause the digital alarm

output for that sequencer to be set.

When the Sample Sequencer is used in the Continuous mode, an analyzer alarm will immediately

close the active sample valve and open the next sample valve. That sample valve will remain open

until the analyzer alarm clears, one minute elapses, or – if the sum of the sample and flush times is

less than one minute – when the timer expires. After one minute, the Sample Sequencer will open

the next sample valve. The Sample Sequencer will continue trying to establish flow every minute

until the analyzer alarm clears.

When the Sample Sequencer is used in the Batch mode, an analyzer alarm will not immediately

close the active sample valve. Instead, when the analyzer alarm is received, the Sample Sequencer

will start a timeout timer. If the Sample Sequencer does not receive an End of Batch indication from

the analyzer or the alarm does not clear before that timeout timer, the Sample Sequencer will close

the current sample valve and open the next valve in the sequence. If the End of Batch indication is

received before the timeout timer, the Sample Sequencer assumes the alarm is not a loss of flow

and continues with normal operation. The operator can adjust the timeout timer by setting each

sample’s Sample Timer.

4.2.3 Calibration Hold Inputs:

Four calibration hold inputs are located on the Sample Sequencer board. These inputs are used to

indicate that the analyzer is performing a calibration. The calibration hold inputs do not perform a

function when the Sample Sequencer is in the Batch mode.

In the Continuous mode, the Sample Sequencer will wait at the active sample with the valve open

when a calibration indication is received. Once the calibration indication clears, the Sample

Sequencer will resume operation entering the Flush state for the sample that was active before the

calibration hold indication was received.

4.2.4 End of Batch Inputs:

Four End of Batch inputs are located on the Sample Sequencer board. These inputs are used to

indicate when a batch type analyzer is finished taking a measurement. Without this input

connected, the Sample Sequencer will never advance to the next sample when the Sample

Sequencer is in the Batch mode. The End of Batch inputs are not used in the Continuous mode.

Sentry Equipment Corp | Sample Sequencer5

12 SPD 5.5.15

4.2.5 Valve Outputs:

Eight valve outputs are located on the Sample Sequencer board. These outputs supply 12 VDC to

operate the sample valves. The eight valves may be divided between four analyzers in any

combination.

4.2.6 Track and Hold Outputs:

Eight analog outputs are provided on the Sample Sequencer board. These outputs are 4-20 mA

outputs. When a valid reading is taken from the analyzer for a given sample, the Sample

Sequencer updates (“Tracks”) the corresponding signal on the appropriate output. When the

sample is not currently being analyzed, the Sample Sequencer “Holds” the corresponding signal on

the appropriate output at its last known value.

4.2.7 Digital Outputs:

A total of twelve digital outputs are available on the Sample Sequencer board. Four of these outputs

are used to replicate the four-analyzer alarm inputs while the remaining eight are used for sample

point indication. An “on” output indicates the point is currently being sampled and the analyzer

reading corresponds to that sample point.

4.2.8 Ethernet Communications:

The Sample Sequencer is capable of connecting to a network for communicating to a PC or control

system via MODBUS®TCP/IP. In addition, the sequencer provides the option to view settings via

embedded web. For more information on these features, refer to Appendix D.

4.3 Optional Manifold Sampling Valve

Although the Sample Sequencer may be used to control most manifold valve arrangements, the

Sentry Manifold Sample Valve offers a convenient optional accessory to obtain a representative

sample. The patented design incorporates block and bleed design and provides continuously

flowing samples with no areas for cross contamination to occur. The valve is available in either four

or eight sample line models. Contact Sentry for more information about this special sampling valve.

Sentry Equipment Corp | Sample Sequencer5

SPD 5.5.15 13

5 OPERATION

To ensure the protection provided by this equipment is not

impaired, this equipment must not be installed or used in any

manner other than that which is specified in this manual.

AVERTISSEMENT

Afin de s’assurer que la protection prévue par cette pièce

d’équipement n’est pas défaillante, cet équipement ne doit

pas être installé ou utilisé de manière autre que spécifié dans

le manuel.

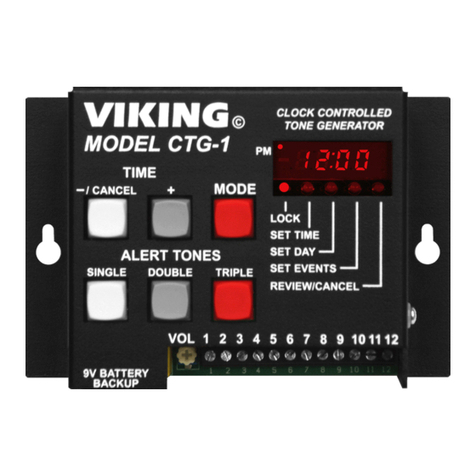

5.1 Description of Controls

The following table and figure describe controls on the Sample Sequencer touch screen display:

Table 1: Control Descriptions

DESCRIPTION FUNCTION

Widgets Touching a widget will take you to the corresponding function screen

Enter button

Various screens will have an enter button in the lower right corner.

Touching this button will take the value you have entered and update

the previous screen with that value.

Escape button

Various screens will have an escape button in the lower left corner.

Touching this button will return you to the previous screen and any

values will not be saved.

Alpha keypad

Various screens will have an alpha keypad for entering data. Use this

keypad to enter necessary data. Press the Enter button when done

using keypad to return to the previous screen with the data you have

entered.

Numeric keypad

Various screens will have a numeric keypad for entering data. Use this

keypad to enter necessary data. Press the Enter button when done

using keypad to return to the previous screen with the data you have

entered.

Save button

Various screens will have a save button in the lower right corner.

Touching this button will save entered values and return you to the

previous screen.

Sentry Equipment Corp | Sample Sequencer5

14 SPD 5.5.15

Figure 4: Sample Sequencer Front Panel

Table of contents

Other Sentry Recording Equipment manuals