Shure ML140HE User manual

Other Shure Recording Equipment manuals

Shure

Shure PSM 200 Quick start guide

Shure

Shure M95ED User manual

Shure

Shure PS9 User manual

Shure

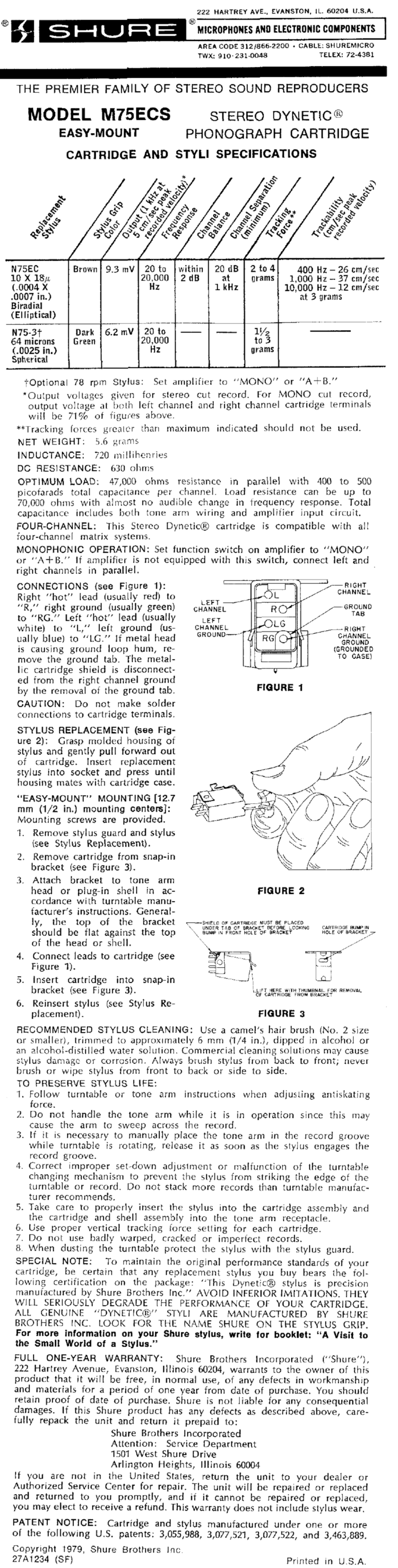

Shure M75ECS User manual

Shure

Shure ANI4IN Series User manual

Shure

Shure M97xE User manual

Shure

Shure ANIUSB-Matrix User manual

Shure

Shure A820-NIC-DANTE User manual

Shure

Shure ANI22 User manual

Shure

Shure ANI4IN Series User manual

Shure

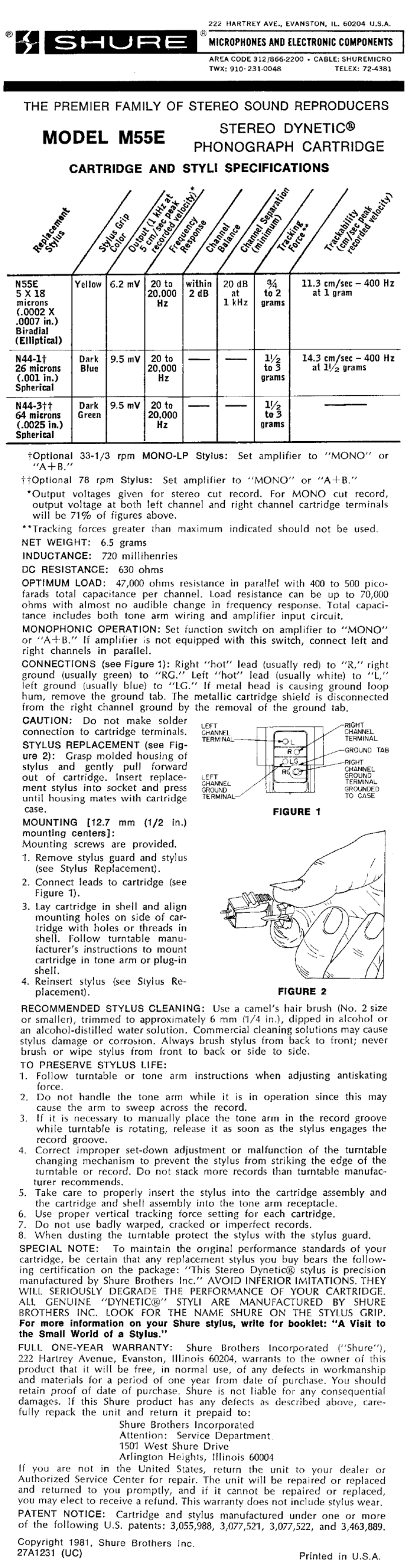

Shure M55E User manual

Shure

Shure MVI User manual

Shure

Shure AMS880 User manual

Shure

Shure MVX2U User manual

Shure

Shure DT15P User manual

Shure

Shure ANIUSB-Matrix User manual

Shure

Shure PSM 900 Programming manual

Shure

Shure Microphone Level Tone Generator A15TG User manual

Shure

Shure LEGENDARY PERFOMANCE MVi User manual

Shure

Shure DFR11EQ Version 5 Parts list manual